The global foundation plate manufacturing market is experiencing steady growth, driven by rising construction activities, infrastructure development, and increasing demand for modular and prefabricated building solutions. According to Mordor Intelligence, the global construction materials market—which includes foundation systems—is projected to grow at a CAGR of over 6.3% from 2023 to 2028, with foundation plates playing a critical role in structural integrity and seismic resilience. Additionally, Grand View Research estimates that the global prefabricated construction market, a key end-user segment for foundation plates, will expand at a CAGR of 6.8% from 2023 to 2030, further fueling demand for high-performance foundation components. As builders and developers prioritize durability, cost-efficiency, and compliance with evolving building codes, manufacturers of foundation plates are innovating with advanced materials and precision engineering. In this evolving landscape, nine leading companies have distinguished themselves through product quality, technical expertise, and market reach—shaping the standards for modern foundation solutions.

Top 9 Foundation Plate Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Steel Base Plate Fabrication

Domain Est. 1996

Website: customeng.com

Key Highlights: We manufacture custom steel compressor base plates, and pump bases used in the power generation industry, petrochemical industry, and industrial manufacturing ……

#2 Sole Plates

Domain Est. 2019

Website: pgisteel.com

Key Highlights: Sole plates are base plates grouted into a concrete foundation. And these plates provide vibration support and leveling support for a machine….

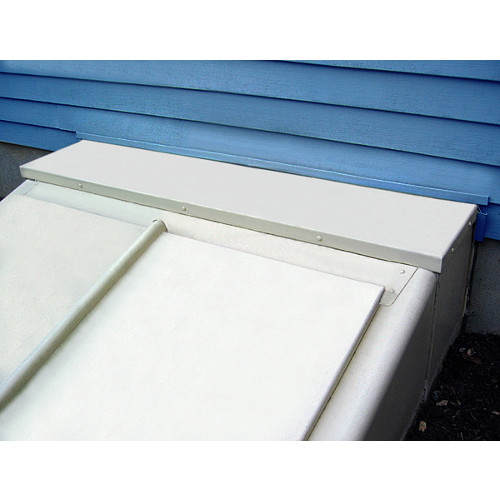

#3 Foundation Plates

Domain Est. 1995

Website: bilco.com

Key Highlights: Foundation plates can be used to improve an areaway’s appearance, cover rough masonry, reduce the inside areaway width, or for side support in corner ……

#4 FRFP® Flat Retrofit Foundation Plate

Domain Est. 1995

Website: strongtie.com

Key Highlights: The FRFP® is designed to connect the mudsill to the foundation and provide lateral load resistance. This flat retrofit foundation plate features a design ……

#5 Base Plates

Domain Est. 2005

Website: 1mta.com

Key Highlights: Base plates are available with holes, t-slots, or plain faces. In our milling range, you will find components suitable for CNC and conventional machines….

#6 Foundation and foundation plates for silo systems

Domain Est. 2007

Website: achberg.com

Key Highlights: We can also deliver ready-to-install foundation plates (two-part) for silos with diameters from 3.0 m to 4.2 m and a total height of 10 m to 12.5 m….

#7 Top & Base Plates

Domain Est. 2013

Website: proxdirect.com

Key Highlights: 24 inch Steel Aluminum Base Plate, Top Plate on a 1′′ Raised Frame for Bolted Box Truss. SKU: XT-BTBP24A…

#8 Steel Base Plates

Domain Est. 2018

Website: coremarkmetals.com

Key Highlights: Buy manufactured steel base plates online. Common applications for square and circular base plates include mounting of equipment or structural lateral load ……

#9 Wind Towers & Foundations

Domain Est. 2020

Website: faccingroup.com

Key Highlights: Discover Faccin plate rolling and bending machines for onshore and offshore wind towers and foundations. Customized machinery for the wind energy industry….

Expert Sourcing Insights for Foundation Plate

2026 Market Trends for Foundation Plates

The global foundation plate market is poised for significant evolution by 2026, driven by advancements in construction technology, sustainability mandates, and shifting infrastructure demands. Foundation plates—critical components in structural systems that distribute loads from columns or walls to the soil—are experiencing innovation in materials, design, and application methodologies.

