The global demand for convenient and resealable packaging solutions has propelled significant growth in the flip cap bottle market, with increasing adoption across the beverage, pharmaceutical, and personal care sectors. According to Grand View Research, the global plastic packaging market—of which flip cap bottles are a key segment—was valued at USD 219.0 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.4% from 2023 to 2030. This growth is driven by rising consumer preference for portable, leak-proof containers and the surge in on-the-go consumption trends. Mordor Intelligence further highlights that the Asia-Pacific region, in particular, is witnessing accelerated demand due to rapid urbanization and expanding middle-class populations. As brands prioritize functionality and sustainability, leading manufacturers are investing in innovative designs using recyclable materials and ergonomic features. In this evolving landscape, the top seven flip cap bottle manufacturers stand out for their technological advancements, scalable production capabilities, and strong global distribution networks—shaping the future of packaging efficiency.

Top 7 Flip Cap Bottle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

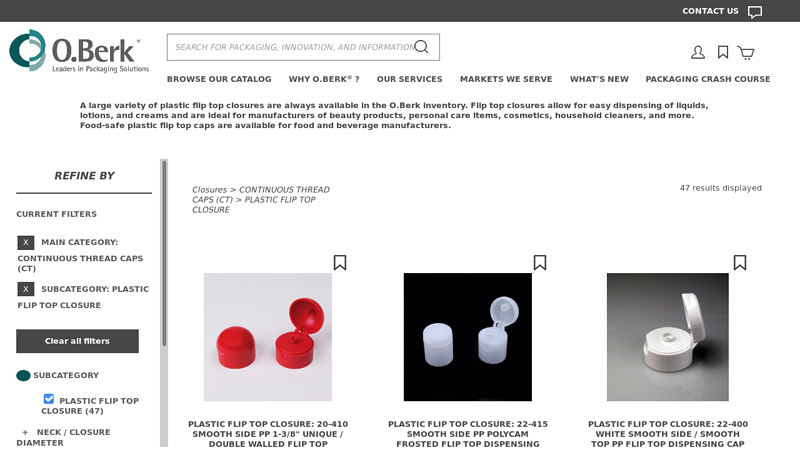

#1 Wholesale & Bulk Plastic Flip Top Closures for Bottles, Jars, Vials

Domain Est. 1997

Website: oberk.com

Key Highlights: Flip top closures allow for easy dispensing of liquids, lotions, and creams and are ideal for manufacturers of beauty products, personal care items, cosmetics, ……

#2 Flip Top Plastic Bottle Cap Manufacturer & Supplier

Domain Est. 1999

Website: sailorplastics.com

Key Highlights: 1–5 day delivery · 30-day returnsSailor Plastic manufacture and supply the fine quality of Flip top plastic Bottles with various color options fit for hney, water, day products an…

#3 Flip Top Caps Manufacturers

Domain Est. 2007

Website: capsandclosures.com

Key Highlights: Caps and Closures offers premium-quality flip top caps for safe, secure, and stylish packaging, available in customized sizes and finishes….

#4 Flip Top Caps

Domain Est. 2019

Website: impackedpackaging.com

Key Highlights: Impacked connects you directly with trusted flip top cap suppliers and flip top cap manufacturers to simplify quoting, sampling, and ordering. Request a quote ……

#5 Low Profile Flip Top Caps

Domain Est. 1997

Website: berlinpackaging.com

Key Highlights: In stock Rating 5.0 5 These flip top caps feature a low-profile height on your bottle. Flip open the cap to reveal an orifice that makes dispensing product easy….

