The demand for durable, lightweight, and weather-resistant mobile home stairs has surged alongside the steady growth of the manufactured housing sector. Fiberglass has emerged as a preferred material due to its corrosion resistance, low maintenance, and structural longevity—particularly critical for outdoor applications. According to Mordor Intelligence, the global fiberglass market was valued at USD 63.6 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2029, driven by increasing adoption in construction and modular housing. This expansion parallels rising production in the U.S. single-section manufactured housing segment, where over 120,000 units were shipped in 2023 alone (U.S. Census Bureau). As suppliers adapt to performance and code-compliance demands, a select group of fiberglass stair manufacturers has risen to prominence, combining innovation with scalable production. These companies are shaping industry standards through enhanced load ratings, customizable designs, and faster lead times—key differentiators in a competitive and growing market. Below are the top six fiberglass mobile home stair manufacturers leading this evolution.

Top 6 Fiberglass Mobile Home Stairs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

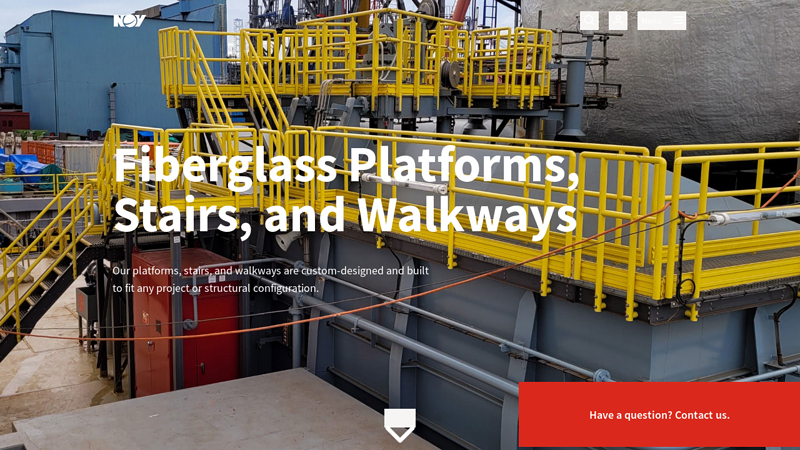

#1 Fiberglass Platforms, Stairs, and Walkways

Domain Est. 1995

Website: nov.com

Key Highlights: Fiberglass Platforms, Stairs, and Walkways. Our platforms, stairs, and walkways are custom-designed and built to fit any project or structural configuration….

#2 Page

Domain Est. 1997

#3 Fiberglass Steps for Your Mobile

Domain Est. 2002

Website: mobilehomepartsstore.com

Key Highlights: We’ll walk you through everything you need to know about fiberglass stairs for your mobile home, from the basics to installation and customization….

#4 Entrance Systems

Domain Est. 2004

Website: stylecrestinc.com

Key Highlights: 48″ Wide Fiberglass Step – 7″ Step Height – 48″ x 29″ Platform – 4 Steps – 28″ Height · 48″ Wide Fiberglass Step – 8″ Step Height – 48″ x 29″ Platform – 2 Steps ……

