The global flock paper market is experiencing steady expansion, driven by rising demand for premium packaging, decorative materials, and eco-friendly alternatives across industries such as automotive, fashion, and luxury goods. According to Grand View Research, the global flocking materials market size was valued at USD 4.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.3% from 2023 to 2030. This growth is fueled by increasing consumer preference for textured, high-end finishes and the expansion of applications in heat transfer labels, wallpaper, and gift wrapping. Parallel insights from Mordor Intelligence highlight robust demand in emerging economies, where urbanization and disposable incomes are accelerating the adoption of decorative and specialty papers. As sustainability becomes a key purchasing criterion, leading manufacturers are innovating with recyclable substrates and low-impact adhesives—making flock paper not only aesthetically appealing but also environmentally responsible. Against this dynamic backdrop, the following list highlights the top 10 flock paper manufacturers shaping the industry through technological advancement, global reach, and product differentiation.

Top 10 Flock Paper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Products

Domain Est. 1998

Website: flocktex.com

Key Highlights: As a flocked materials manufacturer, we at Flock Tex Incorporated deliver precision products and advanced solutions. Discover more….

#2 Flock Tex Inc.

Domain Est. 2004

Website: beautypackaging.com

Key Highlights: Flock Tex Inc. Company Headquarters 200 Founders Dr., Woonsocket, Rhode Island, 02895, US Driving Directions Phone: View Phone Fax: View Fax View website…

#3 #65, 20″ x 26″, 2 Sheets, Non-Adhesive Flock Paper

Domain Est. 1999

Website: edmundoptics.com

Key Highlights: Light Absorbing Black-Out Material is a velvet-like, adhesive, or non-adhesive backing that allows black-out material to be applied to any acceptable ……

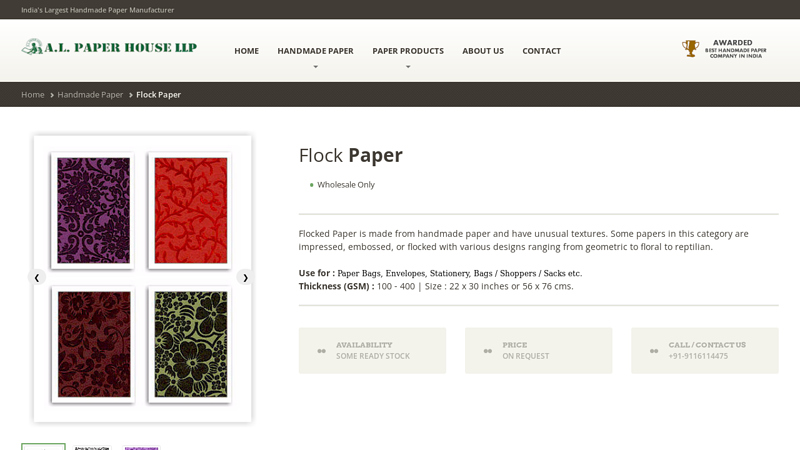

#4 Flock Paper

Domain Est. 2000

Website: alpaperhouse.com

Key Highlights: Flocked Paper is made from handmade paper and have unusual textures. Some papers in this category are impressed, embossed, or flocked with various designs….

#5 About

Domain Est. 2003

Website: krekelbergflockproducts.nl

Key Highlights: Located in the south of the Netherlands next to Belgium and German borders, Krekelberg has been manufacturing flocked polystyrene, flocked paper, flocked board ……

