The global foam board fasteners market is experiencing steady expansion, driven by rising demand in construction, insulation, and signage applications. According to a 2023 report by Grand View Research, the global insulation materials market—where foam board fasteners play a critical role—is projected to grow at a CAGR of 5.8% from 2023 to 2030, fueled by increasing energy efficiency regulations and infrastructure development. Similarly, Mordor Intelligence forecasts the construction fasteners market to expand at a CAGR of over 5.2% during the same period, with foam board fasteners benefiting from adoption in both residential and commercial projects. As sustainable building practices gain momentum and demand for lightweight, durable fastening solutions rises, manufacturers specializing in foam board fasteners are scaling innovation and production. This growing landscape underscores the importance of identifying the top players shaping the industry. Here’s a look at the leading foam board fasteners manufacturers leading this trend.

Top 10 Foam Board Fasteners Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Midwest Fasteners, Inc.

Domain Est. 1998

Website: midwestfasteners.com

Key Highlights: We manufacture and supply a variety of industrial and commercial insulation fasteners, including: Weld Pins; Cup Head Pins; Insulation Hangers (self-stick or …Missing: foam boar…

#2 X

Domain Est. 1995

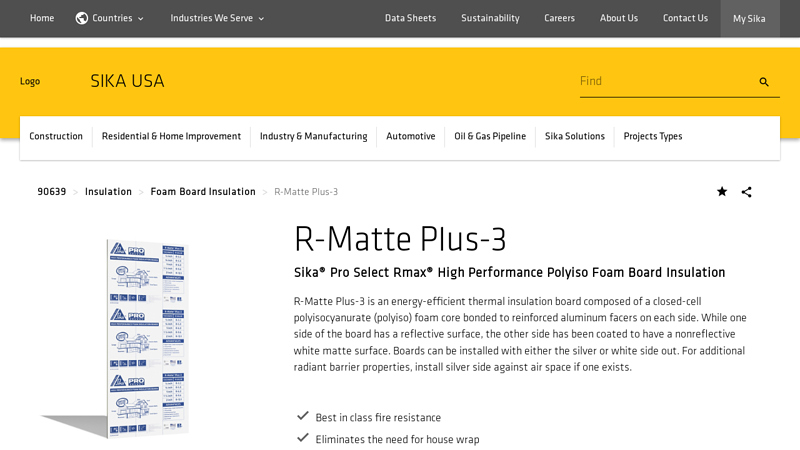

#3 R-Matte Plus-3

Domain Est. 1995

Website: usa.sika.com

Key Highlights: R-Matte Plus-3 is an energy-efficient thermal insulation board composed of a closed-cell polyisocyanurate (polyiso) foam core bonded to reinforced aluminum ……

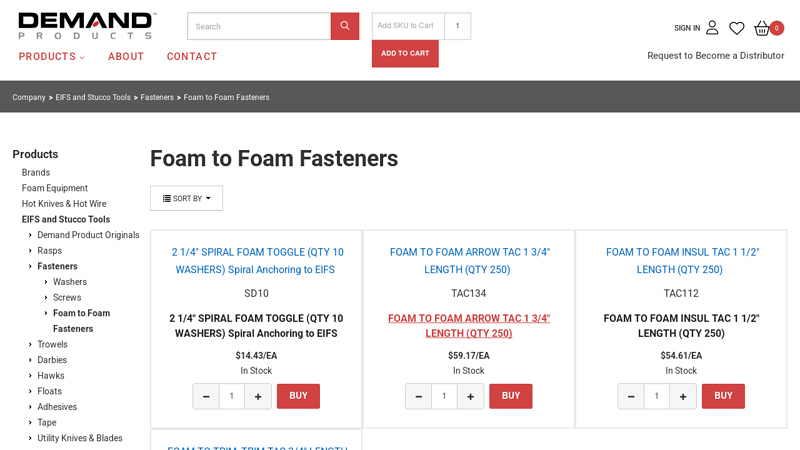

#4 Foam to Foam Fasteners

Domain Est. 1996

#5 GoBoard

Domain Est. 1997

Website: jm.com

Key Highlights: GoBoard by Johns Manville is an ultra-lightweight, waterproof, durable tile backer board that is easy to cut and install, and weighs up to 80% lighter than ……

