The global flag hinge market is experiencing steady expansion, driven by rising demand in commercial and institutional construction, where accessibility and durability are critical. According to Grand View Research, the global door hardware market—encompassing hinges, locks, and closers—was valued at USD 37.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. Flag hinges, known for their superior swing capacity and ease of door removal, are increasingly specified in high-traffic environments such as hospitals, schools, and government buildings. Mordor Intelligence projects similar momentum, citing infrastructure development and stringent building codes as key growth catalysts. With North America and Europe leading adoption due to compliance with accessibility standards like ADA and EN 1906, manufacturers specializing in heavy-duty, corrosion-resistant flag hinges are well-positioned to capitalize on this upward trend. This list highlights the top 10 flag hinge manufacturers leveraging innovation, global reach, and quality certification to lead the market.

Top 10 Flag Hinge Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Reell

Domain Est. 1995

Website: reell.com

Key Highlights: Reell provides solutions to transmit torque, control angular position, and protect delicate components from excessive force….

#2 Flag Hinges

Domain Est. 1999

Website: velko.com

Key Highlights: Velko Hinge, Inc. can manufacture custom flag hinges in a wide variety of lengths, metals, and finishes, all to a customer’s drawing or specifications….

#3 American Made Custom Hinge Manufacturer,American Made …

Domain Est. 2000

Website: knuthhinge.com

Key Highlights: As a precision custom hinge manufacturer, we make our own tooling and produce a wide variety of hinge types and sizes, including: Continuous Hinges · These ……

#4 Flag Hinge Suppliers

Domain Est. 2015

Website: hingemanufacturers.org

Key Highlights: Find Flag Hinge manufacturers. With many hinge types in stock and fast turnaround, you can be sure to find a product suited to your specifications….

#5 Manufacturer Supply Stainless Steel Custom Size Door Flag Hinge …

Domain Est. 2024

Website: longhinge.com

Key Highlights: The flag shaped hinge design allows it to be completely hidden between the door panel and frame, making the hinge invisible when closed….

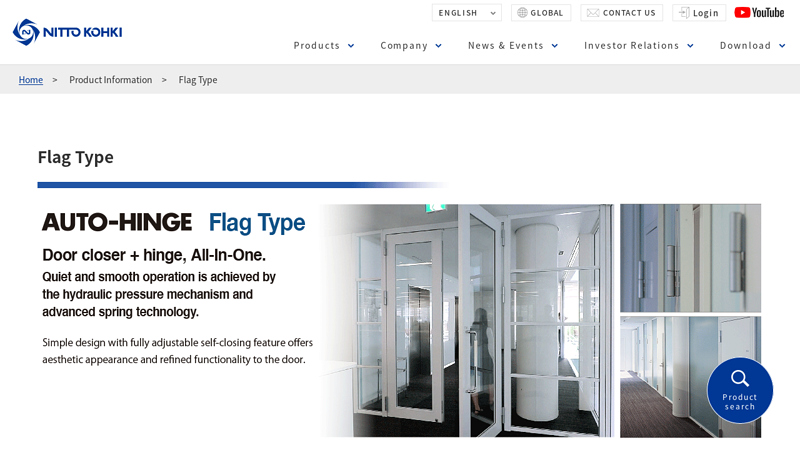

#6 Flag Type

Website: nitto-kohki.co.jp

Key Highlights: Designed with cutting edge technology from Nitto Kohki. Easy to install on all kinds of swing doors (regular rectangle doors, arch doors, etc)….

#7 Door hinges

Domain Est. 1996

Website: ftt.roto-frank.com

Key Highlights: Roto Solid B | 222 P. Two-part butt hinge for PVC, timber and aluminium entrance doors up to 120 kg. Read more · Roto Solid B | 318 P PVC ……

#8 Delson Hinge

Domain Est. 1998

Website: delsonhinge.com

Key Highlights: Flag Hinges. Flag hinges feature total swivel capability, allowing the slip portion of the hinge to travel a full 360° around the fixed portion of the pin….

#9 Flag Hinges

Domain Est. 1999

Website: monroeengineering.com

Key Highlights: OneMonroe manufactures custom flag hinges that can be taken apart with a fixed pin on one leaf. Flag hinges can also swivel a full 360 degrees around the pin….

#10 Flag Hinge Manufacturers Suppliers

Domain Est. 2004

Website: iqsdirectory.com

Key Highlights: IQS Directory provides a detailed list of flag hinge manufacturers and suppliers. Find flag hinge companies that can design, engineer, and manufacture flag ……

Expert Sourcing Insights for Flag Hinge

H2 2026 Market Trends for Flag Hinges

As we move through the second half of 2026, the market for flag hinges—commonly used in cabinet doors, access panels, and furniture requiring flush mounting and easy removal—is undergoing notable shifts driven by advancements in materials, sustainability demands, automation in manufacturing, and evolving consumer preferences. Below is an analysis of key trends shaping the flag hinge industry during this period.