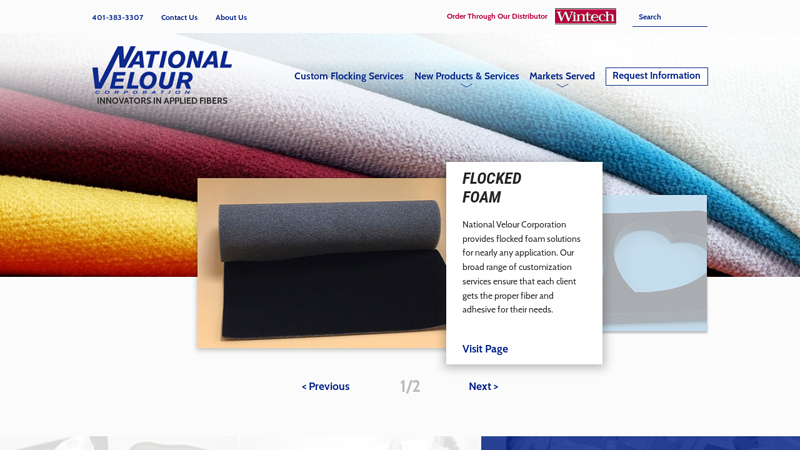

#6 National Velour Corporation

Domain Est. 2004

Website: nationalvelour.com

Key Highlights: National Velour is now a leader in the design of high-tech performance flocked materials and carries the largest, most varied inventory of flocked vinyl, paper ……

#7 Embossed Flock Paper

Domain Est. 2017

Website: shailjapapers.com

Key Highlights: Embossed Flock Paper, Embossed PU, FBB (Virgin Boards), Hi Print, High Print, Uncoated Board, High Smooth Flock Paper, Laid & White, MG Poster Papers, Metallic…

#8 Has Flock Been Hacked?

Domain Est. 2017

Website: flocksafety.com

Key Highlights: No, Flock has never been hacked, and there has not been a leak of Flock information. As license plate readers become more widely used across ……

#9 Whitepaper

Domain Est. 2017

Website: flock.io

Key Highlights: Unleash the power of FLock! Explore our Whitepaper page for academic papers, ecosystem partnerships, and exciting job opportunities….

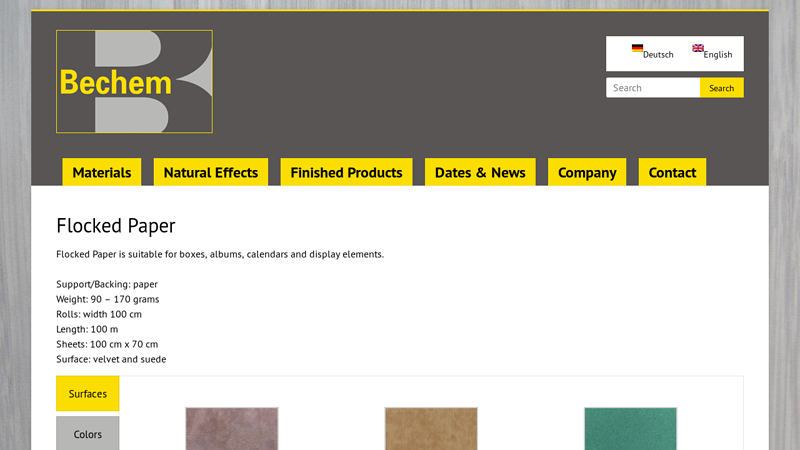

#10 Flocked Paper

Website: bechemgroup.de

Key Highlights: Flocked Paper is suitable for boxes, albums, calendars and display elements. Support/Backing: paper. Weight: 90 – 170 grams. Rolls: width 100 cm. Length: 100 m….

Expert Sourcing Insights for Flock Paper

H2 2026 Market Trends Analysis for Flock Paper

As of H2 2026, the global flock paper market is undergoing a period of strategic transformation, driven by sustainability imperatives, technological innovation, and shifting consumer preferences. Flock Paper — known for its textured, velvet-like finish achieved by adhering tiny fibers (flock) to paper substrates — is positioned at the intersection of premium packaging, luxury branding, and eco-conscious design. Below is an analysis of key market trends shaping the industry in the second half of 2026.

1. Accelerated Demand for Sustainable Luxury Packaging

Sustainability remains the dominant driver in H2 2026. Brands across cosmetics, fashion, and premium gifting are prioritizing eco-friendly materials without compromising on tactile appeal. Flock paper, particularly when produced using biodegradable adhesives and FSC-certified paper, aligns with this demand. Innovations in water-based and solvent-free flocking processes have reduced environmental impact, making flock paper a preferred choice for high-end sustainable packaging. Regulatory pressure in the EU and North America continues to favor recyclable and compostable materials, further boosting adoption.

