The global compact tractor market, a key driver in the rising demand for specialized implements like flail mowers, is experiencing steady expansion. According to Mordor Intelligence, the global compact and sub-compact tractor market was valued at USD 13.3 billion in 2023 and is projected to grow at a CAGR of over 4.5% through 2029, driven by increasing small-scale farming activities, urban landscaping needs, and government support for agricultural mechanization. This growth directly fuels demand for high-performance attachments, with flail mowers emerging as one of the most sought-after implements due to their versatility in managing rough terrain, tall grass, and brush. As farmers and land managers seek durable, efficient mowing solutions compatible with compact tractors, manufacturers are innovating to meet performance, durability, and ease-of-use expectations. In this competitive landscape, identifying the top 9 flail mower manufacturers helps buyers make informed decisions based on reliability, technological advancement, and market reputation.

Top 9 Flail Mowers For Compact Tractors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Flail Mowers

Domain Est. 2001

Website: agindustrial.com

Key Highlights: 9-day delivery 45-day returnsFlail Mowers for Compact and Ag Tractors · Vrisimo Flail Mowers · Vrisimo Brush Shredders · Bomford Turbo Mower · Arm Mowers for Utility Tractors · Arm…

#2 Flail Mowers

Domain Est. 2002

Website: earthtools.com

Key Highlights: We source flail mowers from the Italian manufacturers Berta, BCS, Green Technik, and Bellon to offer our customers a full range of sizes / options….

#3 Flail Mowers

Domain Est. 1995

Website: kuhn.com

Key Highlights: A range of flail mowers adapted to the maintenance of pastures and fallow land but also to the destruction of intermediate crops and plant cover….

#4 Flail Mower Articulating Tractor Attachment

Domain Est. 1997

Website: bobcat.com

Key Highlights: The Flail Mower attachment is the one deck for all your cutting needs up to 3/4″ diameter and ability to transition between rough cut and finish mowing….

#5 Flail Mowers & Toppers Archives

Domain Est. 1997

Website: bomford-turner.com

Key Highlights: … Flail mowers and Rotary toppers are guaranteed to give results. We offer models to fit compact tractors right though to the largest tractors. Turbo Mower….

#6 Flail Mowers (Tractor) Attachments

Domain Est. 2000

Website: diamondmowers.com

Key Highlights: Conquer tough brush and grass with Diamond Mowers’ Tractor Flail Mower Attachment. Made for consistent power, smooth operation & versatile land management….

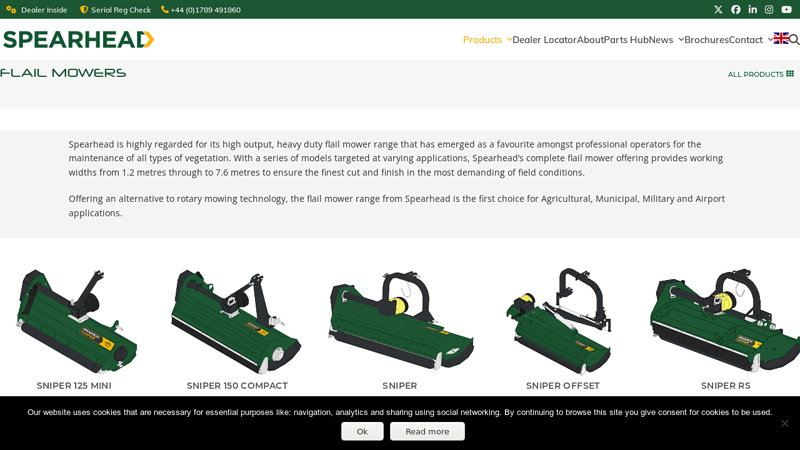

#7 Heavy Duty Flail Mowers

Domain Est. 2005

Website: spearheadmachinery.com

Key Highlights: Spearhead’s complete flail mower offering provides working widths from 1.2 metres through to 7.6 metres to ensure the finest cut and finish….

