The global spandex market is experiencing steady expansion, driven by rising demand for high-performance, flexible textiles across activewear, fashion, and intimate apparel sectors. According to a report by Grand View Research, the global spandex fiber market was valued at USD 7.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.9% from 2023 to 2030. This growth is further fueled by increasing consumer preference for four-way stretch spandex fabrics, which offer superior elasticity, durability, and comfort. With innovation in synthetic fibers and sustainable production methods gaining momentum, manufacturers are scaling up capacities and investing in advanced textile technologies. As demand intensifies, particularly in Asia-Pacific and North America, identifying the leading players in four-way stretch spandex production becomes critical for brands focused on performance, fit, and fabric innovation. Below are the top 10 manufacturers shaping the future of this dynamic segment.

Top 10 Four Way Stretch Spandex Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MH 4 Way Stretch Fabric Manufacturer

Domain Est. 2001

Website: mh-chine.com

Key Highlights: MH is a leading manufacturer and wholesale supplier of 4 Way Stretch Fabric. We offer customization, OEM processing, and international wholesale supply ……

#2 China 4 Way Stretch Spandex Fabric Factory and Manufacturers

Domain Est. 2021

Website: fuzhoutextile.com

Key Highlights: 4 Way Stretch Spandex Fabric Manufacturers, Factory, Suppliers From China, We focus on generating own brand and in combination with a lot of experienced ……

#3 4 Way Stretch Fabric Manufacturer in China

Domain Est. 2022

Website: fabricstrades.com

Key Highlights: A leading private label stretch fabrics supplier/OEM specialized in recycled materials polyester and nylon fabrics in China….

#4 Spandex House Inc.

Domain Est. 1998

Website: spandexhouse.com

Key Highlights: Printed Spandex. Style: PS-10714, Width: 58/60″, Stretch: 4 Way, Color: Multi/White/Chocolate/Gold, Material: Nylon, Description: Four way stretch nylon spandex….

#5 Spandex Fabric

Domain Est. 2001

Website: tvfinc.com

Key Highlights: TVF is a leading supplier of spandex fabric. Stretchable spandex fabric is used for a variety of apparel and athletic applications….

#6 LYCRA®

Domain Est. 1999 | Founded: 1958

Website: lycra.com

Key Highlights: Since 1958, LYCRA® brand spandex (elastane) fiber has transformed the global textile industry to meet your need for comfort, fit and movement….

#7 Specializing in high quality Spandex fabric.

Domain Est. 2004

Website: spandexworld.com

Key Highlights: Spandex World offer one of the largest collections of high quality stretch fabrics. Start your next apparel project….

#8 Custom Printed 4

Domain Est. 2009

Website: fabricondemand.com

Key Highlights: In stock $11.86 deliveryOur 4-Way Poly Spandex is perfect for activewear & other stretchy apparel projects. This high-quality fabric is durable, comfortable, & easy to work with….

