The global demand for Filter Regulator Lubricator (FRL) units has seen steady growth, driven by increasing automation across manufacturing, automotive, and process industries. According to a 2023 report by Mordor Intelligence, the industrial automation market—of which pneumatic components like FRLs are integral—is projected to grow at a CAGR of over 9% from 2023 to 2028. This expansion is mirrored in the pneumatic equipment sector, where reliability and efficiency in compressed air systems have become critical performance indicators. Grand View Research further supports this trajectory, estimating that the global pneumatic equipment market size was valued at USD 19.8 billion in 2022 and is expected to grow at a CAGR of 5.1% through 2030. With rising adoption of Industry 4.0 technologies and heightened focus on energy efficiency, FRL units are playing an increasingly vital role in maintaining optimal pneumatic system performance. As demand surges, a select group of manufacturers have emerged as leaders, combining innovation, precision engineering, and global reach to dominate the landscape. The following list highlights the top 10 FRL manufacturers shaping the future of industrial automation.

Top 10 Filter Regulator Lubricator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1996 | Founded: 1929

Website: monnier.com

Key Highlights: We are Monnier. Monnier, Inc. has been manufacturing the highest quality filters, regulators and lubricators in Algonac, Michigan since 1929….

#2 Compressed Air Filter / Regulator / Lubricator (FRL) Combinations

Domain Est. 1995

Website: ph.parker.com

Key Highlights: Parker’s selection of air preparation (FRL) and dryer solutions comprise compressed-air, desiccant, and membrane dryers including regenerative, PSA, ……

#3 Filter/Regulator and Lubricator

Domain Est. 1996

Website: rosscontrols.com

Key Highlights: Filter/Regulator and Lubricator Combination Units. Bantam Series. Port Sizes 1/8″ & 1/4″; Flow to 23 scfm (651 l/min). Miniature Series. Port Sizes 1/8″ & 1/4″ ……

#4 to Alemite

Domain Est. 1996

Website: skf.com

Key Highlights: Air Filter/Regulator 7936. Filters. Filter Model 5604-3 · Filter Model 5606-3 · Filter Model 5608-3 · Filter Model 5612-2 · Filter Model 5616-2 · Filter Model ……

#5 FRL

Domain Est. 1996

Website: championpneumatic.com

Key Highlights: Champion’s modular Filters-Regulators-Lubricators (FRL’s) are the perfect choice for the most demanding applications with a compact and flexible design….

#6 FRL

Domain Est. 1997

Website: reedmfgco.com

Key Highlights: An FRL (filter-regulator-lubricator) appliance is key to preparing clean air for use in pneumatic system tools. Use of prepared air allows tools and equipment ……

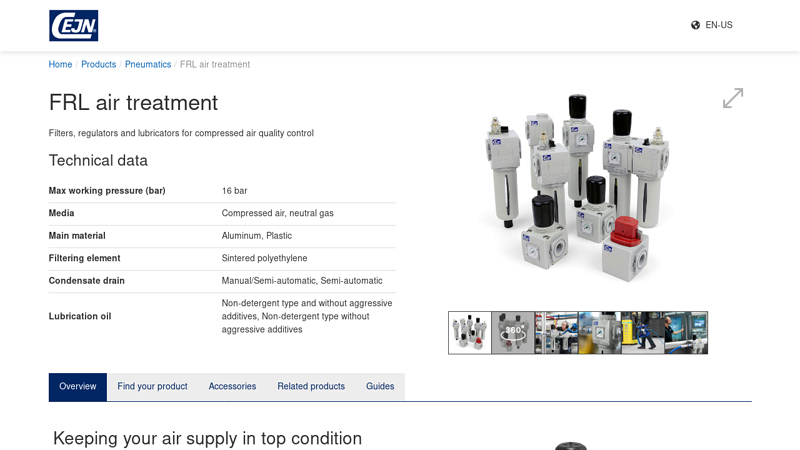

#7 FRL air treatment

Domain Est. 1997

Website: cejn.com

Key Highlights: CEJN FRL systems combine a shut-off valve, filter, regulator and lubricator in a ready-to-use set, ideal when space is limited….

#8 Filter/Regulator/Lubricator Combination

Domain Est. 1998

Website: airengineering.com

Key Highlights: Best Price & FREE Shipping on filter/regulator/lubricator combo. Perfect for the point of use application, one modular item that does it all….

#9 Filter

Domain Est. 2007

Website: prevostusa.com

Key Highlights: The extensive Prevost Filtration range provides professional level equipment for treating compressed air and pneumatic systems….

