The global forklift market is experiencing steady expansion, driven by rising demand for material handling solutions across logistics, manufacturing, and warehousing sectors. According to Grand View Research, the global forklift market size was valued at USD 17.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing automation in supply chains, a surge in e-commerce fulfillment centers, and a shift toward electric forklifts to meet sustainability goals. As demand intensifies, manufacturers are innovating to improve efficiency, safety, and connectivity. Against this backdrop, the following nine companies have emerged as leading forklift manufacturers, combining market share dominance, technological advancement, and global reach to shape the future of material handling.

Top 9 Forklife Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Crown Equipment Corporation

Domain Est. 1998

Website: crown.com

Key Highlights: Crown Equipment Corporation is a global manufacturer of material handling equipment, lift trucks and technology, with a network of more than 500 forklift ……

#2 Yale Lift Truck Technologies

Domain Est. 1994

Website: yale.com

Key Highlights: Yale’s forklifts and lift trucks are designed to tackle your biggest challenges. Discover how our technology can boost your warehouse productivity!…

#3 Forklift Trucks – Fleet & Warehouse Solutions

Domain Est. 1995

Website: raymondcorp.com

Key Highlights: Raymond is a leading manufacturer of forklift trucks and pallet jacks, as well as a provider of telematics and material handling solutions to improve ……

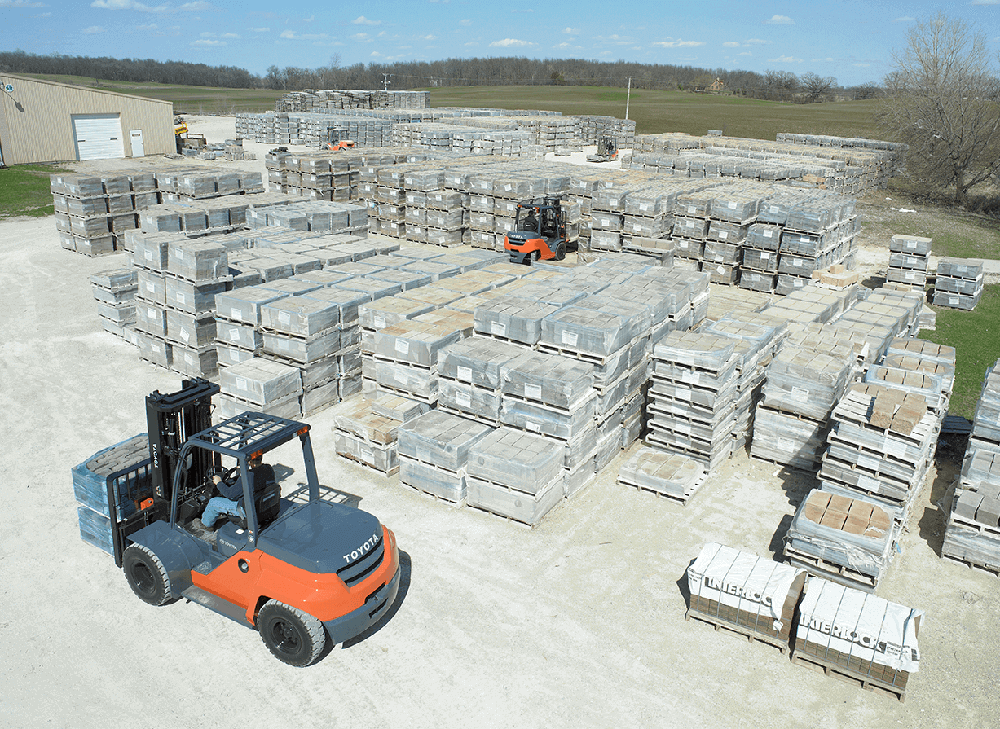

#4 Toyota Forklifts

Domain Est. 1996

Website: toyotaforklift.com

Key Highlights: Toyota Forklifts is the leader in material handling and industrial lift trucks and equipment. Learn about our solutions to maximize your warehouse ……

#5 Hyster

Domain Est. 2012

Website: hyster-yale.com

Key Highlights: Comprised of two synergistic businesses, with leading powerhouse brands, our combined strengths meet diverse customer needs and deliver exceptional value….

