The global plywood market, fueled by rising construction activities and demand for sustainable building materials, is experiencing steady growth. According to Mordor Intelligence, the global plywood market was valued at USD 28.6 billion in 2023 and is projected to grow at a CAGR of over 6.2% through 2029. A key driver within this segment is the increasing adoption of Formply—high-strength, moisture-resistant plywood widely used in formwork for concrete construction. Its durability, reusability, and cost-efficiency make it a preferred choice across residential, commercial, and infrastructure projects. With Asia-Pacific leading both in production and consumption—attributed to rapid urbanization and industrial expansion—the competitive landscape has intensified among manufacturers aiming to innovate and scale. Based on market presence, production capacity, quality certifications, and customer reviews, we’ve analyzed the top seven Formply manufacturers shaping the industry’s future.

Top 7 Formply Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Big River Industries

Website: bigriverindustries.com.au

Key Highlights: Big River is: a major manufacturer of softwood and hardwood formply and structural plywood products in Australia;; a major seller of consumable formwork ……

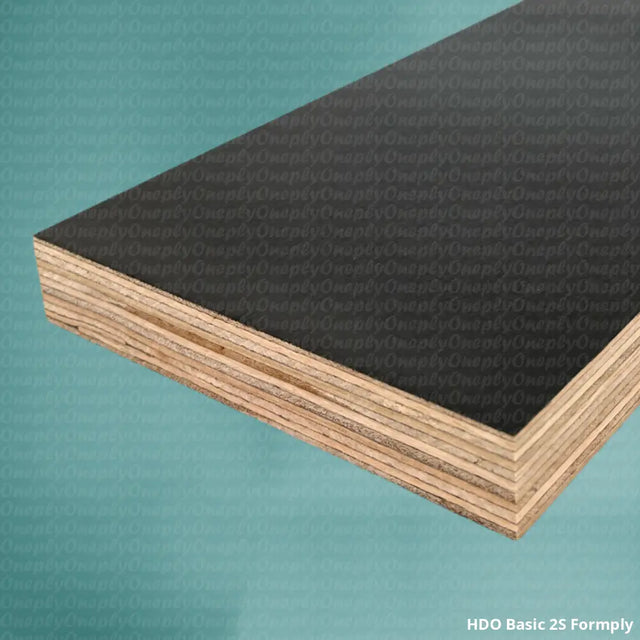

#2 Buy Products from Formply Wood Wholesale

Domain Est. 2002

Website: globy.com

Key Highlights: We specialize in manufacturing and trading Laminted Veneer Lumber (LVL) plywood which is used for Packing, Furniture and Construction, catering to both ……

#3 F17 ( F14 ) Formply

Domain Est. 2013

Website: plywoodinspection.com

Key Highlights: If you’re in search of high-quality custom wooden furniture that blends functionality, aesthetics, and durability, we have excellent news for you. A Chinese- ……

#4 Formply F17: The Double Certified, Durable Choice

Domain Est. 2019

Website: formply-f17.com

Key Highlights: Formply F17, designed for strength and stability. As a double-certified plywood, it offers unmatched durability for various applications….

#5 Formply Australia

Website: formplyaustralia.com.au

Key Highlights: Formply Australia is an Australian company focused on the Formwork Industry and products sourced from legally managed forest plantations derived from suppliers ……

#6 Formply

Website: formply.vn

Key Highlights: Discover top-quality formply designed for robust construction projects. Our formwork plywood ensures durability and precision, ideal for concrete formwork….

#7 Formply NZ Ltd

Website: formply.co.nz

Key Highlights: Formply NZ Ltd are suppliers of Quality Formply, Marine Plywood, High Pressure Laminates (HPL) & Tulsa Plywood. For you plywood needs contact today….

