The global fire safety equipment market is experiencing robust growth, driven by increasing regulatory mandates, rising industrialization, and growing awareness around occupational safety. According to a report by Mordor Intelligence, the global fire protection equipment market was valued at USD 76.8 billion in 2022 and is projected to grow at a CAGR of over 9.5% from 2023 to 2028. A key segment within this landscape is fire-resistant materials, particularly fire blanket rolls—critical for flame suppression in industrial, commercial, and maritime environments. With expanding infrastructure development and stricter safety codes, especially in the oil & gas, automotive, and construction sectors, demand for high-performance fire blanket rolls is on the rise. This surge has led to heightened competition and innovation among manufacturers who specialize in heat- and flame-resistant textile solutions. Below, we explore the top nine fire blanket roll manufacturers leading the market through technological advancement, scalable production, and global certifications.

Top 9 Fire Blanket Roll Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fiberglass Fire Blanket Manufacturers

Domain Est. 2012

Website: wellcoindustries.com

Key Highlights: Wellco Industries has its own fire blanket fiberglass factory in China to produce high quality fiberglass fire blanket fabric roll, and can customize various ……

#2 Welding & Fire Blanket Rolls

Domain Est. 2006

Website: steelguardsafety.com

Key Highlights: These welding blanket rolls or High Temperature Fabrics are used in the fabrication of removable insulation blankets, pipe wrapping, turbine blankets, flange ……

#3 Fire Blanket Manufacturers & Wholesale & Company

Domain Est. 2024

Website: insofire.com

Key Highlights: We developed and improved many fiberglass fabrics, choose the most suitable material to produce fire blankets….

#4 Roll Blankets

Domain Est. 1999

Website: jtillman.com

Key Highlights: Welding Blankets & Roll Goods. Tillman® ArcDefender roll welding blankets are great for covering objects that need to be protected from sparks and spatter….

