The global foil stamping equipment market is experiencing robust growth, driven by rising demand for premium packaging across industries such as luxury goods, publishing, cosmetics, and consumer electronics. According to a report by Mordor Intelligence, the foil stamping machines market was valued at USD 1.27 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This expansion is fueled by the increasing consumer preference for visually distinctive, high-end packaging, alongside advancements in digital and hybrid stamping technologies that improve precision and reduce waste. Grand View Research also highlights the growing adoption of eco-friendly foil materials and automation in printing processes as key market drivers. As brands intensify efforts to stand out on crowded shelves, foil stamping has emerged as a critical differentiator—making the selection of reliable, innovative equipment more important than ever. In this evolving landscape, the following nine manufacturers lead the industry in performance, technological integration, and global reach.

Top 9 Foil Stamping Equipment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Foil Stamping Tooling

Domain Est. 1999

Website: converting-technology.com

Key Highlights: We supply brass hot foil stamping tooling to your requirements and applications. With our diverse manufacturing processes we are able to offer consistent and ……

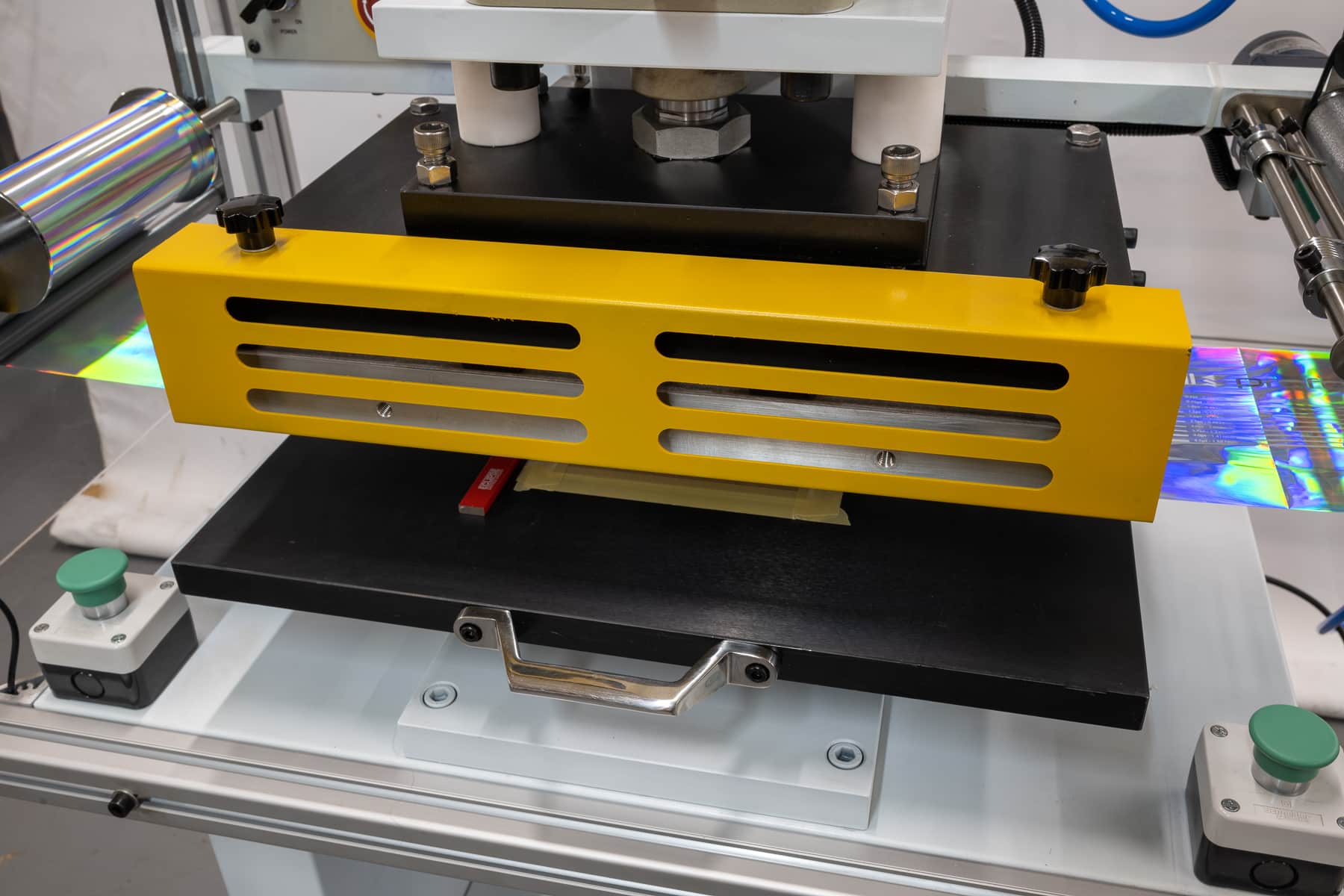

#2 Taiwan’s Leading Printing and Packaging Equipment Manufacturer …

Domain Est. 2003

Website: sblmachinery.com

Key Highlights: Get robust and reliable builds from SBL, a printing and packaging machine manufacturer and supplier of die cutting, creasing, foil stamping machines, and more ……

#3 Hot foil stamping process

Domain Est. 1996

Website: bobst.com

Key Highlights: BOBST hot foil stamping presses cover the complete range of production needs, from straightforward block foiling, through hologram application with pinpoint ……

#4 Foil Stamping

Domain Est. 1996

Website: arque.com

Key Highlights: Foil Stamping For over 60 years, COMERCIAL ARQUÉ S.A. It is focused on the distribution and marketing of printing films, We have formulations for flat, rotary, ……

#5 to Profoil

Domain Est. 2000

Website: profoil.com

Key Highlights: Quality hot foil stamping & embossing consumables from Profoil. Foil blocking. Buy online, fast international delivery. Heidelberg parts supplier. UK Shop….

#6 Hot Stamping Foil

Domain Est. 2000

#7 Infinity Foils

Domain Est. 2005

Website: infinityfoils.com

Key Highlights: Infinity Foils offers a wide variety of vibrant, durable coloured foils perfect for DIY projects for commercial packaging and printing….

#8 Eagle Systems

