The global fiberglass roof panel market is experiencing steady growth, driven by rising demand for lightweight, durable, and corrosion-resistant building materials across residential, commercial, and industrial sectors. According to Grand View Research, the global fiber-reinforced plastic (FRP) market size was valued at USD 56.8 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth is fueled by increasing infrastructure development, especially in emerging economies, and a growing emphasis on energy-efficient and low-maintenance roofing solutions. Fiberglass roof panels, known for their high strength-to-weight ratio, UV resistance, and thermal insulation properties, are becoming a preferred alternative to traditional roofing materials. As demand rises, a select group of manufacturers have emerged as industry leaders, combining innovation, scalability, and consistent product quality to meet evolving market needs. Based on production volume, global reach, technical capabilities, and market reputation, here are the top 9 fiberglass roof panel manufacturers shaping the future of sustainable construction.

Top 9 Fiberglass Roof Panel Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials.Missing: fiberglass panel…

#2 Owens Corning

Domain Est. 1996

Website: owenscorning.com

Key Highlights: Owens Corning has solutions for your building & remodeling needs. Browse through roofing products, insulation, shingles, asphalt, composites solutions, ……

#3 Dipcraft

Domain Est. 1997

Website: dipcraft.com

Key Highlights: Dipcraft Manufacturing has been a national leader in fiberglass building panels. We specialize in high-quality customer service and developing custom solutions….

#4 Large Selection of Corrugated Fiberglass Panels In Stock at ePlastics

Domain Est. 1998

Website: eplastics.com

Key Highlights: 2–5 day delivery 30-day returnsePlastics offers heavy-duty commercial grade fiberglass sheets that are available in either flat or corrugated. We have the largest FRP stock in the …

#5 Corrugated Fiberglass Roofing

Domain Est. 2002

Website: corrugatedmetal.com

Key Highlights: These Corrugated Fiberglass panels are strong, durable, shatter resistant and will not rust, rot, scale or mildew….

#6 Fiberglass Roofing and Skylight Panels

Domain Est. 2015

Website: westernstatesmetalroofing.com

Key Highlights: Available FRP Panels In Stock. Translucent fiberglass roofing and skylight panels. Fiberglass Reinforced Polyester (FRP) are lightweight. Immediate delivery….

#7 Corrugated Fiberglass Roof Sheets

Domain Est. 2015

Website: stabilitamerica.com

Key Highlights: At Stabilit America, we manufacture our fiberglass roof panels using high-quality fiberglass and advanced resins, so they provide the best ……

#8 Creative Composites Group

Domain Est. 2019

Website: creativecompositesgroup.com

Key Highlights: CCG’s comprehensive menu of services takes you from design/build, manufacturing processes and structural fabrication to field support. All Service Offerings….

#9

Website: valtoem.com

Key Highlights: World’s leading provider of fiber-reinforced composite materials by Valto EM provides FRP panels for recreational vehicles, the transportation industry, ……

Expert Sourcing Insights for Fiberglass Roof Panel

2026 Market Trends for Fiberglass Roof Panels

The fiberglass roof panel market is poised for significant transformation by 2026, driven by evolving construction demands, sustainability imperatives, and technological innovation. Here’s a detailed analysis of the key trends shaping the industry:

Rising Demand for Sustainable and Energy-Efficient Building Solutions

Environmental regulations and consumer preferences are pushing the construction sector toward greener materials. Fiberglass roof panels offer inherent advantages in this domain, as they are lightweight, recyclable, and contribute to improved building insulation. By 2026, increasing adoption of green building certifications—such as LEED and BREEAM—will drive demand for fiberglass panels due to their low embodied energy and long service life. Additionally, advancements in reflective coatings and thermal performance will enhance their energy-saving capabilities, making them a preferred choice for both commercial and industrial buildings aiming to reduce HVAC loads.

