The global fiberglass mesh market is experiencing robust growth, driven by rising demand in construction applications such as stucco reinforcement, external thermal insulation composite systems (ETICS), and roofing. According to Grand View Research, the global fiberglass mesh market size was valued at USD 3.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by increasing infrastructure development, especially in emerging economies, and a growing emphasis on energy-efficient building solutions. As stucco finishes remain a preferred exterior cladding due to their durability and aesthetic flexibility, fiberglass mesh—a critical component for crack resistance and structural integrity—has become indispensable. In this competitive landscape, a select group of manufacturers are leading innovation, scalability, and product performance. Based on production capacity, global reach, product quality, and market reputation, the following seven companies stand out as the top fiberglass mesh stucco manufacturers worldwide.

Top 7 Fiberglass Mesh Stucco Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Reinforcing Mesh

Domain Est. 1995

Website: usa.sika.com

Key Highlights: SikaWall®-9000 SRT Mesh. Glass fiber mesh for use with stucco. Let’s Build Something Amazing. Contact Us · Find a Distributor · Download Literature. About Us….

#2 Fiberglass Mesh for Stucco

Domain Est. 1996

Website: stocorp.com

Key Highlights: Rating 4.7 (13) Sto Stucco Mesh is a tri-directional weave, flexible treated glass fiber mesh for use with portland cement stucco brown coats in vertical wall construction….

#3 Stucco Assemblies

Domain Est. 1996

Website: dryvit.com

Key Highlights: StucCoat® stucco wall assemblies offer bold colors, multiple stucco textures, and air/water-resistive barriers in durable one-coat or three-coat systems….

#4 Sunline

Domain Est. 2005

Website: sunlinemesh.com

Key Highlights: Sunline is an online distributor of EIFS fiberglass mesh as well as other EIFS and stucco supplies like EIFS base coat, the finish coat, weather barrier, ……

#5 FibaLath

Domain Est. 2012

Website: adfors.com

Key Highlights: FibaLath is an innovative fiberglass lath for use in stucco applications and exterior/interior manufactured stone and brick facades….

#6 High Quality Stucco Fiberglass Mesh, Plaster Fiberglass Net

Domain Est. 2014

Website: blueoceanplastic.com

Key Highlights: High Quality Stucco Fiberglass Mesh provides 30% higher tensile strength and superior crack resistance. Trusted by 500+ construction suppliers….

#7 Drywall Specialties

Domain Est. 2020

Website: drywallspecialtiesbm.com

Key Highlights: We offer a full line of fiberglass mesh products EIFS and stucco. We stock light mesh, heavy mesh, sticky mesh and standard mesh. By stocking a wide variety of ……

Expert Sourcing Insights for Fiberglass Mesh Stucco

H2: Analysis of 2026 Market Trends for Fiberglass Mesh Stucco

The global fiberglass mesh stucco market is poised for steady growth leading into 2026, driven by rising construction activity, advancements in building materials, and increasing demand for energy-efficient and durable exterior finishes. Fiberglass mesh stucco, a key component in Exterior Insulation and Finish Systems (EIFS), continues to gain traction due to its crack-resistant properties, flexibility, and compatibility with modern insulation techniques.

1. Rising Demand in Residential and Commercial Construction

Urbanization and infrastructure development, particularly in emerging economies across Asia-Pacific, Latin America, and Africa, are fueling demand for cost-effective and long-lasting building materials. Fiberglass mesh stucco is increasingly preferred in both residential and commercial projects due to its ability to enhance structural integrity and provide a smooth, aesthetically pleasing finish. The global push toward affordable housing and smart city initiatives is expected to further boost adoption through 2026.

2. Growth in Green Building Practices

Environmental regulations and sustainability goals are reshaping the construction industry. Fiberglass mesh stucco supports energy-efficient building envelopes by improving thermal performance when integrated with insulation systems. As green building certifications like LEED and BREEAM gain prominence, demand for materials that contribute to energy savings and reduce carbon footprints is expected to rise. Manufacturers are responding by introducing eco-friendly variants with lower embodied carbon and improved recyclability.

3. Technological Advancements and Product Innovation

By 2026, innovations in alkali-resistant (AR) fiberglass formulations are expected to enhance the durability and tensile strength of mesh stucco products. Coatings with improved polymer technology are increasing resistance to moisture, UV radiation, and thermal expansion. These advancements extend the service life of stucco systems, reducing maintenance costs and increasing appeal among contractors and developers.