Domain Est. 2009

Website: thefoilexperts.com

Key Highlights: Eco-Eagle cold foil systems are self contained and fully automatic units that can be installed on virtually any sheetfed offset printing press….

#9 to the website of API Transfer Technologies

Domain Est. 2023

Website: apitransfer.com

Key Highlights: We, API Transfer Technologies, are considered one of the leading suppliers of high-quality transfer products for Hot Stamping (metallised and pigment), ……

Expert Sourcing Insights for Foil Stamping Equipment

H2: 2026 Market Trends for Foil Stamping Equipment

The global foil stamping equipment market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and sustainability imperatives. Key trends shaping the landscape include:

1. Heightened Demand for Premiumization and Customization:

Consumer appetite for luxury, tactile, and visually distinctive packaging (especially in cosmetics, premium beverages, and electronics) continues to surge. This fuels demand for foil stamping to create high-end finishes like holographic, matte metallic, and soft-touch effects. Equipment manufacturers are responding with systems offering greater precision, versatility for complex designs, and faster changeovers to support shorter runs and mass customization.

2. Technological Innovation and Digital Integration:

Hybrid & Digital Foil Stamping: Digital foil solutions (e.g., toner-based, inkjet-receptive coatings) are gaining traction, enabling ultra-short runs, variable data personalization, and on-demand production without physical dies. While traditional hot foil remains dominant for volume, digital hybrid systems combining offset/digital printing with inline foiling are a major growth segment.

* Automation and Smart Manufacturing: Integration of IoT sensors, AI-driven predictive maintenance, and automated job setup (e.g., die registration, pressure calibration) is improving efficiency, reducing waste, and minimizing operator skill requirements. Connectivity with MIS/ERP systems for seamless workflow management is becoming standard.

* Enhanced Precision & Flexibility:* Advancements in servo-driven systems, servo-controlled impression cylinders, and advanced control software allow for tighter registration tolerances (critical for complex multi-layer effects) and easier handling of diverse substrates (thin films, textured papers, rigid plastics).

3. Sustainability as a Core Driver:

Environmental regulations and brand commitments are pushing the industry towards greener solutions:

* Cold Foil Dominance: Cold foil stamping (using UV adhesive) is increasingly favored over traditional hot foil due to lower energy consumption, compatibility with heat-sensitive substrates (like films), and reduced waste.

