The global oil skimmer market is experiencing robust growth, driven by increasing industrialization, stringent environmental regulations, and rising concerns over marine pollution from oil spills. According to Grand View Research, the global oil spill management market size was valued at USD 20.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. Similarly, Mordor Intelligence projects steady growth in demand for oil recovery equipment, with floating oil skimmers playing a pivotal role across offshore drilling, maritime transportation, and wastewater treatment sectors. As environmental compliance becomes a top priority for industries worldwide, the need for reliable, high-efficiency skimming solutions has never been greater—spurring innovation among leading manufacturers. In this context, we highlight the top 10 floating oil skimmer manufacturers that are setting industry benchmarks through advanced technology, scalability, and proven performance in challenging environments.

Top 10 Floating Oil Skimmer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oil Skimmers, Inc.

Domain Est. 2001

Website: oilskim.com

Key Highlights: We are a leading manufacturer of industrial oil skimmers, oil/water separators, and custom waste oil removal solutions with over 50 years in the business….

#2 Industrial & Floating Oil Spill Skimmers

Domain Est. 2001

Website: abasco.com

Key Highlights: ABASCO offers floating oil skimmers for reclaiming crude, refined, animal, or vegetable oils from surface waters, using oleophilic technology….

#3 Abanaki Corporation

Domain Est. 1996

Website: abanaki.com

Key Highlights: Discover Abanaki’s industrial oil skimmers for efficient oil removal, tramp oil cleanup, & coolant system performance in industrial settings….