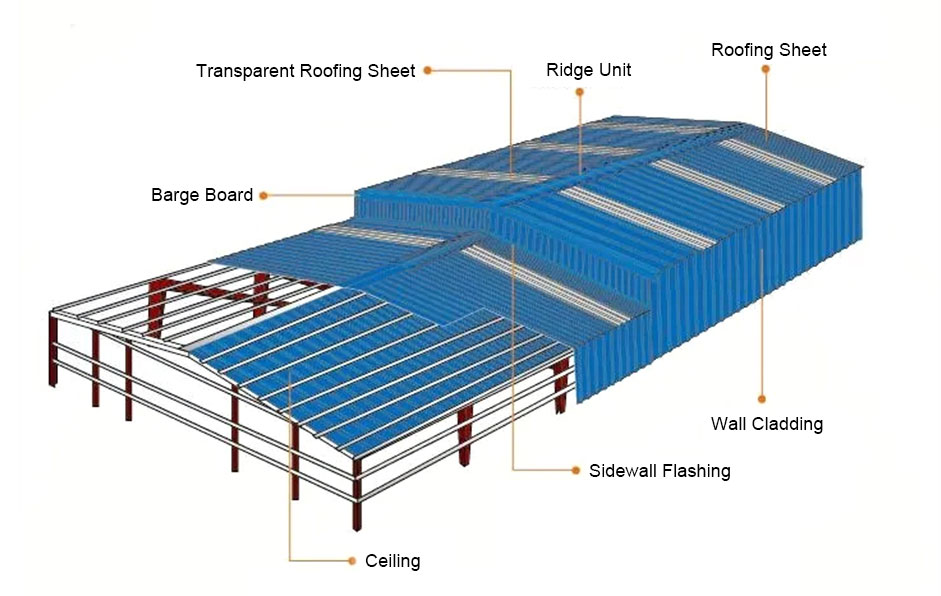

Growth in Industrial and Commercial Construction Sectors

Fiberglass roof panels are particularly well-suited for industrial warehouses, manufacturing facilities, and large commercial complexes due to their durability, corrosion resistance, and natural light transmission (in translucent variants). With global industrial expansion—especially in emerging markets—and the continued growth of e-commerce driving warehouse construction, demand for cost-effective, low-maintenance roofing solutions will surge. By 2026, these sectors are expected to be the primary growth engines for fiberglass roof panels, outpacing residential applications.

Technological Advancements in Material and Design

Innovation in resin formulations, reinforcement fibers, and manufacturing processes will enhance the performance of fiberglass roof panels by 2026. Improved UV resistance, fire retardancy, and impact strength will extend product lifespan and broaden applicability in extreme climates. Additionally, integration with smart building technologies—such as embedded sensors for structural health monitoring—could emerge as a differentiating feature. Customization through digital design tools and modular panel systems will also support faster, more efficient installations, appealing to developers focused on project timelines.

Competitive Pressure and Price Sensitivity

Despite their advantages, fiberglass panels face stiff competition from alternatives like metal roofing, polycarbonate sheets, and composite materials. Fluctuations in raw material prices—particularly for resins and glass fibers—could impact production costs. By 2026, manufacturers will need to focus on cost optimization, economies of scale, and value-added features to maintain competitiveness. Regional price disparities and the availability of lower-cost substitutes may limit growth in price-sensitive markets unless cost-performance ratios are clearly demonstrated.

Regional Market Expansion and Regulatory Influence

Asia-Pacific, particularly China and India, is expected to dominate market growth by 2026 due to rapid urbanization, infrastructure development, and government initiatives promoting industrial construction. North America and Europe will see steady growth driven by retrofitting projects and stricter energy codes. Regulatory frameworks mandating energy efficiency and reduced carbon emissions will act as tailwinds, while local building codes may influence material specifications and adoption rates. Manufacturers who align their products with regional standards will gain a strategic advantage.

In conclusion, the fiberglass roof panel market in 2026 will be shaped by sustainability demands, industrial construction booms, and technological innovation. Companies that invest in R&D, expand regionally, and emphasize lifecycle cost benefits will be best positioned to capture market share in this evolving landscape.

Common Pitfalls Sourcing Fiberglass Roof Panels (Quality, IP)

Sourcing fiberglass roof panels requires careful evaluation to avoid costly mistakes related to product quality and intellectual property (IP) risks. Overlooking these aspects can lead to structural failures, legal disputes, and reputational damage. Below are key pitfalls to watch for:

Poor Material Quality and Manufacturing Defects

Low-quality fiberglass panels often use substandard resin formulations or inadequate glass fiber reinforcement, leading to reduced strength, UV resistance, and lifespan. Common defects include inconsistent thickness, air bubbles, delamination, and poor surface finish. These flaws can compromise weather resistance, cause premature cracking or yellowing, and fail to meet required load-bearing specifications. Always request material test reports (MTRs) and conduct third-party quality inspections before bulk procurement.

