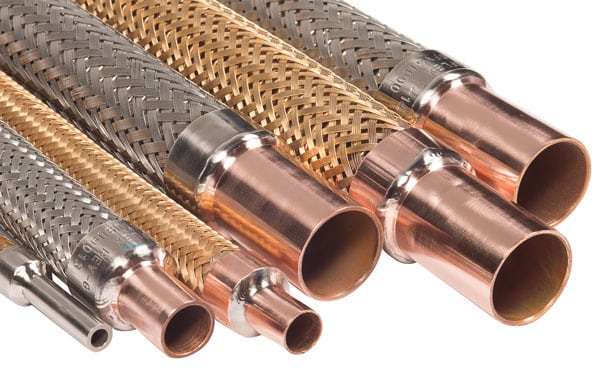

The global flexible sink pipe market is experiencing steady growth, driven by rising demand for efficient plumbing solutions in residential and commercial construction. According to Mordor Intelligence, the global plumbing fixtures and fittings market—of which flexible sink pipes are a critical component—is projected to grow at a CAGR of over 6% from 2023 to 2028. Increasing urbanization, infrastructure development, and a growing emphasis on water efficiency are key factors fueling this expansion. Additionally, Grand View Research reports that the global plumbing market was valued at USD 201.6 billion in 2022 and is expected to expand at a CAGR of 5.8% through 2030, with flexible connectors gaining prominence due to their ease of installation and leak-resistant performance. As demand rises, manufacturers are investing in durable, corrosion-resistant materials like braided stainless steel and advanced polymers. In this evolving landscape, identifying the top flexible sink pipe manufacturers—those combining innovation, compliance, and scalability—is essential for distributors, contractors, and retailers aiming to meet performance and sustainability standards.

Top 10 Flexible Sink Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Omega Flex, Inc.

Domain Est. 1997

Website: omegaflex.com

Key Highlights: Manufacturer of corrugated flexible stainless steel tubing used for natural gas and propane installations in residential and commercial applications….

#2 HDPE Pipe Solutions

Domain Est. 1995

Website: isco-pipe.com

Key Highlights: ISCO is the leading HDPE pipe & fusion equipment supplier in North America, providing expert solutions for municipal, industrial & oil/gas HDPE piping ……

#3 Cresline Plastic Pipe Co.

Domain Est. 1998

Website: cresline.com

Key Highlights: As one of the largest full-line pipe manufacturers, Cresline’s family of companies offers industry leading coast-to-coast service….

#4 JM Eagle™

Domain Est. 2007

Website: jmeagle.com

Key Highlights: JM Eagle · Delivering life’s essentials through the most eco-friendly plastic pipe products on the market. · Express Service Trucks (ESTs) Deliver within 24 hours ……

#5 IPEX Inc.

Domain Est. 2009

Website: ipexna.com

Key Highlights: IPEX Inc. manufactures advanced PVC & CPVC piping systems for several applications for the Canadian market. Learn more….

#6 Flexible Sink Drain Pipe, Manufacturers

Domain Est. 2024

Website: praveenplastic.com

Key Highlights: We make flexible sink drain pipes with smooth surfaces, designed in wavy patterns with grooves and ridges for stretch ability and high strength….

#7 Spears Manufacturing, PVC & CPVC Plastic Pipe Fittings & Valves

Domain Est. 1996

Website: spearsmfg.com

Key Highlights: ISO9001 Certified – PVC & CPVC Sch 40 and 80 fittings molded from 1/8 – 14 inch….

#8 Advanced Drainage Systems

Domain Est. 2000

Website: adspipe.com

Key Highlights: Advanced Drainage Systems provides high-performing, durable pipe and innovative stormwater management solutions. Discover our industry-leading products ……

#9 Viega USA

Domain Est. 2002

Website: viega.us

Key Highlights: Providing secure pipe connections for 125 years. Viega piping systems deliver unparalleled quality and durability in plumbing projects across the nation and ……

#10 PEX

Domain Est. 2013

Website: astralpipes.com

Key Highlights: Explore Astral’s PEX-a pipes designed for long-lasting, flexible piping systems. Ideal for hot and cold water applications with easy installation and ……

Expert Sourcing Insights for Flexible Sink Pipe

2026 Market Trends for Flexible Sink Pipes

The flexible sink pipe market is poised for significant transformation by 2026, driven by evolving consumer demands, technological advancements, and increasing emphasis on sustainability. Key trends shaping the industry include:

Sustainability and Eco-Friendly Materials

Environmental consciousness is becoming a primary driver in plumbing product selection. Consumers and regulatory bodies are increasingly favoring flexible sink pipes made from recycled materials or biodegradable polymers. Manufacturers are responding by reducing plastic content, improving recyclability, and minimizing carbon footprints during production. By 2026, eco-certifications and transparent supply chains will likely become standard competitive differentiators.