#10 Filters, Regulators & Lubrication (FRL)

Domain Est. 2012

Website: grozusa.com

Key Highlights: Free 30-day returnsOur FRL collection features a comprehensive range of high-quality components designed to deliver superior performance and reliability….

Expert Sourcing Insights for Filter Regulator Lubricator

H2: Projected 2026 Market Trends for Filter Regulator Lubricator (FRL) Units

The global Filter Regulator Lubricator (FRL) market is poised for steady growth through 2026, driven by increasing automation across industrial sectors, rising demand for energy-efficient pneumatic systems, and advancements in smart manufacturing. FRL units—critical components in pneumatic systems that ensure clean, regulated, and lubricated air supply—are witnessing technological evolution and market expansion influenced by several key trends.

-

Growth in Industrial Automation and Smart Manufacturing

The proliferation of Industry 4.0 and the adoption of smart factories are significantly boosting demand for reliable and efficient pneumatic systems. FRL units are essential for maintaining optimal performance of automated machinery. By 2026, integration with IoT-enabled sensors and predictive maintenance systems is expected to become standard, allowing real-time monitoring of air quality, pressure fluctuations, and lubrication levels. This trend will enhance system uptime and reduce operational costs. -

Expansion in Automotive and Manufacturing Sectors

The automotive industry remains a major consumer of FRL units due to their use in assembly lines, robotic welding, and painting systems. As electric vehicle (EV) production ramps up globally, new manufacturing facilities will require advanced pneumatic solutions. Additionally, growing industrialization in Asia-Pacific—particularly in China, India, and Southeast Asia—will drive regional FRL demand. -

Energy Efficiency and Sustainability Regulations

With increasing environmental regulations and corporate sustainability goals, manufacturers are prioritizing energy-efficient components. FRL units that minimize air leakage and optimize compressed air usage are gaining traction. By 2026, products featuring low-pressure drop designs, recyclable materials, and reduced oil consumption are expected to dominate premium market segments. -

Technological Innovation and Miniaturization

Equipment manufacturers are demanding compact, modular FRL units to save space in increasingly dense production environments. Innovations in materials (e.g., high-strength polymers) and design (e.g., integrated combination units) are enabling smaller, lighter, and more durable FRLs. Additionally, digital pressure regulators with electronic controls are emerging as a high-growth niche. -

Regional Market Dynamics

North America and Europe will maintain strong demand due to advanced manufacturing infrastructure and retrofitting of legacy systems. However, the Asia-Pacific region is projected to register the highest CAGR, fueled by industrial investments, government initiatives (e.g., “Make in India”), and expanding electronics and semiconductor manufacturing. -

Supply Chain Resilience and Localization

Post-pandemic supply chain disruptions have prompted companies to localize production. By 2026, FRL manufacturers are expected to adopt regionalized supply chains and nearshoring strategies, particularly in North America and Europe, to reduce lead times and enhance responsiveness.

In conclusion, the 2026 FRL market will be shaped by digitalization, sustainability, and regional industrial growth. Companies investing in smart, compact, and energy-efficient FRL solutions are best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Filter Regulator Lubricator (FRL) Units: Quality and IP Rating Issues

When sourcing Filter Regulator Lubricator (FRL) units for pneumatic systems, overlooking critical aspects related to quality and Ingress Protection (IP) ratings can lead to equipment failure, safety hazards, and increased maintenance costs. Below are common pitfalls to avoid:

1. Prioritizing Cost Over Quality

Many buyers focus on upfront cost, opting for low-priced FRL units from unknown or unreliable suppliers. However, cheaper units often use inferior materials (e.g., low-grade plastics, weak seals, or poor-quality diaphragms), leading to:

- Premature failure of internal components

- Inconsistent pressure regulation

- Leakage at joints or seals

- Reduced filtration efficiency, allowing contaminants into the system

Best Practice: Invest in FRL units from reputable manufacturers with proven track records. Higher initial cost often translates to longer service life and lower total cost of ownership.

2. Ignoring IP Rating Requirements

The Ingress Protection (IP) rating indicates the level of protection against solid objects and liquids. A common mistake is selecting FRL units with inadequate IP ratings for the operating environment.

- Outdoor or washdown environments (e.g., food processing, chemical plants): Require high IP ratings (e.g., IP65, IP66, or IP67) to prevent water and dust ingress.

- Indoor, clean environments: May only need IP54 or IP44.

