The global forklift truck market is experiencing robust growth, driven by rising industrial automation, expanding logistics networks, and increased warehouse automation across e-commerce and manufacturing sectors. According to Grand View Research, the global forklift market was valued at USD 83.4 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.1% from 2023 to 2030. Similarly, Mordor Intelligence forecasts a CAGR of over 5.8% during the same period, underlining sustained demand for material handling equipment, particularly electric and automated forklifts. This growth trajectory has intensified competition among manufacturers, with innovation in safety, efficiency, and load capacity becoming key differentiators. As industries seek reliable and high-performance loading solutions, a select group of manufacturers has emerged as leaders in technology, global reach, and product reliability. Below is an analysis of the top nine forklift truck loading manufacturers shaping the future of material handling.

Top 9 Forklift Truck Loading Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

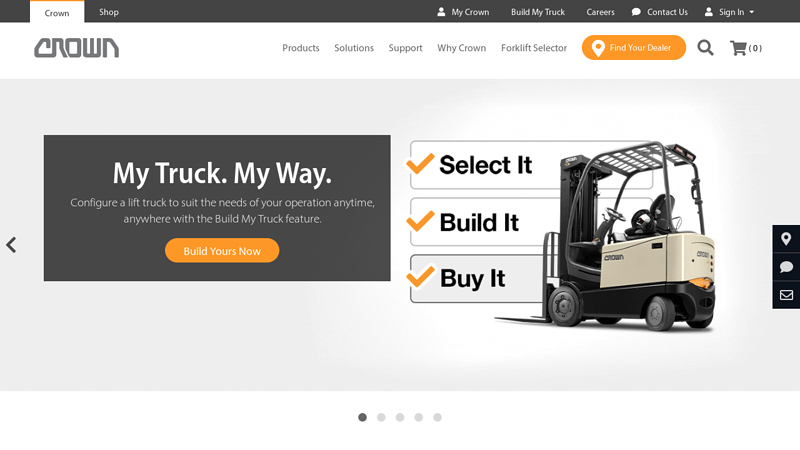

#1 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks and technology, with a network of more than 500 forklift ……

#2 UniCarriers Forklifts

Domain Est. 2020

Website: logisnextamericas.com

Key Highlights: As an American forklift manufacturer that’s proudly part of a global corporation, UniCarriers is committed to enabling our customers to efficiently move goods ……

#3 Yale Lift Truck Technologies

Domain Est. 1994

Website: yale.com

Key Highlights: Yale’s forklifts and lift trucks are designed to tackle your biggest challenges. Discover how our technology can boost your warehouse productivity!…

#4 Toyota Forklifts

Domain Est. 1996

Website: toyotaforklift.com

Key Highlights: Toyota Forklifts is the leader in material handling and industrial lift trucks and equipment. Learn about our solutions to maximize your warehouse ……

#5 Forklift Truck

Domain Est. 2001

Website: linde-mh.com

Key Highlights: The forklift truck is the number one choice for intralogistics. Both versatile and powerful, the industrial truck is ideal for transporting and handling goods….

#6 Forklifts & Lift Trucks

Domain Est. 1997

Website: bobcat.com

Key Highlights: Explore the extensive forklifts and lift trucks lineup of cushion tire, pneumatic tire, electric counterbalance, narrow aisle and pallet trucks and ……

#7 Big Joe Forklifts

Domain Est. 1999

Website: bigjoeforklifts.com

Key Highlights: Discover Big Joe’s innovative lithium-ion forklifts and autonomous solutions, backed by expert support and engineering, for efficient material handling ……

#8 Combilift Forklifts

Domain Est. 1999

Website: combilift.com

Key Highlights: Maximise your warehouse efficiency with Combilift’s award-winning forklifts, including multidirectional and sideloader options for various industries….

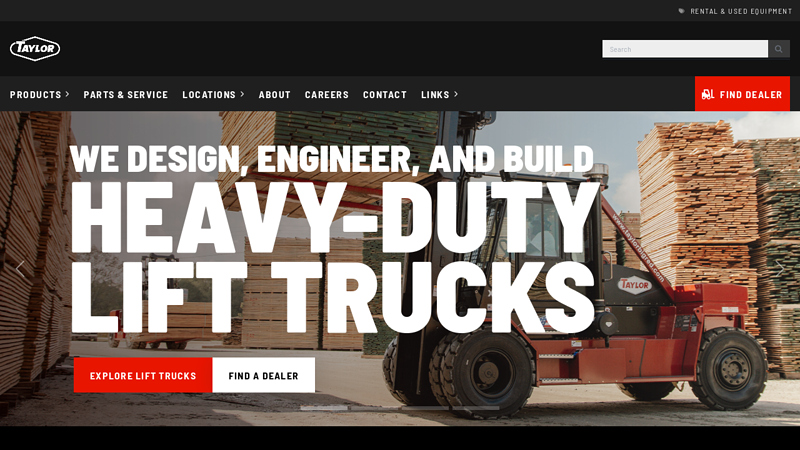

#9 Taylor Forklifts: Heavy

Domain Est. 2000

Website: taylorforklifts.com

Key Highlights: Explore heavy-duty forklifts and container handling equipment from Taylor. Built for tough industries, backed by expert service, parts, and dealer support….