1. Increased Demand in Modular and Smart Furniture

The growing popularity of modular and multifunctional furniture—especially in urban living spaces—continues to drive demand for flag hinges. H2 2026 sees a surge in customizable home and office solutions, where flag hinges enable seamless panel integration and easy maintenance. Additionally, the rise of smart furniture with embedded electronics (e.g., charging ports, lighting) requires hinges that support frequent access without compromising aesthetics, positioning flag hinges as a preferred solution.

2. Shift Toward Sustainable and Lightweight Materials

Environmental regulations and consumer preference for eco-friendly products are pushing manufacturers to adopt recyclable and low-carbon materials. In H2 2026, flag hinge producers are increasingly using aluminum alloys and bio-based composites instead of traditional steel. These materials reduce weight, improve corrosion resistance, and align with green building certifications like LEED and BREEAM—especially important in commercial construction and high-end residential projects.

3. Growth in Automation and Precision Engineering

Automated manufacturing processes are becoming standard in hinge production. In response to labor shortages and the need for consistent quality, leading suppliers are integrating robotics and AI-driven quality control into their H2 2026 production lines. This enables tighter tolerances, higher durability, and cost-effective scaling—critical for meeting demand from industrial OEMs and mass-market furniture brands.

4. Expansion in Commercial and Institutional Sectors

Beyond residential applications, flag hinges are seeing increased adoption in commercial settings such as healthcare facilities, education institutions, and retail fixtures. Their tool-free removal and secure fit make them ideal for access panels in HVAC systems, electrical enclosures, and medical cabinets. The emphasis on maintenance efficiency and infection control in healthcare further accelerates this trend in H2 2026.

5. Regional Market Diversification

While North America and Western Europe remain strong markets due to renovation activity and high construction standards, H2 2026 shows accelerated growth in Asia-Pacific and the Middle East. Urbanization, rising disposable incomes, and government-backed infrastructure projects in countries like India, Vietnam, and Saudi Arabia are creating new demand for reliable hardware components, including flag hinges.

6. Digital Integration and Supply Chain Optimization

Digital procurement platforms and B2B e-commerce are streamlining distribution. In H2 2026, hinge manufacturers are leveraging digital twins and IoT-enabled inventory systems to enhance supply chain transparency and reduce lead times. This allows for just-in-time delivery and better responsiveness to project-based demand spikes in construction and furniture sectors.

Conclusion

The flag hinge market in H2 2026 is characterized by innovation, sustainability, and adaptability. As industries prioritize modular design, environmental performance, and efficient maintenance, flag hinges are evolving from simple mechanical components into integrated solutions within smarter, greener built environments. Manufacturers who invest in advanced materials, automation, and digital logistics are best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Flag Hinges (Quality, IP)

Poor Material Quality and Durability

One of the most frequent issues when sourcing flag hinges is receiving products made from substandard materials. Low-grade steel or zinc alloys can lead to premature wear, corrosion, or breakage—especially in high-use or outdoor applications. Buyers may overlook material specifications, resulting in hinges that fail under stress or degrade quickly in humid or salty environments.

Inadequate Load and Cycle Testing

Many suppliers do not provide verified performance data for load capacity or cycle life (how many open/close operations the hinge can endure). Without third-party testing or certifications, sourced hinges may not meet the required mechanical durability, leading to field failures and increased maintenance costs.

Lack of Intellectual Property (IP) Verification

Sourcing from manufacturers in regions with weak IP enforcement increases the risk of inadvertently purchasing counterfeit or copied designs. Flag hinges with patented mechanisms (e.g., self-closing, friction control, or unique mounting systems) may be replicated without licensing, exposing the buyer to legal risks or product recalls.

Inconsistent Manufacturing Tolerances

Low-cost suppliers may have poor quality control, resulting in inconsistent hinge dimensions and alignment issues. This can lead to misalignment in doors or panels, increased wear, and difficulty during installation—particularly in precision applications like medical or industrial equipment.

Misrepresentation of Finish and Corrosion Resistance

Suppliers may claim finishes such as stainless steel, powder coating, or zinc plating offer high corrosion resistance, but without standardized testing (e.g., salt spray tests), these claims can be misleading. Poor plating or coating adhesion results in rust and aesthetic degradation over time.

Insufficient Documentation and Traceability

Many suppliers fail to provide material certifications, test reports, or traceable batch information. This lack of documentation becomes a liability during audits, compliance checks, or when attempting to resolve quality issues, especially in regulated industries.