Using an IP40-rated unit in a wet area can result in internal corrosion, electrical hazards (if equipped with sensors), and system failure.

Best Practice: Match the IP rating to the environmental conditions. Always verify the IP rating on the product datasheet and ensure compliance with industry standards.

3. Assuming All FRL Units Are Interchangeable

FRL units vary significantly in design, flow capacity, connection size, and material compatibility. Substituting units without verifying specifications can lead to:

- Flow restrictions and pressure drops

- Incompatibility with system pressure ranges

- Chemical degradation when exposed to oils, solvents, or compressed air additives

Best Practice: Cross-check technical specifications (pressure range, flow rate, port size, materials) before replacement or integration.

4. Overlooking Certification and Compliance

In regulated industries (e.g., pharmaceuticals, food & beverage), FRL units must meet specific standards such as ISO 8573 (air quality), FDA compliance, or ATEX for explosive environments. Sourcing non-certified units risks non-compliance and safety incidents.

Best Practice: Confirm that the FRL unit meets relevant industry certifications and regulatory requirements before procurement.

5. Neglecting Maintenance and Serviceability

Low-quality FRL units often lack features like transparent bowls, manual drain valves, or pressure gauges, making inspection and maintenance difficult. This leads to neglected servicing and undetected issues.

Best Practice: Choose FRL units designed for easy maintenance—look for bowl visibility, auto-drain options, and modular construction for part replacement.

By addressing these pitfalls—focusing on quality, correct IP rating, compatibility, compliance, and serviceability—buyers can ensure reliable, safe, and efficient pneumatic system operation.

Logistics & Compliance Guide for Filter Regulator Lubricator (FRL)

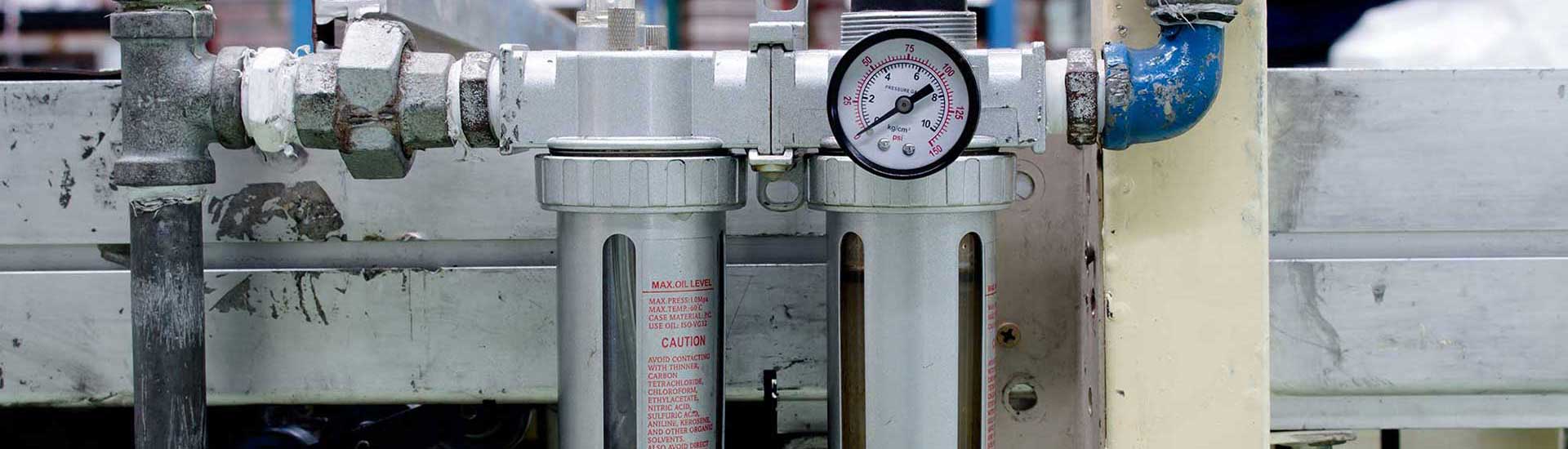

Product Overview

A Filter Regulator Lubricator (FRL) is a combined unit used in pneumatic systems to clean, regulate, and lubricate compressed air. It typically consists of three components: a filter to remove contaminants, a regulator to control pressure, and a lubricator to introduce oil mist into the air stream. Proper handling, storage, transportation, and compliance with applicable regulations are critical to ensure performance, safety, and regulatory adherence throughout the supply chain.

