The global fasteners market, driven by sustained growth in construction and woodworking industries, is projected to expand at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. With interior finishing accounting for a significant share of non-structural fastener demand, molding manufacturers increasingly rely on precision-engineered finishing nails that balance holding power, minimal visibility, and material compatibility. As wood trim, baseboards, and crown molding remain staples in both residential and commercial construction, the need for high-performance fasteners has intensified. This has led to innovations in nail coatings, shank designs, and head styles tailored specifically for delicate molding applications. In this context, selecting the right finishing nail is not merely a matter of cost—it directly impacts product quality, installation efficiency, and long-term durability. Based on performance metrics, industry adoption, and compatibility with pneumatic tools, the following six finishing nails stand out as top choices for molding manufacturers seeking reliable, scalable solutions in a competitive market.

Top 6 Finishing Nails For Molding Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Nails

Domain Est. 1993

#2 Trim Nails

Domain Est. 1995

Website: strongtie.com

Key Highlights: These tape-collated, DA-style angle, 15-gauge finishing nails are ideal for trim and molding applications, featuring a D-style head that provides firm holding ……

#3 Maze Nails Company

Domain Est. 1995

Website: mazenails.com

Key Highlights: Maze Nails have been trusted by professionals for more than a century. Our top quality hot dip galvanizing process delivers superior corrosion resistance….

#4 Finish Nails

Domain Est. 1996

Website: paslode.com

Key Highlights: Paslode finish nails are specially engineered to reduce splitting and protect your finish. Shop the collection now….

#5 Fine Finish Nail

Domain Est. 2000

Website: tremontnail.com

Key Highlights: Fine Finish nails are popular where a slim brad-head nail is appropriate. Often used in furniture repair, cabinet work, batten doors, paneling, and countertops….

#6 Finishing Nails

Domain Est. 2002

Website: grip-rite.com

Key Highlights: Our finishing nails can be used in a range of applications, including: Molding: Use the 16-gauge straight finish nails for crown molding projects. Carpentry ……

Expert Sourcing Insights for Finishing Nails For Molding

H2: 2026 Market Trends for Finishing Nails for Molding

As the construction and remodeling sectors continue to evolve, the market for finishing nails for molding is expected to undergo significant changes by 2026. Driven by advancements in materials, sustainability demands, and shifting consumer preferences, several key trends are shaping the future of this niche fastener segment.

1. Increased Demand from Residential Remodeling

The ongoing rise in home improvement and renovation projects—particularly in North America and Western Europe—is fueling demand for high-quality finishing nails. With homeowners investing in aesthetic upgrades like crown molding, baseboards, and trim work, precision fasteners that ensure clean, invisible installations remain essential. The remodeling boom, supported by low-interest refinancing and aging housing stock, is expected to sustain growth through 2026.

2. Shift Toward Corrosion-Resistant and Specialty Coatings

As moisture-resistant and engineered wood molding products gain popularity, finishing nails with enhanced corrosion resistance—such as those with blued, galvanized, or ceramic coatings—are becoming more prevalent. These specialized finishes prevent staining and rust, especially in kitchens, bathrooms, and coastal regions. By 2026, manufacturers are likely to expand product lines to meet these performance requirements.

3. Growth in Pneumatic and Cordless Nail Gun Compatibility

The widespread adoption of finish nail guns in both professional and DIY markets is driving demand for finishing nails optimized for pneumatic and cordless tools. Standardization in shank diameter (15- and 16-gauge) and head design ensures reliable feeding and reduced jamming. The convenience and speed of nail guns are pushing manufacturers to produce consistent, high-tolerance nails compatible with top tool brands.

4. Sustainability and Eco-Friendly Production

Environmental regulations and consumer preferences are pushing manufacturers to adopt greener production methods. By 2026, expect increased use of recycled steel and low-emission coating technologies in finishing nail manufacturing. Additionally, packaging is shifting toward recyclable materials, aligning with broader industry sustainability goals.

5. Regional Market Diversification

While North America remains the largest market due to high DIY activity and new construction, emerging markets in Southeast Asia and the Middle East are showing growth potential. Urbanization and rising disposable incomes are boosting demand for decorative interior finishes, creating new opportunities for finishing nail suppliers.

6. Technological Integration in Supply Chains

Digital inventory management, e-commerce platforms, and AI-driven demand forecasting are transforming how finishing nails are distributed. By 2026, B2B suppliers and retailers will increasingly rely on real-time data analytics to optimize stock levels and reduce lead times, improving responsiveness to market fluctuations.