Smart Plumbing Integration

The rise of smart home ecosystems is extending into plumbing infrastructure. Flexible sink pipes with embedded leak-detection sensors or corrosion-monitoring capabilities are expected to gain traction. These “smart” components can send alerts to mobile devices, helping prevent water damage and reduce maintenance costs. While still emerging, this trend will accelerate as IoT technology becomes more affordable and widely adopted in residential construction.

Design Flexibility and Aesthetic Appeal

Modern kitchen and bathroom design increasingly values both form and function. Flexible sink pipes are evolving beyond utilitarian gray corrugated hoses to include options in brushed nickel, matte black, and other finishes that complement visible under-sink aesthetics. Enhanced kink resistance and compact bend radii allow for easier installation in tight or unconventional spaces, supporting minimalist and custom cabinetry trends.

Durability and Longevity Focus

With rising labor costs and demand for low-maintenance solutions, consumers are prioritizing longer-lasting products. By 2026, flexible sink pipes made from high-grade stainless steel braiding, reinforced thermoplastics, or hybrid materials will dominate the market. These materials offer superior resistance to heat, pressure, and mineral buildup, reducing the need for frequent replacements.

Regulatory Compliance and Safety Standards

Stricter plumbing codes and health regulations—particularly around lead-free materials and potable water safety—are shaping product development. Flexible sink pipes compliant with NSF/ANSI 372 and 61 standards will be essential, especially in North America and Europe. Manufacturers will need to ensure full traceability and certification to meet regional requirements.

In summary, the 2026 flexible sink pipe market will be defined by innovation in materials, integration with smart technology, and a strong commitment to sustainability and durability—positioning the product as a critical component in modern, efficient, and eco-conscious plumbing systems.

Common Pitfalls When Sourcing Flexible Sink Pipes (Quality, IP)

Sourcing flexible sink pipes—also known as P-trap extensions or sink tailpieces—can seem straightforward, but overlooking key factors can lead to leaks, code violations, and costly repairs. Below are the most common pitfalls related to quality and Ingress Protection (IP) considerations.

Poor Material Quality

One of the most frequent issues is selecting pipes made from substandard materials. Low-grade plastics or thin-gauge metals degrade quickly when exposed to hot water, cleaning chemicals, or physical stress. This can result in cracks, warping, or corrosion, compromising the integrity of the plumbing system.

Inadequate Ingress Protection (IP) Rating

Flexible sink pipes are often used in damp environments, but many off-the-shelf options lack proper IP ratings. While IP ratings are more commonly associated with electrical enclosures, the principle applies: without resistance to water and dust ingress, joints and connections can leak or clog. Pipes with poor sealing mechanisms fail to prevent water spray or moisture from seeping into surrounding cabinetry.

Lack of Pressure and Temperature Resistance

Some flexible pipes are not rated for the temperature or pressure variations typical in residential sink use. Using a pipe not designed for hot water discharge can lead to deformation or failure, especially under continuous exposure. Always verify manufacturer specifications for temperature and pressure limits.

Non-Compliance with Plumbing Codes

Many sourced pipes—especially from unverified suppliers—do not meet local plumbing codes or international standards (e.g., ASTM, ISO, or EN standards). Using non-compliant parts can void warranties, fail inspections, and create liability issues.

Poor Sealing and Connection Design

Even high-quality pipes can fail if the connectors or sealing methods (e.g., rubber washers, compression fittings) are poorly designed. Mismatched thread sizes, lack of O-rings, or flimsy nut mechanisms result in leaks at the joints, which are often hard to detect until damage has occurred.

Misunderstanding “Flexibility” vs. Durability

Excessive flexibility can be a drawback. Overly pliable pipes may kink or sag over time, reducing water flow and promoting sediment buildup. The ideal balance between flexibility for installation and rigidity for long-term performance is often overlooked.

Sourcing from Unverified Suppliers

Purchasing from third-party marketplaces or unknown brands increases the risk of counterfeit or misrepresented products. These may appear identical to certified models but lack the necessary quality controls, leading to early failure and potential health hazards from leaching materials.

Avoiding these pitfalls requires due diligence: sourcing from reputable suppliers, verifying material certifications, checking for appropriate sealing and IP-related features, and ensuring compliance with local plumbing standards.

Logistics & Compliance Guide for Flexible Sink Pipe

Product Overview

Flexible sink pipes, also known as P-traps or sink tailpieces, are plumbing components used to connect a sink drain to the waste system. Typically made from PVC, ABS, stainless steel, or braided nylon with PVC lining, these pipes accommodate misalignment between fixtures and drain lines while preventing sewer gases from entering buildings.

Regulatory Compliance Requirements

International Plumbing Code (IPC)

Flexible sink pipes must comply with IPC standards, particularly Section 1002, which governs trap installation. Key requirements include:

– Maximum vertical drop of 30 inches from fixture outlet to trap weir.

– Minimum trap seal depth of 2 inches.

– No self-siphoning or crown-vented configurations.

– Approved materials and pressure ratings as specified by IPC and manufacturer listings.