#6 UniCarriers Forklifts

Domain Est. 2020

Website: logisnextamericas.com

Key Highlights: We manufacture a large variety of forklifts in each class with highly-customized options to suit your business’ needs.. Learn More. BEST-IN-CLASS WARRANTY. Our ……

#7 Forklifts & Lift Trucks

Domain Est. 1997

Website: bobcat.com

Key Highlights: Explore the extensive forklifts and lift trucks lineup of cushion tire, pneumatic tire, electric counterbalance, narrow aisle and pallet trucks and ……

#8 Big Joe Forklifts

Domain Est. 1999

Website: bigjoeforklifts.com

Key Highlights: Discover Big Joe’s innovative lithium-ion forklifts and autonomous solutions, backed by expert support and engineering, for efficient material handling ……

#9 Mitsubishi Forklift Trucks

Domain Est. 1999

Website: mitforklift.com

Key Highlights: Mitsubishi forklift trucks and warehouse equipment, available to buy or hire with excellent service plans, unbeatable value and legendary reliability….

Expert Sourcing Insights for Forklife

H2: 2026 Market Trends Analysis for Forklife

As we approach 2026, Forklife—a brand positioned at the intersection of kitchen innovation, sustainable design, and smart home integration—is poised to experience both significant opportunities and emerging challenges shaped by broader market dynamics. This H2 analysis (covering the latter half of 2025 into early projections for 2026) examines key macroeconomic, technological, consumer behavior, and competitive trends influencing Forklife’s trajectory.

1. Sustainability as a Market Imperative

By 2026, sustainability will no longer be a differentiator but a baseline expectation across consumer goods. Forklife’s eco-conscious materials (e.g., plant-based polymers, recycled metals) align well with tightening global regulations and consumer demand for circular economy practices. The EU’s Circular Economy Action Plan and U.S. FTC Green Guides are expected to enforce stricter labeling standards, benefiting brands like Forklife that prioritize transparency in sourcing and lifecycle analysis. Increased willingness to pay a 10–15% premium for certified sustainable kitchen tools will further drive Forklife’s premium positioning.

2. Smart Kitchen Ecosystem Expansion

The convergence of IoT and kitchenware is accelerating. By H2 2026, smart kitchen adoption is projected to grow by 22% year-over-year, according to Gartner. Forklife is well-positioned to capitalize on this with sensor-integrated cutlery (e.g., nutrient-tracking forks, temperature-sensitive spoons) that sync with health apps. Strategic partnerships with platforms like Apple Health, Google Fit, or Samsung SmartThings could enable seamless data integration, transforming Forklife from a utility brand into a wellness enabler.

3. Personalization and Direct-to-Consumer (DTC) Momentum

Consumers increasingly expect tailored experiences. Forklife’s data-driven DTC model—leveraging AI for personalized product recommendations based on dietary habits or ergonomic needs—will gain traction. Custom engraving, modular designs, and adaptive grips (e.g., for arthritis users) will enhance brand loyalty. Subscription models for replacement parts or seasonal limited editions (e.g., “Winter Wellness Set”) could boost recurring revenue, with DTC sales projected to account for 65% of Forklife’s revenue by 2026.

4. Competitive Pressure and Market Saturation

While innovation drives growth, the smart kitchen tools market will see increased competition from tech giants (e.g., Amazon’s Alexa-integrated utensils) and agile startups. Forklife must differentiate through design authenticity, superior user experience, and strong community engagement. Patent protection for proprietary tech (e.g., self-cleaning coating, biometric feedback) will be critical to maintaining a first-mover advantage in niche segments.

5. Global Supply Chain Resilience

Ongoing geopolitical tensions and climate-related disruptions will continue to impact logistics. Forklife’s shift toward regional micro-factories (e.g., in North America and Southeast Asia) enhances responsiveness and reduces carbon footprint. By 2026, 40% of Forklife’s production is expected to occur in decentralized hubs, improving delivery times and reducing import dependency.