#9 4

Domain Est. 2019

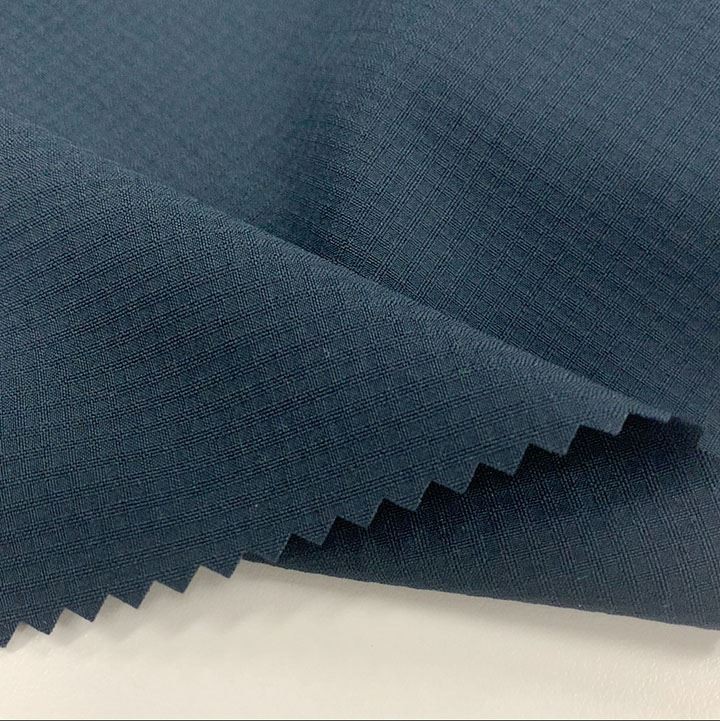

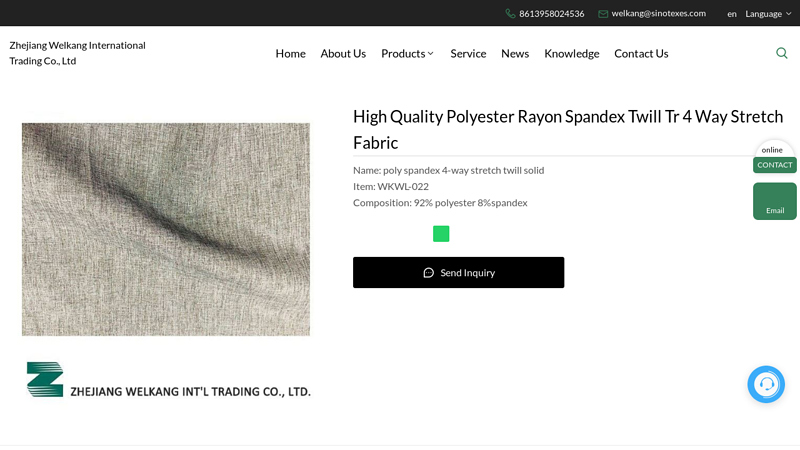

#10 High Quality Polyester Rayon Spandex Twill Tr 4 Way Stretch Fabric

Domain Est. 2020

Website: welkangtextile.com

Key Highlights: Product description: Name poly spandex 4-way stretch twill solid Item WKWL-022 Composition 92% polyester 8%spandex Gsm 120gsm Width 57/58” Color we can dye ……

Expert Sourcing Insights for Four Way Stretch Spandex Fabric

H2: 2026 Market Trends for Four Way Stretch Spandex Fabric

The global market for four way stretch spandex fabric is poised for significant evolution by 2026, driven by shifting consumer preferences, advancements in textile technology, and growing demand across diverse industries. This analysis explores key trends expected to shape the market landscape in 2026 under the H2 (second half) outlook.

-

Rising Demand in Activewear and Athleisure

The athleisure trend continues to gain momentum, with consumers prioritizing comfort, flexibility, and performance in everyday clothing. Four way stretch spandex fabric, known for its superior elasticity in both horizontal and vertical directions, is a preferred material for activewear brands. By H2 2026, increased health consciousness and the normalization of hybrid work environments are expected to sustain robust demand, especially in North America and Europe. -

Expansion in Sustainable and Eco-Friendly Production

Environmental concerns are pushing manufacturers to adopt greener practices. In H2 2026, a growing number of textile producers are anticipated to launch bio-based or recycled spandex variants. Brands are investing in closed-loop recycling systems and waterless dyeing technologies to reduce the environmental impact of four way stretch fabrics. Certifications such as OEKO-TEX® and GRS (Global Recycled Standard) will become key differentiators in the marketplace. -

Technological Innovation in Fabric Performance

Innovation in fiber engineering is enhancing the functional attributes of four way stretch spandex. Anticipated developments by 2026 include moisture-wicking, UV-resistant, and antimicrobial finishes integrated into the fabric. Smart textiles incorporating conductive fibers for wearable tech applications are also expected to gain traction, particularly in performance and medical apparel sectors. -

Growth in Emerging Markets

Asia-Pacific, especially countries like India, Vietnam, and Indonesia, is projected to become a major hub for both production and consumption of four way stretch spandex fabric by H2 2026. Expanding middle-class populations, rising disposable incomes, and increasing urbanization are fueling demand for fashionable and functional apparel. Local manufacturers are also improving production capabilities, reducing reliance on imports. -

