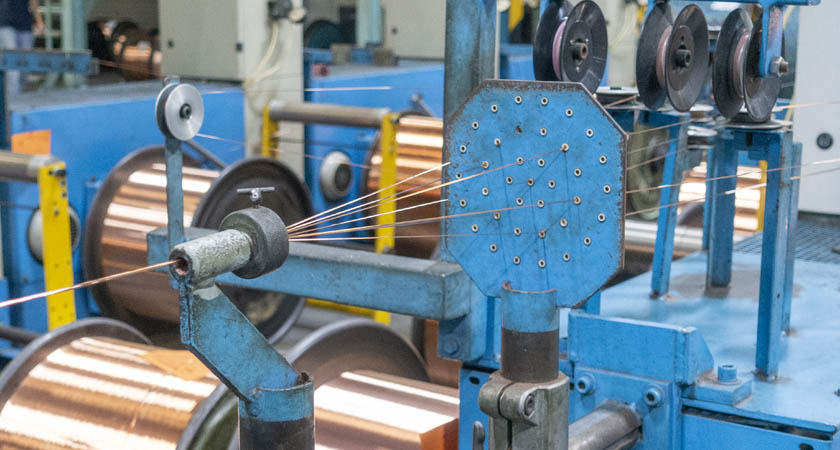

The global flexible cable market is undergoing significant expansion, driven by rising demand across industries such as renewable energy, automation, robotics, and electric vehicles. According to a report by Mordor Intelligence, the market was valued at USD 14.7 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 6.8% from 2024 to 2029. This growth is fueled by the increasing need for high-performance cables that can withstand repeated bending, torsion, and dynamic motion in advanced manufacturing environments and energy infrastructure. Similarly, Grand View Research highlights the expanding application of flexible cables in offshore wind farms and industrial machinery automation as key growth catalysts, with Asia-Pacific emerging as a rapidly growing regional market due to industrial modernization and government-led infrastructure initiatives. As demand for durable, high-flexibility cabling solutions intensifies, manufacturers that offer innovation in materials, longevity, and customization are positioning themselves at the forefront of this evolving landscape. Here’s a look at the top 10 flexible cable manufacturers leading the charge in technology, reliability, and global reach.

Top 10 Flexable Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Galaxy Wire & Cable, Inc.

Domain Est. 1998

Website: galaxywire.com

Key Highlights: Galaxy offers custom wire and custom cable in a wide variety of options for conductors, shielding, enhancements, and materials for insulation and jacketing….

#2 AFC Cable Systems

Domain Est. 2010

Website: atkore.com

Key Highlights: AFC Cable Systems, Inc., a part of Atkore International, is a leading designer, manufacturer and supplier of electrical distribution products….

#3 chainflex® Flexible Cable For Moving Applications

Domain Est. 1995

Website: igus.com

Key Highlights: Flexible cable designed for durable & reliable performance in industrial moving applications. Buy online from stock with no minimum requirements….

#4 Lexco Cable

Domain Est. 2002

Website: lexcocable.com

Key Highlights: Lexco Cable is a wire rope and cable manufacturer that provides custom solutions for a variety of industries including aircraft and ……

#5 Southwire

Domain Est. 1994

Website: southwire.com

Key Highlights: Choose Southwire for your wire and cable needs – we offer high-performance products that are built to last….