2. Growth in Premium E-Commerce and Unboxing Experiences

The rise of direct-to-consumer (DTC) e-commerce, especially in beauty, fragrance, and luxury goods, has elevated the importance of unboxing experiences. In H2 2026, brands are increasingly using flock paper for gift boxes, inserts, and protective liners to convey exclusivity and tactile luxury. The sensory appeal of flock enhances perceived value, driving customer loyalty and social media engagement. Custom flock colors and textures (e.g., soft-touch, matte velvet) are trending to support brand differentiation.

3. Advancements in Digital Printing Compatibility

Technological progress has resolved earlier compatibility issues between flock paper and digital printing. By H2 2026, major suppliers offer flock paper pre-treated for UV and toner-based digital presses, enabling short-run, high-customization production. This supports on-demand manufacturing and personalized packaging — critical for limited editions and niche markets — reducing waste and inventory costs.

4. Regional Market Diversification

While Europe and North America remain core markets due to strong sustainability regulations and high consumer spending, APAC — particularly China, South Korea, and India — is emerging as a high-growth region. Rising disposable incomes and a growing middle class are fueling demand for premium packaging. Local manufacturers are investing in flock paper production, reducing import reliance and shortening supply chains.

5. Increased Competition and Price Pressures

As demand grows, new entrants and material alternatives (e.g., textured coatings, synthetic velvets) are entering the market. This has intensified competition, particularly in mid-tier segments. While premium flock paper maintains strong margins, producers face pressure to innovate and offer cost-effective solutions without sacrificing quality. Vertical integration — combining flocking, printing, and converting — is becoming a key differentiator.

6. Circular Economy and End-of-Life Considerations

End-of-life management is a critical focus in H2 2026. Brands and retailers are scrutinizing the recyclability of composite materials. Flock paper with mono-material construction (e.g., paper-based flock and adhesive systems) is gaining favor over multi-laminated alternatives. Industry collaborations are emerging to develop standardized recycling protocols and improve recovery rates.

Conclusion:

In H2 2026, Flock Paper is evolving from a niche decorative material into a strategic component of sustainable, premium packaging ecosystems. Success in this market requires a balance of innovation, environmental responsibility, and brand alignment. Companies that invest in eco-friendly production, digital integration, and circular design principles are best positioned to capitalize on long-term growth trends.

Common Pitfalls Sourcing Flock Paper (Quality, IP)

Sourcing flock paper—especially for specialized applications like textiles, packaging, or automotive interiors—can present several challenges, particularly concerning quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps mitigate supply chain disruptions, product defects, and legal exposure.

Inconsistent Material Quality

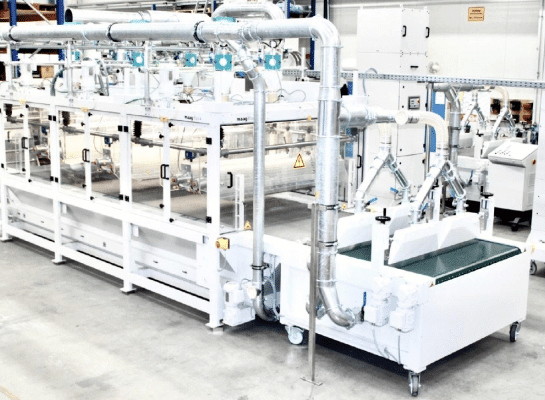

One of the most frequent issues when sourcing flock paper is variability in quality across batches or suppliers. Flock paper quality depends on multiple factors: the type and fineness of the flock fibers (typically nylon, rayon, or polyester), adhesive uniformity, flock density, and base paper integrity. Poor quality control can result in uneven flocking, weak adhesion, color inconsistencies, or poor durability, leading to application failures or customer complaints.

Lack of Standardized Specifications

Many suppliers, especially in emerging markets, may not adhere to internationally recognized quality standards (e.g., ISO, ASTM). Without clear, detailed specifications—such as flock length, grammage, peel strength, and color fastness—buyers risk receiving non-conforming materials. This ambiguity often leads to disputes and rework, increasing costs and delays.

Hidden Supply Chain Complexity

Flock paper is a multi-component product involving raw fiber suppliers, adhesive manufacturers, and converting facilities. A lack of supply chain transparency can obscure the origin of materials, making it difficult to ensure consistency or verify sustainability claims. Sub-tier supplier changes without notification can undermine product performance and traceability.

