The global flush rivets market is experiencing steady growth, driven by increasing demand from the aerospace, automotive, and defense sectors. According to Mordor Intelligence, the global aerospace fasteners market—of which flush rivets are a critical component—was valued at USD 6.8 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Flush rivets, valued for their aerodynamic finish and structural integrity, are particularly vital in aircraft manufacturing, where surface smoothness and fatigue resistance are paramount. Grand View Research further supports this trajectory, noting that advancements in lightweight materials and rising aircraft production are accelerating demand for high-performance fastening solutions. With North America and Europe leading in aerospace manufacturing and Asia-Pacific emerging as a growing hub for aviation assembly, the competitive landscape among flush rivet manufacturers is intensifying. This growing market momentum underscores the importance of identifying key industry players who combine precision engineering, compliance with stringent aviation standards (such as NAS, MS, and AN specifications), and scalable production capabilities. Below, we spotlight the top 8 flush rivet manufacturers shaping the future of modern industrial assembly.

Top 8 Flush Rivets Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Flush Rivets Manufacturer

Domain Est. 2018

Website: m.kmhardware.com

Key Highlights: Discover high-quality flush rivets at Dongguan KingMing Hardware and Plastic Technology Co., Ltd. Reliable manufacturer for your fastening solutions….

#2 2.4 mm pop countersink double flush rivets

Domain Est. 2020

Website: rivets-factory.com

Key Highlights: 1. I am a real rivet manufacturer · 2. We provide free rivet samples · 3. We can provide development and design rivet services · 4. We can ship as fast as 1-3 days….

#3 Flush rivets,Flush rivets Manufacturer & Wholesale Supplier …

Website: surinderrivetsindustries.com

Key Highlights: Flush Rivets, also known as countersunk rivets, provide a smooth, level surface after installation, making them perfect for applications requiring ……

#4 Rivets, Riveting Tools and Equipment

Domain Est. 1996

Website: hansonrivet.com

Key Highlights: We provide high quality rivets, rivet tools, rivet guns, fastener, rivet machines and more! Call (800) 777-4838 for more information….

#5 Blind Rivet Nuts

Domain Est. 1996

Website: pemnet.com

Key Highlights: Learn about how rivet nuts can join panels or provide mounting threads with access to only one side of a hole….

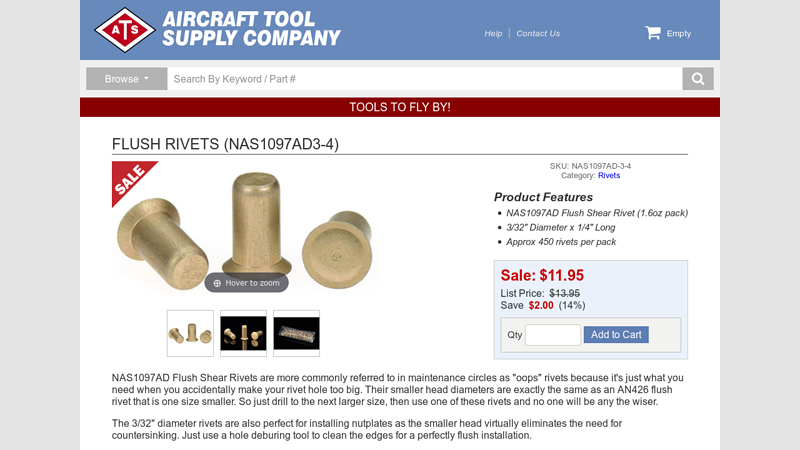

#6 flush rivets (nas1097ad3

Domain Est. 1996

Website: aircraft-tool.com

Key Highlights: Free delivery over $100 30-day returns…

#7 Brown Aviation 1030-2

Domain Est. 2008

Website: autotoolworld.com

Key Highlights: In stock 1–2 day deliveryOur Flush Rivet Sets are manufactured from high alloy steel and heat-treated for long life. Shanks are precision ground and faces are highly polished which…

#8 Rivets Online

Domain Est. 2009 | Founded: 1948

Website: rivetsonline.com

Key Highlights: Founded in 1948, Jay-Cee Sales & Rivet is the nation’s largest distributor of aluminum blind rivets & special fasteners. Contact us or buy online today!…

Expert Sourcing Insights for Flush Rivets

2026 Market Trends for Flush Rivets

The global flush rivets market is poised for significant evolution by 2026, driven by advancements in manufacturing technologies, growing demand from aerospace and transportation sectors, and a heightened focus on lightweight and aerodynamic design. Flush rivets—known for their smooth, flush surface finish that reduces drag and enhances structural aesthetics—are gaining traction across high-performance industries. This analysis explores key market trends expected to shape the flush rivets industry through 2026.