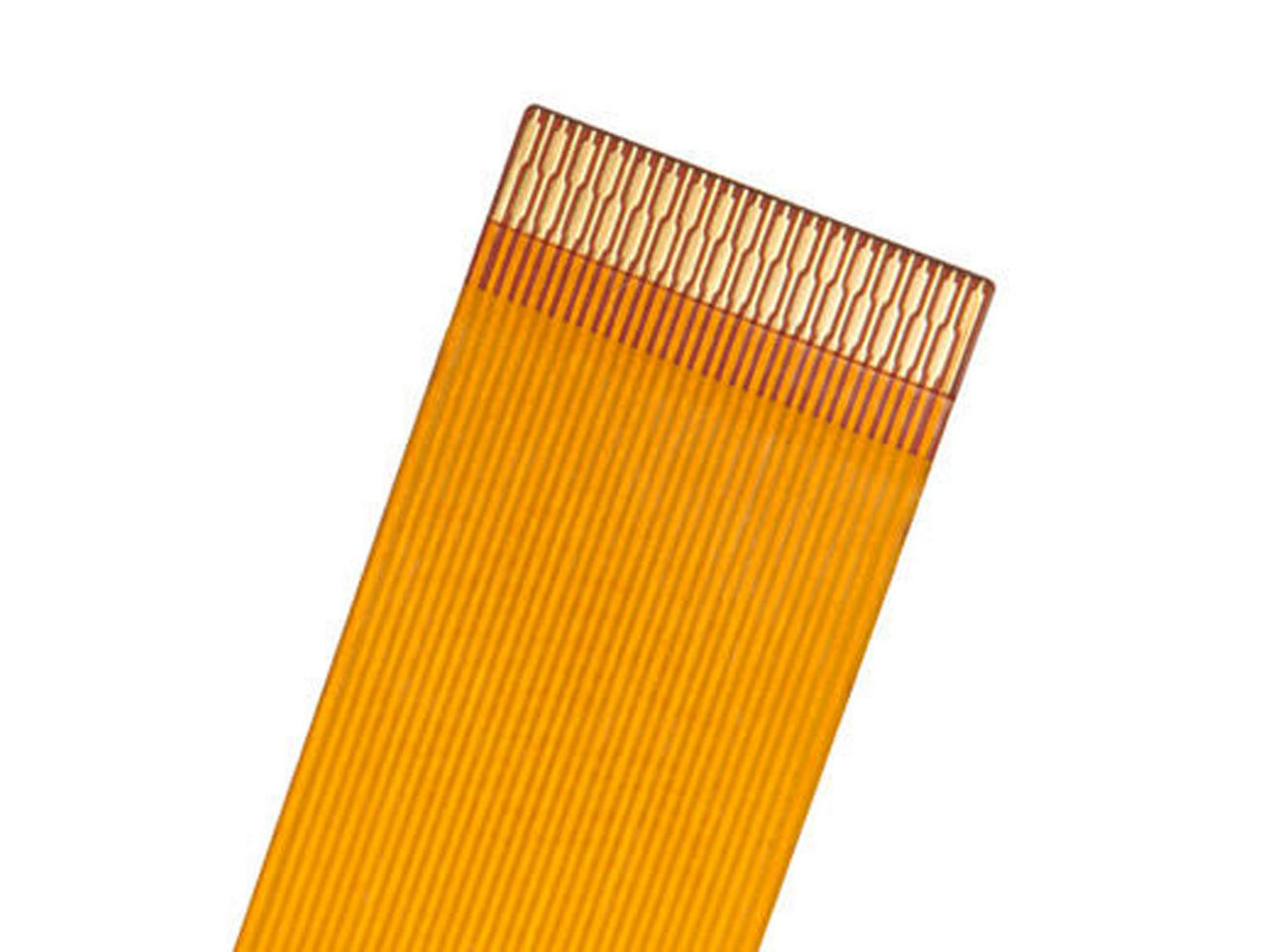

#6 Flat Flexible Cable (FFC)

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: Parlex has years of expertise with a wide range of laminated flexible flat cable to provide superior reliability solutions in dynamic flex and service loop ……

#7 Flexible wires

Domain Est. 1996

Website: axon-cable.com

Key Highlights: High flexible wires made by Axon’ Cable are designed to ease mechanical installation in limited available space. They are insulated with a think wall FEP jacket ……

#8 Flex

Domain Est. 1997

Website: flexcable.com

Key Highlights: A Northern Cable & Automation Company, LLC. Manufacturing Headquarters 5822 N Henkel Rd Howard City, MI 49329 231-937-8000 Phone 231-937-8091 Fax…

#9 Flex Cable

Domain Est. 1997

Website: belden.com

Key Highlights: Flexible cables designed for tight spaces while maintaining physical and mechanical requirements needed for rigorous motion….

#10 US Wire & Cable

Domain Est. 1997 | Founded: 1985

Website: uswireandcable.com

Key Highlights: You Can Count on USW. True to its name, since 1985 U.S. Wire & Cable Corporation has produced cable and extension cords right here on American soil….