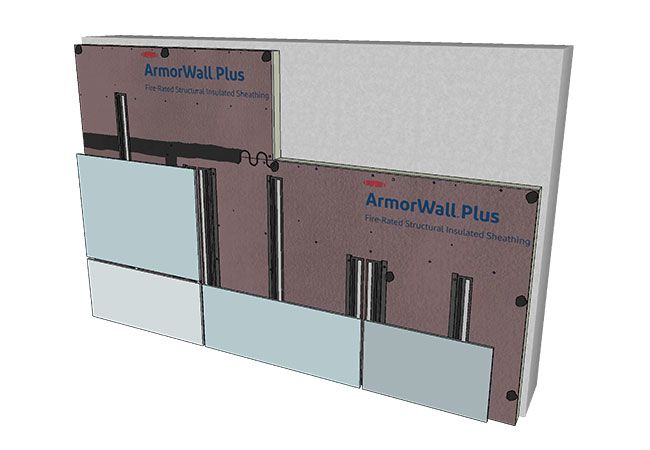

#6 Wall Fasteners & Building Envelope Systems

Domain Est. 1999

Website: trufast.com

Key Highlights: TRUFAST wall fasteners & attachment systems deliver proven strength for gypsum sheathing, masonry, stucco, mineral wool & continuous insulation assemblies….

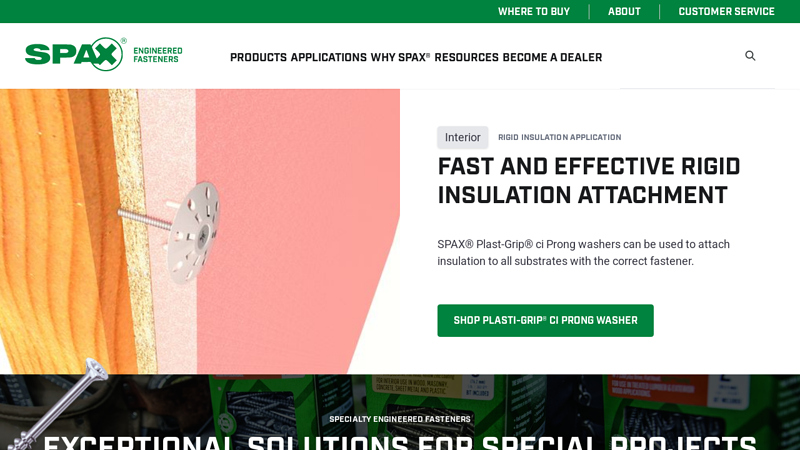

#7 Rigid Insulation Screws and Anchors

Domain Est. 2004

Website: spax.us

Key Highlights: Fast and effective rigid insulation attachment. SPAX® Plast-Grip® ci Prong washers can be used to attach insulation to all substrates with the correct fastener….