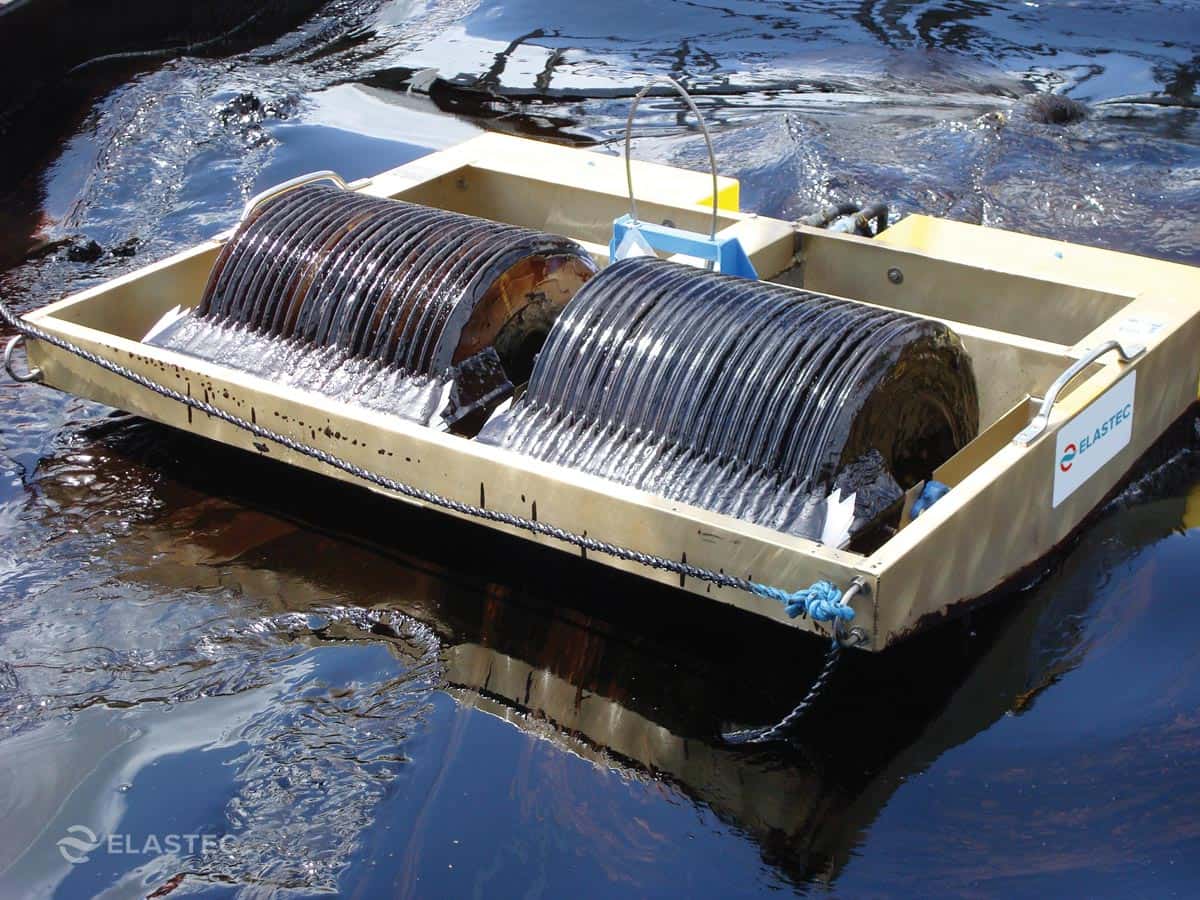

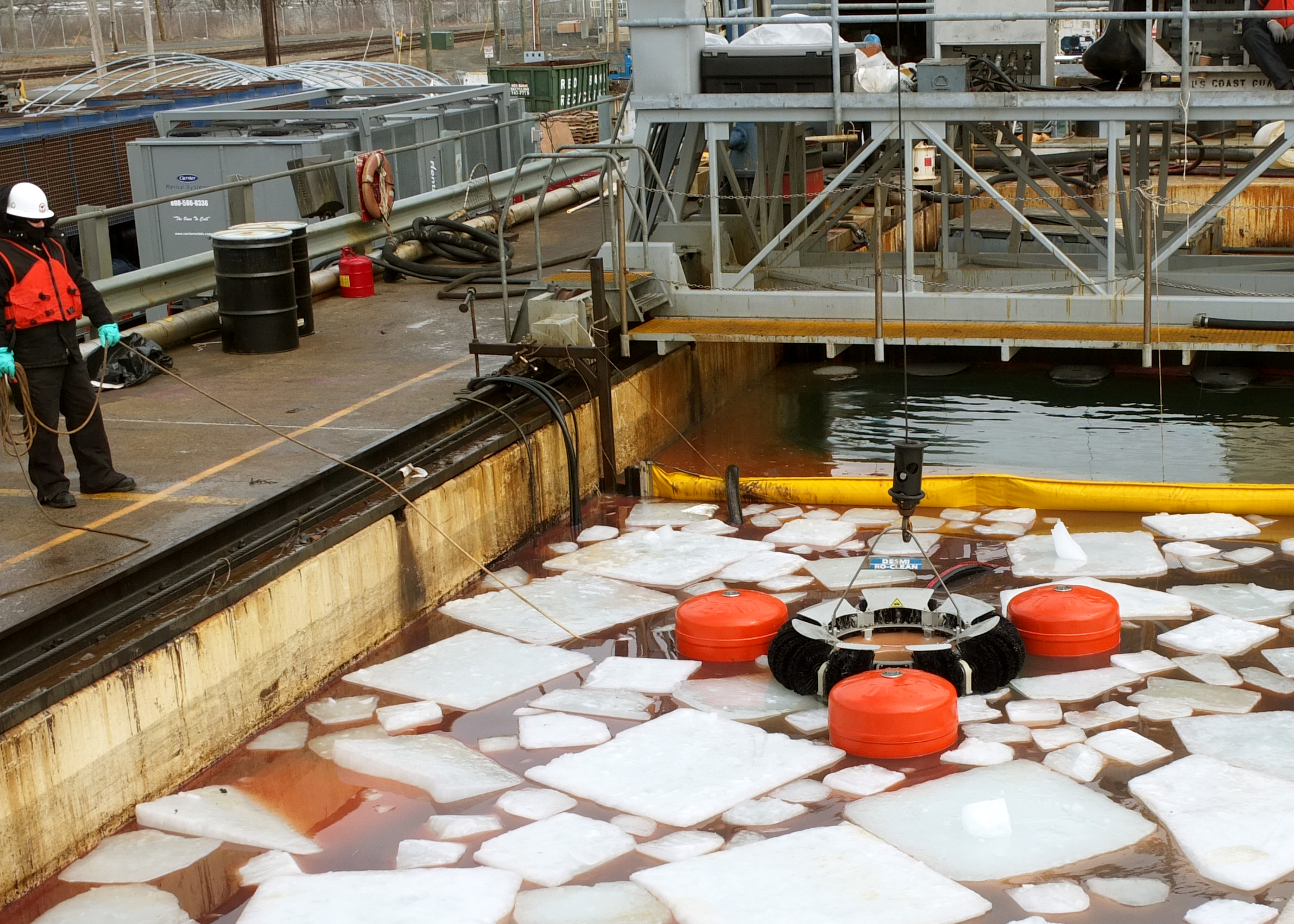

#4 Elastec

Domain Est. 1997

Website: elastec.com

Key Highlights: Elastec is the world’s largest employee-owned manufacturer of oil spill response equipment, including oil skimmers, and containment boom….