In summary, the finishing nails for molding market in 2026 will be characterized by innovation in materials, a focus on tool compatibility, and a strong emphasis on sustainability. As aesthetic craftsmanship continues to influence interior design, the demand for reliable, high-performance fasteners will remain robust across both professional and consumer segments.

Common Pitfalls When Sourcing Finishing Nails for Molding (Quality, IP)

Sourcing finishing nails for molding projects requires careful attention to both quality and intellectual property (IP) considerations—especially when procuring in bulk or from overseas suppliers. Overlooking key factors can lead to substandard installations, product failures, or legal complications. Below are common pitfalls to avoid.

1. Prioritizing Low Cost Over Material Quality

One of the most frequent mistakes is selecting nails based solely on price. Low-cost finishing nails may be made from inferior steel or lack proper coating, leading to rust, splitting wood, or poor holding power. For molding applications, where precision and finish matter, using subpar nails can compromise the entire installation.

Solution: Specify high-quality materials such as hardened steel or stainless steel, and ensure nails have a smooth finish (e.g., bright, blued, or coated) to prevent staining or marring delicate moldings.

2. Ignoring Nail Dimensions and Specifications

Using nails with incorrect length, diameter (gauge), or head design can damage moldings or fail to secure them properly. Too long, and the nail may penetrate through the molding; too short, and it won’t hold adequately.

Solution: Match nail size precisely to the molding thickness and substrate. For most trim work, 1½” to 2″ 15- or 16-gauge nails are standard. Confirm specifications with technical data sheets from the supplier.

3. Overlooking Coating and Corrosion Resistance

In humid environments or when used with certain woods (e.g., pressure-treated or cedar), uncoated or poorly coated nails can corrode, causing discoloration and weakening joints.

Solution: Use nails with appropriate corrosion-resistant coatings such as galvanized, stainless steel, or ceramic-coated finishes, especially for interior bathrooms or exterior trim.

4. Assuming All “Finishing Nails” Are the Same

Not all finishing nails are created equal. Variations in manufacturing precision, head design, shank type (e.g., smooth vs. ring shank), and consistency in size can significantly impact performance.

Solution: Source from reputable manufacturers with consistent quality control. Request samples before bulk ordering to evaluate performance in your specific application.

5. Failing to Verify Compliance with Industry Standards

Some suppliers may claim adherence to ASTM or ANSI standards without certification. Non-compliant nails may not meet strength or dimensional tolerances required for professional molding work.

Solution: Ask for certification or test reports confirming compliance with standards such as ASTM F1667 (Standard Specification for Driven Fasteners).

6. Neglecting Intellectual Property (IP) in Sourcing

When sourcing branded or patented nail designs (e.g., specialized coatings, anti-clog designs, or proprietary head configurations), using counterfeit or cloned products can lead to IP infringement.

Solution: Purchase from authorized distributors or directly from original equipment manufacturers (OEMs). Avoid suppliers offering “compatible” or “equivalent” versions of patented nails without proper licensing.

7. Overlooking Packaging and Logistics Quality

Poor packaging can lead to rust, tangling, or contamination during transit—especially in humid climates. Loose or damaged nails compromise job-site efficiency and quality.

Solution: Insist on factory-sealed, moisture-resistant packaging with clear labeling. Confirm shipping and storage conditions with the supplier.

8. Skipping Supplier Vetting and Due Diligence

Sourcing from unknown suppliers—especially overseas—without verifying their manufacturing capabilities, quality control processes, or business legitimacy increases the risk of receiving counterfeit or substandard products.

Solution: Conduct supplier audits, request references, and use third-party inspection services when sourcing high-volume or mission-critical fasteners.

By avoiding these common pitfalls, contractors, builders, and procurement managers can ensure the finishing nails used for molding installations meet both performance expectations and legal requirements—delivering durable, professional results every time.

Logistics & Compliance Guide for Finishing Nails for Molding

Product Overview

Finishing nails for molding are slender, headless or low-head nails designed for securing wood trim, baseboards, crown molding, and other delicate interior applications. They are typically made from steel (commonly coated with vinyl, blued, or galvanized for corrosion resistance) and range in length from 1 inch to 3 inches. Proper logistics and regulatory compliance are essential for safe, efficient distribution and adherence to international and domestic standards.