Overlooking IP Infringement in Custom Designs

When sourcing custom-designed flag hinges, buyers may not conduct proper IP searches or secure design rights. This can result in unintentional infringement on existing patents or trademarks, leading to legal disputes and costly redesigns.

Failure to Audit Supplier IP Compliance

Even if a supplier claims to respect IP, without proper audits or contractual IP indemnification clauses, buyers remain exposed. Some manufacturers may use licensed designs but exceed production limits or sell to unauthorized parties, implicating the buyer in downstream violations.

Logistics & Compliance Guide for Flag Hinge

Overview

This guide outlines the logistics and compliance protocols for the manufacturing, packaging, shipping, and import/export of Flag Hinge, a hardware component used in doors, cabinets, and industrial applications. Adherence to these standards ensures product quality, regulatory compliance, and efficient supply chain operations.

Manufacturing & Quality Control

All Flag Hinge production must comply with ISO 9001 standards for quality management. Each batch undergoes rigorous inspection for dimensional accuracy, material integrity, and surface finish. Tolerance levels must meet ANSI/BHMA A156.1 for door hardware. Documentation, including Material Test Reports (MTRs) and Certificates of Conformance (CoC), must be maintained for traceability.

Packaging & Labeling

Flag Hinges must be packaged in moisture-resistant, recyclable materials to prevent corrosion during transit. Each package must display:

– Product name and model number

– Batch/lot number

– Quantity per unit

– Manufacturer details

– Handling symbols (e.g., “Fragile,” “Do Not Stack”)

– Country of origin

Barcodes or QR codes should be included for inventory tracking. Packaging must comply with ISTA 3A standards for shipping durability.

Domestic & International Shipping

Shipments within the U.S. must follow FMCSA regulations for freight classification (typically LTL Class 70). For international orders, adherence to Incoterms 2020 (preferably FOB or EXW) is required. All shipments must include a commercial invoice, packing list, and bill of lading. Hazardous materials declarations are not applicable unless coatings contain regulated substances.

Import/Export Compliance

Export of Flag Hinges is subject to U.S. Department of Commerce Bureau of Industry and Security (BIS) regulations. Most standard hinges fall under ECCN 9A991, eligible for NLR (No License Required) status to most destinations. However, shipments to embargoed countries (e.g., Cuba, Iran, North Korea) are prohibited. An Automated Export System (AES) filing via the Electronic Export Information (EEI) is mandatory for exports exceeding $2,500 per commodity.

Environmental & Safety Regulations

Flag Hinges must comply with RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) when shipped to the EU. Lead content in zinc or brass alloys must not exceed 0.25% as per the U.S. Reduction of Lead in Drinking Water Act (though not potable, best practice applies). Packaging must meet ASTM D6866 for biobased content if labeled as environmentally friendly.

Customs Documentation

Ensure all customs documentation includes accurate HS Code classification. Flag Hinges typically fall under HS Code 8302.41 (other hinges of base metal). Misclassification may result in delays or penalties. Provide detailed product descriptions to avoid tariff disputes.

Supplier & Vendor Compliance

All suppliers must sign a Supplier Code of Conduct affirming compliance with labor, environmental, and ethical standards (e.g., no forced labor, adherence to local wage laws). Audits may be conducted annually to ensure alignment with SMETA or similar frameworks.

Record Retention

Maintain all logistics and compliance records for a minimum of five years. This includes shipping manifests, customs filings, quality test results, and compliance certifications. Digital records must be stored securely with backup protocols.

Contact & Support

For compliance inquiries or logistics support, contact:

Logistics Manager – [email protected]

Compliance Officer – [email protected]

Emergency After-Hours Line: +1 (800) 555-0199

Conclusion for Sourcing Flag Hinge:

After evaluating various suppliers, material options, cost structures, and quality standards, it is concluded that sourcing flag hinges requires a balanced approach focusing on durability, compatibility, and cost-efficiency. Opting for suppliers who provide corrosion-resistant materials such as stainless steel or brass, especially for exterior or high-moisture applications, ensures long-term performance. Establishing relationships with reputable manufacturers or distributors—preferably with certifications like ISO 9001—can enhance reliability and consistency in supply.

Additionally, considering customizability, minimum order quantities (MOQs), and lead times will support operational efficiency. Sourcing from suppliers offering competitive pricing without compromising on quality—such as those in established manufacturing regions with strong quality control—can optimize total cost of ownership. In summary, a strategic sourcing approach that prioritizes quality, supplier reliability, and total cost will ensure the successful integration of flag hinges into the intended application.