Expert Sourcing Insights for Flexable Cable

H2: 2026 Market Trends for Flexible Cables

The flexible cable market is poised for dynamic growth and transformation by 2026, driven by technological advancements, evolving industry demands, and global sustainability initiatives. Key trends shaping the market in the second half (H2) of 2026 include:

-

Accelerated Adoption in Automation and Robotics:

The industrial automation sector will remain the primary driver. Demand for high-flex, torsion-resistant cables (e.g., continuous flex, torsional, and double-jacketed cables) will surge as robotics deployment expands in manufacturing, logistics (AGVs/AMRs), and healthcare. Cables with enhanced durability (millions of bending cycles), reduced signal interference (improved shielding), and smaller bend radii will be critical. -

Electric Vehicle (EV) and Charging Infrastructure Boom:

The global push towards electrification will significantly boost demand for specialized flexible cables. High-voltage (HV), high-current charging cables (especially for DC fast chargers) requiring extreme flexibility, heat resistance, and safety certifications (e.g., UL, IEC) will see massive growth. On-vehicle applications (battery interconnects, motor feeds) will also demand ultra-flexible, lightweight solutions. -

Rise of High-Performance Materials:

Material innovation will be crucial. Wider adoption of advanced thermoplastics like TPU (Thermoplastic Polyurethane) and TPE (Thermoplastic Elastomer) will replace traditional PVC due to superior abrasion resistance, low-temperature flexibility, oil resistance, and durability. Bio-based or recyclable materials will gain traction to meet sustainability goals. -

Miniaturization and High-Density Connectivity:

Trends in consumer electronics, medical devices, and aerospace will drive demand for ultra-fine, high-density flexible cables (e.g., micro-coaxial, high-pin-count FFCs/FPCs). These require precision manufacturing, enhanced signal integrity (high-speed data transmission), and extreme flexibility in compact spaces. -

Integration of Smart and Diagnostic Capabilities:

“Smart cables” with embedded sensors (for temperature, strain, or wear monitoring) and diagnostics will emerge, particularly in critical industrial and energy applications. This enables predictive maintenance, reduces downtime, and enhances safety, adding significant value. -

Supply Chain Resilience and Regionalization:

Geopolitical factors and past disruptions will push manufacturers towards regionalized supply chains and dual-sourcing strategies. Nearshoring, especially in North America and Europe, will increase to mitigate risks and ensure faster delivery, impacting sourcing of raw materials and finished cables. -

Sustainability and Regulatory Pressure:

Environmental regulations (e.g., RoHS, REACH) and corporate ESG goals will intensify. Demand will grow for cables with halogen-free, low-smoke zero-halogen (LSZH) jackets, improved recyclability, and lower carbon footprints throughout their lifecycle. Transparency in material sourcing will become essential. -

Growth in Renewable Energy Applications:

The expansion of solar and wind farms will require robust, weather-resistant flexible cables for connections in turbines, trackers, and inverters. Cables must withstand UV radiation, extreme temperatures, and mechanical stress, driving innovation in outdoor-rated flexible solutions.

Conclusion:

By H2 2026, the flexible cable market will be characterized by higher performance, greater specialization, and stronger sustainability focus. Success will depend on manufacturers’ ability to innovate with advanced materials, cater to high-growth sectors like EVs and automation, embrace smart technologies, and build resilient, sustainable supply chains. The market will shift from commodity offerings towards value-added, application-specific solutions.

Common Pitfalls When Sourcing Flexible Cables (Quality and IP)

Sourcing flexible cables—especially for demanding applications—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking key factors can lead to product failures, safety hazards, legal risks, and reputational damage. Below are common pitfalls to avoid:

Poor Material and Construction Quality

One of the most frequent issues is compromising on materials to reduce cost. Low-grade conductors, inadequate shielding, or substandard jacketing materials can result in premature cable failure due to abrasion, bending fatigue, or environmental exposure. Always verify material specifications and test reports for flexibility, temperature resistance, and durability.

Inaccurate or Misleading IP Ratings

Many suppliers claim high Ingress Protection (IP) ratings (e.g., IP67, IP68), but these may not be independently verified. Some cables are only rated when mated with specific connectors, not as standalone components. Always request certified test reports from accredited labs and clarify under what conditions the IP rating applies.

Lack of Compliance and Certification

Flexible cables used in industrial, medical, or automotive applications must often meet regional or industry standards (e.g., UL, CE, RoHS, REACH). Sourcing non-compliant cables can result in regulatory rejection, product recalls, or liability. Ensure all necessary certifications are current and applicable to your target market.

Insufficient Flex Life Testing

Not all “flexible” cables are designed for dynamic applications (e.g., continuous movement in robotics or machinery). Cables marketed as flexible may not withstand repeated bending cycles. Demand flex life data (e.g., number of cycles under specific conditions) and confirm suitability for your motion profile.

Counterfeit or Reverse-Engineered Components

Some suppliers offer cables that mimic well-known branded products but are reverse-engineered or counterfeit. These may infringe on IP rights and lack reliable performance. Sourcing such cables exposes your company to legal action and reliability issues. Always purchase from authorized distributors or reputable manufacturers.