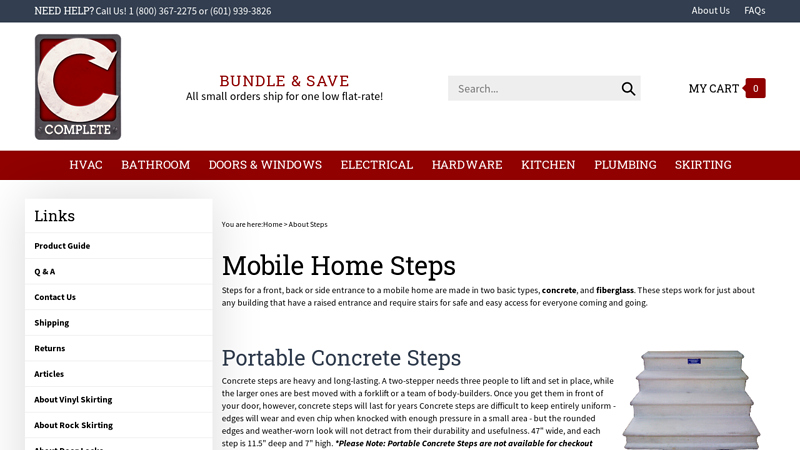

#5 Wooden Concrete Fiberglass Steps for Mobile Homes

Domain Est. 2008

Website: completemobilehomesupply.com

Key Highlights: Free delivery 30-day returnsBuilt around a wooden frame, these fiberglass stairs will last many years withstanding the weather and providing a safe, wide entrance into your buildin…

#6 Steps, Decks & Rails

Domain Est. 2020

Expert Sourcing Insights for Fiberglass Mobile Home Stairs

2026 Market Trends for Fiberglass Mobile Home Stairs

The market for fiberglass mobile home stairs is poised for notable evolution by 2026, driven by shifting consumer preferences, regulatory changes, and advancements in materials and construction. As a durable, low-maintenance alternative to traditional wood or metal stairs, fiberglass is gaining traction in the expanding manufactured housing sector. Here are the key trends expected to shape this niche market:

Increased Demand from the Growing Manufactured Housing Sector

The U.S. and other regions are experiencing a resurgence in manufactured and modular housing as an affordable housing solution. With rising construction costs and housing shortages, demand for mobile and modular homes is projected to remain strong through 2026. This growth directly translates into higher demand for durable, code-compliant exterior components like fiberglass stairs. As manufacturers prioritize long-term value and reduced maintenance, fiberglass—resistant to rot, corrosion, and insects—will become a preferred solution over wood.

Focus on Durability and Low Maintenance

Homeowners and property managers are increasingly prioritizing longevity and minimal upkeep. Fiberglass stairs offer a compelling value proposition: they do not warp, splinter, or rust, and they require little more than occasional washing. As climate patterns become more extreme—with increased rainfall, humidity, and temperature fluctuations—fiberglass’s resilience in diverse environments will make it a standout choice. This durability reduces lifecycle costs, appealing to both individual buyers and affordable housing developers.

Regulatory and Safety Compliance Driving Adoption

Building codes and safety standards for mobile homes, particularly regarding step rise, run, handrails, and slip resistance, are becoming more stringent. Fiberglass stair systems are often engineered to meet or exceed these requirements, featuring slip-resistant treads, integrated handrails, and consistent dimensions. By 2026, compliance will be a major purchasing driver, especially in regions prone to moisture and freeze-thaw cycles where wood degradation poses safety hazards.

Sustainability and Environmental Considerations

Environmental awareness is influencing material choices in construction. While fiberglass is a petroleum-based product, its long service life and recyclability (in some forms) contribute to a lower environmental footprint over time compared to frequently replaced wooden stairs. Additionally, some manufacturers are exploring bio-based resins and improved end-of-life recycling processes, which could enhance fiberglass’s sustainability profile by 2026 and appeal to eco-conscious consumers and green building programs.

Product Innovation and Customization

The fiberglass mobile home stairs market is expected to see greater product differentiation. By 2026, consumers will likely have access to more customizable options—such as varied rise configurations, color integrations (not just surface paint), integrated lighting, and ADA-compliant designs. Advances in molding technology will allow for more aesthetically pleasing finishes that mimic wood grain or modern textures, helping fiberglass stairs blend seamlessly with contemporary mobile home designs.

Supply Chain and Cost Dynamics

While fiberglass offers long-term savings, initial costs can be higher than wood. However, as production scales and supply chains optimize—especially with domestic manufacturing incentives in North America—prices are expected to stabilize or decrease slightly by 2026. Additionally, rising lumber prices and supply volatility will continue to make fiberglass a cost-competitive alternative, further accelerating market penetration.