Rising Demand in Aerospace and Defense

The aerospace and defense sector remains the primary driver of flush rivet consumption. As aircraft manufacturers continue to prioritize fuel efficiency and performance, the demand for aerodynamically optimized components is increasing. Flush rivets are essential in achieving smooth fuselage surfaces, especially in commercial aviation and military aircraft. With global air travel recovering post-pandemic and new aircraft programs (e.g., next-gen narrow-body jets) entering production, OEMs are projected to increase procurement of high-precision flush rivets. Additionally, the modernization of defense fleets in regions like North America and Asia-Pacific will further stimulate demand.

Expansion in Automotive and Transportation Applications

Beyond aerospace, the automotive industry is increasingly adopting flush rivets, particularly in high-end and electric vehicles (EVs). As automakers focus on reducing vehicle weight to improve battery efficiency and performance, aluminum-intensive designs are becoming common. Flush rivets offer superior joint strength and aesthetic finish in aluminum body panels. The rise of structural adhesive bonding combined with riveting (e.g., self-piercing rivets with flush heads) is a growing trend, especially among EV manufacturers like Tesla and Rivian. This hybrid joining method is expected to boost the adoption of flush-type fasteners through 2026.

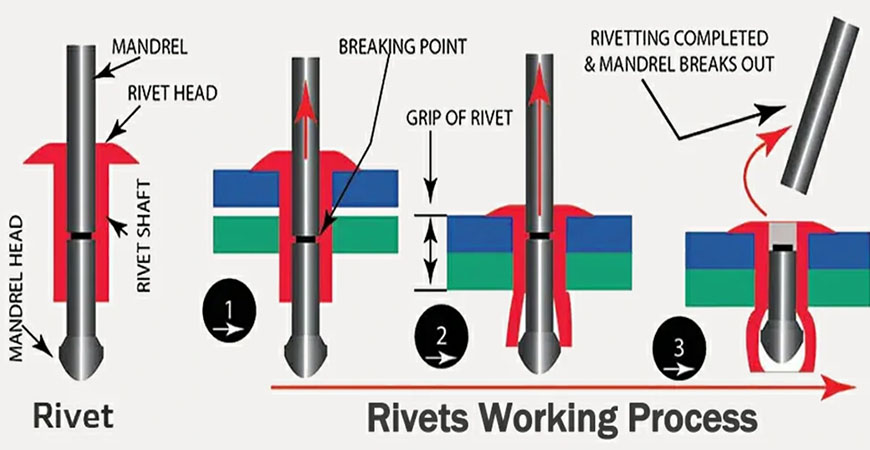

Technological Advancements in Fastening Solutions

Innovation in riveting technology is enhancing the performance and installation efficiency of flush rivets. Automated riveting systems, robotic assembly lines, and smart fastening tools are being integrated into manufacturing processes to improve precision and reduce labor costs. Cold-driven and blind flush rivets are gaining popularity due to their ease of installation in hard-to-reach areas, making them ideal for complex assemblies. Additionally, the development of corrosion-resistant materials—such as titanium, stainless steel, and composite-compatible alloys—is expanding the operational lifespan and application scope of flush rivets.

Regional Market Dynamics

Geographically, North America is expected to maintain its dominance in the flush rivets market, supported by a strong aerospace manufacturing base in the U.S. and Canada. Europe follows closely, driven by Airbus production and stringent emissions regulations pushing lightweight design. Meanwhile, the Asia-Pacific region is anticipated to witness the highest growth rate, fueled by expanding aviation infrastructure in China, India, and Southeast Asia, along with rising domestic aircraft production. Localization of supply chains and government initiatives to support aerospace manufacturing will further accelerate market penetration.

Sustainability and Material Innovation

Environmental concerns are influencing material choices in fastener manufacturing. The push for sustainable aviation and green manufacturing is encouraging the use of recyclable and low-carbon materials in rivet production. Bi-metallic and coated flush rivets designed to reduce galvanic corrosion without harmful chemicals are gaining attention. Moreover, manufacturers are investing in energy-efficient production processes and closed-loop recycling systems to align with global ESG (Environmental, Social, and Governance) standards.

