The global flatbed container trailer market is experiencing steady growth, driven by rising demand for efficient intermodal freight transport and infrastructure development across key regions. According to a report by Mordor Intelligence, the global semi-trailer market—of which flatbed container trailers are a significant segment—is projected to grow at a CAGR of over 4.2% from 2023 to 2028. Similarly, Grand View Research estimates that the global truck trailer market size was valued at USD 58.6 billion in 2022 and is expected to expand at a CAGR of 4.8% from 2023 to 2030. This growth is fueled by expanding e-commerce logistics, increased cross-border trade, and the need for durable, versatile hauling solutions in construction and energy sectors. As demand surges, a select group of manufacturers have distinguished themselves through innovation, quality, and global reach. Below are the top nine flatbed container trailer manufacturers shaping the future of freight transportation.

Top 9 Flatbed Container Trailer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High quality truck trailers

Domain Est. 1998

Website: fontainetrailer.com

Key Highlights: Fontaine is the #1 flatbed trailer manufacturer in North America. Whether you’re a dealer, fleet manager or independent owner, we have trailers to fit your ……

#2 Stoughton Trailers: Semi

Domain Est. 2000

Website: stoughtontrailers.com

Key Highlights: Tailored solutions for your business with Stoughton Trailer, leading semi-trailer manufacturers. Quality-driven, customer-focused excellence!…

#3 Hercules Chassis & Trailers

Domain Est. 2016

Website: herculeschassis.com

Key Highlights: Hercules Chassis is a leading global chassis manufacturer based in Hillsborough, New Jersey. Launched in 1958, the creative know-how of Hercules has made us an ……

#4 Utility Trailer

Domain Est. 1996

Website: utilitytrailer.com

Key Highlights: Every Utility flatbed can be custom built with a variety of options to meet your operational requirements. Learn more. Watch Video. Upcoming Events. more events ……

#5 Big Tex Trailers

Domain Est. 1997

Website: bigtextrailers.com

Key Highlights: Explore the Big Tex trailer lineup built for relentless professionals. Find a quality trailer for reliability, strength, and performance. Shop now!…

#6 PJ Trailers

Domain Est. 1999

Website: pjtrailers.com

Key Highlights: The #1 professional grade trailer company in the USA. Durable dump, gooseneck, tilt, equipment, and utility trailers. View our selection!…

#7 Diamond C Trailers

Domain Est. 2000

Website: diamondc.com

Key Highlights: We offer a robust lineup of PREMIUM TRAILERS – ranging from car haulers and dump trailers all the way to heavy duty equipment, tilt, flatbed gooseneck, and step ……

#8 Build your legacy with a better trailer.

Domain Est. 2000

Website: mactrailer.com

Key Highlights: MAC Trailer builds commercial trailers, parts, and service centers across the US. Find a dealer today….

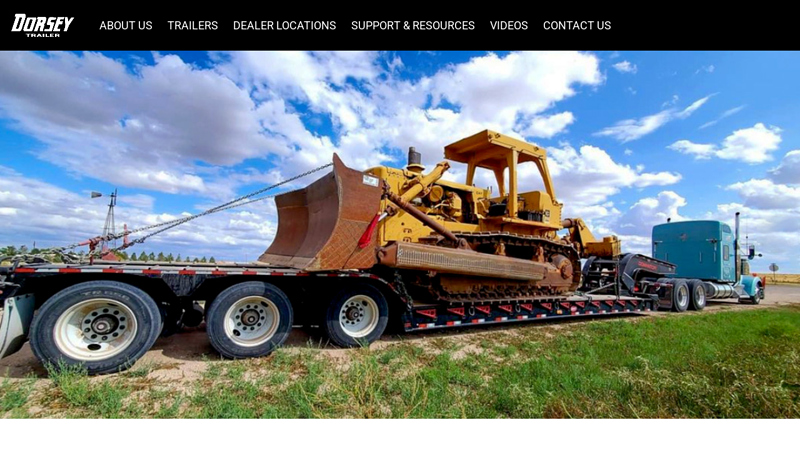

#9 Dorsey Trailer

Domain Est. 2007

Website: dorseytrailer.net

Key Highlights: For over 100 years, Dorsey has been committed to building the most durable trailers on the road. That commitment combined with a dedicated dealer network….