* Eco-Friendly Materials: Demand is rising for equipment compatible with bio-based, recyclable, and compostable foils and adhesives. Manufacturers are focusing on reducing solvent use and energy consumption.

* Waste Reduction: Features like precise adhesive application, closed-loop fluid systems, and optimized foil utilization (e.g., narrow web, splicing) are critical selling points.

4. Growth in Key End-Use Sectors:

Pharmaceuticals & Healthcare: Strict serialization requirements and the need for tamper-evident, premium packaging drive demand for precise, reliable stamping (e.g., for batch codes, logos).

* Luxury & Cosmetics: Remains the primary driver for high-end decorative effects, demanding sophisticated equipment for intricate patterns and special effects.

* Flexible Packaging: Growth in pouches and pouches for food, pet care, and household products increases demand for reliable cold foil integration in flexo and gravure lines.

* Security & Brand Protection:* Foil stamping (especially holographic) remains vital for anti-counterfeiting, requiring specialized, high-security equipment.

5. Regional Shifts and Competitive Landscape:

Asia-Pacific Growth: Rapid industrialization, rising consumer spending, and a booming packaging industry in countries like China, India, and Southeast Asia will be the primary growth engine, attracting significant investment.

* Consolidation & Specialization: The market sees consolidation among established players and the rise of niche innovators focusing on digital/hybrid solutions or specific high-growth segments. Service and support networks are becoming key differentiators.

* Cost-Effectiveness Pressure:* While premiumization drives high-end equipment sales, there’s also demand for more affordable, user-friendly machines for SMEs, particularly in emerging markets.

In conclusion, the 2026 foil stamping equipment market will be characterized by a dynamic interplay between the demand for ever-more sophisticated decorative effects and the imperative for sustainability and operational efficiency. Success will favor manufacturers that innovate in digital/hybrid technologies, prioritize energy efficiency and material compatibility, and offer flexible, automated solutions tailored to the evolving needs of packaging converters across diverse and growing end markets.

Common Pitfalls When Sourcing Foil Stamping Equipment (Quality, IP)

Sourcing foil stamping equipment involves more than just comparing prices and features. Overlooking critical quality and intellectual property (IP) considerations can lead to operational inefficiencies, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Build Quality and Component Sourcing

Many low-cost suppliers cut corners by using substandard materials and components, such as inferior bearings, weak mechanical frames, or low-grade electrical systems. This results in frequent breakdowns, inconsistent stamping quality, and higher long-term maintenance costs. Always request detailed specifications, inspect sample machines, and verify the origin and reputation of critical components.

Lack of Quality Control Processes

Suppliers without certified quality management systems (e.g., ISO 9001) may deliver inconsistent equipment. Without standardized testing procedures, machines can vary significantly between units, affecting registration accuracy, pressure control, and foil transfer consistency. Evaluate the supplier’s QC protocols and ask for test reports or third-party certifications.

Inadequate Technical Support and Spare Parts Availability

Even high-quality machines require maintenance and troubleshooting. Sourcing from suppliers with limited after-sales support—especially in your region—can lead to prolonged downtime. Confirm the availability of spare parts, response times for service, and whether technical documentation is provided in your language.

Intellectual Property Infringement Risks

Some manufacturers produce equipment that copies patented designs or control systems from established brands. Using such machines can expose your business to legal liability, especially in regions with strong IP enforcement. Ensure the supplier has legitimate rights to the technology and design by requesting IP documentation or legal assurances.

Use of Counterfeit or Unlicensed Software

Foil stamping machines often rely on proprietary software for controls and automation. Some suppliers use pirated or reverse-engineered software, which can result in system instability, lack of updates, and legal exposure. Verify software licenses and ask for proof of authorized use.

Misrepresentation of Capabilities and Performance

Suppliers may exaggerate machine speed, precision, or compatibility with specialty foils. Without third-party validation or on-site testing, you may receive equipment that fails to meet production demands. Insist on live demonstrations with your materials and conduct performance audits before finalizing the purchase.

Hidden Costs from Non-Standardization

Equipment that doesn’t adhere to industry standards (e.g., safety, electrical, or interface protocols) can require costly modifications to integrate into existing production lines. Confirm compliance with relevant standards (such as CE, UL, or ANSI) to avoid retrofitting expenses and safety hazards.