Expert Sourcing Insights for Formply

H2 2026 Market Trends for Formply

As the global construction and infrastructure sectors evolve, Formply—a high-strength, durable plywood commonly used in concrete formwork—faces a dynamic market landscape in H2 2026. Several interconnected trends are shaping demand, supply, and innovation in the Formply industry during this period:

1. Surge in Infrastructure Investment Driving Demand

H2 2026 sees continued momentum from major government-led infrastructure programs, particularly in North America (U.S. Infrastructure Act), Europe (Green Deal investments), and Asia-Pacific (China’s urban renewal, India’s National Infrastructure Pipeline). These projects—spanning bridges, highways, and high-rise developments—require extensive concrete formwork, directly boosting Formply consumption. Demand is especially strong for reusable, high-cycle Formply systems that support cost efficiency and sustainability goals.

2. Sustainability and Environmental Regulations Intensify

Environmental compliance is a dominant force. Stricter regulations on formaldehyde emissions (e.g., CARB Phase 3, EU REACH) and increasing demand for low-carbon construction materials are pushing manufacturers toward formaldehyde-free resins (e.g., PMDI) and sustainably sourced timber. Formply products with third-party certifications (FSC, PEFC) are gaining preference in public tenders and green building projects (e.g., LEED, BREEAM-rated developments).

3. Shift Toward Engineered and Reusable Systems

The market is moving beyond traditional single-use Formply sheets. In H2 2026, there’s accelerated adoption of engineered Formply solutions—such as laminated multi-ply panels, waterproof coatings, and precision-cut modular systems—designed for 50+ reuses. Contractors are investing in reusable formwork to reduce long-term costs and waste, supported by rental and leasing models from major suppliers.

4. Supply Chain Resilience and Regional Sourcing

Ongoing geopolitical tensions and logistics volatility have prompted a strategic shift toward regionalized supply chains. In H2 2026, manufacturers in Australia, Europe, and North America are expanding local production capacity to reduce reliance on imported tropical hardwoods (e.g., from Southeast Asia). This trend supports faster delivery times and aligns with “Buy Local” procurement policies in public infrastructure.

5. Digitalization and BIM Integration

Building Information Modeling (BIM) is transforming formwork planning. By H2 2026, leading Formply suppliers offer digital libraries of panel specifications and compatibility data, enabling contractors to pre-fabricate and pre-assemble formwork systems with high accuracy. This integration reduces material waste, labor costs, and project timelines—key drivers in competitive bidding environments.

6. Price Volatility and Raw Material Challenges

Despite positive demand, Formply prices remain sensitive to fluctuations in softwood lumber, phenolic resins, and energy costs. In H2 2026, supply constraints in key resin-producing regions and elevated energy prices in Europe have led to moderate price increases. However, long-term supply contracts and hedging strategies are helping large contractors mitigate risk.

7. Innovation in Alternative Materials

While Formply remains dominant, competition from fiber-reinforced polymer (FRP) and aluminum formwork systems is growing—especially in high-rise and complex architectural projects. However, Formply retains a cost and adaptability advantage in standard applications. R&D efforts are focused on hybrid systems that combine Formply with lightweight composites to enhance performance and durability.

Conclusion

In H2 2026, the Formply market is characterized by strong demand driven by infrastructure growth, a clear shift toward sustainable and reusable solutions, and increasing integration with digital construction workflows. While cost and supply chain pressures persist, innovation and regional manufacturing investments are positioning Formply as a resilient and evolving material in modern concrete construction. Companies that prioritize sustainability, durability, and digital compatibility are best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing Formply: Quality and Intellectual Property Risks

Sourcing Formply—high-performance, engineered plywood used primarily in construction for concrete formwork—can be cost-effective, but it comes with significant risks if not managed carefully. Buyers, especially those sourcing internationally, must be vigilant about both quality consistency and intellectual property (IP) concerns. Below are common pitfalls in these two critical areas.

