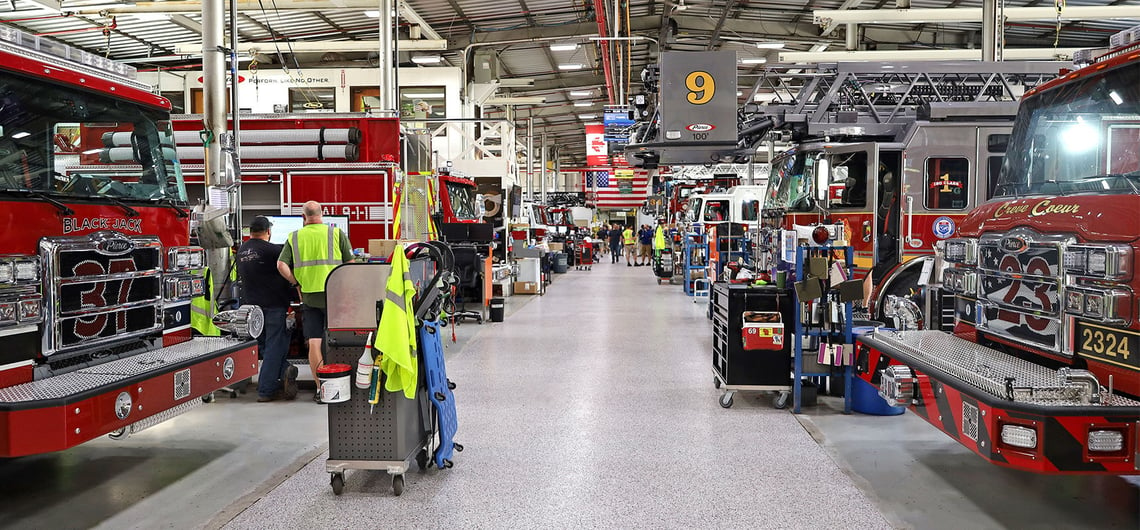

The global turnout gear market, essential for firefighter safety in hazardous environments, is experiencing steady growth driven by rising industrial safety regulations, increasing fire incidents, and technological advancements in protective textiles. According to Mordor Intelligence, the global firefighter turnout gear market was valued at approximately USD 1.3 billion in 2023 and is projected to grow at a CAGR of over 5.8% through 2029. This expansion is further fueled by government mandates for modern protective equipment, coupled with growing awareness of occupational health among first responders. As demand for high-performance, heat-resistant, and lightweight gear rises, manufacturers are investing heavily in innovation—integrating advanced materials like para-aramid fibers and moisture barriers. With North America and Europe leading adoption due to stringent safety standards, and Asia-Pacific witnessing rapid market expansion, the competitive landscape is evolving. Here are the top 10 fireman turnout gear manufacturers leading this critical industry with reliable, certified, and technologically advanced solutions.

Top 10 Fireman Turnout Gear Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Firefighter Apparel Manufacturers

Domain Est. 1987

Website: dupont.com

Key Highlights: Manufacturers for Firefighter Turnout Ensembles, Station Wear, and Wildland Gear made with DuPont™ Nomex® & DuPont™ Kevlar® Fibers · Crewboss · Fire-Dex · MSA/ ……

#2 Fire Fighter Turnout Gear

Domain Est. 1994

Website: milliken.com

Key Highlights: With Assure, Milliken became the first and only U.S.-based manufacturer to offer a non-PFAS fabric for every layer of a firefighter’s turnout gear. Fire ……

#3 INNOTEX

Domain Est. 2012

Website: innotexprotection.com

Key Highlights: Our innovative Tech Rescue gear, Energy gear, Airflow 3D Technology, Gray hoods and interfaces, Endurance knee guard, Reusable Gown……

#4 FIRE-DEX

Domain Est. 1996

Website: firedex.com

Key Highlights: Turnout Gear. Suit up in turnouts built just for you! We offer fully customizable and economical turnout options to meet your department’s unique needs….

#5 Curtis Tools for Heroes: Firefighting Gear

Domain Est. 1999

Website: lncurtis.com

Key Highlights: Curtis carries everything from firefighter turnout gear to wildland PPE, and our online firefighter equipment catalog makes it easy to find exactly what you ……

#6 Turnout Gear

Domain Est. 2004

Website: us.msasafety.com

Key Highlights: Turnout gear that features the most advanced, best-fitting, and longest lasting protection gear for firefighters from trusted manufactuer MSA Globe….