#8 Lipa Agricultural Machinery

Domain Est. 2006

Website: needhamag.com

Key Highlights: We currently stock most of their range of flail mowers for small to large mini excavators, in addition to flail mowers for tractors and skid steer loaders….

#9 FL Series Flail Mower

Domain Est. 2022

Website: ironcraftusa.com

Key Highlights: The FL flail mower range is suitable for tractors from 23 to 40 PTO horsepower with a category 1 hitch. The FL mower is compact and light….

Expert Sourcing Insights for Flail Mowers For Compact Tractors

H2: 2026 Market Trends for Flail Mowers for Compact Tractors

-

Increasing Demand from Residential and Small-Scale Agricultural Users

By 2026, the market for flail mowers designed for compact tractors is expected to see significant growth driven by rising demand from residential landowners, hobby farmers, and small-scale agricultural operations. As rural living and lifestyle properties gain popularity, especially in North America and Europe, more consumers are investing in compact tractors and compatible implements like flail mowers for efficient land maintenance. These users value the versatility, durability, and clean cutting performance of flail mowers for managing overgrown pastures, ditches, and uneven terrain. -

Technological Advancements and Enhanced Operator Comfort

Manufacturers are increasingly integrating smart technologies and ergonomic design improvements into flail mowers. By 2026, expect wider adoption of features such as quick-hitch compatibility, adjustable cutting heights via hydraulic systems, vibration-dampening rotor designs, and improved blade materials for longer wear. Some premium models may include IoT-enabled monitoring systems that track usage, maintenance intervals, and performance metrics—catering to tech-savvy users and professional landscapers seeking efficiency and reduced downtime. -

Emphasis on Sustainability and Fuel Efficiency

Environmental regulations and consumer preferences are pushing manufacturers toward more sustainable solutions. While most flail mowers remain powered by tractor PTO systems, there is a growing interest in compatibility with compact electric tractors. By 2026, the market may see hybrid or fully electric flail mower prototypes optimized for low-emission operation, particularly appealing in eco-conscious regions like Western Europe. Additionally, designs emphasizing fuel-efficient performance and recyclable materials are expected to gain traction. -

Expansion of E-Commerce and Direct-to-Consumer Sales

Online sales channels are transforming how flail mowers are marketed and distributed. By 2026, a larger share of transactions is expected to occur through e-commerce platforms, manufacturer websites, and farm equipment marketplaces. This shift enables smaller manufacturers to reach global audiences and provides consumers with easier access to reviews, comparative tools, and fast delivery options. Digital marketing, augmented reality product demos, and virtual fitment guides are likely to become standard in the sales cycle. -

Regional Market Growth and Competitive Landscape

North America and Europe will remain dominant markets due to high tractor ownership rates and extensive acreage requiring vegetation management. However, emerging markets in Eastern Europe, Latin America, and parts of Asia-Pacific are projected to show above-average growth, fueled by rising rural mechanization and government support for agricultural development. Competition is intensifying, with established brands like Land Pride, Bush Hog, and Woods facing challenges from cost-competitive Asian manufacturers offering reliable mid-tier models. -

Customization and Aftermarket Accessories

Consumers are increasingly seeking customizable flail mower solutions tailored to specific terrain and operational needs. By 2026, the aftermarket for accessories—such as mulching kits, side discharge attachments, protective skid shoes, and LED lighting—will expand significantly. Manufacturers are responding with modular designs that allow easy upgrades and regional adaptations, enhancing product lifecycle and customer loyalty.

Conclusion:

The flail mower market for compact tractors is poised for steady growth by 2026, shaped by technological innovation, evolving user needs, and expanding distribution models. Companies that prioritize versatility, sustainability, and digital integration will be best positioned to capture market share in this competitive and dynamic segment.