Quality-Related Pitfalls

Inconsistent Plywood Grades and Performance

One of the most frequent issues when sourcing Formply is inconsistent quality. Not all products labeled as “Formply” meet the structural or durability standards required for repeated concrete pours. Suppliers may use lower-grade veneers, inadequate adhesives (e.g., non-phenolic resins), or inconsistent layer thickness, leading to warping, delamination, or blowouts during use.

Lack of Compliance with International Standards

Formply must meet specific standards such as AS/NZS 2269 (Australia/New Zealand) or BS EN 13986 (Europe) for structural use. Some imported products are mislabeled or do not undergo proper third-party testing. Buyers may receive material that appears similar but fails under load or moisture exposure.

Poor Moisture and Boil Resistance

Genuine Formply uses waterproof phenol-formaldehyde resins. Substandard alternatives may use urea-formaldehyde or other resins that degrade when exposed to moisture or high temperatures during concrete curing. This compromises formwork integrity and safety.

Inadequate Face Veneer Quality

The smooth, durable face of Formply is critical for achieving a high-quality concrete finish. Poorly sourced products may have scratches, gaps, or inconsistent resin coating, leading to surface defects in the final concrete structure and requiring more labor for finishing.

Intellectual Property and Brand Misrepresentation

Misuse of the “Formply” Trademark

“Formply” is a registered trademark owned by Carter Holt Harvey (CHH) in several countries, including Australia and New Zealand. Unscrupulous suppliers often misuse the term generically to describe any film-faced plywood, misleading buyers into believing they are purchasing an authentic, branded product. This creates legal and reputational risks.

Counterfeit or Knock-Off Products

Some overseas manufacturers produce near-identical copies of branded Formply, including packaging and logos, without authorization. These counterfeit products may carry the same branding but lack the engineering, quality control, and testing of the original, resulting in project failures and potential liability.

Lack of Traceability and Certification

Genuine branded Formply comes with certification of origin, compliance, and performance data. Sourcing from unreliable suppliers may mean missing or falsified documentation, making it difficult to verify authenticity or meet construction compliance requirements.

Legal Exposure from IP Infringement

Importing or specifying counterfeit Formply—knowingly or unknowingly—can expose contractors, architects, or developers to legal action for trademark infringement. In regulated markets, using non-compliant materials may also void warranties or result in project delays.

Best Practices to Avoid Pitfalls

– Source directly from authorized distributors or manufacturers.

– Request third-party test reports and certification (e.g., structural grade, bond durability).

– Verify trademark usage and check IP registration in your jurisdiction.

– Inspect samples rigorously before bulk ordering.

– Include material specifications and compliance clauses in procurement contracts.

By addressing both quality and IP concerns proactively, businesses can mitigate risks and ensure reliable, compliant performance from their Formply supply.

Logistics & Compliance Guide for Formply

Formply, a specialized structural plywood used extensively in concrete formwork, requires careful handling, storage, transportation, and compliance with industry standards to ensure performance, safety, and regulatory adherence. This guide outlines best practices and essential compliance considerations.

Handling and Storage

Proper handling and storage are critical to maintaining Formply’s integrity and extending its service life.

- Avoid Moisture Exposure: Store Formply indoors or under a waterproof cover on elevated, level timber bearers. Never place directly on wet ground to prevent edge swelling and delamination.

- Stacking Guidelines: Stack sheets neatly and vertically or horizontally with even support. For horizontal stacking, do not exceed 2 meters in height. Use dunnage between layers to allow airflow and prevent warping.

- Protect Edges and Surfaces: Handle with care using lifting straps or suction lifters. Avoid dragging or dropping sheets to prevent chipping and surface damage.

- Ventilation: Ensure adequate air circulation around stored stacks to minimize moisture buildup and mold development.

Transportation

Transporting Formply safely ensures it arrives undamaged and ready for use.

- Secure Loading: Sheets must be tightly strapped or banded to pallets or truck beds to prevent shifting during transit. Use edge protectors to prevent damage.

- Weather Protection: Cover loads completely with waterproof tarpaulins to shield from rain, snow, or condensation during transit.