#5 Potential Engineering

Domain Est. 2001

Website: potentialengineering.com

Key Highlights: Buy Oil Skimmers, Hydrocyclone & Coalescer for Oil-Water Separation & Oil Spill Response at Potential Engineering. Our Systems are Used in Wastewater ……

#6 Oil Skimmers – Oil Spill Solutions

Domain Est. 2010

Website: desmiro-clean.com

Key Highlights: Explore top-tier Oil Skimmers designed for efficient Oil Spill clean-up. Our technology guarantees quick, effective, and environmentally safe solutions….

#7 THE SKIMSTER® Floating Oil Skimmer

Domain Est. 1997

Website: hohcorp.com

Key Highlights: The SKIMSTER Floating Oil Skimmer will remove free and dispersed surface oil from wastewater. It works on the principle of a controlled buoyancy weir….

#8 SKIMOIL, LLC

Domain Est. 1998

Website: skimoil.com

Key Highlights: SkimOIL specializes in oil skimmers, oil water separators and oil removal controls & equipment for the oil/gas,general manufacturing, and commercial marine ……

#9 Water Oil Skimmer

Domain Est. 2021

#10 Mini Oil Skimmer Solutions by HC Feng

Domain Est. 2019

Website: hcfeng.com

Key Highlights: The BEST-MINI mini oil skimmer from HC FENG is perfect for handling waste oil and cutting fluid efficiently. The compact size of the mini oil skimmer allows ……

Expert Sourcing Insights for Floating Oil Skimmer

H2: 2026 Market Trends for Floating Oil Skimmers

The global floating oil skimmer market is poised for significant growth and transformation by 2026, driven by increasing environmental regulations, rising offshore oil and gas activities, and growing awareness of marine pollution. Several key trends are expected to shape the market landscape in the coming years:

-

Stricter Environmental Regulations: Governments and international bodies are enforcing more stringent environmental protection standards, particularly in response to oil spills and marine contamination. Regulatory frameworks such as the International Maritime Organization (IMO) guidelines and regional directives (e.g., EU Marine Strategy Framework Directive) are compelling industries to adopt efficient oil recovery systems. This is expected to boost demand for advanced floating oil skimmers in ports, offshore platforms, and shipping operations.

-

Growth in Offshore Oil and Gas Exploration: Despite the global shift toward renewable energy, offshore drilling remains a critical component of the energy mix, especially in regions like the Gulf of Mexico, West Africa, and the Asia-Pacific. Increased exploration and production activities heighten the risk of oil spills, thereby driving the need for reliable oil spill response equipment, including floating skimmers.

-

Technological Advancements: By 2026, floating oil skimmers are expected to incorporate smart technologies such as IoT-enabled monitoring systems, remote operation capabilities, and automated skimming processes. Innovations in materials—such as oil-absorbent polymers and corrosion-resistant composites—are enhancing skimmer efficiency, durability, and maintenance intervals. Additionally, solar-powered and autonomous skimmer units are gaining traction, particularly in remote or ecologically sensitive areas.

-

Expansion of Municipal and Industrial Applications: Beyond marine oil spill response, floating oil skimmers are increasingly being deployed in industrial wastewater treatment, urban stormwater management, and marina operations. Municipalities and industrial facilities are investing in proactive pollution control measures to comply with discharge regulations and protect local waterways, broadening the market beyond traditional oil and gas sectors.

-

Asia-Pacific Market Growth: The Asia-Pacific region is anticipated to witness the fastest market growth due to rapid industrialization, expanding port infrastructure, and increasing maritime trade. Countries like China, India, and Indonesia are investing in environmental protection technologies, creating new opportunities for oil skimmer manufacturers and service providers.

-

Focus on Rapid Deployment and Portability: Emergency preparedness is a growing priority, leading to increased demand for portable, rapidly deployable skimming systems. Modular and inflatable skimmer units that can be quickly transported and assembled are expected to become more common in national and regional oil spill response arsenals.