Supply Chain Resilience and Regionalization

Post-pandemic supply chain disruptions have prompted brands to diversify sourcing strategies. By 2026, there will be a noticeable shift toward regional manufacturing clusters, with nearshoring gaining popularity in regions like Eastern Europe and Latin America. This trend enhances agility, reduces lead times, and supports faster response to market demands for customized and on-demand apparel. -

Increased Adoption in Non-Apparel Sectors

Beyond fashion and sportswear, four way stretch spandex is finding new applications in medical textiles (e.g., compression garments), automotive interiors, and home furnishings. The fabric’s durability and comfort make it ideal for ergonomic designs. H2 2026 will likely see more cross-industry collaborations to develop specialized four way stretch solutions tailored for technical uses.

In conclusion, the H2 2026 outlook for four way stretch spandex fabric is characterized by innovation, sustainability, and expanding applications. As consumer expectations evolve and technology advances, the market is set to grow steadily, offering significant opportunities for manufacturers, brands, and innovators who align with these emerging trends.

Common Pitfalls When Sourcing Four-Way Stretch Spandex Fabric (Quality and Intellectual Property)

Logistics & Compliance Guide for Four Way Stretch Spandex Fabric

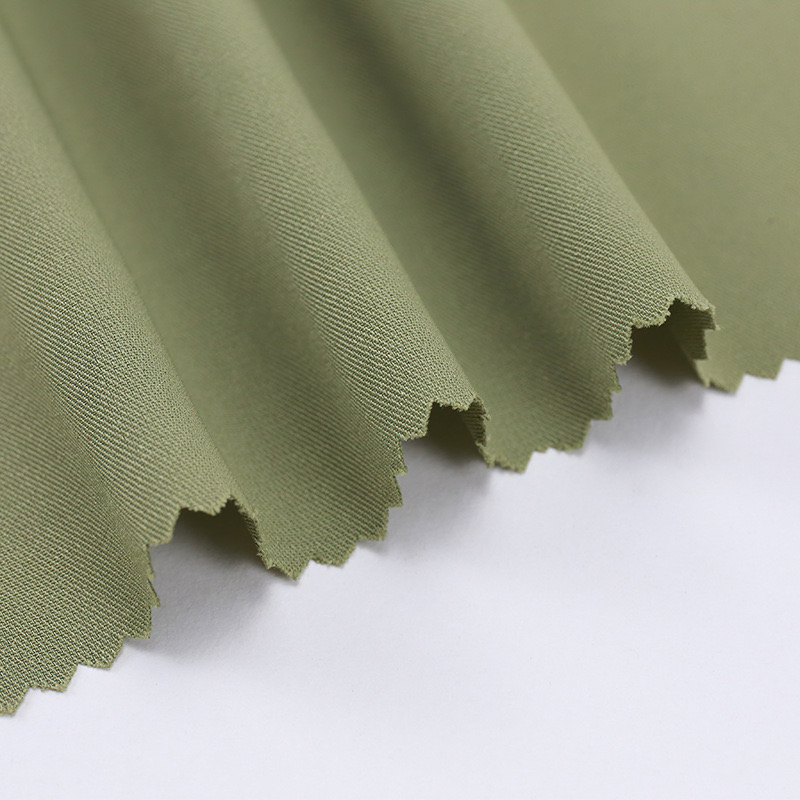

Overview of Four Way Stretch Spandex Fabric

Four Way Stretch Spandex Fabric is a high-performance textile known for its exceptional elasticity in both horizontal and vertical directions. Commonly used in activewear, swimwear, lingerie, and performance apparel, this fabric combines spandex (elastane) with nylon or polyester to deliver flexibility, durability, and comfort. Due to its specialized properties and global demand, proper logistics planning and compliance adherence are critical for international trade.

International Shipping & Handling Requirements

Packaging Standards

- Use moisture-resistant polybags to prevent mildew during transit, especially for sea shipments.

- Wrap fabric rolls in protective plastic or kraft paper to avoid abrasion and contamination.

- Clearly label each package with product details, roll count, weight, dimensions, and handling instructions (e.g., “Do Not Stack,” “Keep Dry”).

Transportation Modes

- Air Freight: Recommended for urgent shipments or smaller consignments; ideal for maintaining fabric quality with controlled environments.