Intellectual Property Infringement Risks

Using patented flocking techniques, patterns, or adhesive formulations without proper licensing can expose buyers to IP litigation. Some suppliers may offer “copy” or “compatible” flock papers that mimic branded products but infringe on existing patents. Buyers who unknowingly source such materials may face legal action, product recalls, or customs seizures, even if the infringement was unintentional.

Misrepresentation of Certifications and Compliance

Suppliers may falsely claim certifications for fire resistance (e.g., FMVSS 302), eco-compliance (e.g., REACH, RoHS), or sustainability (e.g., FSC). Without independent verification, these claims can mislead buyers into using non-compliant materials, especially in regulated industries like automotive or children’s products.

Limited Technical Support and Documentation

Low-cost suppliers may lack the technical expertise to provide adequate product data sheets, safety data sheets (SDS), or application guidance. This absence of support can hinder integration into manufacturing processes and troubleshooting, increasing the risk of production errors.

To avoid these pitfalls, buyers should conduct thorough due diligence, including supplier audits, batch testing, IP landscape reviews, and clear contractual agreements defining quality and compliance requirements.

Logistics & Compliance Guide for Flock Paper

Flock paper, a specialty material coated with short fibers (flock) for a soft, velvety texture, requires careful handling and adherence to regulatory standards throughout its supply chain. This guide outlines key logistics and compliance considerations for manufacturers, distributors, and users of flock paper.

Material Handling & Storage

Flock paper is sensitive to environmental conditions and physical damage. Proper handling preserves its aesthetic and functional qualities.

- Temperature & Humidity Control: Store in a climate-controlled environment (18–24°C, 40–60% RH) to prevent curling, delamination, or static buildup.

- Flat Storage: Keep sheets or rolls flat and supported to avoid warping or creasing. Use pallets and avoid stacking excessive weight.

- Dust & Contamination Prevention: Store in sealed packaging until use to protect against dust, oils, and moisture.

- Static Management: Use antistatic brushes or ionizers during processing to minimize static, which attracts debris.

Packaging & Transportation

Ensure safe transit to maintain product integrity and meet shipping regulations.

- Protective Packaging: Wrap in moisture-resistant, non-abrasive materials (e.g., kraft paper, polyethylene). Use edge protectors for sheets and secure cores for rolls.

- Secure Loading: Prevent shifting during transport by properly strapping pallets and using dunnage.

- Labeling: Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up,” “Protect from Moisture”).

- Transport Compliance: Follow carrier-specific requirements for hazardous materials if applicable (e.g., solvent-based adhesives used in flocking).

Regulatory Compliance

Flock paper products must meet regional and industry-specific regulations, especially regarding chemicals, safety, and labeling.

- REACH & RoHS (EU): Ensure flock materials and adhesives comply with restrictions on SVHCs (Substances of Very High Concern) and hazardous substances like phthalates or heavy metals.

- Proposition 65 (California, USA): Disclose if any components contain listed carcinogens or reproductive toxins.

- FDA Compliance (if applicable): For flock paper used in food packaging, confirm compliance with FDA 21 CFR for indirect food contact materials.

- REACH SVHC Disclosure: Provide SCIP notifications if flock paper contains >0.1% SVHC by weight.

Environmental & Sustainability Standards

Increasing focus on eco-friendly materials affects flock paper production and disposal.

- Recyclability: Declare whether the product is recyclable. Note that adhesive-coated or laminated flock paper may not be easily recyclable.

- FSC/PEFC Certification: Source base paper from sustainably managed forests if applicable.

- Chemical Management: Use water-based or low-VOC adhesives to reduce environmental impact.

- Waste Disposal: Follow local regulations for disposal of non-recyclable flock materials, which may be classified as industrial waste.

Import/Export Considerations

International shipping requires documentation and adherence to customs regulations.

- HS Code Classification: Use appropriate Harmonized System codes (e.g., 4811 for coated paper) for customs declarations.

- Customs Documentation: Provide commercial invoices, packing lists, and certificates of origin.

- Import Restrictions: Verify destination country regulations regarding chemical content, labeling, and packaging materials.

Quality Assurance & Traceability

Maintain consistent quality and enable rapid response to compliance issues.

- Batch Tracking: Implement lot numbering for full traceability from raw materials to finished goods.