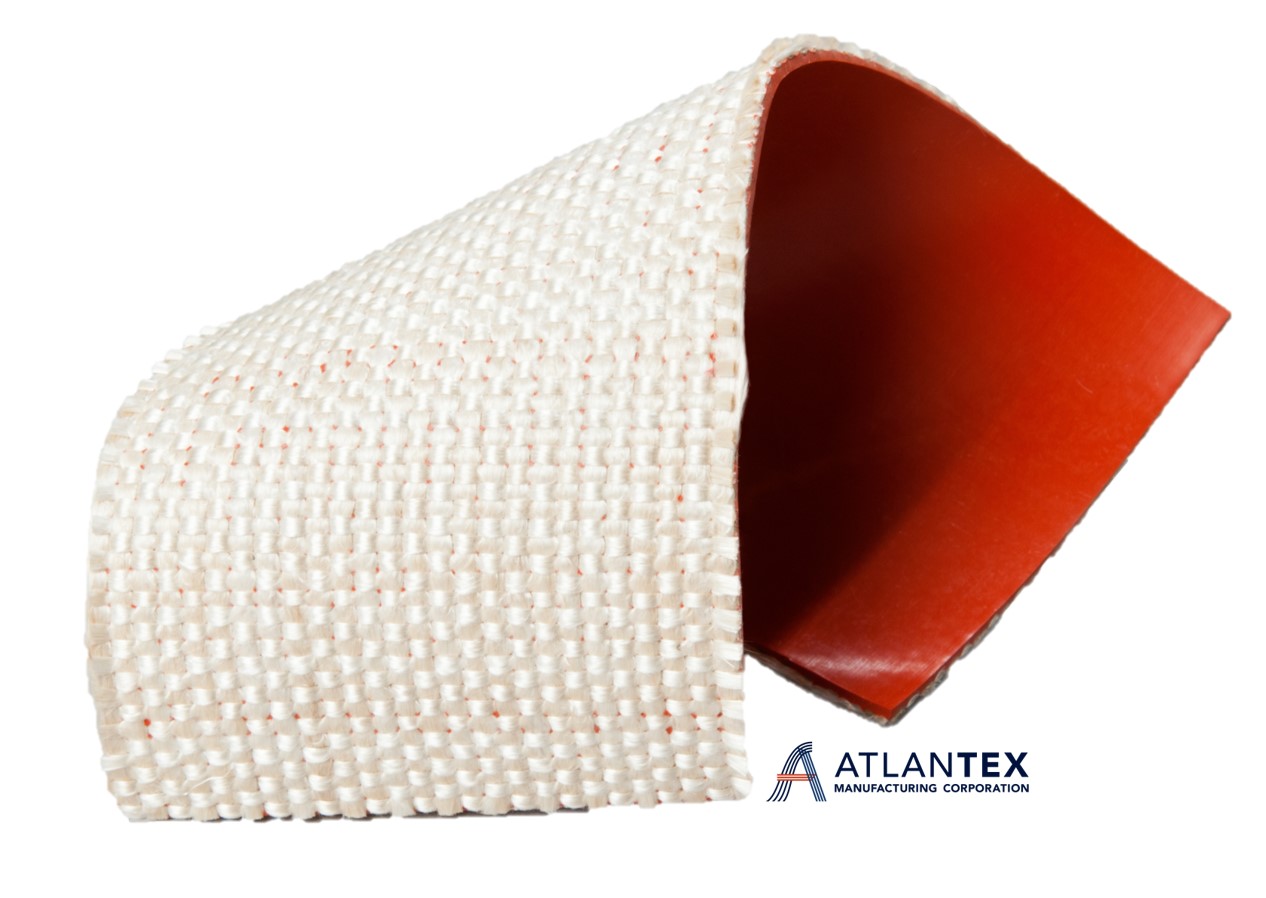

#5 Pyrotex Thermal Blanket

Domain Est. 2003

Website: atlantexmfg.com

Key Highlights: Pyrotex SG Blankets are high temperature heat resistant fabrics designed to meet the protection requirements for hoses, cables, equipment and machinery in all ……

#6 Car Fire Blankets

Domain Est. 2009

Website: bridgehill.com

Key Highlights: Bridgehill EV Fire Blanket | The most efficient way to control and isolate EV fires. Melting point ± 2500 °C. Reusable up to 30 times….

#7 Welding Blankets

Domain Est. 2010

Website: tarpsnow.com

Key Highlights: 3–9 day deliveryThese durable and heat resistant fabric Welding Covers and Heavy Duty Tarps provide excellent protection against dangerous sparks, welding slag, splatter….

#8 Fire Blankets

Domain Est. 2010

Website: chubbfs.com

Key Highlights: Chubb’s range of high quality fire blankets are designed to extinguish small stovetop fires caused by cooking fats and oils, as well as small clothing fires….

#9 Welding Blankets & Roll Goods

Domain Est. 2020

Website: trust-protection.com

Key Highlights: 17 products · 6010 HEAVY DUTY 36OZ BRONZE SILICA WELDING BLANKET · 6010 HEAVY DUTY 36OZ BRONZE SILICA WELDING BLANKET · 6020 HEAVY DUTY 18OZ BRONZE SILICA WELDING ……

Expert Sourcing Insights for Fire Blanket Roll

H2: 2026 Market Trends for Fire Blanket Roll

The global fire blanket roll market is poised for significant growth and transformation by 2026, driven by increased fire safety awareness, stringent regulatory standards, and expanding applications across residential, commercial, and industrial sectors. This analysis explores key trends shaping the fire blanket roll industry in the coming years.

-

Rising Demand in Residential and Commercial Sectors

With urbanization accelerating and building codes becoming more rigorous, fire blanket rolls are increasingly being integrated into fire safety protocols for homes, apartments, hotels, and restaurants. The kitchen fire risk, especially in compact living spaces, has led to a surge in demand for fire blanket rolls as a simple, effective suppression tool. By 2026, residential adoption is expected to grow at a CAGR of over 6%, particularly in regions like Asia-Pacific and North America. -

Regulatory Push and Safety Standards

Governments and fire safety organizations worldwide are updating fire prevention guidelines to include accessible fire suppression tools. In Europe and North America, mandatory installation of fire safety equipment in public and commercial buildings now often includes fire blanket rolls, especially in kitchens and high-risk areas. These regulations will act as a key market driver through 2026. -

Technological Advancements and Material Innovation

Manufacturers are investing in advanced materials such as fiberglass, Kevlar, and ceramic fibers to improve heat resistance, durability, and ease of use. Lightweight, compact, and reusable fire blanket rolls are gaining traction, especially in industrial and marine applications. Smart fire blanket rolls with integrated deployment indicators or IoT-enabled alerts are expected to emerge by 2026, particularly in smart building ecosystems. -

Growth in Industrial and Transportation Applications

Beyond kitchens, fire blanket rolls are being adopted in manufacturing, oil & gas, aerospace, and transportation sectors to manage lithium-ion battery fires and electrical hazards. The rise of electric vehicles (EVs) has created a new niche for fire blanket rolls designed to contain battery thermal runaway incidents. This trend is expected to significantly boost market demand in the industrial segment. -

Expansion in Emerging Markets

Countries in Southeast Asia, Latin America, and the Middle East are witnessing increased investments in infrastructure and fire safety infrastructure. As awareness grows and distribution networks expand, fire blanket rolls are becoming more accessible in these regions. Local manufacturing and partnerships with global suppliers will further accelerate market penetration. -

E-commerce and Direct-to-Consumer Sales

The online retail channel is becoming a major distribution avenue for fire blanket rolls. Educational campaigns through digital platforms are helping consumers understand the importance of fire preparedness, leading to higher direct purchases. By 2026, e-commerce is projected to account for nearly 30% of total fire blanket roll sales.

