The global fire extinguisher market is experiencing steady growth, driven by increasing fire safety regulations, rising urbanization, and expanding industrial and commercial infrastructure. According to Grand View Research, the global fire extinguisher market size was valued at USD 3.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This expansion reflects heightened awareness around fire prevention and the growing demand for reliable safety equipment across sectors such as construction, manufacturing, transportation, and healthcare. In parallel, Mordor Intelligence projects continued market momentum, supported by technological advancements in fire suppression systems and the rising adoption of eco-friendly extinguishing agents. As demand escalates, a handful of large-scale manufacturers are playing a pivotal role in shaping product innovation, compliance, and global supply. The following list highlights the top 10 fire extinguisher manufacturers leading the industry through scale, technological expertise, and extensive distribution networks.

Top 10 Fire Extinguisher Large Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Portable Fire Extinguishers and Spill Control Products

Domain Est. 1995

Website: ansul.com

Key Highlights: Get fast and effective fire protection where it matters most, with our comprehensive portfolio of portable fire extinguishers and spill control technology….

#2 Badger Fire Protection

Domain Est. 1996

Website: badgerfire.com

Key Highlights: Badger Fire Protection offers industrial fire extinguishers and fire suppression systems, in both dry and wet-chemical applications….

#3 Fire Extinguishers for Your

Domain Est. 1996

Website: kidde.com

Key Highlights: Fire extinguishers for the home can help keep your house and family safe from accidental fires. Find Kidde extinguishers for the home, kitchen, car & more.Missing: large manufactu…

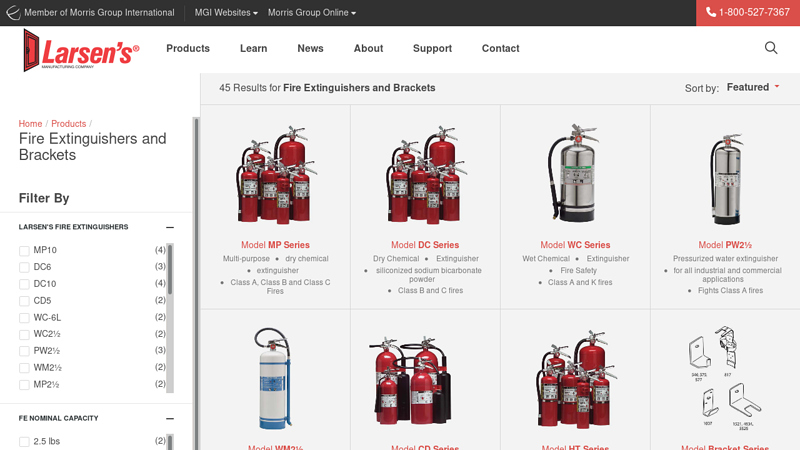

#4 Fire Extinguishers & Brackets

Domain Est. 1997

Website: larsensmfg.com

Key Highlights: Larsen’s Manufacturing Co. is a leading manufacturer of fire extinguishers, including carbon dioxide and multi-use, and fire extinguishers brackets….

#5 Amerex Fire

Domain Est. 1996

Website: amerex-fire.com

Key Highlights: Supportive information for all of our products, including product manuals, tech tips, safety data sheets, basic usage instructions, videos and a host of other ……

#6

Domain Est. 1996

Website: buckeyef.com

Key Highlights: Buckeye Fire offers a complete line of handheld and wheeled fire extinguishers, extinguishing agents, fire suppressing foam concentrates & hardware….

#7 AKE Safety Equipment: STOP

Domain Est. 1997

Website: ake.com

Key Highlights: STOP-FYRE® is a clean-agent, non-corrosive fire extinguisher that protects equipment, vehicles, and buildings with zero mess and no maintenance….

#8 Fire Extinguishers, Amerex, Security Fire Equipment …

Domain Est. 2007

Website: amerexfireextinguishers.com

Key Highlights: Free delivery over $150Fire Extinguisher Sales, Amerex Fire Extinguishers, commercial & residential fire extinguishers, ABC fire extinguishers, fire extinguisher brackets….

#9 Fire Extinguisher Depot

Domain Est. 2012

Website: fireextinguisherdepot.com

Key Highlights: Fire Extinguisher Depot stocks the best fire extinguishers, brackets, cabinets, and accessories. We have the lowest prices and industry leading service….