4. Regional Market Dynamics

North America and Europe remain dominant markets due to established construction industries and stringent building codes that promote high-performance materials. However, the Asia-Pacific region is anticipated to exhibit the highest compound annual growth rate (CAGR), led by China, India, and Southeast Asian countries investing heavily in infrastructure and urban development. Government incentives for modern construction methods are accelerating the adoption of EIFS and associated products like fiberglass mesh.

5. Supply Chain and Raw Material Challenges

Fluctuations in the prices of raw materials such as glass fibers and polymer resins may impact production costs. However, strategic partnerships, localized manufacturing, and investments in recycling technologies are helping companies mitigate supply chain disruptions. The trend toward vertical integration among key players is expected to stabilize supply and improve margins by 2026.

6. Competitive Landscape and Market Consolidation

The market is moderately consolidated, with key players such as Owens Corning, Saint-Gobain, and 3M dominating through product innovation and global distribution networks. Increasing competition is driving mergers, acquisitions, and R&D investments, particularly in developing smart stucco systems with moisture-sensing or self-healing capabilities.

Conclusion

By 2026, the fiberglass mesh stucco market is expected to witness robust growth, supported by construction expansion, sustainability trends, and technological progress. Stakeholders who prioritize innovation, sustainability, and regional market adaptability will be well-positioned to capitalize on emerging opportunities in this evolving sector.

Common Pitfalls Sourcing Fiberglass Mesh Stucco (Quality, IP)

When sourcing fiberglass mesh for stucco applications, buyers often encounter challenges related to product quality and intellectual property (IP) concerns. Understanding these pitfalls is crucial to ensuring long-term performance, compliance, and protection against legal or financial risks.

Quality-Related Pitfalls

Inconsistent Material Composition

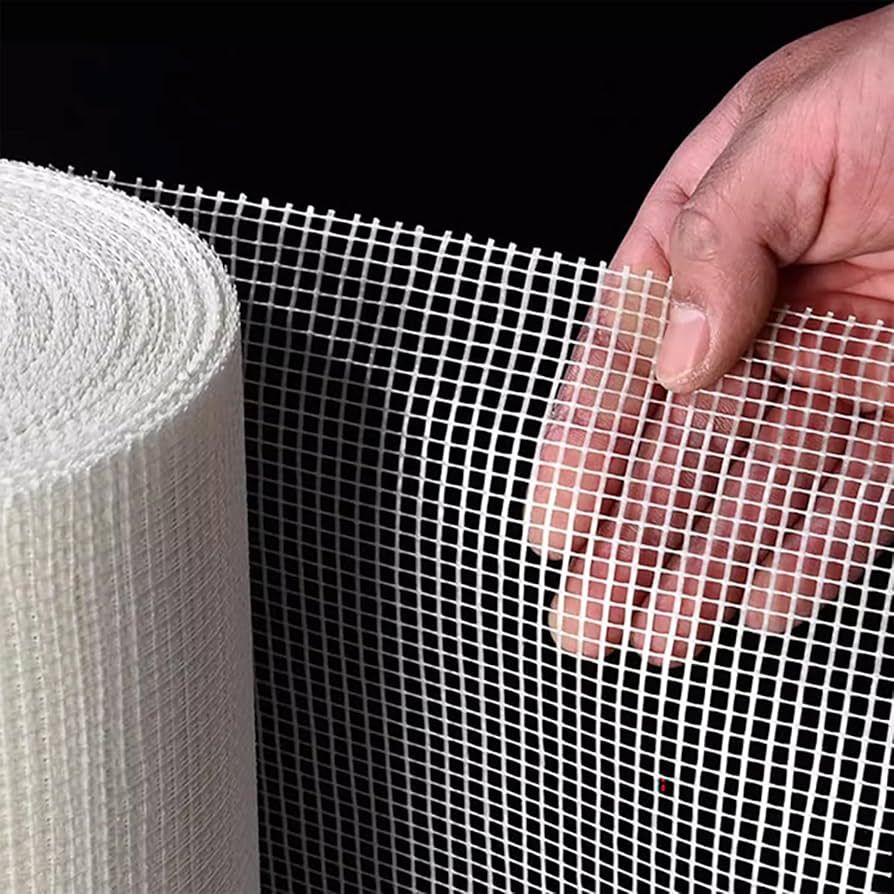

One of the most common quality issues is variability in the fiberglass composition. Low-cost suppliers may use inferior-grade glass fibers or reduce zirconia content, which compromises alkali resistance—the key property that prevents degradation when exposed to cementitious stucco. This leads to premature mesh failure and stucco system cracking.