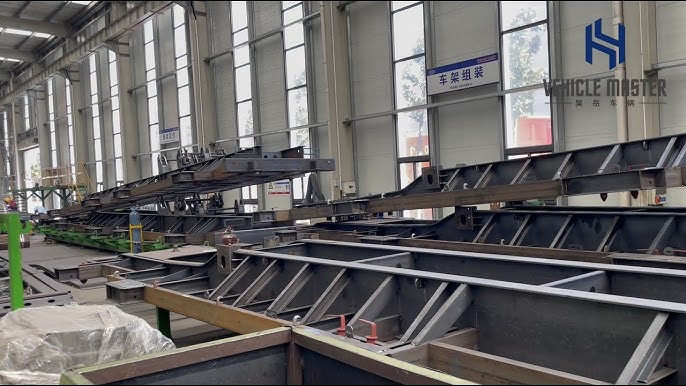

Expert Sourcing Insights for Flatbed Container Trailer

H2: 2026 Market Trends for Flatbed Container Trailers

The global flatbed container trailer market is poised for significant transformation by 2026, driven by evolving logistics demands, regulatory shifts, technological advancements, and sustainability imperatives. This analysis outlines key trends expected to shape the industry during this period.

-

Increased Demand for Intermodal Freight Transport

The growth of global e-commerce and just-in-time supply chains is accelerating the adoption of intermodal transportation. Flatbed container trailers, essential for moving standardized shipping containers between trucks, rail, and ports, are seeing heightened demand. By 2026, intermodal freight volumes are projected to rise—especially in North America and Asia-Pacific—boosting market expansion for flatbed trailers designed for seamless container handling. -

Lightweight and Fuel-Efficient Designs

With rising fuel costs and stricter emissions regulations, manufacturers are investing in lightweight materials such as high-strength steel, aluminum, and composite components. These innovations reduce tare weight, improve payload capacity, and enhance fuel efficiency. By 2026, lightweight flatbed container trailers are expected to dominate new fleet purchases, particularly among large logistics operators aiming to lower operational costs and carbon footprints. -

Electrification and Alternative Powertrains

The commercial vehicle sector’s move toward electrification is influencing trailer design. While trailers themselves are not powered, integration with electric and hybrid trucks requires rethinking aerodynamics, weight distribution, and braking systems. By 2026, flatbed container trailers will increasingly be designed to complement electric powertrains, with features like regenerative braking compatibility and optimized aerodynamic profiles to enhance overall energy efficiency. -

Smart Trailers and IoT Integration

Digitalization is transforming the trailer industry. By 2026, flatbed container trailers will increasingly be equipped with IoT sensors, GPS tracking, load monitoring, and predictive maintenance systems. These smart technologies enable real-time monitoring of cargo condition, trailer location, and structural health, improving safety, reducing downtime, and enhancing supply chain visibility for fleet operators. -

Regulatory Compliance and Safety Standards

Stricter safety and emissions regulations—such as the U.S. EPA’s SmartWay program and Euro VII standards in Europe—are pushing manufacturers to adopt safer, cleaner technologies. Features like advanced braking systems, stability control, and improved lighting are becoming standard. Additionally, regulations around cargo securement and roadworthiness are driving demand for modern, compliant flatbed trailers, especially in developed markets. -

Growth in Emerging Markets

Developing economies in Southeast Asia, Africa, and Latin America are expanding their infrastructure and trade networks, creating new opportunities for flatbed container trailers. As port capacity and cross-border trade increase, demand for reliable, durable trailers will grow. By 2026, these regions are expected to account for a rising share of global flatbed trailer sales, driven by infrastructure investments and urbanization. -

Sustainability and Circular Economy Practices

Environmental concerns are pushing manufacturers toward sustainable production methods. By 2026, leading trailer producers will adopt circular economy principles—using recycled materials, designing for disassembly, and offering end-of-life recycling programs. Customers will increasingly favor suppliers with strong environmental, social, and governance (ESG) credentials, influencing procurement decisions. -

Customization and Modular Designs

To meet diverse cargo and operational needs, modular and customizable flatbed container trailers are gaining traction. Features such as adjustable deck heights, removable sides, and multi-axle configurations allow for greater versatility. By 2026, customization will be a key differentiator among manufacturers, especially for specialized logistics providers.