#7 Bunker Gear

Domain Est. 2005

#8 LION Protects

Domain Est. 2009

Website: lionprotects.com

Key Highlights: LION is the largest provider of fire training equipment and facilities for first responders, having built the last three largest first responder training ……

#9 Dinges Fire Company

Domain Est. 2016

#10 Shop the BEST Fire Equipment and Safety Gear

Domain Est. 1999

Website: firefightersafety.com

Key Highlights: New Safety Equipment and Fire Gear. A large collection of safety boots, Workrite nomex uniforms, helmets, flashlights, fire axes, and more!…

Expert Sourcing Insights for Fireman Turnout Gear

H2: 2026 Market Trends for Fireman Turnout Gear

The global market for firefighter turnout gear is projected to experience steady growth and notable transformation by 2026, driven by technological innovation, increasing safety regulations, and growing awareness of firefighter health and operational efficiency. Key trends shaping the 2026 landscape include:

-

Enhanced Material Innovation

By 2026, the integration of advanced, lightweight, and thermally protective materials such as meta-aramids (e.g., Nomex), para-aramids (e.g., Kevlar), and next-generation modacrylic blends will dominate the turnout gear market. Manufacturers are investing in nanotechnology and phase-change materials (PCMs) to improve heat resistance, moisture management, and wearer comfort, especially in prolonged firefighting scenarios. -

Focus on Health and Cancer Risk Reduction

Growing awareness of the link between contaminated turnout gear and elevated cancer risks among firefighters is driving demand for gear with improved contamination resistance and easier decontamination protocols. By 2026, products featuring antimicrobial treatments, seamless barrier layers, and integrated cleaning indicators are expected to become standard, especially in North America and Europe. -

Customization and Ergonomic Design

The trend toward personalized protective equipment will gain momentum, with manufacturers offering modular, customizable turnout gear solutions tailored to body types, climates, and departmental needs. Improved ergonomics—such as articulated joints and adjustable fits—will enhance mobility and reduce fatigue during operations. -

Smart Gear Integration

Wearable technology is increasingly being embedded into turnout gear. By 2026, smart turnout suits with integrated sensors for monitoring vital signs, thermal exposure, and location tracking (via IoT connectivity) will see broader adoption. These innovations support real-time health surveillance and operational decision-making, particularly in urban fire departments with access to digital command systems. -

Regulatory Compliance and Global Standards

Stricter enforcement of standards such as NFPA 1971 (2022 and 2025 editions) in the U.S. and similar regulations in the EU and Asia-Pacific will push manufacturers to align products with updated safety benchmarks. This includes enhanced performance requirements for thermal protection, durability, and retroreflective visibility. -

Sustainability and Circular Economy Initiatives

Environmental concerns are prompting gear manufacturers to explore recyclable materials and sustainable production methods. By 2026, brands will increasingly offer take-back programs, gear refurbishment services, and eco-conscious product lines to meet both consumer demand and regulatory pressures. -

Market Expansion in Emerging Regions

Countries in Asia-Pacific, Latin America, and the Middle East are investing in modernizing fire services, leading to rising demand for high-performance turnout gear. Local partnerships, cost-effective product tiers, and training programs will be key strategies for global suppliers entering these markets.

In summary, the 2026 fireman turnout gear market will be defined by a convergence of safety, technology, and sustainability. Fire departments, manufacturers, and regulators will increasingly collaborate to ensure that turnout gear not only protects against immediate physical hazards but also contributes to long-term firefighter health and operational readiness.

Common Pitfalls When Sourcing Fireman Turnout Gear: Quality and Intellectual Property (IP) Concerns

Sourcing fireman turnout gear—critical protective equipment for firefighters—requires careful attention to both quality standards and intellectual property (IP) integrity. Poor sourcing decisions can compromise firefighter safety, expose organizations to legal risks, and damage reputations. Below are common pitfalls to avoid in these two key areas.

Quality-Related Pitfalls

1. Selecting Suppliers Based Solely on Price

One of the most frequent mistakes is prioritizing low cost over performance. Turnout gear must meet stringent safety standards (such as NFPA 1971 in the U.S.), and cheaper alternatives may use substandard materials or construction, leading to inadequate thermal protection, reduced durability, or failure under extreme conditions.

2. Inadequate Verification of Compliance with Safety Standards

Suppliers may claim compliance with NFPA, EN, or other standards without proper third-party certification. Relying on self-declared certifications or expired test reports can result in sourcing non-compliant gear. Always verify certification through recognized bodies like UL, SEI, or SAI Global.