#10 Pye

Domain Est. 2022

Website: pyebarkerfs.com

Key Highlights: We offer all the necessary specialties including portable fire extinguishers, restaurant fire suppression, special hazard systems, fire sprinklers, fire alarms ……

Expert Sourcing Insights for Fire Extinguisher Large

H2: Projected Market Trends for Large Fire Extinguishers in 2026

The global market for large fire extinguishers is poised for significant transformation by 2026, driven by evolving safety regulations, technological advancements, and growing awareness of fire risk management across industrial, commercial, and public infrastructure sectors. This analysis outlines key trends expected to shape the large fire extinguisher market in 2026, focusing on demand drivers, technological innovation, regional dynamics, and regulatory influences.

-

Rising Demand from Industrial and Commercial Sectors

Industrial facilities such as oil and gas refineries, chemical plants, and manufacturing units remain primary consumers of large fire extinguishers due to stringent safety requirements and high fire risks. By 2026, increased investments in industrial automation and expansion in emerging economies—particularly in Asia-Pacific and Latin America—are expected to boost demand. Additionally, the growth of large-scale commercial complexes, data centers, and logistics warehouses will further stimulate the need for robust fire suppression systems, including large-capacity portable and fixed extinguishers. -

Shift Toward Environmentally Friendly Fire Suppression Agents

Environmental regulations are influencing the formulation of fire extinguishing agents. Traditional halon-based and hydrofluorocarbon (HFC) extinguishers are being phased out due to their high global warming potential (GWP). By 2026, the market is expected to see a greater adoption of eco-friendly alternatives such as clean agents (e.g., Novec 1230, FM-200), water mist systems, and advanced dry powders with lower environmental impact. This trend is especially pronounced in Europe and North America, where regulatory frameworks like the EU F-Gas Regulation and U.S. EPA SNAP program are accelerating the transition. -

Integration of Smart Technology and IoT

Smart fire safety systems are gaining traction, and large fire extinguishers are no exception. By 2026, manufacturers are expected to increasingly incorporate IoT-enabled sensors that monitor pressure levels, tampering, and maintenance needs in real time. These connected devices allow facility managers to ensure compliance and reduce downtime through predictive maintenance. The integration of smart extinguishers into broader building management systems (BMS) will enhance emergency response efficiency and support data-driven safety audits. -

Regulatory Compliance as a Market Driver

Governments and international bodies are tightening fire safety codes, particularly for high-risk environments. In 2026, compliance with standards such as NFPA 10 (Standard for Portable Fire Extinguishers) and ISO 7190 will be mandatory in most developed and developing markets. These regulations often specify minimum sizes, placement, and servicing intervals for large extinguishers, directly influencing procurement patterns. In regions like the Middle East and Southeast Asia, rising urbanization and infrastructure development are prompting the adoption of stricter fire safety protocols, further expanding market opportunities. -

Regional Market Growth Disparities

While North America and Europe will maintain steady growth due to replacement cycles and regulatory upgrades, the Asia-Pacific region is expected to lead market expansion in 2026. Countries such as China, India, and Indonesia are witnessing rapid industrialization and urban development, necessitating large-scale fire protection systems. Government-led safety initiatives and public infrastructure projects, including metro systems and smart cities, will be key demand catalysts. -

Focus on Training and Maintenance Services

As fire extinguishers grow in complexity and capacity, end-users are placing greater emphasis on training and maintenance. By 2026, market leaders are expected to offer bundled service solutions, including installation, staff training, and digital maintenance tracking. This shift toward value-added services will improve customer retention and open new revenue streams for manufacturers and distributors.

Conclusion

The large fire extinguisher market in 2026 will be characterized by innovation, sustainability, and digital integration. Driven by regulatory mandates, industrial growth, and technological progress, the sector is moving beyond basic fire suppression toward intelligent, eco-conscious solutions. Companies that adapt to these trends—by investing in R&D, expanding service offerings, and targeting high-growth regions—will be well-positioned to capture market share in the evolving fire safety landscape.

Common Pitfalls When Sourcing Large Fire Extinguishers (Quality, IP)

Sourcing large fire extinguishers—especially those with specific quality standards and Ingress Protection (IP) ratings—can present several challenges. Failing to address these pitfalls can compromise safety, compliance, and operational effectiveness. Below are key issues to watch for:

Poor Manufacturing Quality

One of the most significant risks is selecting extinguishers from manufacturers that cut corners on materials or assembly. Low-quality units may use substandard steel for the cylinder, leading to corrosion or pressure failure. Internal components like valves and seals may degrade prematurely, resulting in leaks or failure during discharge. Always verify compliance with recognized standards such as ISO 9001, and insist on third-party testing certifications.

