The global drain and plumbing fixtures market is experiencing steady expansion, driven by rising residential and commercial construction activities, increased focus on hygiene, and advancements in plumbing technologies. According to Grand View Research, the global plumbing fixtures market size was valued at USD 138.6 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. As kitchen design evolves toward greater functionality and water efficiency, floor drains are becoming a critical component—not only for safety and moisture control but also for meeting stringent building codes and improving indoor air quality. With demand surging in both residential and luxury kitchen segments, manufacturers are innovating with materials like stainless steel, anti-odor seals, and modular designs tailored for high-traffic spaces. This growing emphasis on performance and compliance has elevated the importance of reliable floor drain solutions, setting the stage for the top nine manufacturers leading the charge in quality, engineering, and market presence.

Top 9 Floor Drain In Kitchen Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Jay R. Smith Mfg. Co.

Domain Est. 1996

Website: jrsmith.com

Key Highlights: Jay R. Smith Mfg. Co. is a leading manufacturer of quality engineered plumbing and drainage products in the non-residential construction industry….

#2 Sioux Chief: Rough Plumbing Products

Domain Est. 1997

Website: siouxchief.com

Key Highlights: Panels · Drainage · Specification Drainage · Floor Drains · Floor Sinks · Roof Drains · Cleanouts · Fixture Carriers · Commercial Drainage · Floor Drains ……

#3 Floor Drains

Domain Est. 1995

Website: zurn.com

Key Highlights: Commercial floor drains from Zurn provides a complete plumbing fixtures of line floor drains that are durable and easy to install….

#4 Floor & Area Drains

Domain Est. 1995

Website: watts.com

Key Highlights: Check out our full range of floor and area drain products. Pronto Adjustable Drain with Integrated Level. SpecHUB. Build Your Spec in Under 5 Minutes….

#5 Floor Drains & Channels Product Selector

Domain Est. 1996

Website: blucher.com

Key Highlights: Floor Drains & Channels Product Selector. Please select one of the following categories to narrow down your product search. Pipes & ……

#6 Stainless Floor Drains

Domain Est. 2004

Website: awimfg.com

Key Highlights: The Round Top Stainless Steel Drain offers the same features as our standard square drain but in a round top plate. Construction Multiple Basket and Cover ……

#7 LUXE Linear Drains

Domain Est. 2009

Website: lineardrains.com

Key Highlights: The clean look of linear drains. All LUXE Linear Drain products are 100% stainless steel. Our linear drains are unmatched in both craftsmanship and aesthetics….

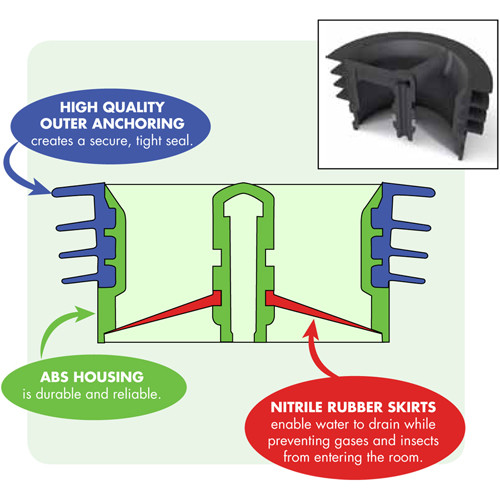

#8 Green Drain™, Inc

Domain Est. 2014

Website: greendrains.com

Key Highlights: Green Drain™, a globally multi-patented floor drain solution, allows for the flow of water and debris, while blocking gases, odors and pests….

#9 Drains Unlimited

Domain Est. 2018

Website: drains-unlimited.com

Key Highlights: Drains Unlimited has been involved in the design and manufacture of stainless steel floor drains, grease traps, strip channels, shower channels, and linear ……

Expert Sourcing Insights for Floor Drain In Kitchen

2026 Market Trends for Floor Drain in Kitchen

Growing Demand for Hygienic and Efficient Kitchen Designs

In 2026, the demand for floor drains in kitchens is expected to rise significantly, driven by increasing consumer focus on hygiene, water management, and durable kitchen infrastructure. With more homeowners and commercial establishments prioritizing cleanliness and safety, floor drains are becoming a standard feature not only in commercial kitchens but also in modern residential designs. The trend is particularly evident in open-concept kitchens and luxury homes, where effective water runoff solutions are essential for preventing slips, mold, and structural damage.