By proactively addressing these quality and IP-related pitfalls, businesses can ensure reliable, legally compliant foil stamping operations and protect their long-term investments.

Logistics & Compliance Guide for Foil Stamping Equipment

Overview

Foil stamping equipment, used in printing and packaging industries to apply metallic or pigmented foil to substrates, requires careful attention to logistics and regulatory compliance during shipping, import/export, installation, and operation. This guide outlines key considerations to ensure safe, legal, and efficient handling of foil stamping machinery across international and domestic supply chains.

Shipping & Transportation

Ensure proper packaging and handling protocols are followed to protect sensitive components such as dies, heating elements, and precision alignment systems. Use custom crating with cushioning materials to prevent vibration and impact damage during transit. Choose freight carriers experienced in handling industrial printing equipment, and confirm that shipment includes liftgate service and inside delivery if required. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include detailed packing lists.

Import & Export Compliance

Foil stamping machines may be subject to international trade regulations depending on their origin, destination, and technical specifications. Verify the Harmonized System (HS) code—typically under heading 8441 (Other printing machinery)—and ensure accurate documentation, including commercial invoices, packing lists, and certificates of origin. Check for export controls, especially if the equipment includes advanced automation or software subject to ITAR or EAR regulations. Importers must comply with local customs requirements, including duties, taxes, and product conformity standards.

Safety & Regulatory Standards

Foil stamping equipment must meet applicable safety standards in the destination market. In the U.S., compliance with OSHA and ANSI B11.0 safety standards for machinery is required. In the EU, machines must carry the CE marking and conform to the Machinery Directive (2006/42/EC), Low Voltage Directive (2014/35/EU), and Electromagnetic Compatibility (EMC) Directive (2014/30/EU). Manufacturers should provide an EC Declaration of Conformity and technical file upon request. Ensure equipment includes emergency stop mechanisms, protective guards, and proper electrical grounding.

Electrical & Environmental Requirements

Verify voltage, phase, and frequency compatibility with local power supplies (e.g., 110V/60Hz in North America vs. 230V/50Hz in Europe). Use transformers or voltage stabilizers if necessary. Confirm compliance with RoHS (Restriction of Hazardous Substances) and REACH regulations, particularly for electronic components and materials used in construction. Proper disposal of worn dies, foils, and cleaning solvents must adhere to local environmental regulations.

Installation & Site Preparation

Prepare the installation site according to manufacturer specifications, ensuring adequate floor space, ventilation, and access for maintenance. The area should be clean, dry, and free from excessive dust or moisture. Confirm that compressed air (if required) meets specified pressure and purity standards. All installation and initial calibration should be performed by qualified technicians in accordance with the equipment manual.

Training & Operational Compliance

Provide operator and maintenance personnel with comprehensive training on safe operation, routine maintenance, and emergency procedures. Maintain records of training and equipment servicing. Implement lockout/tagout (LOTO) procedures during maintenance to comply with safety regulations. Regularly inspect safety devices and ensure user manuals and warning labels are available in the local language.

Documentation & Recordkeeping

Retain all compliance documentation, including certificates of conformity, safety data sheets (SDS) for consumables, service logs, and import/export filings. These records may be required during inspections or audits by regulatory authorities or insurance providers.

Conclusion

Effective logistics and compliance management for foil stamping equipment minimizes delays, ensures workplace safety, and supports regulatory adherence across global operations. Proactive planning, coordination with certified partners, and adherence to technical and legal standards are essential for successful deployment and operation.

Conclusion:

After a thorough evaluation of available foil stamping equipment, it is evident that the selection process must balance quality, production capacity, automation level, and long-term cost-efficiency. Both traditional hydraulic and modern servo-driven foil stamping machines offer distinct advantages depending on the specific needs of the operation—whether it’s high-speed production, precision detailing, or flexibility in handling various substrates.

Investing in equipment from reputable manufacturers with strong technical support and spare parts availability ensures reliability and minimizes downtime. Additionally, considering future scalability and integration with existing print finishing workflows is crucial for sustainable growth.

Ultimately, the recommended sourcing strategy involves selecting a foil stamping machine that aligns with current production demands while offering the adaptability to accommodate future advancements in packaging and print technologies. A well-chosen system will enhance product aesthetics, improve operational efficiency, and provide a strong return on investment through superior finishing quality and customer satisfaction.