The global fitness equipment market is experiencing robust growth, driven by rising health awareness, increasing gym memberships, and the expanding popularity of home workouts. According to a report by Mordor Intelligence, the market was valued at USD 11.5 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029. A critical yet often overlooked component within this ecosystem is fitness machine cables—durable, high-tension elements essential for resistance training equipment such as cable crossover machines, functional trainers, and pulley systems. As demand for reliable and high-performance fitness gear rises, so does the need for premium-grade cables capable of withstanding repeated stress and ensuring user safety. This growth trajectory, supported by Grand View Research noting increased manufacturing investments in durable fitness components, has intensified competition among component suppliers. The following list highlights the top 10 fitness machine cables manufacturers leading innovation, quality assurance, and global supply chain efficiency in this expanding niche.

Top 10 Fitness Machine Cables Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Body

Domain Est. 1997

Website: bodysolid.com

Key Highlights: Body-Solid, Inc. is an American manufacturer and distributor of home and commercial strength & conditioning equipment including home gyms, smith machines, racks ……

#2 Keiser

Domain Est. 1995

Website: keiser.com

Key Highlights: Keiser makes the ultimate fitness equipment for your market sector. Sports Performance, Tactical, Medical, Longevity, Commercial, A400 Technology….

#3 EXERFLEXPRO® Fitness Cables

Domain Est. 1997

Website: loosco.com

Key Highlights: EXERFLEXPRO® fitness cables, a top choice for superior smoothness, flexibility, and safety. Made in the USA for optimal workout performance….

#4 Fitness Wire Rope

Domain Est. 2002

Website: lexcocable.com

Key Highlights: Lexco Cable is an industry-leading wire rope assembly manufacturer providing innovative assemblies, products, and solutions for fitness cable applications….

#5 Crossover cable machines for gyms

Domain Est. 1995

#6 Cable Machines and Functional Strength Training

Domain Est. 1995

Website: lifefitness.com

Key Highlights: Cables & Functional Strength Training. Your go-to supplier for every cable machine and functional strength training need. Contact Us….

#7 Commercial Exercise Equipment

Domain Est. 1996

Website: truefitness.com

Key Highlights: We sell various types of commercial exercise equipment, including treadmills, stationary bikes, stretching cages, weightlifting machines, and more….

#8 Strength

Domain Est. 2001

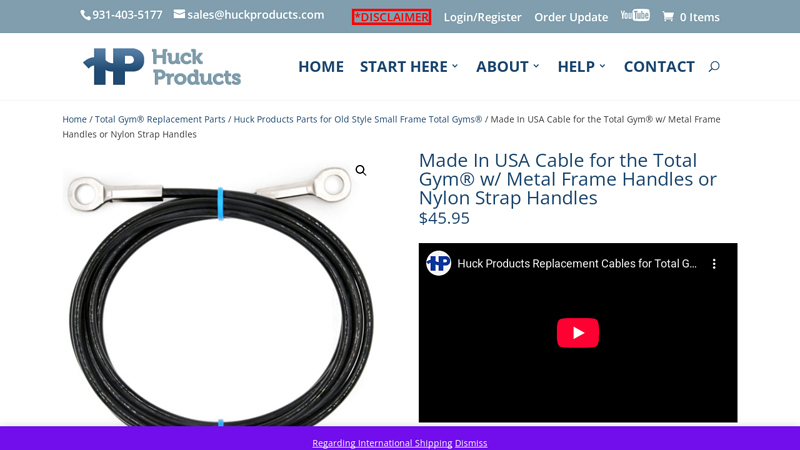

#9 Made In USA Cable for the Total Gym® w/ Metal Frame Handles or …

Domain Est. 2002

Website: huckproducts.com

Key Highlights: In stock Rating 4.7 9 The cable on this page is the Huck Products Replacement Cable for any retail Total Gym® with Metal Frame Handles (look at the handle frame, not the grip) or…