Inadequate Weather and UV Resistance

Not all fiberglass panels offer equal protection against sunlight and environmental exposure. Panels lacking proper UV inhibitors or protective gel coats degrade rapidly, becoming brittle and discolored. This reduces light transmission (for translucent panels) and structural integrity. Ensure the supplier specifies UV resistance standards (e.g., ASTM G154) and provides warranty details covering yellowing and strength retention over time.

Misrepresentation of Fire and Safety Ratings

Some suppliers falsely claim compliance with fire safety standards such as ASTM E84 or UL 723. Using non-compliant panels in commercial or public buildings can violate building codes and pose serious safety hazards. Verify certifications through independent testing labs and request valid compliance documentation before purchase.

Intellectual Property Infringement Risks

Sourcing from manufacturers that replicate patented designs, profiles, or production techniques can expose buyers to IP litigation. This is especially common with high-performance or architecturally distinctive panels. Always assess the supplier’s R&D credentials, request proof of IP ownership or licensing, and avoid unusually low-priced products that may indicate design copying.

Lack of Traceability and Certification

Reputable suppliers provide full traceability, including batch numbers, production dates, and compliance certifications. Missing or falsified documentation is a red flag. Insist on ISO 9001 certification for quality management and confirm adherence to industry standards like ANSI or EN for roofing materials.

Inconsistent Product Dimensions and Tolerances

Poor manufacturing control leads to variations in panel length, width, and curvature. This causes installation difficulties, gaps in the roof system, and compromised weatherproofing. Review tolerance specifications (e.g., ±2mm) and perform incoming quality checks on sample shipments.

Insufficient Technical Support and Warranty

Some suppliers offer limited technical guidance or unenforceable warranties. Ensure the supplier provides detailed installation manuals, engineering support, and a clear warranty covering material defects and performance under specified conditions. Ambiguous or voided warranties upon third-party installation are common warning signs.

Avoiding these pitfalls requires due diligence, supplier vetting, and clear contractual terms focused on quality assurance and IP compliance.

Logistics & Compliance Guide for Fiberglass Roof Panels

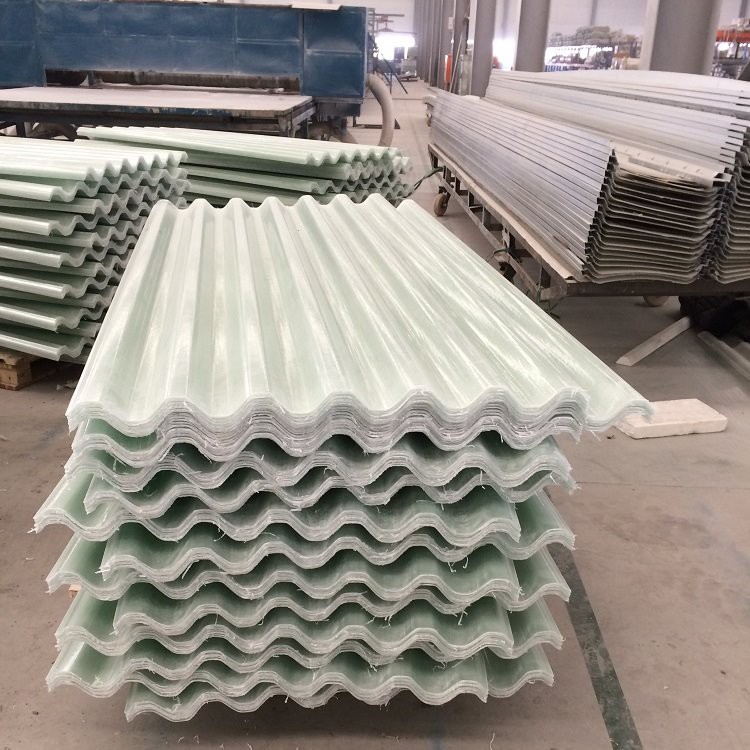

Product Overview

Fiberglass roof panels are lightweight, durable, and corrosion-resistant roofing materials commonly used in industrial, agricultural, and commercial buildings. These composite panels typically consist of a fiberglass-reinforced polyester resin matrix with UV-protective gel coat layers. Proper handling, transportation, and compliance with regulatory standards are essential to ensure product integrity and safety.

