The global soldering materials market, driven by increasing demand in electronics manufacturing, automotive, and telecommunications, is projected to grow at a CAGR of 6.8% from 2023 to 2030, according to Grand View Research. With the rising production of printed circuit boards (PCBs) and miniaturized electronic components, the need for high-performance flux in electrical soldering has become critical. As manufacturers prioritize reliability, environmental compliance, and efficiency, the selection of flux—ranging from rosin-based to no-clean formulations—plays a pivotal role in ensuring optimal solder joint integrity. Advances in lead-free soldering technologies and tightening regulatory standards, particularly under RoHS and REACH, are further shaping innovation in flux formulations. Mordor Intelligence highlights that Asia-Pacific dominates market share, fueled by robust electronics assembly in China, Japan, and South Korea, intensifying competition among key flux suppliers. Against this backdrop, identifying the top manufacturers delivering consistent quality, technical support, and scalable solutions is essential for OEMs and contract manufacturers aiming to maintain product reliability and operational efficiency.

Top 10 Flux For Electrical Soldering Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Kester

Domain Est. 1995

Website: kester.com

Key Highlights: Element Solutions Inc. Products · Solder Wire · Liquid Solder Flux · Solder Paste · Tacky Solder Flux · Preforms · Bar ……

#2 Interflux Electronics

Domain Est. 1996

Website: interflux.com

Key Highlights: Interflux Electronics specialises in researching, developing and producing soldering materials for electronics manufacturers. Best known for soldering ……

#3 Soldering Fluxes

Domain Est. 2006

Website: harrisproductsgroup.com

Key Highlights: To ensure the best connections, Harris designs, develops and manufacturers soldering fluxes for specific solders and applications….

#4 FluxPlus™ Paste Flux

Domain Est. 1993

Website: nordson.com

Key Highlights: Controlled flux spread as a result of precise dispensing · Holds small parts in place before soldering · Delivers more flux compared to flux-core wire solder ……

#5 Wave Flux

Domain Est. 1995

Website: indium.com

Key Highlights: Indium Corporation offers a full line of competitive, state-of-the-art wave solder fluxes, including alcohol-based, VOC-free, water-wash, and rosin-based ……

#6 Superior Flux Page

Domain Est. 1997

Website: superiorflux.com

Key Highlights: Superior Flux manufactures a wide range of fluxes for soldering, brazing and welding. Our soldering line includes fluxes that can stand up to the rigors of ……

#7 Soldering Flux

Domain Est. 1997

Website: mgchemicals.com

Key Highlights: MG Chemicals soldering flux provides high tack-force and superior wetting for both leaded and non-leaded solder alloys. The flux comes in both liquid and paste ……

#8 SRA Soldering Products

Domain Est. 1998

Website: sra-solder.com

Key Highlights: 1–6 day delivery 30-day returns135 Flux and Tip Tinner. SRA Rosin Paste Flux #135 with a Soldering Iron Tip Tinner. $13.99. Pre-Order Now! Please contact us for Stock Details. Pre-…

#9 Solder Flux & Liquid Flux Products

Domain Est. 2018

Website: macdermidalpha.com

Key Highlights: Our liquid flux products improve wetting, minimize defects, and ensure strong, electrochemically reliable joints, enhancing overall quality and performance….

#10 Electronic Solder Flux

Website: canfieldmetals.com

Key Highlights: BOW® fluxes are available as no-clean, VOC-Free, water-soluble and rosin based fluxes that can be packaged in pints, gallon containers and 55 gallon drums….

Expert Sourcing Insights for Flux For Electrical Soldering

H2: Market Trends for Flux for Electrical Soldering (2026 Outlook)

As we approach 2026, the global market for flux used in electrical soldering is undergoing significant transformation, driven by advancements in electronics manufacturing, regulatory changes, and shifting consumer demands. This analysis explores key trends shaping the flux for electrical soldering sector under the H2 framework—highlighting Hybrid Technologies, Heightened Environmental Regulations, High-Reliability Demands, Human-Machine Integration, and Hyper-Personalization in Application.