- Vehicle Suitability: Use flatbed or enclosed trucks with sufficient load capacity and restraint systems compliant with road transport regulations (e.g., Australian Load Restraint Guide, U.S. DOT standards).

- Forklift Safety: When loading/unloading, use appropriate forklifts with adequate capacity. Ensure operators are trained and follow site safety protocols.

Compliance and Certification

Formply must meet regulatory and industry standards depending on the region and application.

- Product Standards:

- In Australia/NZ: Comply with AS/NZS 2269 (Plywood – Structural) and AS 3623 (Domestic and Low-Rise Housing).

- In the EU: Must meet EN 13986 and EN 636 standards, with CE marking indicating conformity.

- In the USA: Follow APA – The Engineered Wood Association standards (e.g., PRP-112 for plywood).

- Fire Safety: In certain applications, especially high-rise construction, Formply may need to meet fire resistance requirements (e.g., AS 1530.3 in Australia or ASTM E84 in the U.S.).

- Environmental and Emissions Compliance: Ensure compliance with formaldehyde emission standards such as CARB Phase 2 (U.S.), EPA TSCA Title VI, or E0/E1 ratings (EU). Documentation like EPDs (Environmental Product Declarations) may be required for green building certifications (e.g., LEED, Green Star).

- Chain of Custody: For sustainably sourced timber, verify FSC® or PEFC™ certification, especially for public or environmentally sensitive projects.

Site Usage and Safety

Safe and compliant use of Formply on construction sites enhances efficiency and worker protection.

- Personal Protective Equipment (PPE): Workers should wear gloves, eye protection, and dust masks when cutting or sanding Formply to minimize exposure to wood dust and resins.

- Cutting and Machining: Use sharp blades and appropriate tools to reduce splintering. Collect and dispose of off-cuts responsibly.

- Reuse and Inspection: Inspect Formply before each reuse for signs of delamination, warping, or edge damage. Repair or discard compromised sheets to maintain formwork integrity.

- Disposal: Dispose of waste Formply in accordance with local regulations. Reuse off-cuts where possible or recycle through approved wood waste channels.

Documentation and Traceability

Maintain accurate records to support compliance and quality assurance.

- Mill Certificates: Retain supplier-provided mill test certificates confirming compliance with relevant standards.

- Batch Tracking: Log batch numbers and delivery dates to enable traceability in case of quality issues.

- Site Audit Readiness: Keep handling, storage, and inspection records available for project audits or regulatory inspections.

Adhering to this logistics and compliance guide ensures Formply performs reliably in formwork applications while meeting safety, environmental, and regulatory requirements across the supply chain.

Conclusion on Sourcing Formply

Sourcing Formply requires a strategic approach that balances quality, cost, availability, and sustainability. As a structural plywood commonly used in construction—especially for concrete forming—Formply must meet specific performance standards to ensure durability, reusability, and a smooth concrete finish. After evaluating suppliers, material specifications, and logistical considerations, it is clear that choosing the right Formply provider involves more than just price comparison.

Key factors such as compliance with industry standards (e.g., BS EN 13986 or AS/NZS 2271), the quality of the phenolic film surface, the number of reuses, moisture resistance, and consistent thickness are critical in determining suitability for a project. Additionally, sourcing from reputable suppliers—locally or internationally—with reliable supply chains helps minimize project delays and ensures consistency in material performance.

Sustainability and certifications, such as PEFC or FSC, are increasingly important for environmentally responsible construction, and should be considered when selecting a supplier. Establishing long-term relationships with trusted vendors can lead to better pricing, technical support, and just-in-time delivery, all of which contribute to efficient project execution.

In conclusion, successful sourcing of Formply hinges on a thorough evaluation of technical specifications, supplier reliability, and project-specific requirements. Prioritizing quality and consistency over upfront cost ensures better performance on site, reduces waste, and ultimately supports safer, more cost-effective construction outcomes.