Packaging & Handling Requirements

Fiberglass roof panels must be packaged to prevent surface damage, breakage, and exposure to environmental factors. Panels should be stacked flat on wooden pallets with protective spacers between each layer to avoid scratching. Edges should be aligned and secured with strapping or shrink wrap. Use edge protectors to prevent chipping during transit. Always handle panels with clean gloves to avoid contamination and use mechanical lifting equipment (e.g., forklifts) to minimize manual strain and risk of cracking.

Transportation Guidelines

Transport fiberglass roof panels in covered trucks or containers to protect against rain, UV exposure, and debris. Secure loads with straps or chains to prevent shifting during transit. Avoid excessive overhang beyond the vehicle’s edge—maximum overhang should not exceed 1 meter (3 feet) and must be clearly marked with flags. Maintain a stable temperature during transport; avoid prolonged exposure to extreme heat or freezing conditions, which may affect resin integrity.

Storage Recommendations

Store panels under a dry, covered area on a level, well-ventilated surface. Keep pallets elevated off the ground using wooden beams to prevent moisture absorption. Limit stack height to manufacturer specifications (typically no more than 1.5 meters or 5 feet) to prevent bottom-layer deformation. Protect stored panels from direct sunlight to minimize UV degradation, even if they have UV inhibitors. Rotate stock using the “first in, first out” (FIFO) method to ensure older materials are used first.

Regulatory Compliance

Fiberglass roof panels must comply with relevant national and international standards. In the United States, panels should meet ASTM E108 for fire testing of roofing materials and UL 790 for fire resistance. Ensure compliance with local building codes such as the International Building Code (IBC) and International Residential Code (IRC). Panels used in commercial applications may require compliance with FM Global Approval Standard 4471 for Class 1 or Class 2 ratings.

Environmental & Safety Regulations

Manufacturers and distributors must adhere to environmental regulations regarding volatile organic compound (VOC) emissions during production, as governed by the U.S. Environmental Protection Agency (EPA) or equivalent bodies. Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) must be available, detailing handling precautions, flammability, and disposal methods. Fiberglass waste must be disposed of in accordance with local hazardous waste regulations if resin content exceeds thresholds.

Import/Export Considerations

For international shipments, ensure compliance with destination country regulations. Panels may require certifications such as CE marking in the European Union under Construction Products Regulation (CPR) EN 14907. Accurate Harmonized System (HS) codes (e.g., 3926.30 for plastic plates, sheets, and profile shapes) must be used for customs clearance. Include documentation such as commercial invoices, packing lists, certificates of origin, and test reports to facilitate smooth customs processing.

Quality Assurance & Documentation

Maintain traceability through batch numbering and quality control records. Provide compliance certificates, test reports (e.g., fire, impact, load resistance), and warranty documentation with each shipment. Conduct regular inspections during loading and unloading to identify and report any damage promptly. Retain shipping records and compliance documentation for a minimum of five years for audit purposes.

Emergency Response & Incident Management

In the event of panel breakage or resin leakage during transport or storage, follow established spill response procedures. Isolate the area, wear appropriate PPE (gloves, goggles, respirator), and clean up debris using non-sparking tools. Consult the SDS for specific disposal instructions. Report major incidents to relevant authorities and initiate root cause analysis to prevent recurrence.

In conclusion, sourcing fiberglass roof panels offers a practical and cost-effective solution for various roofing applications due to their durability, lightweight nature, and resistance to corrosion and UV damage. These panels provide excellent light transmission, making them ideal for natural daylighting in industrial, commercial, and agricultural buildings. When sourcing, it is essential to consider factors such as panel thickness, UV protection coating, fire resistance ratings, and compatibility with existing roof structures. Working with reputable suppliers who provide quality certifications and warranties ensures long-term performance and reliability. Additionally, evaluating pricing, lead times, and logistical requirements contributes to a successful procurement process. Overall, careful supplier selection and attention to technical specifications will help maximize the benefits of fiberglass roof panels in terms of energy efficiency, maintenance reduction, and building sustainability.