Inadequate Documentation and Traceability

Poor documentation—such as missing test reports, material disclosures, or batch traceability—can hinder quality control and compliance audits. Ensure suppliers provide full technical documentation and maintain traceability for every production batch.

Overlooking Environmental and Chemical Resistance

Flexible cables used in harsh environments must resist oils, chemicals, UV exposure, and extreme temperatures. Assuming standard cables are sufficient without validating resistance can lead to rapid degradation. Confirm compatibility with your operating environment through chemical resistance charts and test data.

Ignoring Intellectual Property Rights

Using cable designs or proprietary technologies (e.g., patented shielding methods, conductor layouts) without proper licensing can lead to IP infringement claims. Conduct due diligence to ensure the cables you source do not violate existing patents or trademarks.

Selecting Based on Price Alone

While cost is important, choosing the cheapest option often results in compromised performance, safety, and longevity. Invest in quality cables from trusted suppliers—even at a higher upfront cost—to avoid downtime, warranty claims, and safety incidents.

Avoiding these pitfalls requires thorough vetting of suppliers, clear specification requirements, and ongoing quality assurance. Prioritizing both technical performance and legal compliance ensures reliable and sustainable sourcing of flexible cables.

Logistics & Compliance Guide for Flexible Cable

Overview

This guide outlines the essential logistics and compliance considerations for the handling, transportation, storage, and regulatory adherence of flexible cables. Proper management ensures product integrity, safety, and legal compliance across the supply chain.

Packaging Requirements

Flexible cables must be packaged to prevent damage during transit. Use spools, reels, or coiled packaging secured with protective wrapping (e.g., shrink wrap or corrugated cardboard). Avoid sharp bends or compression. Clearly label packages with product details, batch numbers, and handling instructions (e.g., “Do Not Drop” or “Keep Dry”).

Storage Conditions

Store flexible cables in a dry, temperature-controlled environment (typically 5°C to 35°C). Avoid exposure to direct sunlight, moisture, and corrosive substances. Keep reels upright on pallets to prevent deformation. Ensure adequate ventilation and rodent protection in storage areas.

Transportation Guidelines

Use enclosed vehicles to protect cables from weather and physical damage. Secure reels to prevent rolling or shifting during transit. For international shipments, comply with IATA, IMDG, or ADR regulations if applicable. Avoid extreme temperature exposure during long hauls.

Regulatory Compliance

Ensure flexible cables comply with relevant regional and international standards:

– EU: Conform to RoHS (Restriction of Hazardous Substances) and REACH regulations. CE marking is mandatory for applicable product categories.

– USA: Comply with UL standards (e.g., UL 62) and FCC regulations if cables are used in electronic devices.

– Canada: Adhere to CSA certification requirements.

– Other Regions: Follow local electrical safety and environmental directives (e.g., CCC in China, PSE in Japan).

Documentation

Maintain accurate documentation including:

– Certificate of Conformity (CoC)

– Safety Data Sheet (SDS), if applicable

– Test reports (e.g., flame resistance, conductivity)

– Bill of Materials (BOM) for traceability

– Export documentation (commercial invoice, packing list, COO) for international shipments

Labeling and Marking

Each cable or spool must be permanently marked with:

– Manufacturer name or trademark

– Cable type and specifications (voltage, gauge, insulation type)

– Compliance marks (e.g., UL, CE)

– Lot or batch number

– Manufacturing date

Environmental and Safety Handling

Dispose of damaged or obsolete cables in accordance with local e-waste regulations. Recycle materials where possible. During handling, use appropriate PPE (gloves, safety footwear) to prevent injury from sharp edges or heavy reels.

Quality Assurance and Audits

Conduct periodic audits of logistics partners and internal processes to ensure compliance. Maintain records of inspections, non-conformances, and corrective actions. Implement a traceability system for full supply chain visibility.

Emergency Procedures

In case of damage, contamination, or regulatory non-compliance, immediately isolate affected stock and notify relevant stakeholders. Follow recall protocols if required by regulatory authorities. Document all incident details for reporting and improvement.

Contact and Support

For compliance inquiries or logistics support, contact:

[Insert Company Compliance Officer Name]

Email: [email protected]

Phone: +[Insert Phone Number]

Ensure all team members are trained on this guide and updated on regulatory changes.