National Sanitation Foundation (NSF) Certification

Flexible pipes used in food service or potable water-adjacent applications (e.g., kitchen sinks) require NSF/ANSI 14 and NSF/ANSI 61 certification. These ensure:

– Material safety and resistance to leaching of harmful substances.

– Suitability for contact with drinking water.

– Durability under typical household and commercial conditions.

CE Marking (European Market)

For distribution in the EU, flexible sink pipes must bear the CE mark, demonstrating conformity with:

– Construction Products Regulation (CPR) – Regulation (EU) No 305/2011.

– Harmonized standards such as EN 1452 (for PVC-U pipes) or EN 1329 (for soil and waste piping).

– Declaration of Performance (DoP) issued by the manufacturer.

UKCA Marking (United Kingdom)

Post-Brexit, products sold in Great Britain must comply with UKCA marking requirements, including:

– Alignment with UK versions of EU standards (e.g., BS EN standards).

– UK Conformity Assessed (UKCA) marking for applicable plumbing products.

– Documentation and traceability per UK market surveillance regulations.

Packaging and Labeling

Mandatory Labels

- Product name and material type (e.g., “Flexible PVC Sink Pipe – 1.25” Diameter”).

- Size specifications (length, diameter, thread type).

- Manufacturer name, address, and contact information.

- Compliance markings (NSF, UPC, CE, UKCA, etc.) as applicable.

- Installation warnings (e.g., “Not for use with boiling water” or “Maximum temperature: 82°C/180°F”).

Packaging Requirements

- Individual units should be shrink-wrapped or boxed to prevent kinking or deformation.

- Bulk shipments require protective cartons with cushioning to avoid damage during transit.

- Labels must include handling instructions (e.g., “Do Not Stack,” “Fragile,” “Keep Dry”).

Shipping and Transportation

Domestic (U.S.)

- Use standard LTL (Less Than Truckload) or parcel shipping for retail quantities.

- Ensure compliance with Department of Transportation (DOT) regulations for non-hazardous goods.

- Avoid exposure to extreme temperatures during storage and transit to prevent warping (especially for plastic variants).

International

- Comply with International Maritime Dangerous Goods (IMDG) Code if shipping by sea (flexible pipes are typically non-hazardous).

- Provide Harmonized System (HS) Code for customs: 3917.33 (plastic tubes, pipes, and hoses) or 7308.90 (steel tubes and pipes), depending on material.

- Include commercial invoice, packing list, and certificate of origin with each shipment.

Import and Customs Clearance

United States

- Declare under HTSUS code 3917.33.0000 (plastic) or 7308.90.9980 (metal).

- Ensure compliance with EPA and state-level plumbing codes.

- FDA does not regulate sink pipes unless in direct contact with potable water; NSF 61 certification recommended in such cases.

European Union

- Submit EORI-numbered customs declaration.

- Provide DoP and CE certification documentation.

- Comply with REACH and RoHS regulations regarding chemical content.

Canada

- Comply with Canadian Standards Association (CSA) B125 series for plumbing fittings.

- Use HS Code 3917.33.00.10 for plastic pipes.

- Shipments may require evaluation by the Canadian Construction Materials Centre (CCMC).

Storage and Handling

Warehouse Guidelines

- Store in a dry, temperature-controlled environment (10°C to 30°C / 50°F to 86°F).

- Stack no higher than 5 feet to prevent crushing.

- Keep away from direct sunlight to avoid UV degradation (especially for PVC).

Shelf Life

- PVC and ABS models: up to 5 years when stored properly.

- Stainless steel and braided types: indefinite, provided they remain corrosion-free.

End-of-Life and Environmental Compliance

Recycling

- PVC and ABS components can be recycled under Resin Identification Codes 3 and 7.

- Metal-reinforced or composite pipes may require separation before recycling.

- Provide end-user guidance on local disposal regulations.

WEEE and RoHS (EU)

- Although not typically classified as electronic equipment, flexible pipes containing metallic braiding may fall under RoHS restrictions for lead, cadmium, and other hazardous substances.

- Ensure compliance when applicable.

Conclusion

Flexible sink pipes must meet diverse regional plumbing, safety, and environmental standards. Suppliers and distributors should maintain up-to-date compliance documentation, ensure proper labeling and packaging, and adhere to transportation best practices to ensure market access and customer safety. Regular audits of certification status and supply chain practices are recommended.

In conclusion, sourcing a flexible sink pipe requires careful consideration of material quality, durability, compatibility with existing plumbing, and adherence to local plumbing codes. Options such as stainless steel, braided nylon, or plastic offer varying benefits in terms of flexibility, resistance to kinking, and protection against leaks. It is essential to evaluate dimensions, connection types, and pressure ratings to ensure a proper fit and long-term performance. Sourcing from reputable suppliers or manufacturers can guarantee reliability and compliance with safety standards. By prioritizing quality and compatibility, you can effectively select a flexible sink pipe that meets functional needs, reduces maintenance issues, and supports efficient plumbing operations.