-

Sustainability and Circular Economy Initiatives: There is a growing emphasis on recycling recovered oil and minimizing waste. Advanced skimmers that integrate separation and storage systems enable the reclamation of oil for reuse or proper disposal, aligning with circular economy principles and corporate sustainability goals.

In conclusion, the 2026 floating oil skimmer market will be shaped by regulatory pressures, technological innovation, and expanding applications across industries and geographies. Companies that invest in R&D, comply with environmental standards, and offer scalable, efficient solutions will be well-positioned to capitalize on this evolving market.

Common Pitfalls When Sourcing a Floating Oil Skimmer (Quality, IP)

Sourcing a Floating Oil Skimmer requires careful consideration to avoid performance, durability, and legal issues. Overlooking key factors related to quality and intellectual property (IP) can lead to costly failures, operational downtime, and potential legal exposure.

Poor Material Quality and Construction

One of the most frequent pitfalls is selecting a skimmer made with substandard materials or poor manufacturing practices. Low-cost options often use inferior plastics, thin-gauge metals, or non-corrosion-resistant components that degrade quickly in harsh environments (e.g., saltwater, chemicals, UV exposure). This leads to premature failure, leaks, or breakdowns, increasing maintenance costs and reducing equipment lifespan. Always verify material specifications (e.g., UV-stabilized polyethylene, stainless steel 316) and request proof of testing or certifications.

Inadequate IP Due Diligence

Failing to assess the intellectual property status of the skimmer design or technology can expose buyers to legal risks. Some suppliers may offer products that infringe on patented designs, especially in competitive markets with many copycat models. Using such equipment could result in cease-and-desist orders, litigation, or forced removal from service. Conduct basic IP checks—ask for patent numbers, verify trademarks, and ensure the supplier has the right to manufacture and sell the product.

Misrepresentation of Performance Claims

Suppliers may exaggerate oil recovery rates, efficiency, or operational capabilities (e.g., flow rates, oil viscosity handling, wave tolerance). Without independent verification or performance data under real-world conditions, buyers risk purchasing equipment that underperforms. Always request third-party test reports, case studies, or pilot trials before committing to large-scale procurement.

Lack of Compliance with International Standards

A quality skimmer should meet relevant international standards (e.g., ISO, API, IMO for marine applications). Sourcing non-compliant equipment can lead to regulatory issues, failed inspections, or ineligibility for insurance coverage. Verify that the product adheres to applicable standards and that certifications are current and issued by accredited bodies.

Insufficient After-Sales Support and Documentation

Even high-quality skimmers require maintenance, spare parts, and technical support. Sourcing from suppliers without reliable service networks or comprehensive documentation (e.g., operation manuals, maintenance guides, CAD drawings) creates long-term operational risks. Ensure post-purchase support is contractually defined and that technical documentation does not infringe on third-party IP.

Overlooking Design Originality and Reverse Engineering Risks

Some suppliers offer skimmers that closely mimic patented designs. While they may appear cost-effective, these products could be reverse-engineered copies, raising IP infringement concerns. Evaluate the originality of the design and insist on transparency about the engineering process and design ownership to avoid legal complications.

Logistics & Compliance Guide for Floating Oil Skimmer

Overview

This guide outlines the essential logistics considerations and compliance requirements for the transportation, deployment, operation, and maintenance of a floating oil skimmer. Adhering to these guidelines ensures operational efficiency, regulatory compliance, and environmental protection.

Regulatory Compliance Requirements

Environmental Regulations

Floating oil skimmers are subject to environmental protection laws designed to prevent oil spills and mitigate pollution. Key regulations include:

– MARPOL Annex I (International Convention for the Prevention of Pollution from Ships): Requires oil spill response preparedness and equipment such as skimmers for vessels operating in international waters.

– U.S. Clean Water Act (CWA) and Oil Pollution Act (OPA 90): Mandate spill prevention, response planning, and the use of approved oil recovery equipment. Facilities must report spills and demonstrate access to response tools.

– EU Marine Strategy Framework Directive (MSFD): Promotes good environmental status of marine waters, including rapid response to pollution incidents.

Operators must ensure the skimmer meets the performance standards set by regulatory bodies such as the U.S. Environmental Protection Agency (EPA) or equivalent national agencies.