In conclusion, the 2026 market for fiberglass mobile home stairs will be characterized by growth, innovation, and increasing recognition of the material’s performance advantages. As the manufactured housing industry expands and demands higher quality, sustainable solutions, fiberglass stairs are well-positioned to capture a larger share of the market, supported by evolving consumer expectations and regulatory landscapes.

Common Pitfalls When Sourcing Fiberglass Mobile Home Stairs (Quality & Intellectual Property)

Sourcing fiberglass mobile home stairs requires careful attention to both product quality and intellectual property (IP) concerns. Overlooking these areas can lead to safety risks, legal issues, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Construction

One of the most frequent issues is receiving fiberglass stairs made with substandard materials or faulty manufacturing processes. Low-quality resins, inadequate reinforcement, or inconsistent wall thickness can compromise structural integrity, leading to premature cracking, warping, or failure under load. Always verify material specifications (e.g., marine-grade fiberglass, UV-stabilized resin) and request third-party test reports for load capacity and durability.

Inadequate Weather and UV Resistance

Fiberglass stairs exposed to sunlight and outdoor elements must be formulated to resist UV degradation and thermal expansion. Stairs lacking proper UV inhibitors or protective gel coats may yellow, become brittle, or delaminate over time. Ensure suppliers use weather-resistant formulations and conduct accelerated weathering tests.

Non-Compliance with Safety and Building Codes

Many generic or off-brand fiberglass stairs fail to meet U.S. building codes (e.g., IRC, HUD standards for manufactured homes) for step height, tread depth, handrail requirements, and slip resistance. Sourcing non-compliant stairs can result in failed inspections, liability exposure, or costly replacements. Confirm that products are certified to relevant standards such as ANSI or ASTM.

Misrepresentation of Load Ratings

Suppliers may exaggerate load-bearing capabilities without proper engineering validation. Stairs marketed as “heavy-duty” may not support the claimed weight (e.g., 300+ lbs). Request certified load test documentation and verify compliance with OSHA or IBC structural requirements.

Intellectual Property Infringement Risks

Sourcing stairs from manufacturers that copy patented designs or trademarks can expose buyers to legal liability. Some overseas or unbranded suppliers replicate popular stair models protected by design patents or trade dress. Always vet suppliers for IP compliance and avoid products that closely mimic branded designs without authorization.

Lack of Traceability and Manufacturer Accountability

Purchasing from unknown or unverified suppliers can lead to difficulties in tracking product origin, obtaining warranties, or addressing defects. Absence of clear manufacturer markings, serial numbers, or contact information increases risk. Prioritize suppliers with transparent operations and verifiable business credentials.

Inconsistent Dimensions and Fit Issues

Off-the-shelf fiberglass stairs may not accommodate variations in mobile home porch heights or entry configurations. Poor dimensional accuracy leads to installation problems and safety hazards. Confirm customization options and tolerance specifications before ordering in bulk.

Insufficient Warranty and After-Sales Support

Low-cost suppliers often offer limited or no warranty coverage. Without proper support, resolving quality issues becomes difficult and expensive. Evaluate warranty terms, availability of replacement parts, and responsiveness of customer service before finalizing a supplier.

Avoiding these pitfalls requires due diligence in supplier selection, product verification, and legal compliance. Partnering with reputable, IP-compliant manufacturers ensures durable, code-compliant stairs and reduces long-term risk.

Logistics & Compliance Guide for Fiberglass Mobile Home Stairs

Product Overview

Fiberglass mobile home stairs are durable, weather-resistant access solutions designed specifically for manufactured and mobile homes. Constructed from reinforced fiberglass, these stairs offer long-term structural integrity, low maintenance, and resistance to corrosion, rot, and insect damage. They are commonly used in residential, multi-family, and temporary housing applications.

Shipping & Handling

- Packaging: Fiberglass stairs are typically shipped in protective crates or reinforced cardboard with corner guards to prevent chipping or cracking during transit.

- Weight & Dimensions: Average unit weight ranges from 40 to 70 lbs depending on size; common configurations include 3-, 4-, or 5-step models. Confirm exact dimensions with the manufacturer prior to shipment.