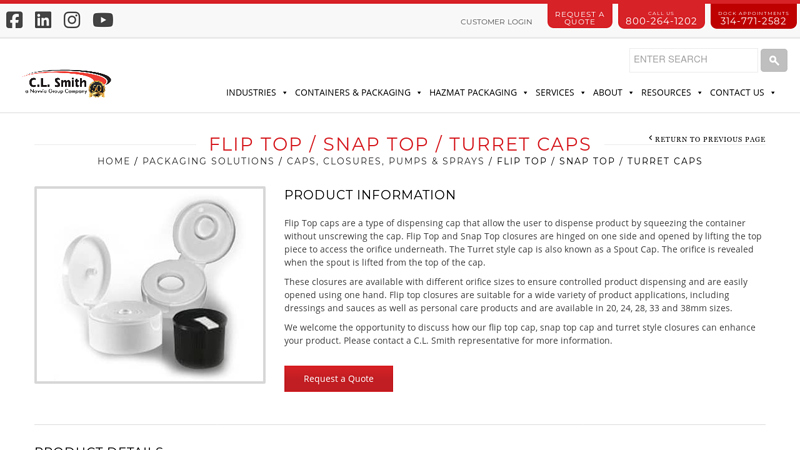

#6 Flip Top / Snap Top / Turret Caps

Domain Est. 1998

Website: clsmith.com

Key Highlights: 3-day deliveryFlip Top caps are a type of dispensing cap that allow the user to dispense product by squeezing the container without unscrewing the cap….

#7 All Products

Domain Est. 2013

Website: flipitcap.com

Key Highlights: Free delivery Free 30-day returnsThe ultimate solution for getting every drop out of your bottles on items such as shampoos, conditioners, lotions, soaps, condiments and more!…

Expert Sourcing Insights for Flip Cap Bottle

H2: Projected 2026 Market Trends for Flip Cap Bottles

The global market for flip cap bottles is poised for notable expansion by 2026, driven by evolving consumer preferences, sustainability initiatives, and advancements in packaging technology. As industries prioritize convenience, hygiene, and eco-friendliness, flip cap bottles—commonly used in beverages, personal care, pharmaceuticals, and household products—are gaining increased traction. Below are key trends expected to shape the flip cap bottle market in 2026:

-

Rising Demand for On-the-Go Packaging

The fast-paced lifestyle of modern consumers continues to fuel demand for portable and resealable packaging solutions. Flip cap bottles offer ease of use, controlled dispensing, and leak resistance, making them ideal for sports drinks, liquid supplements, shampoos, and hand sanitizers. By 2026, this segment is expected to see robust growth, particularly in urban and health-conscious markets. -

Sustainability and Eco-Friendly Materials

Environmental concerns are pushing manufacturers toward recyclable and bio-based plastics such as rPET (recycled polyethylene terephthalate) and bioplastics. Brands are increasingly adopting flip cap bottles made from sustainable materials to align with regulatory standards and consumer expectations. In 2026, the integration of mono-material designs—easier to recycle—will likely become a market differentiator. -

Innovation in Tamper-Evident and Hygienic Designs

With heightened awareness around product safety, especially post-pandemic, tamper-evident flip caps are gaining preference. These features assure consumers of product integrity and are especially critical in pharmaceutical and infant care applications. By 2026, smart flip caps with integrated indicators (e.g., freshness or usage tracking) may begin entering the mainstream. -

Growth in E-Commerce and Direct-to-Consumer Models

The expansion of online retail channels requires packaging that is durable, compact, and shipping-friendly. Flip cap bottles meet these requirements with their secure closures and stackable designs. As DTC brands in wellness and beauty continue to grow, so will demand for customizable, aesthetically appealing flip cap solutions. -

Regional Market Expansion

While North America and Europe remain dominant due to stringent packaging regulations and high consumer awareness, the Asia-Pacific region is expected to witness the fastest growth by 2026. Increasing urbanization, rising disposable incomes, and expanding middle-class populations in countries like India and Indonesia will drive adoption across beverage and personal care sectors. -

Customization and Brand Differentiation

Brands are leveraging flip cap bottles for enhanced branding through unique shapes, colors, and ergonomic designs. In 2026, advanced molding technologies and digital printing will allow greater customization, helping brands stand out on shelves and online platforms. -

Regulatory and Compliance Pressures

Governments worldwide are tightening plastic usage regulations. This will push manufacturers to adopt compliant materials and incorporate higher recycled content in flip cap bottles. By 2026, regulatory alignment across regions could standardize sustainable packaging practices, influencing global supply chains.