1. Hybrid Technologies Driving Flux Innovation

The integration of hybrid manufacturing processes—combining traditional soldering with additive manufacturing (3D printing of electronics) and automated precision assembly—is accelerating the demand for advanced flux formulations. By 2026, fluxes are expected to support dual-cure mechanisms (e.g., thermal and UV-activated) and exhibit compatibility with both leaded and lead-free solder alloys. Hybrid conductive inks and nano-silver pastes are emerging alongside traditional solder, requiring fluxes that can manage complex metallurgical interactions without compromising joint integrity.

Moreover, the rise of heterogeneous integration in semiconductor packaging (e.g., chiplets, 2.5D/3D ICs) demands ultra-low residue (ultra-no-clean) fluxes with excellent thermal stability and minimal outgassing—critical for aerospace, automotive, and high-performance computing applications.

2. Heightened Environmental Regulations and Green Chemistry

Environmental regulations, particularly in the EU (RoHS, REACH) and Asia-Pacific (China RoHS, Green Manufacturing Initiatives), are pushing flux manufacturers toward sustainable formulations. By 2026, water-soluble and bio-based fluxes derived from renewable resources (e.g., plant-derived activators) are expected to gain market share. Volatile organic compound (VOC) emissions are under increased scrutiny, prompting a shift toward low-VOC or VOC-free flux chemistries.

Additionally, recyclability and end-of-life considerations are influencing flux selection. Flux residues must now not only ensure reliability but also facilitate PCB recycling, aligning with circular economy goals. Expect broader adoption of no-clean fluxes with benign decomposition byproducts, reducing post-soldering cleaning steps and energy consumption.

3. High-Reliability Demands in Critical Applications

The proliferation of electric vehicles (EVs), 5G infrastructure, and advanced driver-assistance systems (ADAS) is elevating the need for high-reliability solder joints. Fluxes must support soldering under thermal cycling, moisture exposure, and mechanical stress. By 2026, flux formulations will increasingly be tailored for harsh environments, featuring enhanced corrosion inhibition, halogen-free compositions (to prevent electrochemical migration), and improved wetting performance on challenging substrates like aluminum nitride or ceramic packages.

Automotive and medical electronics sectors are leading this trend, with demand for fluxes that meet IPC J-STD-004B and IEC 61190 standards. Real-time monitoring of flux activity via embedded sensors or inline analytics may also emerge, ensuring process consistency and traceability.

4. Human-Machine Integration in Soldering Processes

Advancements in Industry 4.0 and smart manufacturing are transforming how flux is applied and monitored. By 2026, closed-loop feedback systems combining vision inspection, machine learning, and robotic dispensing will optimize flux deposition—minimizing waste and ensuring uniform coverage. Smart flux delivery systems will adjust volume and composition based on real-time board temperature, humidity, and component density.

Human operators will increasingly collaborate with cobots (collaborative robots) in rework and prototyping environments, relying on user-friendly, low-fume fluxes that maintain safety without sacrificing performance. Augmented reality (AR) interfaces may guide technicians in selecting the optimal flux type for specific repair scenarios.

5. Hyper-Personalization in Application and Formulation

Market fragmentation and product differentiation are driving demand for customized flux solutions. In 2026, flux suppliers will offer modular chemistries—allowing electronics manufacturers to fine-tune activator strength, viscosity, and residue characteristics for niche applications (e.g., wearable electronics, flexible PCBs, or micro-optoelectromechanical systems).

Digital platforms may enable “flux configurators,” where engineers input parameters (substrate material, solder alloy, process temperature) and receive tailored recommendations. Small-batch, on-demand manufacturing of specialty fluxes via digital supply chains will reduce inventory costs and accelerate innovation cycles.