Conclusion

The flatbed container trailer market in 2026 will be defined by innovation, efficiency, and sustainability. As global trade evolves and technology advances, stakeholders across the supply chain—from manufacturers to fleet operators—must adapt to these trends to remain competitive. Investments in lightweight materials, smart technologies, and sustainable practices will be critical to capturing growth opportunities in this dynamic market.

Common Pitfalls When Sourcing Flatbed Container Trailers (Quality and Intellectual Property)

Poor Quality Materials and Construction

One of the most frequent issues when sourcing flatbed container trailers—especially from low-cost manufacturers—is the use of substandard materials. Buyers may encounter trailers constructed with inferior-grade steel, inadequate welding, or weak axle systems. These compromises can lead to structural failures, reduced load capacity, and shorter service life, ultimately increasing maintenance costs and safety risks.

Lack of Compliance with International Standards

Many suppliers, particularly in emerging markets, may not adhere to recognized international safety and engineering standards such as ISO, DOT, or ADR. Trailers that fail to meet these standards can face import restrictions, fail inspections, or pose safety hazards. Ensuring compliance during the sourcing process is critical for legal operation in target markets.

Inadequate Load Testing and Certification

Reputable manufacturers conduct rigorous load, stress, and fatigue testing. However, some suppliers may skip or falsify these tests, providing documentation without actual validation. This increases the risk of field failures and liability issues. Always verify third-party certifications and request test reports.

Intellectual Property (IP) Infringement Risks

Sourcing flatbed trailers from certain regions may expose buyers to IP violations, such as unauthorized replication of patented designs, proprietary suspension systems, or branded components. Using or importing such trailers can lead to legal action, customs seizures, or reputational damage, especially in IP-sensitive markets like the U.S. or EU.

Insufficient Documentation and Traceability

Poor record-keeping by suppliers—including missing material certifications, weld logs, or design specifications—can create problems during audits, insurance claims, or regulatory inspections. Lack of traceability also complicates quality control and after-sales support.

Hidden Costs from Rework and Repairs

Initial cost savings can quickly disappear when trailers require modifications, repairs, or premature replacement due to quality issues. Hidden costs may include shipping corrections, downtime, and labor for retrofitting, eroding the total cost of ownership benefits.

Limited After-Sales Support and Spare Parts Availability

Some suppliers offer little to no technical support, warranty service, or spare parts supply. This is especially problematic for fleets operating across regions, where downtime can significantly impact logistics efficiency.

Mitigation Strategies

To avoid these pitfalls, conduct thorough due diligence on suppliers, request physical samples, perform factory audits, verify certifications, and include IP protection clauses in contracts. Partnering with reputable manufacturers and using third-party inspection services can significantly reduce risks.

Logistics & Compliance Guide for Flatbed Container Trailer

Overview of Flatbed Container Trailers

Flatbed container trailers, also known as skeletal trailers or container chassis, are specialized semi-trailers designed to transport intermodal shipping containers. They feature a lightweight, frame-only structure with locking mechanisms (twist locks) at each corner to secure containers. These trailers are commonly used in ports, rail intermodal facilities, and drayage operations, enabling seamless transfer of containers between ships, trains, and trucks.

Key Logistics Considerations

Weight Distribution and Axle Load

Ensure proper weight distribution across the trailer’s axles to comply with legal weight limits. Overloading or uneven load distribution can lead to fines, safety hazards, and vehicle damage. Use certified scales to verify gross vehicle weight (GVW), axle group weights, and compliance with state or national regulations (e.g., U.S. Federal Bridge Formula).