Packaging and Handling

FRL units must be packaged to prevent physical damage, contamination, and moisture ingress during transit. Use manufacturer-recommended packaging that includes protective end caps on ports, cushioning materials, and moisture barriers. Handle units with care to avoid impact or vibration damage. Always lift by the body of the unit—not by accessories or gauges. Store in a clean, dry, temperature-controlled environment away from direct sunlight and corrosive agents.

Storage Conditions

Store FRLs in their original packaging in a climate-controlled environment with temperatures between 5°C and 40°C (41°F to 104°F) and relative humidity below 80%. Avoid locations with excessive dust, vibration, or chemical fumes. Units should be stored horizontally if specified by the manufacturer. Periodically inspect stored inventory for signs of packaging degradation or moisture exposure.

Transportation Requirements

FRLs may be transported via air, sea, or ground freight in accordance with international and national transport regulations. Ensure packages are clearly labeled with handling instructions (e.g., “Fragile,” “This Side Up”). When shipping internationally, comply with IATA (air), IMDG (sea), or ADR (road) regulations as applicable. Do not transport FRLs filled with oil unless explicitly approved for such shipment—most units should be shipped dry.

Import/Export Compliance

Verify that FRL units comply with destination country regulations regarding product standards, labeling, and documentation. Key considerations include:

– Customs Classification: Use correct HS codes (e.g., 8481.80 for valves and regulators).

– Certifications: Ensure units meet regional standards such as CE (Europe), UKCA (UK), or UL/cUL (North America).

– Documentation: Provide commercial invoices, packing lists, certificates of origin, and conformity (e.g., Declaration of Conformity).

– Restricted Substances: Confirm compliance with RoHS, REACH (EU), and other chemical regulations.

Regulatory Standards and Certifications

FRLs must meet relevant industry and safety standards depending on the region of use:

– ISO 4414: Pneumatic fluid power – General rules relating to systems.

– ISO 8573: Compressed air purity classes.

– CE Marking: Required for sale in the European Economic Area; indicates compliance with EU directives (e.g., Pressure Equipment Directive 2014/68/EU, if applicable).

– ASME/ANSI B40.100: For pressure gauges, if included.

– ATEX/IECEx: Required if used in explosive atmospheres.

Environmental and Safety Compliance

Dispose of packaging and defective units in accordance with local waste management regulations. Used lubricators may contain residual oil—treat as hazardous waste if applicable. Follow OSHA (US), HSE (UK), or equivalent workplace safety guidelines during installation and maintenance. Provide Safety Data Sheets (SDS) for any lubricants shipped with or recommended for use in the FRL.

Labeling and Traceability

Each FRL unit must have permanent labeling including:

– Manufacturer name and address

– Model and serial number

– Maximum operating pressure and temperature

– Flow rate and port size

– Compliance markings (e.g., CE, UL)

– Date of manufacture

Maintain traceability through batch/lot records for quality control and recall management.

Installation and Use Compliance

Ensure end users install FRLs in accordance with manufacturer instructions and applicable codes (e.g., NFPA 99 for medical air systems, if relevant). Only trained personnel should perform installation and maintenance. Regular inspection and servicing are required to maintain compliance with operational safety standards.

Documentation and Recordkeeping

Retain records of:

– Certificates of Conformity and test reports

– Shipping and customs documentation

– Quality inspections and non-conformance reports

– Regulatory updates and compliance audits

Maintain records for a minimum of 10 years or as required by regional regulations.

Conclusion

Proper logistics and compliance management for Filter Regulator Lubricators ensures product integrity, safety, and legal conformity across global markets. Adherence to packaging, transportation, regulatory, and documentation requirements minimizes risks and supports reliable performance in pneumatic applications.

Conclusion for Sourcing Filter Regulator Lubricator (FRL):

After a thorough evaluation of technical requirements, supplier capabilities, cost considerations, and long-term operational needs, the sourcing of Filter Regulator Lubricator (FRL) units should prioritize reliability, quality, and compatibility with existing pneumatic systems. Selecting suppliers that offer certified products meeting international standards (such as ISO 8573 and CE marking), proven durability, and responsive technical support will ensure optimal performance and reduced downtime. Additionally, considering total cost of ownership—factoring in energy efficiency, maintenance requirements, and service life—will deliver greater value over time. A strategic sourcing approach, combining competitive pricing with reliable supply chain partners, will enhance system efficiency and support sustainable operations across industrial applications.