#10 XMARK Strength Training Equipment

Domain Est. 2009

Website: xmarkfitness.com

Key Highlights: Free delivery 30-day returnsXMARK offers a full line of commercial and home gym equipment for strength training, including power racks, functional trainers, bumper plates, barbells…

Expert Sourcing Insights for Fitness Machine Cables

H2: 2026 Market Trends for Fitness Machine Cables

The global market for fitness machine cables is poised for significant evolution by 2026, driven by shifting consumer behaviors, technological advancements, and the expanding fitness ecosystem. As a critical yet often overlooked component of resistance and functional training equipment, cable systems are becoming smarter, more durable, and more integrated. Here are the key trends expected to shape the fitness machine cables market in 2026:

1. Surge in Home and Hybrid Fitness Adoption

The post-pandemic fitness landscape continues to favor home and hybrid training models. By 2026, demand for compact, multi-functional cable machines—like functional trainers, wall-mounted pulley systems, and all-in-one home gyms—will rise. Consumers seek space-efficient solutions that deliver commercial-grade performance, increasing the need for high-quality, corrosion-resistant cables designed for consistent home use.

2. Advancements in Cable Materials and Coatings

Safety and longevity are top priorities. By 2026, manufacturers will increasingly adopt high-tensile synthetic cables (e.g., ultra-high-molecular-weight polyethylene – UHMWPE) and improved steel cable coatings (e.g., polymer-jacketed or marine-grade galvanized steel). These materials reduce fraying, enhance smoothness, and resist wear from sweat and environmental exposure—critical for both commercial and home gyms.

3. Smart Integration and IoT-Enabled Systems

Fitness technology will extend to cable mechanisms. Smart cables with embedded sensors will track resistance levels, repetitions, speed, and form in real time. Integrated with fitness apps and AI coaching platforms, these systems will offer personalized feedback. By 2026, premium cable machines will feature digital resistance adjustment and data synchronization, transforming passive cables into active performance tools.

4. Focus on Durability and Low Maintenance

Commercial facilities and high-use home users demand reliability. Cable systems will feature modular designs with quick-release mechanisms for easy replacement. Sealed pulleys, self-lubricating sheaves, and maintenance-free cable guides will become industry standards, reducing downtime and service costs.

5. Sustainability and Ethical Manufacturing

Environmental concerns will influence material sourcing and production. By 2026, leading brands will emphasize recyclable materials, reduced packaging, and ethical supply chains. Biodegradable cable coatings and transparent manufacturing practices will differentiate eco-conscious brands in a competitive market.

6. Growth in Functional and Group Training Spaces

The popularity of functional fitness (e.g., CrossFit, HIIT) will boost demand for versatile cable attachments and multi-user cable rigs. Facilities will invest in modular cable towers and wall systems that support dynamic group workouts, requiring robust, high-cycle cables capable of withstanding intense use.

7. Regional Market Expansion

Asia-Pacific and Latin America will see accelerated growth due to rising middle-class fitness spending and expanding gym chains. Localized production and cost-effective cable solutions will emerge to meet demand in price-sensitive markets, while North America and Europe focus on innovation and premium features.

Conclusion:

By 2026, the fitness machine cables market will be defined by innovation in materials, smart technology integration, and responsiveness to diverse consumer needs. Cables will transition from passive components to intelligent, high-performance elements central to next-generation fitness experiences—driving demand across home, commercial, and hybrid sectors.

Common Pitfalls When Sourcing Fitness Machine Cables: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Fitness Machine Cables

Navigating the logistics and compliance landscape for fitness machine cables is essential to ensure safe, efficient distribution and adherence to international standards. This guide outlines key considerations for manufacturers, distributors, and retailers.

Product Classification and HS Code

Fitness machine cables are typically classified under the broader category of fitness equipment components. The Harmonized System (HS) code commonly used is 8479.89.9480 – “Machines and mechanical appliances having individual functions, not specified elsewhere, parts thereof.” However, classification may vary by country; consult local customs authorities for precise codes to ensure accurate duty assessment and import compliance.