Poor Coating Application

The polymer coating (typically acrylic or copolymer) on fiberglass mesh enhances flexibility, tensile strength, and bond performance. Inadequate or uneven coating can result in reduced durability, poor adhesion to stucco, and vulnerability to moisture ingress. Sourcing from manufacturers without strict quality control processes increases the risk of receiving inconsistently coated mesh.

Misrepresented Performance Metrics

Some suppliers may exaggerate or falsify technical specifications such as tensile strength, weight per square meter, or elongation at break. Without third-party test certifications (e.g., ASTM D848, D3973), it’s difficult to verify these claims, leading to substandard performance in the field.

Lack of Standard Compliance

Reputable fiberglass mesh should meet industry standards like ASTM C1170 (for stucco base coats) or EIFS-specific requirements. Sourcing from non-compliant suppliers can result in products that don’t perform as expected, jeopardizing building envelope integrity and potentially voiding warranties.

Intellectual Property (IP) Risks

Use of Counterfeit or Clone Products

Some manufacturers produce fiberglass mesh that mimics patented designs or branded products (e.g., knockoffs of well-known brands like Saint-Gobain or Owens Corning). These clones may infringe on design patents, trademarks, or technical innovations, exposing the buyer to legal liability or supply chain disruptions.

Unauthorized Manufacturing Techniques

Advanced mesh products often incorporate proprietary weaving patterns, coating technologies, or resin formulations protected by patents. Sourcing from suppliers who replicate these methods without licensing can lead to IP infringement claims, especially if the product is used in commercial or large-scale construction projects.

Lack of Traceability and Documentation

Reputable suppliers provide full documentation, including certificates of conformance, material safety data sheets (MSDS), and IP compliance statements. When sourcing from obscure or offshore manufacturers, this documentation may be incomplete or falsified, increasing exposure to IP litigation and quality disputes.

Conclusion

To mitigate these pitfalls, buyers should vet suppliers thoroughly, demand verifiable test data and compliance certifications, and ensure that purchased products do not infringe on existing intellectual property. Partnering with established, transparent manufacturers reduces both quality and legal risks in stucco mesh sourcing.