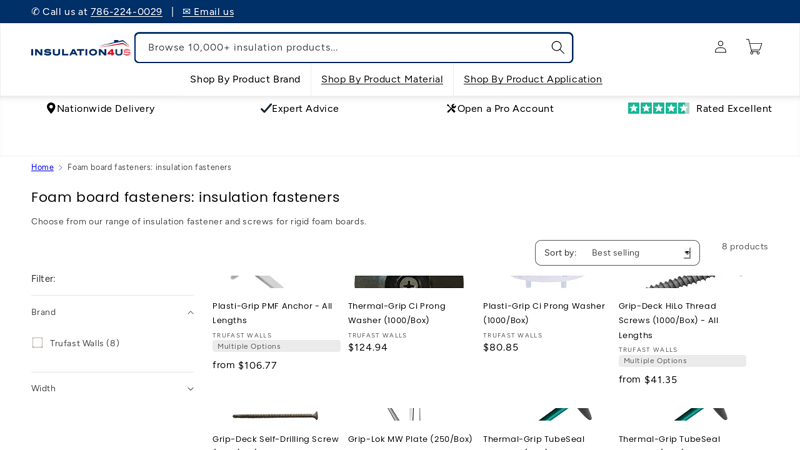

#8 Foam Board Fasteners

Domain Est. 2014

Website: insulation4us.com

Key Highlights: 30-day returnsThis category hosts a variety of products including Plasti-Grip anchors, prong washers, Grip-Deck screws, and Grip-Lok washers and plates….

#9 Atlas Roof & Wall Insulation

Domain Est. 2017

Website: atlasrwi.com

Key Highlights: Atlas now has eight top-of-the-line polyiso manufacturing facilities that produce millions of board feet each year. … AC Foam Nail Base Fastener · Online ……

#10 Insulation Fastening Systems

Domain Est. 2020

Website: trufastwalls.com

Key Highlights: TRUFAST Walls manufactures Fasteners to attach continuous insulation. TRUFAST has developed labor-saving, energy efficient solutions to attach continuous …Missing: foam board…

Expert Sourcing Insights for Foam Board Fasteners

H2: 2026 Market Trends for Foam Board Fasteners

The global market for foam board fasteners is poised for steady growth and transformation by 2026, driven by advancements in construction techniques, increasing demand for energy-efficient buildings, and the expansion of insulation applications across residential, commercial, and industrial sectors. This analysis explores key trends shaping the foam board fastener market in 2026 under the H2 framework—highlighting drivers, innovations, regional dynamics, and competitive landscape.

1. Rising Demand for Energy Efficiency and Building Insulation

A primary driver of the foam board fastener market in 2026 is the global emphasis on energy conservation and sustainable construction. Governments and regulatory bodies are implementing stricter building codes and energy efficiency standards, such as the International Energy Conservation Code (IECC) and EU Energy Performance of Buildings Directive (EPBD). These regulations promote the use of continuous insulation (CI), where foam board insulation is secured using specialized fasteners. As a result, demand for high-performance, durable fasteners designed for polystyrene, polyisocyanurate, and polyurethane foam boards continues to rise.

2. Technological Innovations in Fastener Design

Manufacturers are investing in R&D to develop foam board fasteners with enhanced holding strength, thermal efficiency, and ease of installation. Key innovations include:

– Low thermal conductivity fasteners that minimize thermal bridging.

– Self-drilling and self-tapping designs for faster installation on metal, wood, and concrete substrates.

– UV-resistant and corrosion-proof materials to improve longevity in harsh climates.

– Smart fasteners integrated with sensors for structural health monitoring (emerging in high-end commercial projects).

These advancements are improving system performance and reducing labor costs, making foam board systems more attractive to contractors.

3. Growth in Residential and Commercial Construction

The global construction sector is rebounding post-pandemic, with significant investments in new housing and retrofitting projects. In North America and Europe, renovation of aging building stock is driving demand for exterior insulation and finish systems (EIFS) and insulated sheathing—both reliant on foam board fasteners. Meanwhile, urbanization in Asia-Pacific, particularly in China and India, is fueling large-scale commercial developments that require effective insulation solutions.

4. Regional Market Dynamics

– North America: Expected to dominate the market due to stringent energy codes and high adoption of advanced building materials. The U.S. and Canada are leading in EIFS and continuous insulation applications.

– Europe: Strong regulatory support for net-zero buildings is accelerating the use of foam board insulation and compatible fastening systems.

– Asia-Pacific: Fastest-growing region, driven by infrastructure development and government incentives for green buildings.

– Latin America and Middle East: Emerging markets with increasing construction activity, though adoption is slower due to cost sensitivity.