In summary, the 2026 flip cap bottle market will be shaped by a confluence of convenience, sustainability, innovation, and regional dynamics. Companies that invest in eco-conscious materials, smart packaging features, and consumer-centric designs will be well-positioned to lead in this evolving landscape.

Common Pitfalls Sourcing Flip Cap Bottles (Quality, IP)

Sourcing flip cap bottles, especially from overseas suppliers, can present several challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is crucial to ensuring a successful and risk-mitigated procurement process.

Quality Consistency and Material Standards

One of the most frequent issues when sourcing flip cap bottles is inconsistent product quality. Suppliers may deliver initial samples that meet specifications, but subsequent production batches can vary significantly in material thickness, color accuracy, cap tightness, or overall durability. This inconsistency often stems from the use of recycled or substandard plastics, variations in molding processes, or inadequate quality control procedures. Additionally, bottles may not comply with required food-grade or safety standards (e.g., FDA, EU regulations), posing risks for consumer use.

Mold and Design Replication Without Authorization

When you provide a custom mold or design for flip cap bottles, there is a significant risk that the supplier may replicate it for other clients without your permission. This is a serious intellectual property (IP) violation. Overseas manufacturers, particularly in regions with less stringent IP enforcement, might produce identical or similar bottles for competitors, diluting your brand’s uniqueness and potentially undercutting your market position.

Lack of IP Protection in Supplier Contracts

Many sourcing agreements fail to include comprehensive IP clauses. Without a clearly defined contract that assigns ownership of molds, designs, and tooling to the buyer and prohibits unauthorized use or duplication, you may have limited legal recourse if your design is copied. Verbal assurances are not sufficient—IP rights must be explicitly stated and legally enforceable in the supplier’s jurisdiction.

Hidden Tooling Costs and Ownership Disputes

Suppliers may offer low per-unit pricing but retain ownership of the molds used to produce the bottles. This creates dependency and limits your flexibility to switch manufacturers. If the mold is not transferred or replicated easily, you could face delays or additional costs when trying to source from another vendor. Confirming upfront who owns the tooling—and ensuring it can be transferred or duplicated—is essential.

Inadequate Testing and Compliance Documentation

Flip cap bottles often require performance testing for leakage, impact resistance, and chemical compatibility—especially if used for beverages, cosmetics, or pharmaceuticals. Some suppliers may not conduct rigorous testing or may provide falsified compliance certificates. Relying solely on supplier-provided documentation without independent verification can lead to product failures or regulatory issues in your target market.

Supply Chain and Communication Challenges

Poor communication, cultural differences, and time zone gaps can lead to misunderstandings about specifications, timelines, and quality expectations. Without regular oversight or on-the-ground quality inspections, defects may go unnoticed until after shipment, resulting in costly recalls or customer dissatisfaction.

To mitigate these risks, it’s advisable to conduct thorough due diligence on suppliers, use legally binding contracts with strong IP protections, perform third-party quality audits, and maintain clear communication throughout the sourcing process.

Logistics & Compliance Guide for Flip Cap Bottles

Product Overview

Flip cap bottles are commonly used in industries such as beverages, personal care, pharmaceuticals, and household chemicals. These containers typically consist of a plastic or glass bottle with a hinged or attached cap that flips open for easy access. Ensuring proper logistics handling and compliance with regulations is essential for safety, quality, and legal requirements.

Material & Packaging Specifications

- Bottle Materials: HDPE, PET, glass, or PP—ensure compatibility with contents (e.g., food-grade, chemical-resistant).

- Cap Materials: Typically polypropylene (PP) or polyethylene (PE) with a tamper-evident seal if required.