Conclusion

By 2026, the flux for electrical soldering market will be defined by adaptability, sustainability, and intelligence. The convergence of H2 trends—Hybrid Technologies, Heightened Environmental Regulations, High-Reliability Demands, Human-Machine Integration, and Hyper-Personalization—will redefine product specifications and supply chain dynamics. Companies that embrace formulation innovation, digital integration, and eco-conscious design will lead the next phase of growth in this essential segment of electronic assembly.

Common Pitfalls Sourcing Flux for Electrical Soldering (Quality, IP)

Sourcing the right flux for electrical soldering is critical for ensuring reliable, high-quality solder joints and long-term product performance. However, several common pitfalls related to quality and intellectual property (IP) can compromise results if not carefully managed.

Poor Flux Quality Leading to Reliability Issues

One of the most significant risks when sourcing flux—especially from low-cost or unverified suppliers—is receiving substandard products. Poor-quality flux may contain inconsistent chemical formulations, incorrect activator concentrations, or contaminants. This can result in incomplete solder wetting, increased solder balling, or flux residues that are corrosive or electrically conductive. Over time, these issues can lead to electrical shorts, dendritic growth, and field failures, undermining product reliability and increasing warranty costs.

Lack of Documentation and Traceability

Many budget suppliers fail to provide comprehensive technical documentation, such as Material Safety Data Sheets (MSDS), IPC compliance certificates, or batch traceability records. Without such documentation, it becomes difficult to verify that the flux meets industry standards (e.g., IPC-J-STD-004) or to trace the root cause of soldering defects during failure analysis. This lack of transparency can also pose compliance risks, especially in regulated industries like medical or aerospace.

Intellectual Property (IP) Concerns with Generic or Reverse-Engineered Fluxes

Some third-party or generic fluxes are reverse-engineered to mimic the performance of branded formulations. While this may reduce cost, it raises potential IP infringement issues, especially if the original formula is patented or protected as a trade secret. Using such fluxes could expose your company to legal liability or supply chain disruption if the supplier is challenged. Additionally, reverse-engineered products often lack the rigorous R&D and quality control of the original, leading to inconsistent performance.

Inadequate Compatibility with Specific Processes

Fluxes vary widely in formulation (rosin-based, water-soluble, no-clean, etc.) and are designed for specific soldering methods (wave, reflow, hand soldering). Sourcing a flux without verifying compatibility with your process parameters—such as temperature profile, cleaning requirements, or component sensitivity—can result in poor solder joint formation or residue-related field failures. Generic suppliers may not provide adequate application support, increasing the risk of process mismatch.

Hidden Costs from Rework and Field Failures

While low-cost flux may appear economical upfront, poor performance can lead to increased rework rates, higher scrap, and long-term field failures. These hidden costs often far exceed the initial savings. Moreover, if flux residues compromise product reliability, the resulting damage to brand reputation and potential liability claims can be substantial.

Mitigation Strategies

To avoid these pitfalls, prioritize suppliers with verifiable quality certifications (e.g., ISO 9001), transparent documentation, and a track record of compliance with industry standards. Conduct thorough qualification testing before full-scale adoption, and ensure that any alternative flux does not infringe on protected IP. When in doubt, consult with technical experts or original equipment manufacturers (OEMs) to validate compatibility and performance.

Logistics & Compliance Guide for Flux for Electrical Soldering

This guide outlines the key logistics and compliance considerations for handling, storing, transporting, and disposing of flux used in electrical soldering applications. Adhering to these guidelines ensures safety, regulatory compliance, and operational efficiency.

Regulatory Classification and Documentation

Flux for electrical soldering is typically classified based on its chemical composition (e.g., rosin-based, water-soluble, no-clean). Accurate classification under international and national regulations (e.g., GHS, REACH, RoHS) is essential. Key documentation includes:

- Safety Data Sheet (SDS): Must be provided by the manufacturer and accessible to all personnel. The SDS details hazards, first-aid measures, handling, storage, and disposal procedures.