Growing Adoption of High-Performance Materials

By 2026, the use of advanced composite and high-strength steel foundation plates is expected to rise significantly. These materials offer superior load-bearing capacity, corrosion resistance, and longevity, particularly in challenging environments such as coastal or seismic zones. The integration of fiber-reinforced polymers (FRPs) and corrosion-resistant coatings will enhance durability, reducing lifecycle maintenance costs and extending service life—factors increasingly prioritized by developers and public infrastructure projects.

Digitalization and Smart Foundation Systems

Digital engineering tools, including Building Information Modeling (BIM) and AI-driven structural analysis, will streamline foundation plate design and installation. By 2026, smart foundation plates embedded with sensors for real-time load monitoring and structural health assessment are likely to gain traction, especially in high-value commercial and critical infrastructure projects. This trend supports predictive maintenance and improves safety compliance, aligning with the broader smart city and Industry 4.0 movements.

Sustainability and Green Construction Standards

Environmental regulations and green building certifications (e.g., LEED, BREEAM) will drive demand for sustainable foundation solutions. Manufacturers will increasingly adopt recycled steel and low-carbon production processes. Additionally, optimized plate designs—minimizing material use without sacrificing performance—will support circular economy principles and reduce embodied carbon in construction, a key metric in 2026’s regulatory landscape.

Regional Infrastructure Development

Emerging markets in Asia-Pacific, the Middle East, and Africa will be key growth drivers due to large-scale urbanization and infrastructure investments. In contrast, North America and Europe will focus on retrofitting aging infrastructure, where modular and adaptable foundation plates will be in high demand. This geographic divergence will encourage product customization and localized manufacturing strategies.

Consolidation and Innovation in Supply Chains

The foundation plate sector is expected to see increased consolidation among suppliers, driven by economies of scale and the need for R&D investment. Partnerships between material scientists, engineering firms, and construction companies will accelerate innovation, particularly in pre-fabricated and modular foundation systems that improve construction speed and precision.

In conclusion, the 2026 foundation plate market will be defined by technological integration, material innovation, and sustainability, positioning the component not just as a structural necessity but as a smart, eco-efficient element of modern construction.

Common Pitfalls Sourcing Foundation Plate (Quality, IP)

Sourcing foundation plates—especially in industries like oil & gas, construction, or heavy machinery—can present significant challenges related to material quality and intellectual property (IP) protection. Overlooking these aspects can lead to structural failures, legal disputes, project delays, and reputational damage.

Poor Material Quality and Non-Compliance

One of the most frequent pitfalls is procuring foundation plates made from substandard materials or that fail to meet required industry specifications (e.g., ASTM, ISO, or API standards). This can occur when suppliers cut costs by using inferior steel grades, improper heat treatment, or inadequate corrosion resistance. Poor quality may not be immediately apparent but can lead to premature failure under load or in harsh environments.

Inadequate Certification and Traceability

Many suppliers fail to provide proper material test reports (MTRs), mill certifications, or full traceability from raw material to finished product. Without these documents, verifying the authenticity and compliance of the foundation plate becomes difficult, increasing the risk of using non-conforming parts in critical applications.

Lack of Quality Control at Supplier Level

Some manufacturers, especially in regions with less stringent regulatory oversight, may lack robust quality management systems (e.g., ISO 9001). This increases the likelihood of dimensional inaccuracies, welding defects, or surface imperfections that compromise structural integrity.

Counterfeit or Reverse-Engineered Components

In markets with weak IP enforcement, there is a risk of sourcing foundation plates that are counterfeit or reverse-engineered from proprietary designs. These products may mimic appearance but fail to meet performance standards, potentially infringing on patents or design rights held by original equipment manufacturers (OEMs).

Intellectual Property Infringement Risks

Using or sourcing foundation plates based on patented designs, specialized geometries, or proprietary mounting configurations without proper licensing can expose the buyer to legal action. This is especially critical when replicating components from OEMs without authorization, even if outsourced to third-party fabricators.

Insufficient Supplier Vetting

Failing to conduct thorough due diligence on suppliers—such as site audits, review of past performance, or verification of certifications—can result in partnering with unreliable vendors. This increases exposure to both quality issues and IP-related liabilities.