Inaccurate or Missing IP Ratings

Large fire extinguishers deployed in harsh environments (e.g., outdoor, industrial, or marine settings) require proper Ingress Protection (IP) ratings to resist dust, moisture, and corrosion. A common pitfall is suppliers claiming an IP rating without certification or providing units with inadequate seals and enclosures. Always request documented proof of IP testing (e.g., IEC 60529) and verify that both the extinguisher and its mounting hardware meet the required rating (e.g., IP65 or higher for outdoor use).

Non-Compliance with Regional Safety Standards

Fire safety regulations vary by country and region (e.g., UL in the U.S., CE in Europe, AS/NZS in Australia). Sourcing extinguishers not certified for the target market can lead to failed inspections, legal liability, or ineffective performance. Ensure extinguishers carry the correct local certifications and are listed with accredited testing laboratories.

Inadequate Pressure and Discharge Testing

Large extinguishers must undergo rigorous hydrostatic and discharge testing to ensure reliability. Some suppliers may skip or falsify test records. Verify that each unit comes with a valid test certificate, including pressure ratings, burst test results, and periodic inspection schedules. Units without proper documentation should be rejected.

Misrepresentation of Extinguisher Capacity and Type

Suppliers may misstate the actual capacity (e.g., 50kg vs. 45kg) or mislabel the extinguishing agent (e.g., claiming Class K when it’s only Class B/C). This can lead to improper fire response. Always cross-check technical specifications against independent certifications and conduct spot checks upon delivery.

Poor Corrosion Resistance and Finish

Large extinguishers in coastal or industrial areas require robust anti-corrosion protection. Units with thin powder coating or galvanization may rust quickly, compromising integrity. Inspect the finish quality and confirm use of corrosion-resistant materials, especially for outdoor-mounted units.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including batch numbers, manufacturing dates, and maintenance logs. Sourcing from vendors without proper documentation makes it difficult to manage inspections, recalls, or warranty claims. Demand comprehensive records before finalizing procurement.

Avoiding these pitfalls requires due diligence, supplier vetting, and insistence on verified certifications. Prioritizing quality and compliance ensures that large fire extinguishers perform reliably when needed most.

Logistics & Compliance Guide for Fire Extinguisher (Large)

Overview and Scope

This guide outlines the logistics handling, transportation, storage, and regulatory compliance requirements for large fire extinguishers, typically defined as units exceeding 10 lbs (4.5 kg) or 2.5 gallons (9.5 L) in capacity. Proper management is essential to ensure safety, legal compliance, and operational readiness.

Regulatory Framework and Applicable Standards

Large fire extinguishers are subject to multiple national and international regulations due to their pressurized contents and potential hazards. Key regulatory standards include:

– OSHA 29 CFR 1910.157 – Workplace fire extinguisher requirements (placement, inspection, maintenance).

– NFPA 10: Standard for Portable Fire Extinguishers – Installation, inspection, testing, and maintenance guidelines.

– DOT 49 CFR Parts 100–185 – U.S. Department of Transportation regulations for the safe transportation of hazardous materials.

– IATA Dangerous Goods Regulations (DGR) – Air transport compliance for international shipments.

– IMDG Code – International Maritime Dangerous Goods Code for sea freight.

Compliance with these standards is mandatory during storage, handling, and transportation.

Classification and Hazard Identification

Large fire extinguishers are generally classified as hazardous materials due to internal pressure and, in some cases, chemical content. Classification depends on extinguisher type:

– Water, Foam, or Dry Chemical (e.g., ABC) – Typically Class 2.2 (Non-flammable, non-toxic gas) under DOT and UN regulations.

– CO₂ Extinguishers – Classified as UN 1044, Compressed Gas, Non-flammable, Non-toxic, Hazard Class 2.2.

– Clean Agent (e.g., Halotron, FE-36) – May fall under Class 2.2 or require additional handling due to environmental impact (e.g., ozone depletion potential).

Always verify the Safety Data Sheet (SDS) and labeling to determine exact classification.

Packaging and Labeling Requirements

Proper packaging and labeling are critical for safe transport:

– Use manufacturer-certified packaging designed to prevent valve damage and leakage.

– Secure safety pin and tamper seal; ensure the discharge horn or nozzle is protected.

– Affix appropriate hazard labels: Class 2.2 Gas label and “Cylinder” marking.