Regulatory Compliance Standards

Fitness machine cables must comply with safety and performance standards to protect end users and meet legal requirements in target markets:

- United States (USA): Comply with standards set by the American Society for Testing and Materials (ASTM), particularly ASTM F2001 for general fitness equipment safety. Additionally, cables should meet Consumer Product Safety Commission (CPSC) guidelines for mechanical integrity and user safety.

- European Union (EU): Must adhere to the Machinery Directive (2006/42/EC) and be CE marked. Compliance with EN 957-1 (stationary training equipment – safety requirements) is critical. Cables must undergo risk assessment for tensile strength, fatigue resistance, and resistance to fraying.

- Canada: Follow Health Canada‘s Consumer Product Safety regulations and CSA Group standards (e.g., CSA Z213.1). Importers must ensure compliance with the Consumer Chemicals and Containers Regulations, 2001 (CCCR, 2001) if applicable.

- Australia/New Zealand: Comply with AS/NZS 2772.1 and relevant sections of the AS/NZS 2314 standard for fitness equipment. The Australian Competition & Consumer Commission (ACCC) oversees product safety enforcement.

Material and Labeling Requirements

- Materials: Cables must be made from durable, corrosion-resistant materials (e.g., galvanized steel or high-tensile synthetic fibers) and include protective sheathing where necessary. All materials should be free from restricted substances under REACH (EU) and Proposition 65 (California, USA).

- Labeling: Each cable or packaging must include:

- Manufacturer name and contact information

- Model and part number

- Maximum load capacity (in kg/lbs)

- Compliance markings (e.g., CE, CSA)

- Warnings regarding inspection, maintenance, and replacement

Packaging and Transportation

Proper packaging ensures cables arrive undamaged and meet shipping regulations:

- Packaging: Use moisture-resistant, durable packaging. Coiled cables should be secured to prevent deformation. Include protective end caps to prevent fraying.

- Shipping Methods: Suitable for air, sea, and ground freight. Avoid extreme temperatures and humidity during transit.

- Hazardous Materials: Fitness machine cables are generally non-hazardous and not subject to IATA, IMDG, or ADR regulations, unless coated with restricted chemicals.

Import/Export Documentation

Ensure all shipments are accompanied by accurate documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Conformity (CoC) or Declaration of Conformity (DoC)

- CE Certificate (for EU exports)

- Test Reports (tensile strength, durability)

- Import License (if required by destination country)

Quality Assurance and Testing

Implement a robust QA process:

- Conduct tensile strength testing (minimum 1,000–2,000 lbs depending on application)

- Perform fatigue testing (minimum 50,000 cycles)

- Regular third-party audits and lab testing (e.g., Intertek, SGS, TÜV)

- Maintain traceability through batch/lot numbering

Warranty and End-of-Life Considerations

- Provide a minimum 1-year warranty against manufacturing defects.

- Include end-user instructions for regular inspection and safe disposal.

- Where applicable, comply with WEEE (EU) directives for responsible recycling of fitness equipment components.

By following this guide, stakeholders can ensure fitness machine cables are transported efficiently, legally compliant, and safe for consumers worldwide. Regularly review regulatory updates and maintain open communication with logistics partners and compliance consultants.

In conclusion, sourcing fitness machine cables requires careful consideration of quality, durability, material specifications, and supplier reliability. High-quality cables made from galvanized or stainless steel with proper coatings ensure longevity and smooth performance under repeated stress. It’s essential to partner with reputable suppliers who adhere to industry standards and can provide consistent product quality, certifications, and technical support. Evaluating factors such as tensile strength, flexibility, and compatibility with various fitness equipment designs will help ensure optimal functionality and user safety. Ultimately, investing time in thorough supplier vetting and product testing leads to reliable, cost-effective sourcing solutions that enhance the overall performance and lifespan of fitness machines.