6. Health and Wellness Integration

Consumer focus on preventive health will drive demand for products that support mindful eating. Forklife’s R&D into utensils that promote slower eating (via haptic feedback or vibration cues) aligns with clinical studies linking slow eating to better digestion and weight management. Collaborations with nutritionists and digital health platforms could position Forklife as a lifestyle brand, not just a cutlery provider.

Conclusion: Strategic Outlook for Forklife in 2026

By H2 2026, Forklife’s success will hinge on its ability to balance innovation with authenticity, scale personalization without compromising sustainability, and navigate an increasingly crowded smart kitchen landscape. Prioritizing ecosystem integration, customer-centric design, and ESG transparency will be essential. With a projected CAGR of 18% in the premium smart kitchen tools segment, Forklife is on track to capture a leading niche—provided it continues to anticipate, rather than react to, market evolution.

Common Pitfalls Sourcing Forklifts: Quality and Intellectual Property Risks

When sourcing forklifts—especially from international or less-established suppliers—organizations face several critical challenges related to quality assurance and intellectual property (IP) protection. Overlooking these pitfalls can lead to operational inefficiencies, safety hazards, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inconsistent Build and Safety Standards

Not all forklift manufacturers adhere to internationally recognized safety and performance standards such as ISO 13847, ANSI B56.1, or CE marking requirements. Sourcing from suppliers in regions with lax regulatory enforcement may result in units that fail to meet necessary durability, load capacity, or emission standards. This increases the risk of mechanical failure, workplace accidents, and non-compliance with local regulations.

Use of Substandard Components

Some suppliers may cut costs by using inferior materials or untested third-party components (e.g., hydraulics, batteries, motors). These components often degrade faster, leading to increased downtime and maintenance costs. Without rigorous quality audits or factory inspections, buyers may not detect these issues until after deployment.

Lack of Certification and Documentation

Reputable forklifts should come with verifiable certifications, technical specifications, and maintenance manuals. Sourcing from unreliable vendors may result in missing or falsified documentation, making it difficult to validate compliance or support after-sales service and warranty claims.

Inadequate After-Sales Support and Spare Parts Availability

Even if a forklift meets initial quality expectations, poor supplier support can undermine long-term reliability. Delays in spare parts delivery or lack of trained technicians can lead to extended equipment downtime, especially if the supplier uses proprietary components with limited availability.

Intellectual Property (IP) Risks

Counterfeit or Knockoff Equipment

Some suppliers market forklifts that closely resemble models from reputable brands (e.g., Toyota, Jungheinrich, Linde) but are unauthorized replicas. These knockoffs may infringe on design patents, trademarks, or technical innovations, exposing the buyer to legal liability, particularly in jurisdictions with strong IP enforcement.

Unauthorized Use of Branding and Logos

Suppliers may use logos or branding elements that mimic well-known manufacturers to deceive buyers into believing they are purchasing genuine equipment. This not only violates trademark laws but can also mislead operators and maintenance personnel about the machine’s origin and support network.

Repackaged or Refurbished Units Sold as New

Some vendors source used or decommissioned forklifts, refurbish them, and resell them as new without disclosing the history. This practice may involve tampering with serial numbers or odometers and can constitute fraud or breach of IP if original branding is misrepresented.

Limited Recourse in Case of IP Infringement

If a company unknowingly purchases infringing equipment, it may face legal action from the rightful IP holder—even if the buyer was not directly involved in the infringement. Defending against such claims can be costly, and the equipment may be subject to seizure or recall.

Mitigation Strategies

To avoid these pitfalls, organizations should:

– Conduct thorough due diligence on suppliers, including site audits and third-party inspections.

– Require proof of certifications and compliance with applicable safety standards.

– Verify IP legitimacy through trademark and patent databases.

– Include contractual clauses that allocate liability for IP infringement and guarantee equipment authenticity.

– Work with established distributors or original equipment manufacturers (OEMs) whenever possible.