Expert Sourcing Insights for Forklift Truck Loading

H2: 2026 Market Trends for Forklift Truck Loading

The forklift truck loading market is poised for significant transformation by 2026, driven by technological innovation, evolving logistics demands, and a growing emphasis on sustainability and operational efficiency. Below are key market trends expected to shape the industry in 2026:

1. Accelerated Adoption of Automation and AI Integration

By 2026, automation will be a dominant force in forklift truck loading operations. Autonomous forklifts equipped with AI-driven navigation systems, machine learning algorithms, and real-time sensor feedback will increasingly replace manual labor in warehouses and distribution centers. These smart forklifts will optimize load paths, reduce human error, and improve loading precision, especially in high-throughput environments like e-commerce fulfillment centers.

2. Electrification and Zero-Emission Solutions

Environmental regulations and corporate sustainability goals will continue to push the shift from internal combustion (IC) engines to electric forklifts. By 2026, electric and hydrogen-powered forklifts are expected to capture over 50% of the global market. Fast-charging batteries and improved energy density will enhance uptime and reduce operational costs, making electric models more viable for heavy-duty loading applications.

3. Integration with Warehouse Management Systems (WMS) and IoT

Forklifts will increasingly function as connected nodes within broader logistics ecosystems. Through IoT-enabled telematics, fleet managers will monitor real-time loading performance, fuel/battery consumption, and maintenance needs. Seamless integration with WMS and ERP platforms will allow for predictive loading schedules, dynamic task allocation, and improved inventory accuracy.

4. Rise of Smart Loading Technologies

Advanced vision systems, 3D load scanning, and weight-distribution sensors will become standard on next-gen forklifts. These technologies will ensure optimal cargo placement during loading, minimizing damage and maximizing trailer/container space utilization. In 2026, smart loading systems will reduce freight costs by up to 15% through improved load efficiency.

5. Growth in Last-Mile and E-Commerce Logistics

The continued expansion of e-commerce will drive demand for agile, compact forklifts capable of rapid loading in urban distribution hubs. Forklifts designed for narrow aisles and multi-level loading operations will be in high demand, especially in automated micro-fulfillment centers located close to consumers.

6. Emphasis on Operator Safety and Ergonomics

Regulatory pressures and workforce shortages will lead manufacturers to prioritize forklift designs that enhance operator safety during loading tasks. Features such as collision avoidance systems, stability control, and augmented reality (AR) guidance displays will become more prevalent, reducing accidents and training time.

7. Regional Market Diversification

While North America and Europe will lead in adopting advanced forklift technologies, Asia-Pacific—particularly China, India, and Southeast Asia—will experience the highest growth rates due to industrial expansion and modernization of logistics infrastructure. Local production and government incentives will further accelerate market penetration.

In conclusion, the 2026 forklift truck loading market will be defined by intelligence, connectivity, and sustainability. Companies that invest in integrated, automated, and eco-friendly loading solutions will gain a competitive edge in an increasingly digital and efficiency-driven supply chain landscape.

Common Pitfalls in Sourcing Forklift Truck Loading Equipment (Quality, IP)

Sourcing forklift truck loading equipment—such as dock levelers, vehicle restraints, and loading bay accessories—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to safety hazards, operational inefficiencies, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Quality Standards and Materials

One of the most frequent issues when sourcing forklift loading equipment is compromising on quality to reduce costs. Low-quality materials, such as substandard steel or inadequate hydraulic components, can lead to premature wear, structural failure, and safety incidents. Equipment that cannot withstand heavy forklift traffic or harsh environments may result in costly downtime and increased maintenance.

Lack of Compliance with Safety and Industry Standards

Forklift loading systems must comply with regional and international safety standards (e.g., OSHA in the U.S., CE marking in Europe, AS/NZS in Australia). Sourcing non-compliant equipment—whether due to ignorance or supplier misrepresentation—exposes companies to regulatory penalties, insurance issues, and workplace accidents.

Inadequate Supplier Vetting and Due Diligence

Choosing suppliers based solely on price without verifying certifications, manufacturing processes, or track record increases the risk of receiving defective or counterfeit products. Reliable suppliers should provide test reports, ISO certifications, and references from similar industrial clients.

Intellectual Property Infringement

Sourcing from manufacturers who copy patented designs—such as unique hydraulic mechanisms, safety interlocks, or ergonomic features—can inadvertently expose the buyer to legal liability. Even if the buyer is unaware, using or importing IP-infringing equipment may lead to cease-and-desist orders, product seizures, or lawsuits, especially in jurisdictions with strong IP enforcement.