- Packaging Configuration: Bottles are often packed in corrugated cardboard cases, shrink-wrapped trays, or bundled with protective dividers to prevent damage during transit.

- Labeling: Must include product name, volume, batch/lot number, expiration date (if applicable), manufacturer details, and hazard symbols (if relevant).

Regulatory Compliance

- FDA Compliance (USA): For food, beverage, or pharmaceutical use, bottles and caps must meet FDA 21 CFR standards for food-contact materials.

- EU Regulations: Comply with Regulation (EC) No 1935/2004 for food contact materials and REACH for chemical safety.

- Child-Resistant Packaging: Required for certain pharmaceuticals or hazardous substances under the Poison Prevention Packaging Act (PPPA) in the U.S. or equivalent EU directives.

- Tamper-Evident Features: Required for over-the-counter (OTC) drugs and certain consumer products under FDA and EU guidelines.

- Recycling & Environmental Compliance: Label with resin identification codes (e.g., #1 PET, #2 HDPE). Comply with local recycling and extended producer responsibility (EPR) laws.

Transportation & Handling

- Stackability: Ensure packaging design supports stable stacking to prevent collapse during shipping.

- Palletization: Use slip sheets or pallets to secure cases; maximum stack height should follow safety guidelines.

- Temperature Control: For temperature-sensitive contents, use insulated packaging and cold chain logistics if necessary.

- Hazardous Materials: If transporting hazardous liquids (e.g., disinfectants), comply with DOT (U.S.) or ADR (Europe) regulations, including proper UN-certified packaging and labeling.

- Drop & Impact Testing: Packaging should meet ISTA or ASTM standards to withstand typical shipping stresses.

Storage Conditions

- Environment: Store in a cool, dry place away from direct sunlight and extreme temperatures.

- Shelf Life: Monitor expiration dates for contents; rotate stock using FIFO (First In, First Out) method.

- Segregation: Separate incompatible materials (e.g., flammable liquids from oxidizers) in storage areas.

Import/Export Considerations

- Customs Documentation: Include commercial invoice, packing list, certificate of origin, and material safety data sheet (MSDS/SDS) if applicable.

- Tariff Classifications: Use correct HS codes (e.g., 3923.30 for plastic bottles) based on material and use.

- Country-Specific Requirements: Verify labeling, language, and safety standards for destination countries (e.g., bilingual labeling in Canada, CE marking in Europe).

Quality Control & Traceability

- Batch Tracking: Implement a system to track lot numbers from production to distribution for recall readiness.

- Leak & Seal Testing: Conduct routine quality checks on cap closure integrity.

- Compliance Audits: Regularly audit suppliers and packaging processes to ensure adherence to standards.

Sustainability & End-of-Life

- Recyclability: Design for recyclability—avoid mixed materials that hinder separation.

- Eco-Labeling: Use recognized environmental labels (e.g., How2Recycle) to inform consumers.

- Take-Back Programs: Consider participation in bottle return or recycling initiatives where available.

Conclusion

Proper logistics and compliance for flip cap bottles require attention to material safety, regulatory standards, transportation integrity, and environmental responsibility. Adhering to this guide helps ensure product safety, legal compliance, and customer satisfaction across global markets.

Conclusion:

Sourcing flip cap bottles involves a careful evaluation of material quality, durability, functionality, supplier reliability, and cost-effectiveness. These bottles are ideal for a variety of applications—particularly in personal care, food & beverage, and pharmaceutical industries—due to their convenience, leak-proof design, and user-friendly dispensing. When sourcing, it is essential to partner with reputable manufacturers who adhere to regulatory standards (such as FDA or EU compliance) and can provide customization options in size, color, and material (e.g., HDPE, PP, or PET). Additionally, considering sustainability trends, opting for recyclable or eco-friendly materials can enhance brand image and meet growing consumer demand for environmentally responsible packaging. Overall, a strategic sourcing approach ensures the acquisition of high-quality flip cap bottles that align with both product needs and long-term business goals.