- Handling Instructions: Use mechanical aids (e.g., forklifts, hand trucks) when moving stairs. Avoid dragging or dropping; always lift from base supports.

- Storage: Store horizontally on a flat, dry surface off the ground. Protect from prolonged UV exposure and extreme temperatures prior to installation.

Transportation Guidelines

- Carrier Requirements: Use freight carriers experienced in handling building materials. Ensure proper loading and securement to prevent movement during transit.

- Freight Class: Fiberglass stairs generally fall under NMFC class 150–175, depending on density and packaging. Confirm with your freight provider for accurate quoting.

- Delivery Conditions: Inspect upon delivery for damage. Document and report any issues immediately to the carrier and supplier.

Installation & Site Preparation

- Foundation: Stairs must be installed on a level, stable surface such as concrete, pavers, or approved composite pads. Avoid settling-prone soils.

- Clearance: Maintain minimum 36-inch clearance in front of the entry door and ensure proper step height compliance (typically 7.5″–8″ rise per step).

- Anchoring: Secure stairs to the mobile home frame and ground using manufacturer-recommended hardware. Include anti-slip treads and handrails where required.

Regulatory Compliance

- HUD Code (24 CFR Part 3280): Stairs used on HUD-certified manufactured homes must comply with safety and structural standards outlined in the Federal Manufactured Home Construction and Safety Standards. This includes load capacity (minimum 40 lbs per sq ft), guardrail requirements (if over 30″ from ground), and egress dimensions.

- ICC/IRC (International Residential Code): For site-built or non-HUD installations, stairs must meet local building codes based on IRC Chapter 3 and 10, including uniform riser height, tread depth (minimum 10″), and handrail specifications.

- ADA Considerations: While mobile home stairs are generally exempt from full ADA requirements, accessible design principles should be considered for universal usability, especially in rental or multi-family settings.

Safety & Maintenance

- Inspection: Conduct quarterly inspections for cracks, warping, loose components, or worn non-slip surfaces.

- Cleaning: Clean with mild soap and water. Avoid harsh chemicals or pressure washing, which may degrade the fiberglass surface.

- Repairs: Minor surface damage can be repaired with fiberglass resin kits. Structural damage requires professional assessment or replacement.

Environmental & Disposal Considerations

- Sustainability: Fiberglass is recyclable in some regions through specialized facilities. Contact local waste management for proper disposal protocols.

- End-of-Life: Do not incinerate; dispose of in accordance with local hazardous waste regulations if composite materials are present.

Documentation & Certification

- Manufacturer Certification: Ensure each unit is accompanied by a certificate of compliance indicating adherence to HUD, ASTM, or relevant building standards.

- Warranty: Typical warranties range from 5 to 10 years against structural defects. Retain all purchase and installation records.

- Installation Manual: Follow the manufacturer’s instructions precisely for warranty validity and safety compliance.

Summary

Proper logistics planning and compliance with federal, state, and local regulations are essential for the safe and effective use of fiberglass mobile home stairs. By adhering to shipping best practices, installation standards, and ongoing maintenance protocols, providers and homeowners can ensure long-term durability and occupant safety.

In conclusion, sourcing fiberglass mobile home stairs offers a durable, low-maintenance, and weather-resistant solution for homeowners seeking reliable and long-lasting access to their mobile homes. Fiberglass stairs are lightweight yet strong, resistant to rot, rust, and insect damage, and require minimal upkeep compared to wood or metal alternatives. When sourcing, it’s important to consider factors such as dimensions, load capacity, compliance with safety standards (such as ICC or HUD codes), and local climate conditions. Purchasing from reputable manufacturers or suppliers ensures quality construction and proper warranties. Whether buying pre-fabricated models or custom-designed units, fiberglass stairs represent a smart investment that combines safety, longevity, and ease of installation, ultimately enhancing both the functionality and value of a mobile home.