Counterfeit or “Knock-Off” Products

Some suppliers offer equipment that mimics well-known brands but lacks the original engineering, durability, or safety features. These counterfeit products often cut corners on design and materials, posing significant safety risks. They may also lack proper documentation or traceability, complicating warranty claims and maintenance.

Insufficient Technical Documentation and Support

Low-cost suppliers may fail to provide comprehensive installation manuals, maintenance guides, or spare parts lists. This lack of documentation hampers proper setup and long-term serviceability, leading to operational disruptions and higher lifecycle costs.

Ignoring After-Sales Service and Warranty Terms

Equipment failures are inevitable over time. Sourcing from suppliers with weak or non-existent after-sales support—especially in remote regions—can result in extended downtime. Unclear or restrictive warranty terms may also leave buyers exposed to unexpected repair costs.

Overlooking Customization and Compatibility

Forklift loading equipment must integrate seamlessly with existing infrastructure (e.g., dock heights, trailer types, forklift models). Sourcing standardized solutions without assessing site-specific requirements can result in poor performance or unsafe operations.

Failure to Conduct On-Site Audits or Product Testing

Relying solely on brochures or supplier claims without conducting factory audits or requesting product samples increases the risk of quality discrepancies. Physical testing under load conditions can reveal weaknesses not evident in specifications.

Supply Chain and Lead Time Risks

Sourcing from distant or unreliable suppliers can lead to delays, especially when custom parts or replacement components are needed. Extended lead times disrupt operations and reduce resilience in maintenance planning.

By proactively addressing these pitfalls—through rigorous supplier evaluation, adherence to quality standards, and attention to intellectual property rights—organizations can ensure safer, more reliable, and legally compliant forklift truck loading operations.

Logistics & Compliance Guide for Forklift Truck Loading

Proper forklift truck loading is essential for operational efficiency, workplace safety, and regulatory compliance. This guide outlines best practices and compliance requirements to ensure safe and effective material handling.

Understanding Load Capacity and Stability

Every forklift has a rated load capacity, typically displayed on a data plate. This capacity varies based on load center distance, mast tilt, and attachments. Exceeding the load capacity or improperly balancing the load can result in tip-overs, dropped loads, and serious injuries. Always consult the forklift’s load capacity chart before lifting.

Pre-Loading Inspection Procedures

Conduct a thorough pre-operation inspection of the forklift, including:

– Checking for fluid leaks (hydraulic, engine oil, coolant)

– Ensuring tires are properly inflated and free of damage

– Testing brakes, steering, and hydraulic controls

– Verifying the condition of forks (cracks, bends, or excessive wear)

Document inspections daily using a standardized checklist to comply with OSHA 29 CFR 1910.178 regulations.

Proper Load Handling Techniques

- Center the load evenly on the forks, as close to the mast as possible

- Lift the load only after ensuring it is secure and balanced

- Tilt the mast slightly backward to stabilize the load during transport

- Keep the load low (4–6 inches off the ground) while moving

- Travel with the load pointed uphill when on an incline

Avoid sudden starts, stops, or sharp turns to prevent load shifting.

Compliance with OSHA and ANSI Standards

Forklift operations must comply with OSHA 29 CFR 1910.178 and ANSI/ITSDF B56.1 safety standards. Key compliance requirements include:

– Operator certification through formal training and evaluation

– Use of seat belts and other safety restraints

– Prohibition of unauthorized or untrained personnel from operating forklifts

– Adherence to site-specific speed limits and traffic rules

Regular audits and training refreshers are required to maintain compliance.

Loading and Unloading from Trailers and Shipping Containers

Ensure trailers are properly secured with wheel chocks and restraint systems (e.g., trailer locks) before entering. Check floor conditions for damage or obstructions. When loading containers, distribute weight evenly and avoid overloading one side. Communicate clearly with dock personnel using standardized hand signals or radios.

Environmental and Site-Specific Considerations

Adjust forklift operation for environmental factors such as wet floors, uneven surfaces, or poor lighting. Use appropriate forklift types (e.g., electric for indoor use, propane or diesel for outdoor) to minimize emissions and fire risks. Maintain clear aisles and adequate signage to prevent collisions.

Documentation and Incident Reporting

Maintain records of operator training, equipment inspections, and maintenance logs. Report and investigate any near-misses or accidents immediately. Use findings to update safety protocols and prevent recurrence.

By adhering to these logistics and compliance guidelines, organizations can ensure safe, efficient, and legally compliant forklift loading operations.

Conclusion: Sourcing Forklift Truck Loading

In conclusion, effective sourcing of forklift truck loading operations is essential for optimizing material handling efficiency, ensuring workplace safety, and reducing operational costs. By carefully selecting reliable suppliers, evaluating equipment specifications, and considering factors such as load capacity, fuel type, and maintenance support, businesses can enhance productivity and adaptability in their logistics and warehousing processes. Additionally, incorporating trained personnel and adhering to safety standards further strengthens the reliability of forklift operations. Strategic sourcing not only improves equipment performance but also contributes to long-term cost savings and operational sustainability, making it a critical component in supply chain management.