Conclusion

The fire blanket roll market is set for robust expansion by 2026, fueled by regulatory support, technological innovation, and growing fire safety consciousness. Companies that focus on product differentiation, compliance, and market education will be well-positioned to capitalize on these emerging opportunities across diverse end-use sectors.

Common Pitfalls When Sourcing Fire Blanket Roll (Quality and IP)

Sourcing fire blanket rolls requires careful attention to both quality standards and intellectual property (IP) considerations. Overlooking these aspects can lead to safety risks, legal issues, and reputational damage. Below are key pitfalls to avoid:

Inadequate Material Quality and Certification

One of the most frequent pitfalls is selecting fire blanket rolls that do not meet required fire resistance standards. Inferior materials may fail under high heat, compromising safety. Always verify that the product complies with recognized certifications such as EN 1869, UL, or ASTM. Avoid suppliers who cannot provide up-to-date test reports or third-party certification documents.

Lack of Consistent Thickness and Weight

Fire blanket performance heavily depends on fabric thickness and weight per square meter. Sourcing rolls with inconsistent or substandard specifications can result in uneven fire protection. Ensure technical datasheets clearly state GSM (grams per square meter) and thickness, and request samples to verify consistency across batches.

Poor Seam and Edge Integrity

Weak seams or fraying edges can cause the blanket to tear during deployment. Some low-cost suppliers use improper stitching or fail to hem edges properly. Evaluate sample rolls for seam strength and edge finishing to prevent field failures.

Misrepresentation of Fiber Composition

Suppliers may claim the blanket is made from 100% fiberglass or other high-performance fibers, but substitute lower-grade materials to cut costs. Conduct fiber analysis or request material composition reports to confirm authenticity. Misleading claims can also constitute IP or labeling violations.

Ignoring Intellectual Property Rights

Sourcing fire blanket rolls from manufacturers who infringe on patented technologies or registered designs exposes buyers to legal liability. For example, using a flame-retardant treatment or weave pattern protected by IP without authorization may lead to lawsuits or customs seizures. Conduct due diligence on the supplier’s right to manufacture and sell the product.

Copying Branded or Proprietary Designs

Some suppliers replicate well-known branded fire blankets, including logos, packaging, or performance claims. Purchasing counterfeit or imitation products not only violates IP laws but also risks receiving subpar quality. Always verify trademarks and avoid suppliers offering “equivalent” versions of proprietary products without proper licensing.

Incomplete or Missing Documentation

Reputable suppliers provide full technical documentation, safety data sheets (SDS), and compliance certificates. Lack of transparency in documentation is a red flag for both quality and IP issues. Ensure all paperwork is available in your required language and jurisdiction.

Overlooking Country of Origin and Import Regulations

Different countries have specific import rules regarding fire safety products and IP enforcement. Sourcing from regions with weak IP protections increases the risk of receiving counterfeit goods. Additionally, non-compliant products may be rejected at customs, causing delays and financial loss.

Failure to Audit Suppliers

Relying solely on product samples or claims without auditing the manufacturer’s facility can lead to unexpected quality drops. Conduct on-site or third-party audits to assess production processes, quality control systems, and IP compliance practices.

Choosing Price Over Performance and Legitimacy

While cost is a factor, prioritizing low pricing often leads to compromised quality and potential IP violations. A slightly higher investment in certified, legally compliant fire blanket rolls ensures safety, regulatory approval, and long-term reliability.

By addressing these pitfalls proactively, buyers can source fire blanket rolls that meet both performance standards and legal requirements, minimizing risk and ensuring end-user safety.

Logistics & Compliance Guide for Fire Blanket Roll

Product Classification and Identification

Fire blanket rolls are classified as fire safety equipment designed to smother small fires, particularly those involving cooking oils or electrical sources. They are typically made from flame-resistant materials such as fiberglass or wool, treated with fire-retardant chemicals. Proper identification includes product name, material composition, size (length and width), weight per meter or roll, and compliance markings (e.g., CE, UKCA, or other regional certifications). A unique SKU or product code should be assigned for inventory and tracking purposes.