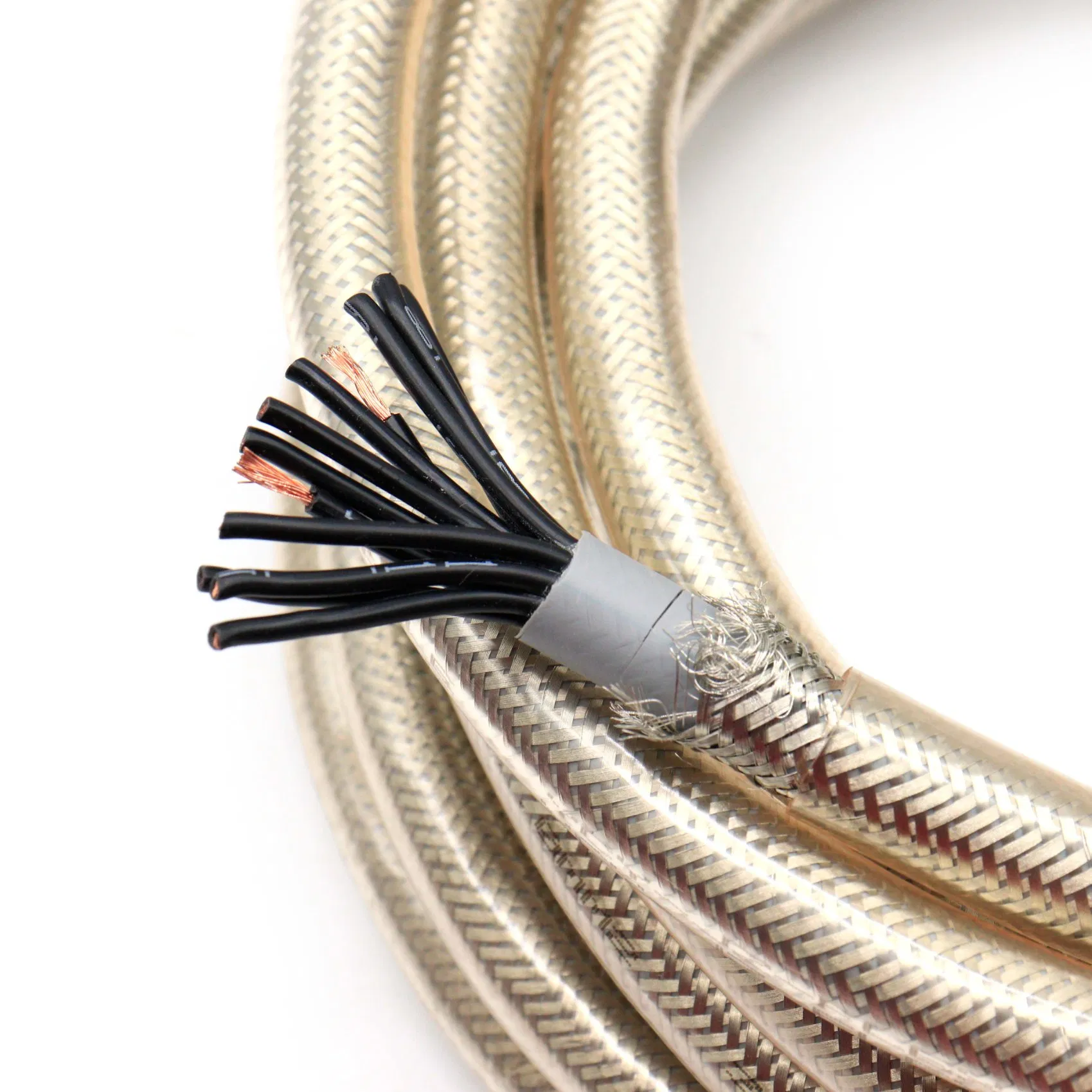

Conclusion on Sourcing Flexible Cables

In conclusion, sourcing flexible cables requires a comprehensive evaluation of technical specifications, application requirements, quality standards, and supplier reliability. Flexible cables are critical in dynamic environments such as automation, robotics, and moving machinery, where repeated bending, torsion, and vibration demand high durability and performance. Selecting the right cable involves understanding factors such as conductor material (typically fine-stranded copper), insulation and jacketing materials (e.g., PUR, PVC, or TPE for abrasion and chemical resistance), shielding for EMI protection, and compliance with industry standards (e.g., UL, CE, RoHS).

To ensure long-term reliability and cost-efficiency, it is essential to partner with reputable suppliers who offer consistent quality, technical support, and traceability. Additionally, considering total cost of ownership—not just initial price—helps avoid premature failures and downtime. By aligning cable specifications with operational demands and conducting thorough supplier assessments, organizations can secure flexible cables that enhance system performance, safety, and longevity.