Conclusion

By 2026, the flush rivets market will be shaped by technological innovation, sectoral demand from aerospace and electric mobility, and regional industrial growth. As industries continue to prioritize performance, efficiency, and sustainability, flush rivets will remain a critical component in advanced manufacturing. Companies that invest in R&D, automation, and eco-friendly materials are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing Flush Rivets (Quality, IP)

Sourcing flush rivets—especially for aerospace, automotive, and defense applications—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, regulatory non-compliance, and legal risks. Below are key pitfalls to avoid:

Quality-Related Pitfalls

1. Inconsistent Material Composition

Using substandard or incorrect alloys (e.g., substituting 2117-T4 for certified 2024-T4) can compromise strength and corrosion resistance. Always verify material certifications (e.g., mill test reports, AMS/ASTM compliance) and conduct third-party testing when sourcing from unfamiliar suppliers.

2. Poor Dimensional Accuracy and Surface Finish

Flush rivets must meet tight tolerances to ensure proper fit and aerodynamic smoothness. Inconsistent head profiles or shank diameters can lead to gaps, misalignment, or increased drag. Require detailed inspection reports and use first-article testing (FAI) per AS9102.

3. Inadequate Heat Treatment

Improper heat treatment affects mechanical properties like shear and tensile strength. Rivets that are under- or over-aged may fail prematurely. Confirm that suppliers follow documented heat treat processes traceable to industry standards (e.g., AMS2770).

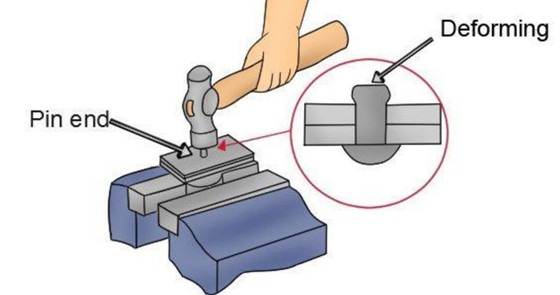

4. Weak or Inconsistent Driving Characteristics

Poorly formed rivets may not upset correctly during installation, leading to incomplete shop heads or cracking. This is often due to inconsistent rivet body formation or improper alloy temper. Evaluate rivet performance through installation trials under production-like conditions.

5. Lack of Traceability and Certification

Reputable applications demand full traceability (lot numbers, heat numbers, inspection records). Suppliers who cannot provide full documentation may be cutting corners. Insist on full conformance to AS9100 and NADCAP accreditation where applicable.

Intellectual Property (IP)-Related Pitfalls

1. Sourcing from Unauthorized or Counterfeit Suppliers

Some suppliers offer “equivalent” flush rivets that infringe on proprietary designs (e.g., CherryMAX®, Huck, or Avdel®). These may mimic form and fit but violate patents and lack performance validation. Always source from authorized distributors or licensed manufacturers.

2. Use of Proprietary Designs Without Licensing

Certain flush rivet designs are protected by utility or design patents. Using or replicating them without permission—even if technically functional—can lead to IP litigation. Conduct thorough IP due diligence and avoid reverse-engineered products.

3. Lack of IP Clarity in Contracts

Supplier agreements should clearly state IP ownership, especially if custom rivets are developed. Ambiguity may allow the supplier to claim rights or sell identical products to competitors. Ensure contracts include IP assignment and confidentiality clauses.

4. Infringement Through “Look-Alike” Products

Even if a rivet meets specs, its design may infringe on patented features like lock mechanisms, break grooves, or mandrel configurations. Consult legal counsel or IP experts when evaluating off-brand alternatives.

5. Export Control and ITAR Compliance Risks

Certain high-performance rivets fall under ITAR (International Traffic in Arms Regulations) or EAR (Export Administration Regulations). Sourcing from non-compliant suppliers—especially offshore—can result in severe penalties. Verify supplier compliance status before procurement.

Mitigation Strategies

- Audit suppliers regularly (on-site or remote) for quality systems and IP practices.

- Require full documentation: COC (Certificate of Conformance), MTRs, FAI reports, and IP licenses.

- Use trusted supply chains and avoid gray-market distributors.

- Engage legal counsel to review contracts and assess IP risks.

By proactively addressing these pitfalls, organizations can ensure reliable performance, regulatory compliance, and legal protection when sourcing flush rivets.