Regulatory Compliance Requirements

Fire blanket rolls must comply with regional and international safety standards. In the European Union, compliance with EN 1869:1997 is mandatory, requiring fire blankets to withstand ignition from a 500 ml pan of burning oil for at least 60 seconds without flame penetration. In the UK, the UKCA mark is required post-Brexit, while in the US, adherence to NFPA standards may apply depending on the application. Manufacturers and distributors must provide evidence of third-party testing and certification. Documentation such as Declaration of Conformity (DoC) and test reports must accompany shipments.

Packaging and Labeling Standards

Fire blanket rolls should be vacuum-sealed or tightly wrapped in moisture-resistant, durable plastic to prevent contamination and damage during transit. Each roll must be labeled with essential information including product name, batch/lot number, manufacturing and expiry dates, compliance marks, handling instructions (e.g., “Keep Dry,” “Do Not Fold Sharply”), and safety warnings. Multilingual labeling may be required for international distribution. Tamper-evident packaging is recommended to ensure product integrity.

Storage Conditions

Store fire blanket rolls in a cool, dry, and well-ventilated area, away from direct sunlight, heat sources, and humidity. Ideal storage temperatures range between 5°C and 35°C. Rolls should be kept on pallets or shelves to avoid floor moisture and protected from dust and chemical exposure. Ensure adequate spacing between stacks for air circulation and easy access during inventory checks. Avoid compressing rolls under heavy loads to prevent material deformation.

Transportation and Shipping Guidelines

When shipping fire blanket rolls, use sturdy corrugated cardboard boxes or protective roll containers to prevent crushing or abrasion. Secure loads on pallets using stretch wrap or strapping to minimize movement during transit. Clearly label outer packaging with orientation arrows (“This Way Up”), fragile indicators if applicable, and proper shipping names. For air freight, ensure packaging meets IATA requirements for non-hazardous goods. Ground and sea shipments should comply with IMDG or ADR regulations as appropriate, though fire blankets are typically non-hazardous.

Import/Export Documentation

For international logistics, prepare a complete set of documentation including commercial invoice, packing list, bill of lading or air waybill, and certificate of origin. Include copies of compliance certifications (e.g., CE, UKCA, test reports) and the Declaration of Conformity. Verify tariff classifications (HS Code – typically 5911.31 or similar for textile fire protection fabrics) and confirm any import duties or taxes applicable in the destination country. Some regions may require additional permits or conformity assessments upon entry.

Quality Control and Batch Tracking

Implement a quality assurance process that includes random sampling of incoming and outgoing rolls for material integrity, size accuracy, and labeling correctness. Maintain batch traceability through serialized batch numbers and a documented production log. In the event of a recall or compliance audit, this system allows rapid identification and isolation of affected batches. Retain quality records for a minimum of five years or as required by local regulations.

End-of-Life and Environmental Considerations

Fire blanket rolls are generally non-hazardous at end-of-life but should not be disposed of in regular landfill if contaminated with hazardous substances (e.g., oil residues). Recycle or dispose of according to local waste regulations. Fiberglass-based blankets may require special handling due to fiber content. Provide disposal guidelines in product documentation. Manufacturers are encouraged to follow WEEE or RoHS directives where applicable, particularly if metal components (e.g., containment box parts) are included.

Training and Handling Procedures

Personnel involved in logistics—warehouse staff, packers, and transport handlers—should receive training on proper handling techniques to avoid damaging the fire blanket material. Emphasize the importance of avoiding sharp objects, excessive bending, or exposure to moisture. Training should also cover recognition of compliance labels and reporting of damaged or non-conforming products. Maintain training records for audit purposes.

Conclusion for Sourcing Fire Blanket Roll:

Sourcing fire blanket rolls is a critical step in ensuring effective fire safety measures in industrial, commercial, and residential environments. After evaluating suppliers, material quality, compliance standards (such as EN 1869 or ASTM), cost-efficiency, and customization options, it is evident that partnering with reputable manufacturers who provide durable, certified, and competitively priced fire blanket rolls is essential. Bulk sourcing not only reduces per-unit costs but also ensures consistent availability for large-scale safety programs. Prioritizing flame-resistant materials like fiberglass or wool, coupled with proper packaging and logistical support, enhances both safety reliability and operational efficiency. In conclusion, strategic sourcing of fire blanket rolls contributes significantly to fire risk mitigation, regulatory compliance, and overall workplace safety, making it a vital investment for any fire prevention strategy.