- Product Declaration: Confirm compliance with RoHS (Restriction of Hazardous Substances) and other applicable directives, particularly for electronics manufacturing.

- Customs Documentation: For international shipping, ensure Harmonized System (HS) code accuracy and provide commercial invoices, packing lists, and import/export declarations as required.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for safe handling and regulatory compliance:

- Sealed Containers: Flux must be stored in leak-proof, chemical-resistant containers to prevent contamination and evaporation.

- GHS-Compliant Labels: All containers must display GHS hazard pictograms, signal words (e.g., “Warning”), hazard statements, and precautionary statements.

- Secondary Containment: Use spill trays or bunds when storing bulk quantities to contain potential leaks.

- Batch and Expiry Information: Clearly label containers with batch numbers and shelf life to ensure traceability and prevent use of degraded product.

Storage Conditions

Flux must be stored under controlled conditions to maintain stability and safety:

- Temperature Control: Store in a cool, dry place with temperatures typically between 10°C and 25°C (50°F–77°F). Avoid exposure to direct sunlight or heat sources.

- Ventilation: Ensure storage areas are well-ventilated to prevent vapor accumulation, especially for solvent-based fluxes.

- Segregation: Keep flux away from strong oxidizers, acids, and incompatible materials. Store flammable formulations in approved flammable liquid cabinets if required.

- Fire Safety: Prohibit smoking and open flames in storage areas. Maintain appropriate fire suppression equipment nearby.

Transportation Guidelines

Transporting flux requires adherence to hazardous materials regulations when applicable:

- Hazardous Materials Classification: Determine if the flux meets criteria for UN Class 3 (Flammable Liquids) or other hazardous categories. Most no-clean and water-soluble fluxes may be non-hazardous if non-flammable.

- Packaging Standards: Use UN-certified packaging for hazardous shipments, including inner and outer containers with adequate cushioning.

- Transport Documentation: Include proper shipping names, UN numbers, hazard class, and packaging group on transport documents.

- Carrier Compliance: Use carriers certified to handle hazardous or chemical goods, and ensure drivers are trained in emergency response.

Handling and Use Procedures

Safe handling minimizes exposure and ensures product integrity:

- Personal Protective Equipment (PPE): Require gloves (nitrile or neoprene), safety goggles, and lab coats. Use respiratory protection if ventilation is inadequate.

- Minimize Exposure: Use dispensing systems to reduce skin contact and vapor inhalation. Avoid prolonged or repeated exposure.

- Spill Response: Have spill kits (absorbents, neutralizers) readily available. Clean spills immediately using appropriate procedures per the SDS.

Waste Disposal and Environmental Compliance

Flux waste must be managed in accordance with environmental regulations:

- Waste Classification: Determine if spent flux, cleaning residues, or contaminated materials are hazardous based on local regulations.

- Authorized Disposal: Use licensed waste disposal contractors for hazardous waste. Follow RCRA (U.S.), WEEE, or equivalent frameworks.

- Recycling Options: Where possible, recycle flux containers or reclaim materials through approved programs.

- Record Keeping: Maintain logs of waste generation, storage, and disposal for audit and compliance purposes.

Compliance Monitoring and Training

Ensure ongoing compliance through structured management practices:

- Employee Training: Conduct regular training on SDS review, safe handling, emergency procedures, and regulatory updates.

- Audits and Inspections: Perform routine checks of storage areas, labeling, and documentation to ensure adherence to standards.

- Regulatory Updates: Monitor changes in chemical regulations (e.g., EPA, ECHA) and adapt procedures accordingly.

Adhering to this logistics and compliance guide ensures the safe and lawful use of flux in electrical soldering operations, protecting personnel, the environment, and your organization’s regulatory standing.