3. Poor Material and Construction Quality

Low-quality outer shells, moisture barriers, or thermal liners can degrade quickly or fail during use. For example, inferior moisture barriers may lead to steam burns, while weak stitching or seam construction can result in gear tearing during rescue operations.

4. Lack of Consistent Quality Control

Especially when sourcing from overseas manufacturers, inconsistent production batches are common. Without rigorous incoming inspections or on-site quality audits, departments may receive gear that varies significantly in fit, protection, and durability.

5. Insufficient Field Testing and Real-World Validation

Gear that performs well in lab tests may not hold up in real firefighting conditions. Sourcing gear without field validation or user feedback from fire departments increases the risk of procuring equipment that fails in practical use.

Intellectual Property (IP)-Related Pitfalls

1. Sourcing Counterfeit or Knock-Off Gear

Unauthorized replicas of branded turnout gear (e.g., mimicking designs from Lion, MSA, or Bullard) are common in some markets. These counterfeit products often infringe on trademarks, patents, and design rights, and typically fail to meet required safety standards.

2. Unlicensed Manufacturing and Distribution

Some suppliers may produce gear using patented technologies (e.g., specific thermal liner systems or moisture barrier laminates) without proper licensing. Purchasing such gear can expose departments to legal liability, especially if an injury occurs and IP violations are discovered.

3. Misrepresentation of Brand Affiliation

Suppliers may falsely imply endorsement or partnership with well-known brands through logos, packaging, or website content. This can mislead buyers into believing they are purchasing authentic, IP-protected gear when they are not.

4. Use of Proprietary Designs Without Permission

Even if gear appears similar to a branded product, copying patented design elements—such as cut patterns, interface systems, or reflective trim layouts—can constitute IP infringement. Sourcing such gear, even unknowingly, may lead to recalls or legal action.

5. Lack of Transparency in Supply Chain

Opaque supply chains make it difficult to trace whether materials or designs are legally sourced. Without clear documentation from suppliers about IP rights and licensing, organizations risk purchasing gear that violates intellectual property laws.

Best Practices to Avoid Pitfalls

- Verify certifications through official databases.

- Conduct factory audits or use third-party inspection services.

- Require proof of IP compliance, including licensing agreements for patented technologies.

- Purchase directly from authorized distributors or manufacturers.

- Engage legal counsel when evaluating high-value or long-term contracts.

By addressing both quality and IP concerns proactively, fire departments and procurement agencies can ensure they source turnout gear that is safe, compliant, and legally sound.

Logistics & Compliance Guide for Fireman Turnout Gear

This guide outlines the essential logistics considerations and compliance requirements for managing fireman turnout gear—from procurement and inventory to maintenance, usage, and disposal—ensuring operational readiness and adherence to safety standards.

Regulatory Compliance Overview

Fireman turnout gear must comply with national and international safety standards to ensure adequate protection for firefighters. Primary regulatory standards include:

- NFPA 1971: Standard on Selection, Care, and Maintenance of Structural Fire Fighting Protective Ensembles – This is the foundational standard in the United States, specifying design, performance, testing, and certification requirements for turnout gear.

- OSHA 29 CFR 1910.132 – Requires employers to assess workplace hazards and provide appropriate personal protective equipment (PPE), including turnout gear, with proper training and maintenance protocols.

- ANSI/ISEA 101-2014 – Establishes garment sizing and labeling standards to improve fit and traceability.

- International Standards (e.g., EN 469 in the EU) – For departments operating or sourcing gear internationally, compliance with regional standards may be required.

All turnout gear must be NFPA-compliant and certified by an accredited third party such as UL (Underwriters Laboratories) or SEI (Safety Equipment Institute).

Procurement and Supplier Management

When sourcing turnout gear, fire departments must ensure suppliers meet stringent quality and compliance criteria:

- Certified Manufacturers: Procure gear only from manufacturers with current NFPA 1971 certification and documented quality control processes.

- Traceability: Each garment must include a unique serial number and compliance tag detailing model, size, manufacture date, and certification.

- Documentation: Suppliers must provide compliance certificates, user manuals, and care instructions with each order.

- Sustainability and Lead Times: Evaluate supplier delivery timelines, warranty terms, and options for sustainable or recyclable materials.

Inventory and Distribution Logistics

Effective inventory management ensures gear is available when needed and remains within service life limits.

- Barcode/RFID Tracking: Implement a digital tracking system to monitor each gear set’s location, usage history, inspection dates, and maintenance records.