Securement Requirements

Although containers are secured using built-in twist locks, operators must confirm that all four corner castings are properly locked. Additional straps or chains are generally not required unless transporting non-standard or damaged containers. Always conduct pre-trip inspections to verify lock functionality.

Route Planning and Clearance

Due to the height of loaded containers (typically 8’6” to 9’6”), plan routes to avoid low bridges, overpasses, and restricted roads. Use GPS systems with commercial vehicle routing to ensure adequate vertical and lateral clearance. Notify dispatch if route changes due to construction or road closures.

Intermodal Handoff Procedures

At ports and rail terminals, ensure proper documentation (e.g., gate tickets, bills of lading) is completed. Confirm container condition during pickup and delivery using a pre-trip inspection report. Communicate any damage or seal discrepancies immediately to the terminal or carrier.

Regulatory Compliance

DOT and FMCSA Regulations (U.S.)

Operators must comply with Federal Motor Carrier Safety Administration (FMCSA) rules, including:

– Hours of Service (HOS) for driver logs (ELD required)

– Vehicle maintenance and inspection (Form DVIR)

– Driver qualification files and drug/alcohol testing

– Cargo securement standards (49 CFR Part 393, Subpart I)

International Standards (ISO)

Flatbed trailers must support ISO-standard containers (20’, 40’, 45’, 48’, 53’). Twist locks must comply with ISO 1161 for corner fittings. Ensure container markings (CSC plate, tare weight, max gross weight) are visible and valid.

State and Local Requirements

Some states impose additional rules, such as:

– Permits for overweight or oversize loads (even if container is standard size)

– Restrictions on lane usage or travel times in urban areas

– Emissions compliance (e.g., California Air Resources Board – CARB)

Cross-Border Compliance (U.S.-Canada/Mexico)

For international transport:

– Ensure valid customs documentation (e.g., customs bond, electronic export information)

– Drivers must carry valid passport, visa, and work authorization

– Comply with FAST, Free and Secure Trade program requirements if applicable

Maintenance and Safety

Routine Inspection Checklist

Conduct daily pre-trip and post-trip inspections covering:

– Tire condition and inflation

– Brake system (air pressure, brake pads, lines)

– Suspension and axle integrity

– Lights and reflectors

– Twist lock operation and locking pin security

– Fifth wheel and kingpin engagement

Preventive Maintenance

Follow manufacturer-recommended service intervals for:

– Lubrication of pivot points and landing gear

– Brake adjustments and air system drainage

– Axle and wheel bearing inspection

– Replacement of worn or damaged components

Best Practices for Operators

- Always confirm container weight and center of gravity before transport.

- Use spotters or cameras when maneuvering in tight spaces.

- Communicate clearly with terminal staff during pickup and drop-off.

- Keep emergency contact information and carrier protocols accessible.

- Train drivers on container handling, securement, and compliance updates.

By adhering to these logistics and compliance guidelines, operators can ensure the safe, efficient, and legal transport of containers using flatbed container trailers.

Conclusion for Sourcing Flatbed Container Trailers

Sourcing flatbed container trailers requires a strategic approach that balances quality, cost, durability, and compliance with operational and regulatory standards. After evaluating various suppliers, specifications, and market options, it is evident that selecting the right trailer involves careful consideration of payload capacity, structural materials, axle configuration, braking systems, and customization options to suit specific transportation needs.

Partnering with reputable manufacturers who adhere to international standards—such as ISO, DOT, or ADR—ensures reliability, safety, and longevity of the equipment. Additionally, factoring in after-sales service, warranty terms, and spare parts availability contributes to minimizing downtime and maximizing return on investment.

Ultimately, a well-informed sourcing decision leads to enhanced operational efficiency, reduced maintenance costs, and improved cargo security. By prioritizing quality over initial cost and aligning trailer specifications with business requirements, companies can build a resilient and scalable logistics fleet capable of supporting current and future transport demands.