- Testing & Certification: Conduct regular testing for adhesion strength, colorfastness, and chemical compliance. Maintain up-to-date test reports.

- Supplier Audits: Verify compliance of raw material suppliers (e.g., flock fiber, adhesives, base paper).

Workplace Safety (OSHA & Local Standards)

Protect personnel involved in handling and processing flock paper.

- Dust Control: Install ventilation systems when cutting or grinding flock paper to minimize inhalable fiber exposure.

- PPE Requirements: Provide gloves, masks, and eye protection where necessary.

- Fire Safety: Store away from ignition sources; flock fibers may be flammable depending on composition.

Adhering to this logistics and compliance framework ensures safe, legal, and efficient handling of flock paper across global markets while supporting sustainability and customer trust.

Conclusion on Sourcing Flock Paper

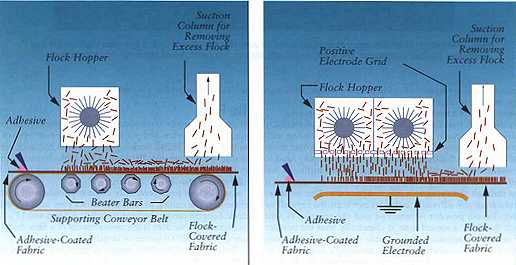

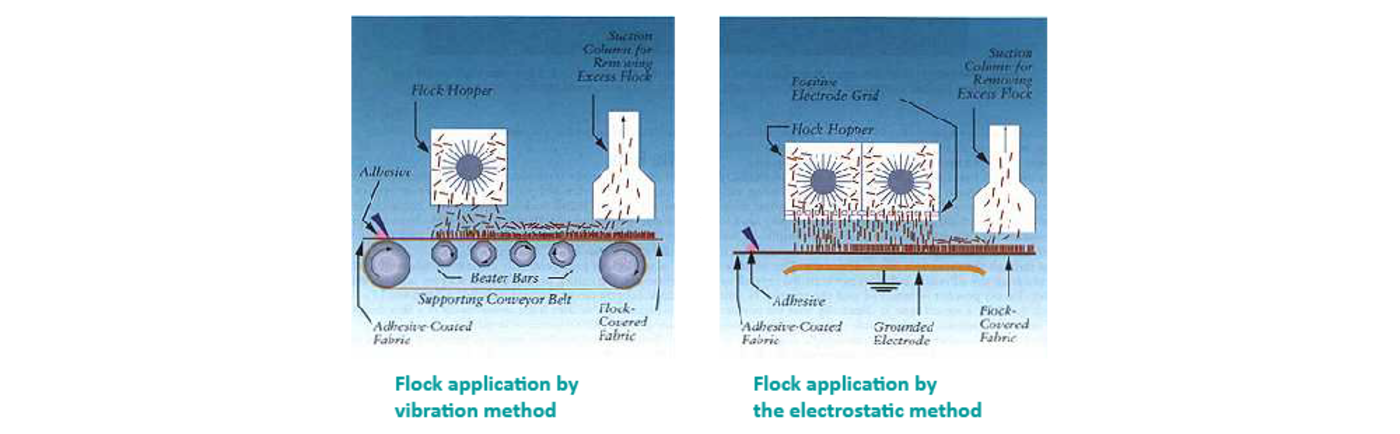

Sourcing flock paper requires a strategic approach that balances quality, cost, sustainability, and supply chain reliability. After evaluating potential suppliers, material specifications, and market availability, it is evident that selecting the right source involves thorough due diligence. Key factors such as fiber composition, adhesive compatibility, flocking technique (electrostatic or mechanical), color consistency, and environmental certifications must align with the intended application—whether for packaging, crafts, textiles, or industrial uses.

Building relationships with reputable suppliers who demonstrate production transparency, quality control measures, and compliance with environmental and safety standards ensures long-term success. Additionally, considering local versus international sourcing can impact lead times, transportation costs, and carbon footprint, making regional suppliers a viable option for more sustainable and responsive operations.

In conclusion, effective sourcing of flock paper hinges on clear requirements, ongoing supplier evaluation, and a commitment to quality and sustainability. By prioritizing these elements, businesses can secure a reliable supply of flock paper that meets both performance standards and corporate responsibility goals.