5. Sustainability and Material Sourcing

Environmental concerns are pushing manufacturers to adopt recyclable materials and reduce carbon footprints. Foam board fasteners made from recycled plastics or bio-based polymers are gaining traction. Additionally, life cycle assessments (LCAs) are becoming critical in product selection, favoring fasteners with longer service lives and minimal environmental impact.

6. Competitive Landscape and Market Consolidation

The foam board fastener market remains fragmented but is witnessing consolidation as larger players acquire niche innovators. Key companies such as ITW Construction, Simpson Strong-Tie, and BASF are expanding product portfolios and geographic reach. Differentiation is increasingly based on technical support, compatibility with insulation brands, and compliance with regional building standards.

Conclusion

By 2026, the foam board fastener market will be shaped by regulatory pressures, technological innovation, and the global push for sustainable construction. Stakeholders who prioritize performance, compatibility, and environmental responsibility are likely to gain a competitive edge. As insulation becomes integral to modern building design, foam board fasteners will play a critical—but often underappreciated—role in achieving energy efficiency and structural integrity.

Common Pitfalls Sourcing Foam Board Fasteners (Quality, IP)

Sourcing foam board fasteners—often used in construction, insulation, and signage—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to product failure, legal disputes, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most common issues is receiving fasteners made from substandard materials. Low-quality plastics or metals may degrade quickly when exposed to UV light, moisture, or temperature fluctuations, especially in outdoor applications. This leads to fastener failure, compromising the integrity of the foam board installation. Always verify material specifications (e.g., UV resistance, tensile strength) and request third-party test reports.

Inconsistent Manufacturing Tolerances

Inferior manufacturing processes can result in inconsistent thread formation, head shape, or length. These inconsistencies affect ease of installation and holding strength. Fasteners that don’t fit properly can damage the foam board or fail to secure it adequately. Ensure suppliers adhere to strict quality control standards and conduct regular batch testing.

Misrepresentation of Load-Bearing Capacity

Some suppliers exaggerate the performance metrics of their fasteners, such as pull-out strength or shear resistance. Relying on unverified claims can result in structural failures. Always demand certified performance data and consider independent testing if large-scale or safety-critical projects are involved.

Lack of Compliance with Industry Standards

Foam board fasteners used in construction may need to comply with regional building codes or fire safety regulations (e.g., ASTM, EN standards). Sourcing non-compliant fasteners can lead to rejected installations or liability issues. Confirm that the product meets all applicable standards for your market.

Intellectual Property Infringement

Sourcing fasteners that mimic patented designs—such as proprietary head types, thread configurations, or installation systems—can expose your business to IP litigation. Many leading fastener manufacturers hold patents on innovative designs intended to improve performance or ease of use. Always verify the legal status of the design and obtain documentation from the supplier confirming freedom to operate.

Use of Counterfeit or Grey Market Products

Deals that seem too good to be true may involve counterfeit fasteners bearing fake trademarks or diverted (grey market) goods not intended for your region. These products often lack quality assurance and may not be supported by warranties. Source from authorized distributors or directly from reputable manufacturers.

Inadequate Documentation and Traceability

Lack of proper documentation—such as material certifications, test reports, or batch traceability—can complicate quality audits or failure investigations. Ensure suppliers provide full documentation to support compliance and quality claims.

Avoiding these pitfalls requires due diligence in supplier selection, clear specifications, and proactive verification of both product quality and IP legitimacy.

Logistics & Compliance Guide for Foam Board Fasteners

This guide outlines essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of foam board fasteners, ensuring efficient supply chain operations and legal conformity.

Product Classification and Identification

Foam board fasteners—commonly including plastic caps, washers, screws, or specialized clips used to secure insulation or signage panels—must be accurately classified for logistics and regulatory purposes. Typically categorized under construction hardware or fastening systems, these items should carry clear SKUs, barcodes, and product descriptions. Ensure Harmonized System (HS) codes are correctly assigned (e.g., 7318.19 for certain steel screws or 3926.30 for plastic fasteners) to facilitate customs clearance and tariff determination.