- Ocean Freight: Cost-effective for bulk shipments; ensure containers are dry and ventilated to prevent moisture damage.

- Land Freight: Suitable for regional distribution; use covered trucks with climate control if necessary.

Storage Conditions

- Store in a cool, dry, and well-ventilated area away from direct sunlight to prevent UV degradation.

- Maintain temperature between 15°C and 25°C and humidity levels below 65%.

- Keep rolls stored horizontally on pallets to prevent deformation.

Customs & Regulatory Compliance

Harmonized System (HS) Code Classification

- Typical HS Code: 5402.47 (Synthetic filament yarn, not covered by another heading, containing elastomeric yarn).

Note: Final classification may vary by country; confirm with local customs authorities.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading (or Air Waybill)

- Certificate of Origin (may be required for preferential tariff treatment under trade agreements)

- Textile Declaration (required in EU, US, and other regions specifying fiber content)

Country-Specific Regulations

United States

- Comply with FTC labeling rules: fiber content, country of origin, care instructions.

- Subject to potential Section 301 tariffs on Chinese-origin goods; verify sourcing.

European Union

- Must meet REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations.

- No restricted substances (e.g., AZO dyes, formaldehyde) above permissible limits.

- Textile labeling regulation (EU) No 1007/2011 requires accurate fiber composition.

Canada

- Textile labeling regulated by the Textile Labelling Act; bilingual (English/French) labels required.

- CBSA may require import permits depending on country of origin.

Japan

- Compliance with JIS L standards for textile quality and labeling.

- Required marking of fiber content under the Household Goods Quality Labeling Act.

Environmental & Safety Compliance

Restricted Substances

- Ensure fabric complies with global standards such as OEKO-TEX® STANDARD 100, bluesign®, or ZDHC (Zero Discharge of Hazardous Chemicals).

- Test for harmful substances including phthalates, heavy metals, and allergenic dyes.

Sustainability Considerations

- Provide documentation on recycled content if applicable (e.g., recycled polyester blends).

- Supply chain transparency: disclose mills and manufacturing locations where possible.

Quality Control & Inspection Protocols

- Conduct pre-shipment inspections to verify weight, width, stretch recovery, colorfastness, and roll integrity.

- Use third-party inspection services (e.g., SGS, Bureau Veritas) for high-volume shipments.

- Retain lab dips and physical samples for quality reference.

Risk Mitigation & Best Practices

- Partner with freight forwarders experienced in textile logistics.

- Obtain cargo insurance covering damage, delay, and loss.

- Monitor trade policy updates (e.g., tariffs, sanctions) affecting spandex or textile imports.

- Maintain up-to-date compliance certifications and audit trails.

Conclusion

Successfully managing the logistics and compliance of Four Way Stretch Spandex Fabric requires coordination across packaging, transportation, regulatory adherence, and quality assurance. By following this guide, businesses can ensure smooth international shipments, reduce customs delays, and maintain product integrity and legal compliance in target markets.

Conclusion:

Sourcing four-way stretch spandex fabric requires a strategic approach that balances quality, cost, sustainability, and reliability. This versatile material, known for its exceptional elasticity, durability, and comfort, is in high demand across activewear, swimwear, intimate apparel, and performance fashion industries. After thorough evaluation of potential suppliers, several key factors stand out: material composition (typically 80–90% nylon or polyester and 10–20% spandex), fabric weight, color fastness, moisture-wicking properties, and environmental certifications.

A successful sourcing strategy involves partnering with manufacturers who demonstrate consistent quality control, ethical production practices, and the capability to scale according to demand. Attending trade shows, requesting fabric swatches, and conducting third-party audits can mitigate risks and ensure compliance with brand standards. Additionally, building long-term relationships with suppliers fosters better communication, innovation, and responsiveness to market changes.

In conclusion, securing a reliable source for four-way stretch spandex fabric is not only critical for maintaining product performance and customer satisfaction but also for supporting sustainable and responsible supply chain practices. With careful due diligence and a focus on partnership, brands can ensure a steady supply of high-performance fabric that meets both consumer expectations and business goals.