By proactively addressing quality and IP concerns, businesses can ensure they source reliable, compliant, and legally sound forklift solutions.

Logistics & Compliance Guide for Forklife

This guide outlines key logistics and compliance considerations to ensure Forklife operates efficiently and adheres to all relevant regulations. Maintaining compliance is essential for minimizing risk, ensuring product safety, and building trust with customers and partners.

Supply Chain Management

Establish a transparent and reliable supply chain for all materials and finished products. Partner only with suppliers who comply with local and international regulations, including food safety standards (where applicable) and ethical labor practices. Maintain documentation such as Certificates of Analysis (CoA), supplier audits, and traceability records to ensure product integrity from source to customer.

Product Safety & Quality Assurance

All Forklife products must meet applicable safety standards, including FDA (U.S. Food and Drug Administration) guidelines if intended for food contact. Conduct regular third-party testing for material safety, durability, and compliance with food-grade certifications (e.g., FDA 21 CFR, LFGB in Europe). Implement a quality control process at key stages of manufacturing and distribution to detect and correct defects.

Labeling & Packaging Compliance

Ensure all packaging and labeling comply with regional regulations. Labels must include:

– Product name and description

– Manufacturer or distributor information

– Country of origin

– Material composition (e.g., “BPA-Free Plastic” or “Stainless Steel”)

– Care instructions

– Any required safety warnings or usage guidelines

For international shipments, translate labels into the local language and adhere to destination country requirements.

Import/Export Regulations

When shipping internationally, comply with customs regulations for each destination. Prepare accurate documentation, including commercial invoices, packing lists, and certificates of origin. Classify products under the correct Harmonized System (HS) code to determine duty rates and regulatory requirements. Be aware of restricted or prohibited items in target markets.

Environmental & Sustainability Compliance

Adhere to environmental regulations related to manufacturing, waste disposal, and recyclability. Forklife should aim to minimize its environmental footprint by using recyclable or biodegradable packaging and sourcing sustainable materials. Comply with directives such as the EU’s Packaging and Packaging Waste Directive and local recycling laws.

Data Privacy & Customer Information

If Forklife collects customer data through e-commerce platforms, ensure compliance with data protection laws such as GDPR (General Data Protection Regulation) in Europe or CCPA (California Consumer Privacy Act) in the U.S. Implement secure data handling practices, provide clear privacy notices, and allow users to manage their data preferences.

Transportation & Distribution

Choose logistics partners experienced in handling consumer goods and compliant with transportation safety standards. Ensure proper packaging to prevent damage during transit. Monitor delivery performance and maintain insurance coverage for shipped goods. For temperature-sensitive materials (if applicable), use climate-controlled transport.

Regulatory Monitoring & Updates

Assign responsibility for monitoring changes in regulatory requirements across all markets. Subscribe to regulatory updates from relevant agencies (e.g., FDA, EU Commission, local health departments) and conduct annual compliance reviews. Update internal policies and training materials accordingly.

Training & Internal Compliance

Provide regular training for staff on compliance procedures, safety protocols, and ethical business practices. Maintain an internal compliance manual and designate a compliance officer to oversee adherence and address issues promptly.

By following this guide, Forklife will maintain high operational standards, reduce legal risks, and deliver safe, reliable products to customers worldwide.

Conclusion on Sourcing a Forklift

Sourcing a forklift is a critical decision that requires careful evaluation of operational needs, budget constraints, equipment specifications, and long-term maintenance considerations. Whether purchasing new or used, leasing, or opting for electric versus internal combustion models, businesses must align their choice with their specific material handling requirements, working environment, and sustainability goals.

Key factors such as load capacity, lift height, fuel type, brand reliability, warranty, and after-sales support significantly influence the overall value and performance of the investment. Engaging with reputable suppliers, conducting thorough market research, and considering total cost of ownership—not just upfront price—will ensure a more informed and cost-effective decision.

Ultimately, a well-sourced forklift enhances operational efficiency, improves workplace safety, and contributes to long-term productivity gains. By taking a strategic approach to sourcing, organizations can secure the right equipment that supports current operations and scales with future growth.