Logistics & Compliance Guide for Flush Rivets

Overview

Flush rivets are specialized fasteners designed to sit flush with or below the surface of the materials they join, commonly used in aerospace, automotive, and high-precision engineering applications where aerodynamics, aesthetics, and structural integrity are critical. This guide outlines key logistics considerations and compliance requirements for the handling, transportation, storage, and regulatory adherence of flush rivets.

Material Specifications and Standards

Flush rivets must comply with industry-specific material and performance standards. Common standards include:

– ASTM F468: Standard specification for blind rivets (including flush head types).

– NASM (National Aerospace Standard Metric): Widely used in aerospace applications.

– MS (Military Standard): Governs rivet dimensions, materials, and strength for defense applications.

– ISO 15977: Specifies requirements for blind rivets with break mandrel and flush head.

Ensure all flush rivets are certified and supplied with material test reports (MTRs) or certificates of conformance (CoC).

Packaging and Labeling

Proper packaging ensures rivets arrive undamaged and traceable:

– Use moisture-resistant, sealed packaging to prevent corrosion, especially for aluminum or steel rivets.

– Label packages with: part number, quantity, material type, finish (e.g., cadmium-plated, anodized), manufacturer, batch/lot number, and date of manufacture.

– Include handling symbols (e.g., “Fragile,” “Keep Dry”) per ISO 780.

– For export, ensure labeling complies with destination country requirements (e.g., bilingual labels in Canada, CE marking in EU).

Storage Requirements

- Store in a controlled environment: temperature between 15–25°C and relative humidity below 60%.

- Keep rivets off the floor on pallets or shelves to prevent moisture absorption and contamination.

- Protect from direct sunlight, chemicals, and corrosive atmospheres.

- Follow FIFO (First In, First Out) inventory management to prevent aging or obsolescence.

Transportation and Handling

- Use padded containers or dividers to prevent movement and surface damage during transit.

- Avoid extreme temperatures and prolonged exposure to humidity during shipping.

- Handle with clean gloves to prevent oil or moisture transfer, especially for corrosion-prone materials.

- For air freight, comply with IATA Dangerous Goods Regulations if rivets are made from restricted or hazardous materials (rare, but applicable to certain coatings or alloys).

Regulatory Compliance

- REACH (EU): Ensure rivet materials (especially coatings) do not contain Substances of Very High Concern (SVHC) above threshold levels.

- RoHS (EU): Verify compliance if rivets are used in electrical/electronic equipment.

- ITAR/EAR (USA): Some high-performance rivets (e.g., titanium or specialized alloys) may be subject to export controls. Confirm classification under USML or CCL.

- Customs Documentation: Provide accurate HS codes (e.g., 7318.15 for steel rivets), CoO (Certificate of Origin), and commercial invoices for international shipments.

Quality Assurance and Traceability

- Maintain full traceability from raw material to finished product using lot/batch tracking.

- Conduct periodic audits of suppliers and logistics partners.

- Retain documentation (CoC, test reports, shipping records) for a minimum of 10 years in aerospace applications.

Disposal and Environmental Considerations

- Dispose of defective or excess rivets according to local waste regulations.

- Recycle metal rivets through certified scrap metal processors.

- Properly handle and dispose of any hazardous coatings or plating materials per EPA or equivalent guidelines.

Conclusion

Effective logistics and compliance management for flush rivets ensures product integrity, regulatory adherence, and operational efficiency. By following standardized procedures for handling, storage, transportation, and documentation, organizations can minimize risk and support quality in high-performance applications.

Conclusion on Sourcing Flush Rivets

In conclusion, sourcing flush rivets requires a careful evaluation of material specifications, dimensional accuracy, strength requirements, and compliance with industry standards such as MS, NAS, or ASTM. The choice of material—typically aluminum, stainless steel, or titanium—should align with the application’s environmental and performance demands, particularly in aerospace, automotive, or high-performance structural assemblies where aerodynamics and stress distribution are critical.

Reliable suppliers with certifications (e.g., ISO, AS9100) and traceable quality control processes are essential to ensure consistency and reliability. Additionally, considering factors such as quantity, lead times, cost-efficiency, and technical support can significantly impact project timelines and final product integrity.

Ultimately, successful sourcing of flush rivets hinges on balancing quality, compliance, and supply chain efficiency to achieve optimal performance in precision-critical applications. Establishing strong relationships with reputable fastener distributors or manufacturers will support long-term reliability and operational success.