Common Pitfalls When Sourcing Flail Mowers for Compact Tractors (Quality & IP)

Sourcing flail mowers for compact tractors involves navigating several potential pitfalls, particularly concerning quality and intellectual property (IP). Being aware of these issues can help ensure you invest in reliable, legally compliant equipment.

Poor Build Quality and Materials

Many low-cost flail mowers use substandard steel for blades, hammers, and housing, leading to rapid wear, frequent breakage, and safety hazards. Thin-walled housings may dent or crack under impact, compromising operator safety and reducing the machine’s lifespan. Inferior bearings and gearboxes often fail prematurely, increasing downtime and maintenance costs. Always verify material specifications and construction details before purchase.

Inadequate Safety Features

Some imported or budget models lack essential safety components such as proper shielding, safety decals, or emergency stop mechanisms. Non-compliant designs may not meet regional safety standards (e.g., CE or ANSI), exposing buyers to liability and potential regulatory penalties. Ensure the flail mower includes certified safety guards, proper PTO shielding, and meets applicable safety regulations.

Misleading Performance Claims

Suppliers may exaggerate cutting capacity, horsepower requirements, or durability. For example, a mower advertised for a 25 HP tractor might struggle or fail on a machine at the lower end of its stated range. Verify performance claims with independent reviews, user testimonials, or third-party testing data before committing.

Lack of After-Sales Support and Spare Parts

Cheap or overseas-sourced mowers often come with limited or nonexistent local support. Replacement blades, belts, or gearbox parts may be difficult to source, leading to extended downtime. Confirm the availability of spare parts and technical support—preferably from a domestic distributor or manufacturer with a service network.

Intellectual Property (IP) Infringement

Some manufacturers produce flail mowers that closely mimic patented designs from reputable brands, potentially violating IP rights. Purchasing such equipment may expose the buyer to legal risks, especially in regions with strict IP enforcement. Additionally, counterfeit or clone products often lack quality control and performance validation, increasing long-term costs and safety concerns.

Incompatible or Poorly Designed Hitches and PTO Systems

Not all flail mowers are engineered to properly integrate with compact tractor hitch systems (e.g., Category 1 three-point hitch) or PTO shafts. Misalignment, excessive vibration, or improper mounting can damage both the mower and the tractor. Verify compatibility with your specific tractor model and ensure the mower includes appropriate adapters and mounting hardware.

Omission of Warranty or Limited Coverage

Low-cost suppliers may offer little to no warranty, or provide coverage that’s difficult to enforce internationally. A lack of warranty often reflects low confidence in product durability. Always opt for suppliers offering clear, comprehensive warranty terms backed by accessible service channels.

Avoiding these pitfalls requires thorough due diligence—researching suppliers, inspecting build quality, verifying compliance, and prioritizing brands with established reputations for both quality and IP integrity.

Logistics & Compliance Guide for Flail Mowers for Compact Tractors

Overview

Flail mowers for compact tractors are robust landscaping implements designed to cut grass, brush, and light vegetation. Efficient logistics and compliance are essential for safe handling, transportation, and operation. This guide outlines key considerations for shipping, storage, import/export regulations, safety standards, and environmental compliance.

Packaging and Handling

- Secure Crating: Ship flail mowers in heavy-duty wooden crates or palletized with reinforced strapping to prevent movement during transit.

- Protective Wrapping: Use weather-resistant wrapping (e.g., shrink wrap or plastic covers) to shield blades and hydraulic components from moisture and corrosion.

- Lifting Points: Ensure all units have clearly marked lifting points. Use forklifts or cranes with appropriate slings—never lift by blades, PTO shafts, or cutting chambers.

- Blade Immobilization: Secure rotating blades using locking pins or brackets to prevent injury during handling.

Transportation Requirements

- Weight and Dimensions: Verify the mower’s weight and dimensions (including packaging) to comply with road transport limits. Most compact tractor flail mowers range from 200–800 lbs (90–360 kg) and 4–7 ft (1.2–2.1 m) in width.