Packaging and Labeling Requirements

Finishing nails are generally packaged in bulk quantities (e.g., boxes, cartons, or reels) for retail or wholesale distribution. Packaging must meet the following standards:

– Durability: Use moisture-resistant, crush-proof materials (e.g., corrugated cardboard with reinforced edges) to protect nails during transit.

– Labeling: Each package must include:

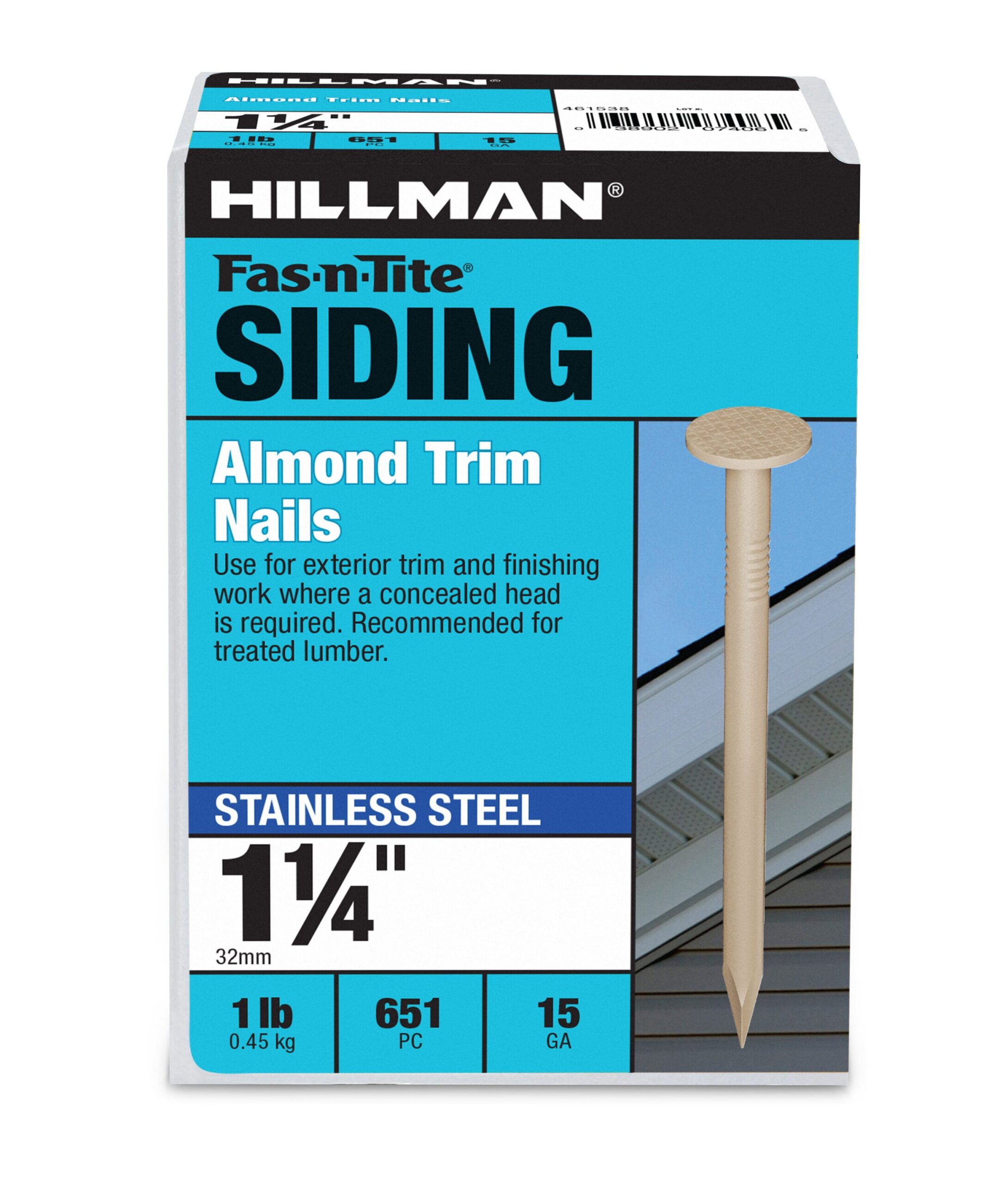

– Product name (e.g., “1-1/4” Vinyl-Coated Finishing Nails”)

– Nail length, gauge (diameter), and material (e.g., steel)

– Quantity (e.g., 1 lb, 500 pcs)

– Manufacturer or distributor name and contact information

– Country of origin (required for import/export)

– Safety warnings (e.g., “Caution: Sharp Object”)

– Retail Compliance: In the U.S., labels must comply with FTC guidelines; in the EU, with CE marking directives where applicable.