Conclusion on Sourcing Flux for Electrical Soldering:

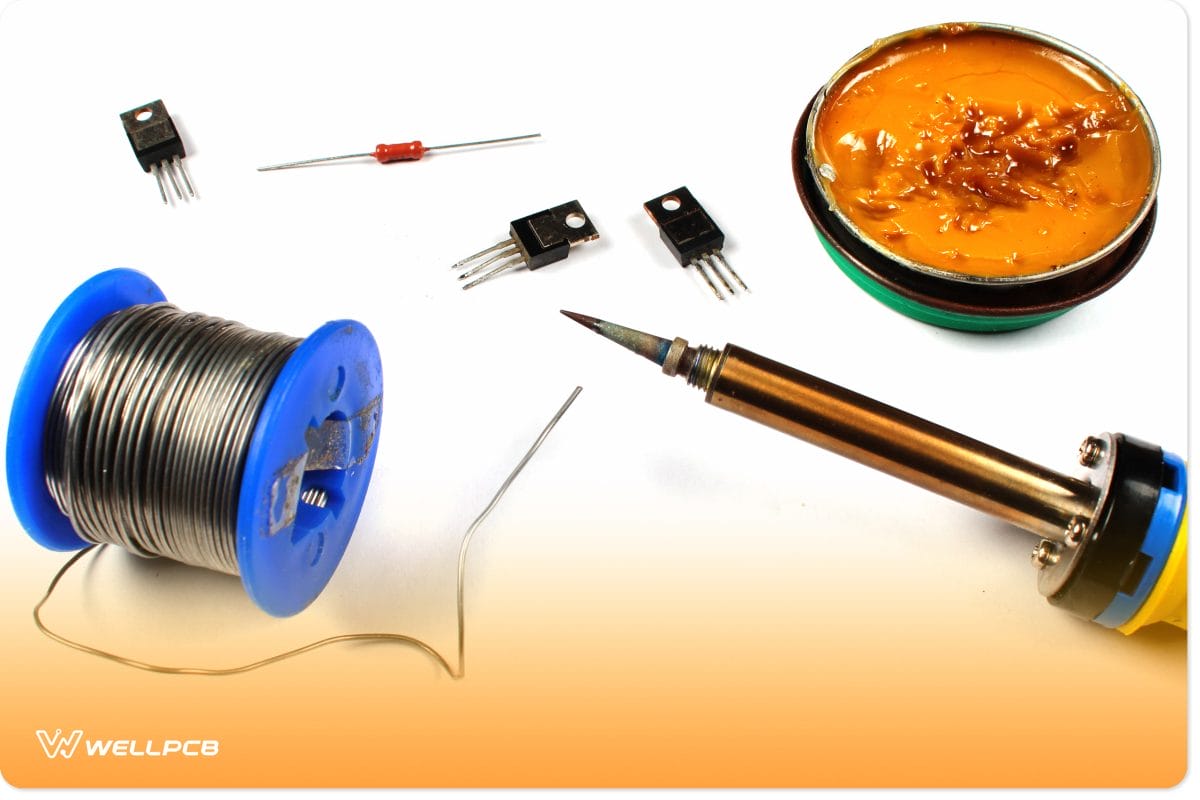

Selecting the right flux for electrical soldering is critical to ensuring reliable, high-quality solder joints and long-term circuit performance. When sourcing flux, it is essential to consider factors such as flux type (rosin-based, water-soluble, or no-clean), activation level, compatibility with components and PCB finishes, and compliance with industry standards such as IPC and RoHS.

For most electronics applications, no-clean fluxes offer a practical balance of performance and convenience, minimizing post-soldering cleaning while maintaining joint integrity. However, in high-reliability or sensitive environments, water-soluble or low-residue rosin-based fluxes may be preferable despite the need for thorough cleaning.

Reliable sourcing involves choosing reputable suppliers and well-documented products to ensure consistency, traceability, and safety. Additionally, proper storage and handling of flux are vital to maintain its effectiveness over time.

In summary, thoughtful selection and responsible sourcing of flux—aligned with specific application requirements and manufacturing processes—contribute significantly to soldering reliability, product quality, and overall production efficiency in electronics assembly.