Equipment Certification & Standards

- Type-Approval Certification: Some jurisdictions require oil skimmers to be type-approved by recognized bodies (e.g., U.S. Coast Guard, IMO, or classification societies like DNV or ABS).

- Performance Testing: Skimmers should be tested according to ASTM F2709 (Standard Test Method for Determining the Recovery Rate of a Skimmer System) or equivalent standards to validate efficiency claims.

- EMC and Electrical Safety: If the skimmer includes electrical components, compliance with IEC 60092 (marine electrical systems) or relevant local electrical safety codes may be required.

Transportation & Logistics Planning

Packaging and Storage

- Secure Packaging: Skimmers should be disassembled (if applicable), drained of fluids, and stored in weather-resistant containers or crates to prevent corrosion and damage during transit.

- Mooring and Support: Use padded supports and straps to immobilize the skimmer and prevent movement. Exposed components (e.g., weirs, drive systems) must be protected.

- Labeling: Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include compliance documentation.

Domestic and International Shipping

- Hazard Classification: While oil skimmers are typically non-hazardous, residual oils or fuels in associated equipment (e.g., pumps, generators) may require classification under IATA/IMDG Code.

- Customs Documentation: For cross-border shipments, provide a commercial invoice, packing list, bill of lading, and certificate of origin. Include technical specifications to demonstrate non-hazardous status.

- Import/Export Controls: Verify if the equipment contains materials or technology subject to export controls (e.g., EAR in the U.S.).

Deployment and Operational Compliance

Site Permits and Notifications

- Obtain necessary permits for deploying oil skimmers in navigable waters, especially in protected areas or near shorelines.

- Notify relevant authorities (e.g., local coast guard, environmental agency) before deployment, particularly during spill response.

- Comply with local regulations regarding noise, emissions, and vessel traffic.

Crew Training and Safety

- Operators must be trained in safe deployment, maintenance, and emergency procedures.

- Follow OSHA (or equivalent) guidelines for workplace safety, including PPE (personal protective equipment) and confined space protocols if working onboard vessels.

- Maintain spill response plans that include skimmer deployment procedures and waste handling protocols.

Waste Management and Disposal

Collected Oil-Water Mixture

- Segregate recovered oil from water in accordance with local waste disposal laws.

- Store recovered oil in approved, labeled containers and dispose of it through licensed hazardous waste handlers.

- Maintain manifests and disposal records for audit and compliance reporting.

Recordkeeping

- Keep logs of skimmer usage, maintenance, spill response activities, and disposal records.

- Retain equipment certification documents, training records, and regulatory correspondence.

Maintenance and Inspection

Routine Maintenance

- Follow manufacturer guidelines for inspections, lubrication, cleaning, and part replacement.

- Inspect for wear, corrosion, and damage after each use or at scheduled intervals.

Regulatory Inspections

- Participate in periodic audits by regulatory agencies to verify equipment readiness and compliance.

- Ensure the skimmer is included in facility or vessel oil spill response plans, which may be subject to inspection.

Conclusion

Proper logistics planning and adherence to compliance standards are critical for the effective and legal use of floating oil skimmers. Operators must stay informed about evolving environmental regulations and maintain accurate documentation to ensure readiness for oil spill response and regulatory scrutiny.

Conclusion for Sourcing a Floating Oil Skimmer

In conclusion, sourcing a floating oil skimmer is a strategic and essential step in maintaining environmental compliance, protecting water quality, and ensuring operational efficiency in industries such as marine, manufacturing, wastewater treatment, and oil and gas. After a thorough evaluation of available options, considering factors such as skimmer type (e.g., belt, drum, disc, or weir), oil recovery rate, durability, ease of maintenance, adaptability to different conditions (e.g., calm or rough water), and cost-effectiveness, it is clear that selecting the right skimmer must be aligned with specific operational needs and environmental conditions.

Moreover, partnering with reputable suppliers who offer reliable technical support, warranties, and proven performance records enhances long-term success. A well-chosen floating oil skimmer not only reduces ongoing environmental impact but also lowers remediation costs, improves safety, and supports sustainable practices.

Ultimately, investing in the appropriate floating oil skimmer is not just a regulatory necessity but a proactive measure towards environmental stewardship and operational resilience. Careful sourcing today leads to cleaner water, regulatory compliance, and long-term cost savings tomorrow.