Transportation and Handling

- Domestic Shipping (U.S. and Canada):

- Use standard freight methods: LTL (Less-Than-Truckload) or parcel shipping for small orders.

- Secure loads with straps or pallet wrap; stack boxes to prevent crushing.

- Avoid exposure to moisture to prevent rust (especially for non-galvanized nails).

- International Shipping:

- Ship via sea freight (FCL or LCL) or air freight for urgent needs.

- Comply with ISPM 15 for wooden pallets (heat-treated and stamped).

- Use moisture-barrier wrapping or desiccants in containerized shipments.

- Hazard Classification:

- Finishing nails are generally non-hazardous under DOT, IATA, and IMDG regulations.

- Sharp objects must be securely packaged to prevent injury during handling.

Regulatory Compliance

- United States:

- CPSC (Consumer Product Safety Commission): No specific regulation for nails, but packaging must include injury warnings.

- Cal/OSHA: Workplace handling guidelines apply for bulk storage; sharp object protocols must be followed.

- EPA: If using zinc-coated (galvanized) nails, be aware of potential zinc runoff regulations in certain environmental zones.

- European Union:

- REACH (EC 1907/2006): Ensure nails do not contain restricted substances above threshold limits (e.g., lead, cadmium).

- RoHS: Not typically applicable to nails unless part of an electronic assembly.

- Canada:

- Health Canada: Follow general consumer product safety guidelines under the Canada Consumer Product Safety Act (CCPSA).

- Labeling: Bilingual (English/French) packaging required.

Import and Export Documentation

For cross-border shipments, ensure the following documents are prepared:

– Commercial Invoice: Includes product description, value, quantity, and Harmonized System (HS) Code.

– Packing List: Details weight, dimensions, and number of packages.

– Bill of Lading (BOL) or Air Waybill (AWB): Issued by carrier for shipment tracking.

– Certificate of Origin: May be required for preferential tariffs (e.g., USMCA).

– Customs Declarations: Accurate HS Code classification is critical:

– Typical HS Code: 7317.00 (Iron or steel nails, brads, staples, & similar articles).

– Confirm exact code with local customs authority based on coating and use.

Storage and Inventory Management

- Warehousing:

- Store in dry, temperature-controlled environments to prevent rust.

- Elevate pallets off the floor to avoid moisture absorption.

- Implement FIFO (First-In, First-Out) inventory rotation.

- Safety:

- Use protective gloves and footwear when handling bulk nails.

- Clearly mark storage areas with “Sharp Objects” signage.

Sustainability and Disposal

- Recyclability: Steel nails are 100% recyclable. Encourage end-user recycling through retailer take-back programs or scrap metal facilities.

- Packaging: Use recyclable cardboard and minimize plastic content.

- Waste Management: Discarded nails should be collected in puncture-resistant containers and disposed of as scrap metal.

Summary

Efficient logistics and strict compliance are vital for the global distribution of finishing nails for molding. Adhere to packaging, labeling, transportation, and regulatory standards in target markets to ensure safety, avoid customs delays, and maintain product integrity. Regular audits and documentation updates help maintain ongoing compliance.

In conclusion, sourcing finishing nails for molding requires careful consideration of several key factors to ensure a professional, durable, and aesthetically pleasing result. The choice of nail length, gauge, head style, and material should align with the type of molding, substrate, and environmental conditions (e.g., humidity or potential for corrosion). Prioritizing quality—such as using coated or stainless steel nails in moisture-prone areas—helps prevent issues like rust stains or nail pops over time.

Using the right tools, like a finishing nailer, enhances precision and efficiency, especially on large projects. Additionally, sourcing from reputable suppliers ensures consistent product quality and availability. Whether purchasing in bulk for commercial jobs or smaller quantities for DIY projects, comparing prices, reading reviews, and verifying specifications will lead to better long-term outcomes.

Ultimately, investing time in selecting the right finishing nails and reliable suppliers contributes to a seamless installation, a cleaner finish, and increased longevity of the molding work—making it a critical step in any trim or finish carpentry project.