Advancements in Drain Design and Materials

The floor drain market will see notable innovation in materials and design by 2026. Stainless steel, polymer composites, and antimicrobial-coated grates are gaining popularity due to their durability and resistance to corrosion and bacterial growth. Additionally, low-profile and minimalist drain covers are being integrated seamlessly into tile and stone flooring, supporting aesthetic continuity in high-end kitchen renovations. These design improvements are making floor drains more appealing to residential consumers who previously viewed them as utilitarian or industrial.

Expansion in Residential Applications

Traditionally used in commercial and industrial kitchens, floor drains are increasingly being adopted in residential settings. This shift is fueled by the rise of large-scale kitchen remodels, outdoor kitchen installations, and homes in flood-prone areas. Homebuilders and designers are incorporating floor drains into luxury kitchens with high-traffic zones, near sinks, or in areas with underfloor heating systems where moisture control is critical. The 2026 market will reflect this residential expansion, with manufacturers introducing compact, quiet, and easy-to-maintain models tailored for home use.

Smart Drainage and IoT Integration

A key emerging trend in 2026 is the integration of smart technology into kitchen floor drains. Sensors that detect water accumulation, blockages, or leaks are being embedded into drain systems, allowing real-time alerts via home automation platforms. These smart drains can trigger automatic shut-off valves or pump activation, minimizing water damage risks. As smart homes become more prevalent, the convergence of plumbing infrastructure with IoT ecosystems will enhance the functionality and appeal of kitchen floor drains.

Sustainability and Water Conservation Focus

Environmental concerns are shaping the floor drain market, with a push toward sustainable materials and water-efficient systems. Recycled metals and eco-friendly polymers are being used in drain manufacturing, aligning with green building certifications like LEED and WELL. Some advanced systems incorporate water recovery mechanisms, channeling drained water to greywater recycling units for irrigation or non-potable uses. This sustainability angle will be a major selling point in 2026, especially in eco-conscious markets.

Regional Market Growth and Regulatory Influence

Regional variations will influence the adoption of kitchen floor drains. In Asia-Pacific and parts of Europe, stringent building codes related to fire safety and hygiene are mandating floor drains in commercial kitchen spaces, driving market growth. In North America, adoption is rising due to insurance incentives and homeowner demand for resilient infrastructure. Regulatory support, combined with urbanization and rising construction activity, will contribute to a compound annual growth rate (CAGR) of approximately 6.5% in the global kitchen floor drain market through 2026.

Conclusion

By 2026, the floor drain in kitchen market will be characterized by innovation, expanded residential applications, and integration with smart and sustainable technologies. As consumer expectations evolve and building standards become more rigorous, floor drains will transition from functional necessities to intelligent, design-conscious components of modern kitchen spaces. Manufacturers and designers who align with these trends will be well-positioned to capture growing market opportunities.

Common Pitfalls When Sourcing a Floor Drain for the Kitchen (Quality and IP Rating)

Sourcing a floor drain for kitchen use requires careful attention to both quality and Ingress Protection (IP) ratings. Overlooking these aspects can lead to costly repairs, hygiene issues, and safety hazards. Here are the most common pitfalls to avoid:

Choosing Low-Quality Materials

Selecting a floor drain made from substandard materials—such as thin-gauge stainless steel, poor-grade plastic, or uncoated metals—can result in rapid corrosion, warping, or cracking under frequent exposure to hot water, grease, and cleaning chemicals. Low-quality grates may bend under foot traffic or equipment, compromising safety and functionality.

Ignoring IP Rating Requirements

The IP (Ingress Protection) rating indicates the level of protection against solids and liquids. In a kitchen environment, where water, grease, and debris are common, choosing a drain with an inadequate IP rating (e.g., below IP67) can allow water and contaminants to seep into the subfloor or drainage system, leading to mold, structural damage, or electrical hazards in areas with nearby electrical installations.

Mismatched Drain Capacity and Kitchen Load

Using a floor drain with insufficient flow capacity for the volume of water and waste generated in a commercial kitchen can result in slow drainage or overflow. This is especially critical in high-traffic kitchens where large quantities of water are used for cleaning. Undersized traps or narrow channels reduce efficiency and increase maintenance needs.

Poor Sealing and Leak Risks

Low-quality drains often feature weak or poorly designed seals between the body and the grate or pipe connections. Over time, this can lead to leaks beneath the floor, damaging structural elements and promoting bacterial growth. A proper watertight seal is essential for hygiene and longevity.

Inadequate Odor and Pest Prevention

Drains with ineffective or poorly maintained traps (especially if made from low-quality materials that degrade quickly) can fail to block sewer gases and pests. This is a major hygiene concern in food preparation areas and may result in health code violations.