– Include proper shipping name (e.g., “Non-flammable compressed gas in cylinder”) and UN number (e.g., UN 1044).

– Include shipper/consignee information and orientation arrows if required.

For international shipments, ensure compliance with IATA or IMDG labeling standards based on mode of transport.

Transportation Guidelines

Transport of large fire extinguishers must follow strict procedures:

– Ground (DOT): Secure upright in a well-ventilated vehicle. Use restraints to prevent rolling or impact. Avoid extreme temperatures.

– Air (IATA): Subject to quantity and pressure limits. Most large extinguishers are permitted as cargo if properly labeled and packaged; crew/passenger carry-on restrictions apply.

– Sea (IMDG): Must be stowed in accordance with segregation and ventilation rules. Include proper documentation in the Dangerous Goods Declaration.

Never transport damaged, leaking, or corroded extinguishers.

Storage and Handling Procedures

Safe storage minimizes risks and ensures compliance:

– Store upright in a dry, well-ventilated area away from heat sources (>120°F/49°C) and direct sunlight.

– Maintain clear access and avoid clutter; follow OSHA/NFPA placement guidelines (e.g., within 30–75 ft of hazard zones).

– Protect from physical damage using wall brackets or cabinets.

– Conduct monthly visual inspections per NFPA 10: check pressure gauge, seal integrity, corrosion, and accessibility.

– Maintain service tags and log inspection dates.

Maintenance and Recharge Compliance

Fire extinguishers must be serviced regularly:

– Annual Inspection: Full visual and mechanical check by a certified technician.

– 6-Year Maintenance (Internal Examination): Required for most large extinguishers—discharge, inspect internals, reassemble, and recharge.

– Hydrostatic Testing: Conducted every 5–12 years (varies by type and material) to test cylinder integrity.

– After use (even partial), extinguishers must be recharged or replaced immediately.

Only licensed professionals should perform maintenance and recharge procedures.

Disposal and Decommissioning

End-of-life extinguishers cannot be discarded in regular waste:

– Depressurize and empty contents by a certified technician.

– Recycle metal cylinders through approved hazardous waste or scrap metal facilities.

– Follow EPA and local regulations for disposal of chemical agents (e.g., dry powder, halogenated agents).

– Maintain disposal records for compliance audits.

Documentation and Recordkeeping

Maintain comprehensive records to demonstrate compliance:

– Inspection logs (monthly, annual, 6-year, hydrostatic)

– Maintenance and recharge certificates

– Shipping manifests and hazardous materials declarations

– Disposal records and recycling certificates

– Training records for personnel handling extinguishers

Retention period: Minimum 3–5 years, or per organizational policy.

Training and Personnel Safety

All personnel involved in logistics or maintenance must receive training on:

– Hazard identification and PPE use (gloves, eye protection)

– Safe handling and lifting techniques (large extinguishers can weigh 20–100+ lbs)

– Emergency response for leaks or damage

– Regulatory requirements (DOT, OSHA, NFPA)

Training should be documented and refreshed annually.

Emergency Response and Incident Reporting

In case of damage, leakage, or accidental discharge:

– Evacuate and ventilate the area.

– For CO₂ or clean agent discharge, avoid confined spaces due to asphyxiation risk.

– Report incidents to supervisor and safety officer.

– Document the event and initiate corrective actions.

– Notify authorities if hazardous materials are released into the environment.

Conclusion

Proper logistics and compliance management of large fire extinguishers ensures safety, regulatory adherence, and equipment reliability. Adherence to OSHA, NFPA, DOT, IATA, and IMDG standards is essential throughout the lifecycle—from procurement to disposal. Regular training, documentation, and inspections are critical components of an effective fire safety program.

Conclusion for Sourcing Large Fire Extinguishers:

Sourcing large fire extinguishers is a critical step in ensuring robust fire safety for commercial, industrial, or high-risk environments. After evaluating suppliers, product specifications, compliance standards, cost, and maintenance support, it is evident that selecting the right extinguisher involves more than just capacity—factors such as type (e.g., CO2, dry chemical, foam), ease of servicing, durability, and certification to local and international standards (such as NFPA, UL, or EN) are essential. A strategic sourcing approach should prioritize reliability, long-term performance, and supplier reputation to ensure safety compliance and operational efficiency. Ultimately, investing in high-quality, appropriately sized fire extinguishers not only enhances emergency response capabilities but also demonstrates a commitment to workplace safety and regulatory adherence.