Ambiguous Contractual Terms

Poorly defined procurement contracts may omit critical clauses related to material specifications, IP ownership, liability for non-compliance, or warranty terms. This creates ambiguity in case of disputes and limits recourse when quality or IP issues arise.

To mitigate these risks, organizations should implement rigorous supplier qualification processes, require full documentation and certification, conduct independent inspections, and ensure legal review of IP considerations before sourcing foundation plates.

Logistics & Compliance Guide for Foundation Plate

This guide outlines the essential logistics procedures and compliance requirements for handling, transporting, and managing Foundation Plate components. Adherence to these standards ensures safety, regulatory compliance, and operational efficiency across all project phases.

Shipping and Handling Procedures

All Foundation Plates must be shipped in protective packaging to prevent damage during transit. Secure stacking and bracing are required to avoid shifting or deformation. Handlers must use appropriate lifting equipment (e.g., forklifts with spreader bars or overhead cranes) and follow load capacity guidelines. Never drag or drop Foundation Plates. Documentation, including packing slips and material certifications, must accompany each shipment.

Storage Requirements

Store Foundation Plates in a dry, level, and well-ventilated area away from moisture, corrosive substances, and extreme temperatures. Plates should be elevated on wooden pallets or stands to prevent ground contact and corrosion. Ensure proper spacing between stacked units to maintain structural integrity and allow for inspection access. Outdoor storage requires waterproof coverings that permit ventilation to avoid condensation.

Transportation Regulations

Transport of Foundation Plates must comply with local, national, and international transportation laws, including weight limits, load securement standards (e.g., DOT in the U.S., ADR in Europe), and hazardous material regulations if applicable. Oversized loads require special permits and escort vehicles where mandated. Drivers and carriers must be trained in handling heavy construction materials and emergency response protocols.

Quality and Compliance Documentation

Each Foundation Plate must be accompanied by a Certificate of Conformance (CoC) and Mill Test Report (MTR) verifying material composition, mechanical properties, and compliance with ASTM, ISO, or project-specific standards (e.g., ASTM A36, ISO 9001). All documentation must be retained for audit purposes and submitted to project stakeholders as required.

Environmental and Safety Compliance

Handling and installation of Foundation Plates must adhere to OSHA (or equivalent) safety regulations, including proper personal protective equipment (PPE), fall protection, and confined space procedures when applicable. Spill containment measures must be in place if coatings or lubricants are used. Dispose of packaging and waste materials in accordance with local environmental regulations (e.g., EPA, REACH).

Import/Export Controls

For international shipments, ensure compliance with customs regulations, export controls (e.g., EAR, ITAR if applicable), and import tariffs. Accurate Harmonized System (HS) codes must be used, and all required licenses or authorizations obtained prior to shipment. Maintain records of all export documentation for a minimum of five years.

Inspection and Audit Readiness

All logistics processes must support traceability and audit readiness. Implement a digital or paper-based tracking system to log receipt, storage duration, movement, and installation of each Foundation Plate. Regular internal audits should verify compliance with this guide and relevant standards. Be prepared for third-party inspections at any project stage.

Corrective Actions and Non-Conformance Reporting

Any deviation from logistics or compliance protocols must be reported immediately through the Non-Conformance Report (NCR) system. Document the issue, initiate containment actions, and implement corrective measures to prevent recurrence. All NCRs must be reviewed by the quality assurance team and resolved before further processing or installation.

Conclusion for Sourcing Foundation Plate

In conclusion, the successful sourcing of foundation plates requires a comprehensive approach that balances material quality, cost-efficiency, supplier reliability, and compliance with industry standards. Selecting the appropriate grade of steel—typically ASTM A36 or similar—ensures structural integrity and durability under load-bearing conditions. Evaluating suppliers based on track record, production capability, and adherence to specifications is critical to maintaining project timelines and quality control.

Additionally, factors such as lead time, logistics, and total landed cost must be carefully assessed to optimize procurement decisions. Engaging with pre-qualified vendors, obtaining material certifications, and conducting periodic quality audits further mitigate risks associated with substandard products.

Ultimately, strategic sourcing of foundation plates not only supports structural safety and longevity but also contributes to overall project efficiency and cost management. A well-structured procurement process ensures that foundation plates meet engineering requirements and contribute reliably to the stability of the entire structure.