Packaging and Labeling Requirements

Proper packaging is essential to prevent damage during transit and ensure compliance with international shipping standards. Foam board fasteners should be packed in moisture-resistant, durable containers such as corrugated boxes or sealed polybags, with adequate cushioning to prevent shifting. Labels must include:

- Product name and SKU

- Quantity per pack

- Manufacturer or supplier information

- Batch/lot number and date of manufacture

- Handling symbols (e.g., “Fragile,” “This Way Up”)

- Safety and disposal information if applicable

For international shipments, multilingual labeling may be required depending on destination markets.

Storage Conditions and Shelf Life

Store foam board fasteners in a dry, temperature-controlled environment (15–25°C / 59–77°F) away from direct sunlight and sources of heat or moisture. Prolonged exposure to UV light or extreme temperatures may degrade plastic components. While most fasteners do not have strict expiration dates, inspect periodically for signs of material degradation, especially in humid climates. Implement FIFO (First In, First Out) inventory practices to maintain product integrity.

Transportation and Freight Considerations

Choose appropriate freight modes (road, air, or sea) based on volume, urgency, and destination. Fasteners are generally non-hazardous and classified as general cargo, but verify with carriers to ensure compliance with IATA, IMDG, or ADR regulations if shipping internationally. Use palletized loads secured with stretch wrap to prevent movement during transit. For air freight, comply with dimensional weight calculations and airline-specific packaging rules.

Regulatory Compliance

Ensure foam board fasteners meet relevant regional and international standards:

- RoHS (EU): Restriction of Hazardous Substances—verify that metallic and plastic components comply with lead, cadmium, and other restricted substance limits.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals—confirm declaration of Substances of Very High Concern (SVHC).

- CPSC (USA): Consumer Product Safety Commission—applicable if fasteners are sold in consumer DIY kits.

- UL or ICC-ES (USA/Canada): If fasteners are part of a structural or insulation assembly, verify listings for building code compliance.

Maintain documentation such as Declarations of Conformity (DoC), test reports, and material safety data sheets (MSDS/SDS) as required.

Import and Export Documentation

Prepare complete documentation for cross-border shipments, including:

- Commercial invoice

- Packing list

- Bill of lading or air waybill

- Certificate of Origin

- Import/export licenses (if required)

- HS code classification proof

Ensure all documents reflect accurate descriptions and values to avoid customs delays or penalties.

Sustainability and End-of-Life Compliance

Foam board fasteners, especially plastic variants, should be designed with recyclability in mind. Provide disposal guidance on packaging or datasheets, noting whether components are recyclable (e.g., PP, PE, or ABS plastics). Adhere to local waste electrical and electronic equipment (WEEE) directives if applicable, and support take-back programs where mandated.

Quality Assurance and Traceability

Implement a traceability system that records batch numbers, production dates, and shipping destinations. Conduct regular quality audits of packaging, labeling, and product consistency. Address non-conformances promptly through corrective action reports (CARs) and supplier reviews to maintain compliance and customer trust.

By adhering to this logistics and compliance framework, stakeholders can ensure the safe, legal, and efficient distribution of foam board fasteners across global supply chains.

In conclusion, sourcing foam board fasteners requires careful consideration of project-specific needs, including the type of foam board, application environment, required holding strength, and installation method. Options such as plastic cap screws, washers, specialized foam-compatible screws, and adhesive anchors each offer unique advantages depending on whether the project is temporary or permanent, indoor or outdoor. It is essential to source fasteners from reputable suppliers that offer corrosion-resistant, durable materials suited to insulation and lightweight panel applications. Additionally, evaluating cost-efficiency, availability, and compatibility with installation tools ensures optimal performance and long-term reliability. By aligning fastener selection with both technical requirements and sourcing practicality, builders and contractors can achieve secure, efficient, and lasting foam board installations.