- Sizing and Fit Management: Maintain accurate sizing data for personnel; ensure gear is properly fitted to avoid safety gaps or mobility issues.

- Deployment Protocols: Establish procedures for issuing gear during onboarding, reassignments, or replacements due to damage or retirement.

- Mobile and Reserve Units: Maintain a buffer stock for mutual aid responses, new hires, or emergency replacements.

Inspection, Cleaning, and Maintenance

Routine care is essential for preserving gear integrity and ensuring compliance with NFPA 1851, the standard on selection, care, and maintenance.

- Daily Inspection (User Level): Firefighters must inspect gear after each use for visible damage, contamination, or moisture.

- Advanced Inspection (6-Month Intervals): Conducted by trained facility personnel or third-party service providers to assess thermal protective performance (TPP), moisture barriers, and seam integrity.

- Cleaning Protocols:

- Perform routine cleaning after exposure to smoke, chemicals, or bodily fluids.

- Use only manufacturer-approved detergents and washing procedures (machine or hand wash).

- Avoid bleach, fabric softeners, and high-heat drying.

- Repairs: Only NFPA 1851-compliant repair centers may conduct repairs; unauthorized modifications void certification.

Storage and Environmental Controls

Proper storage prevents premature degradation:

- Dry, Ventilated Environment: Store gear in a clean area with low humidity and no direct sunlight.

- Avoid Compression: Hang jackets and pants; do not store folded under heavy objects.

- Decontamination Before Storage: Ensure gear is cleaned and fully dried before returning to storage to prevent mold and chemical degradation.

Gear Retirement and Disposal

Turnout gear has a finite service life and must be retired to maintain safety.

- Service Life: Per NFPA 1851, structural turnout gear should be retired after 10 years from the date of manufacture, regardless of condition.

- Early Retirement Triggers:

- Failed advanced inspection

- Severe contamination (e.g., hazardous chemicals, biohazards)

- Irreparable damage

- Decertification and Disposal:

- Remove or deface NFPA compliance tags.

- Cut or mark gear to prevent reuse in emergency operations.

- Recycle when possible through manufacturer take-back programs or specialized textile recyclers.

Training and Documentation

Personnel must be trained in proper use, care, and compliance procedures.

- Annual Training: Conduct mandatory training on NFPA 1851 requirements, inspection techniques, and decontamination procedures.

- Recordkeeping: Maintain logs for each gear set, including:

- Issue and return dates

- Inspection and cleaning records

- Repair history

- Retirement/disposal documentation

- Audits: Perform annual compliance audits to ensure adherence to protocols and regulatory standards.

Emergency and Mutual Aid Considerations

- Compatibility: Ensure gear issued for mutual aid responses meets the minimum standards of the assisting jurisdiction.

- Deployment Kits: Pre-stage spare gear sets in command vehicles or emergency caches for rapid deployment.

- Cross-Jurisdictional Compliance: Verify that gear complies with both home and receiving authority regulations during joint operations.

Summary

Managing fireman turnout gear requires a systematic approach integrating regulatory compliance, meticulous logistics, and disciplined maintenance. By adhering to NFPA, OSHA, and manufacturer guidelines, fire departments protect their personnel, ensure operational effectiveness, and maintain legal and safety compliance throughout the gear lifecycle.

Conclusion: Sourcing Firefighter Turnout Gear

Sourcing firefighter turnout gear is a critical responsibility that directly impacts the safety, performance, and well-being of firefighters. Given the life-threatening environments they operate in, it is essential to procure turnout gear that meets or exceeds current NFPA 1971 standards for thermal protection, durability, mobility, and moisture barrier performance. A strategic sourcing approach should prioritize quality, compliance, and long-term value over initial cost savings.

Engaging with reputable manufacturers, conducting thorough evaluations of material technology, fit, and customization options, and considering lifecycle costs—including maintenance, repair, and replacement—are key factors in making informed procurement decisions. Additionally, incorporating feedback from frontline firefighters ensures that the selected gear supports practical field requirements.

Sustainable sourcing practices, such as evaluating warranty terms, repair programs, and end-of-life recycling options, further enhance the value and environmental responsibility of the procurement process.

In conclusion, sourcing turnout gear demands a comprehensive, safety-first approach that balances technical performance, user needs, and long-term operational efficiency. By doing so, fire departments can ensure their personnel are equipped with reliable, high-performance protective gear, ultimately enhancing firefighter safety and mission readiness.