- Trailer & Load Securing: Transport on flatbed or landscape trailers. Use ratchet straps, chains, or load bars to secure the unit at multiple anchor points.

- Overhang Limits: Ensure overhang (front/rear/side) complies with local DOT regulations (e.g., U.S. FMCSA recommends no more than 4 ft beyond rear of vehicle).

- Hazardous Components: If hydraulic fluid or fuel is present, ensure containers are sealed and labeled per transportation safety standards (e.g., DOT 49 CFR).

Import/Export Compliance

- HS Codes: Use Harmonized System (HS) code 8433.52.00 (for lawn and garden machinery) or 8433.90 (other agricultural machinery), depending on design and use. Confirm with local customs authority.

- Documentation: Prepare commercial invoice, packing list, bill of lading, and certificate of origin. Include detailed product specifications.

- Tariffs and Duties: Check country-specific tariffs; many countries (e.g., U.S., EU) offer reduced or zero duty for agricultural machinery under certain conditions.

- CE, UKCA, and Other Marks: For EU/UK markets, ensure compliance with Machinery Directive 2006/42/EC (CE/UKCA marking required). Include Declaration of Conformity.

- EPA and CARB Compliance: For U.S. sales, verify that any attached power units (e.g., hydraulic motors) meet EPA emission standards. CARB compliance may be required in California.

Safety and Operational Compliance

- Operator Manuals: Provide manuals in local language, including assembly, operation, maintenance, and safety warnings per ISO 3600 and ANSI B71.4 standards.

- Guarding and Shields: Ensure all rotating parts (PTO, flails, belts) are equipped with factory-installed guards. Verify compliance with OSHA 29 CFR 1910.212 (U.S.) or equivalent.

- Warning Labels: Affix durable, multilingual safety labels (e.g., “Danger – Rotating Blades,” “PTO Engagement Warning”) in visible locations.

- Hitch and PTO Compatibility: Confirm three-point hitch category (typically Category I for compact tractors) and PTO shaft type (e.g., 540 rpm) match regional tractor standards.

Environmental and Disposal Regulations

- Noise Emissions: Comply with EU Directive 2000/14/EC noise limits (typically <105 dB(A) at operator position). Test and certify if required.

- Lubricants and Fluids: Use biodegradable hydraulic oils where possible. Provide disposal instructions for used oil and grease per EPA or EU WEEE/ELV directives.

- End-of-Life Handling: Design for recyclability (steel, rubber components). Follow local regulations for disposal of non-recyclable parts.

Maintenance and Warranty Logistics

- Spare Parts Availability: Maintain inventory of high-wear parts (flail blades, belts, bearings) in regional distribution centers to reduce downtime.

- Warranty Registration: Offer online registration with proof of purchase and date of sale. Track serial numbers for recall management.

- Service Network: Partner with authorized dealers or service centers trained in flail mower maintenance and safety protocols.

Conclusion

Adhering to logistics and compliance standards ensures the safe delivery, legal import/export, and responsible operation of flail mowers for compact tractors. Regular audits, up-to-date documentation, and alignment with regional regulations are critical for global market success.

In conclusion, sourcing flail mowers for compact tractors requires careful consideration of several key factors to ensure optimal performance, durability, and compatibility. It is essential to match the mower’s cutting width, power requirements (PTO), and hitch type to the specifications of the compact tractor to guarantee efficient operation and avoid mechanical strain. Quality construction, blade type, and ease of maintenance significantly influence long-term reliability and operational costs. Evaluating reputable suppliers, reading customer reviews, and comparing warranty and after-sales support can help identify dependable brands and models. Additionally, balancing upfront investment with long-term value will lead to a more sustainable and cost-effective purchase. By prioritizing compatibility, build quality, and supplier credibility, buyers can source a flail mower that enhances productivity and meets the demands of diverse mowing applications, from pasture maintenance to roadside clearing.