Overlooking Ease of Maintenance

High-quality kitchen floor drains should be designed for easy cleaning and maintenance. Drains with complex, non-removable grates or hard-to-access traps increase downtime and labor costs. Poor design can also trap debris, accelerating wear and reducing IP effectiveness over time.

Failing to Verify Compliance and Certification

Not all floor drains meet industry standards for food-safe environments (e.g., NSF, ISO, or local health codes). Sourcing a drain without proper certification can lead to compliance issues during inspections, especially in commercial kitchens.

By avoiding these common pitfalls—prioritizing durable materials, verifying correct IP ratings (ideally IP67 or higher), ensuring adequate capacity, and selecting certified, easy-to-maintain models—you can ensure reliable, safe, and hygienic drainage in your kitchen.

Logistics & Compliance Guide for Floor Drain in Kitchen

Purpose and Importance

A floor drain in a kitchen serves a critical role in managing water runoff, preventing flooding, and maintaining hygiene. Proper logistics and compliance are essential for safety, sanitation, and adherence to regulatory standards in both commercial and residential settings.

Regulatory Standards and Codes

Compliance with local, national, and industry-specific regulations is mandatory. Key standards include:

– International Plumbing Code (IPC): Specifies requirements for drain placement, slope, trap type, and venting.

– International Building Code (IBC): Governs structural integration and accessibility.

– Health Department Regulations: Mandates for commercial kitchens to prevent contamination and ensure cleanability.

– Americans with Disabilities Act (ADA): Ensures floor drains do not create trip hazards or impede accessibility in public facilities.

Design and Installation Requirements

- Location: Drains should be installed at the lowest point of the floor and near areas prone to water exposure (e.g., sinks, dishwashers, prep zones).

- Slope and Grading: Minimum floor slope of 1/8 inch per foot (1% gradient) toward the drain to ensure efficient water flow.

- Trap and Venting: Must include a P-trap to prevent sewer gases and a properly connected vent to maintain air pressure and drainage efficiency.

- Material and Construction: Use corrosion-resistant materials such as stainless steel or approved polymer. Grates must be durable, cleanable, and meet load-bearing requirements.

Hygiene and Sanitation Compliance

- Cleanability: Drain design must allow for easy cleaning and microbial control. Removable grates and smooth surfaces are recommended.

- Backflow Prevention: Install check valves or air gaps where required to prevent contaminated water from re-entering the kitchen.

- Odor Control: Ensure traps are water-filled at all times; consider enzymatic drain treatments in high-usage environments.

Maintenance and Inspection Logistics

- Routine Cleaning: Schedule regular cleaning to prevent grease, food debris, and biofilm buildup. Frequency depends on kitchen usage (daily in commercial settings).

- Inspection Schedule: Conduct monthly visual inspections and annual professional assessments to verify compliance and functionality.

- Recordkeeping: Maintain logs of maintenance, repairs, and inspections for health and safety audits.

Environmental and Safety Considerations

- Grease Interceptors: Required in commercial kitchens to capture fats, oils, and grease (FOG) before they enter the drainage system.

- Spill Response: Integrate floor drains into emergency spill protocols to facilitate rapid water removal.

- Slip Resistance: Surrounding flooring must remain slip-resistant even when wet, and drain grates should be flush or low-profile to avoid tripping hazards.

Documentation and Certification

- Permits: Obtain necessary plumbing and construction permits prior to installation.

- As-Built Drawings: Maintain updated diagrams showing drain location, piping, and connections.

- Compliance Certification: Secure approval from local authorities or third-party inspectors upon installation or renovation.

Conclusion

A properly installed and maintained floor drain in the kitchen is essential for operational efficiency, regulatory compliance, and public health. Adhering to plumbing codes, sanitation standards, and maintenance protocols ensures long-term safety and functionality across all kitchen environments.

In conclusion, selecting the appropriate floor drain for a kitchen is a critical aspect of ensuring hygiene, functionality, and long-term safety in the space. A well-chosen floor drain effectively manages wastewater, prevents water accumulation, minimizes slip hazards, and supports compliance with health and safety regulations. Key factors to consider include material durability (such as stainless steel for resistance to corrosion and heavy use), proper sizing and flow rate to handle expected water volume, trap design to prevent odors and pest entry, and ease of maintenance and cleaning.

Additionally, proper placement in accordance with kitchen layout and local plumbing codes is essential for optimal performance. Whether in a residential, commercial, or industrial kitchen, investing in a high-quality floor drain from a reputable supplier ensures reliable operation, reduces the risk of water damage, and contributes to a sanitary and efficient working environment. Ultimately, thoughtful sourcing of a floor drain not only enhances functionality but also supports long-term cost savings and operational efficiency.