Logistics & Compliance Guide for Fiberglass Mesh Stucco

Overview of Fiberglass Mesh Stucco

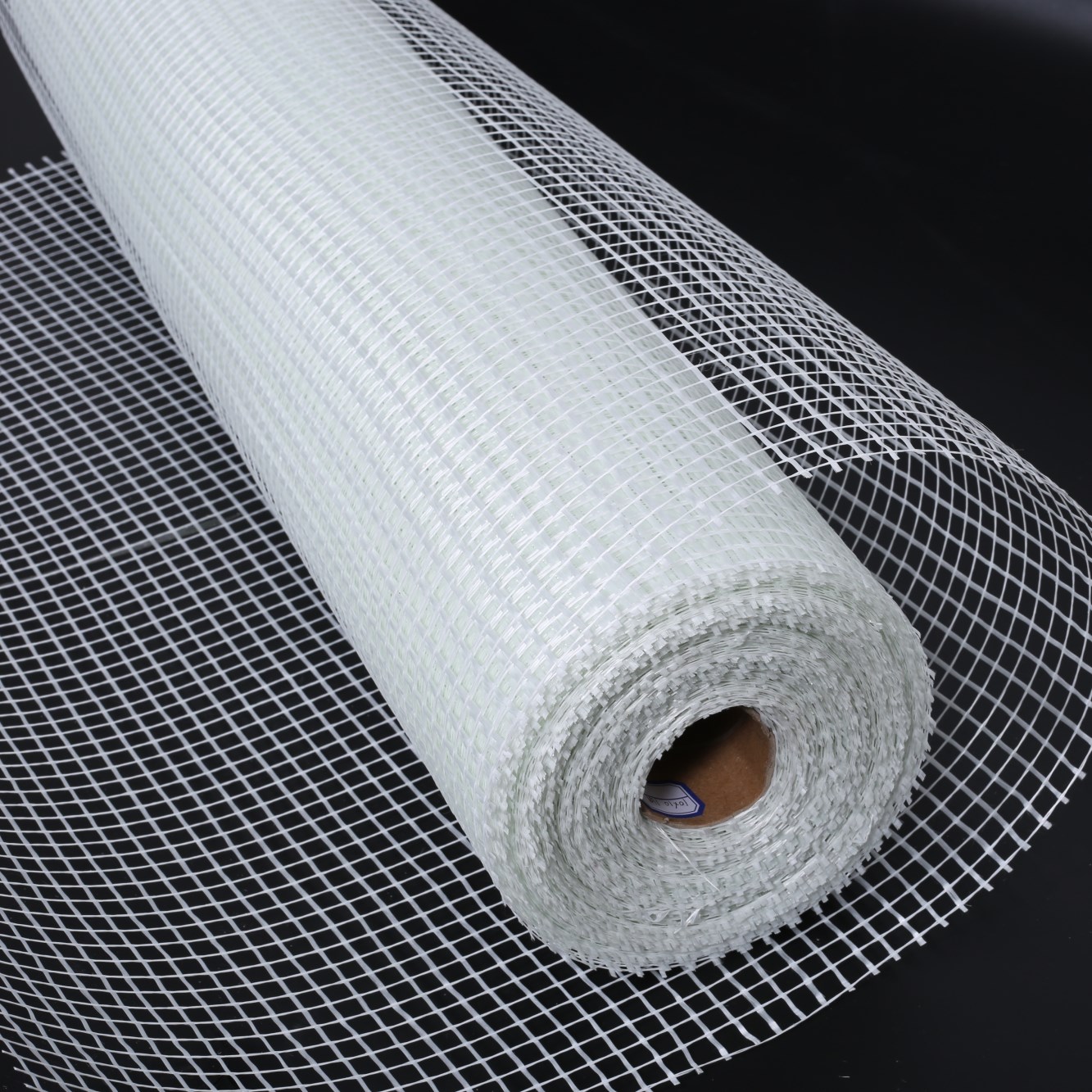

Fiberglass mesh stucco is a reinforcing material used in exterior insulation and finish systems (EIFS) and traditional stucco applications. It provides crack resistance, tensile strength, and long-term durability to stucco finishes. Ensuring proper logistics and compliance is critical for performance, safety, and adherence to building codes.

Transportation and Handling

Proper transportation and handling protect the integrity of fiberglass mesh stucco during transit and on-site storage.

Packaging and Load Securing

Fiberglass mesh is typically supplied in rolls packed on wooden or plastic cores and wrapped in moisture-resistant polyethylene film. Rolls should be stored vertically to prevent deformation. During transport, rolls must be secured on pallets using straps or shrink wrap to prevent shifting, crushing, or exposure to weather.

Environmental Precautions

Avoid exposure to moisture, direct sunlight, and extreme temperatures. Prolonged UV exposure can degrade the alkali-resistant coating on the fiberglass. Store rolls under cover in a dry, well-ventilated area. If stored outdoors temporarily, ensure the packaging remains intact and elevate pallets off the ground.

Storage Requirements

On-Site Storage

Keep all rolls in their original packaging until ready for use. Store indoors whenever possible. If outdoor storage is necessary, cover with waterproof tarps and ensure airflow to prevent condensation. Avoid stacking materials directly on soil or concrete without a moisture barrier.

Shelf Life and Inventory

Fiberglass mesh generally has a shelf life of 2–3 years when stored properly. Rotate stock using first-in, first-out (FIFO) principles to minimize aging. Inspect rolls prior to installation for signs of moisture damage, tearing, or coating degradation.

Regulatory and Compliance Standards

Compliance ensures that fiberglass mesh stucco meets safety, performance, and environmental requirements.

Building Code Compliance

Fiberglass mesh used in stucco systems must comply with relevant building codes such as the International Building Code (IBC) and International Residential Code (IRC). Verify that the product meets ASTM C1178 for fiberglass mesh used in Portland cement-based stucco or ASTM E283/E330 for air leakage and structural performance in EIFS applications.

Material Certification

Ensure the mesh carries certification from recognized bodies such as the American Society for Testing and Materials (ASTM) or the International Code Council (ICC). Look for Evaluation Service (ICC-ES) reports that confirm code compliance for specific stucco systems.

VOC and Environmental Regulations

While fiberglass mesh itself is inert, associated adhesives or base coats may contain volatile organic compounds (VOCs). Confirm that all ancillary materials comply with EPA and local air quality regulations (e.g., SCAQMD Rule 1113, OTC VOC guidelines).

Installation Compliance and Best Practices

Manufacturer Guidelines

Follow the manufacturer’s installation instructions precisely, including overlap requirements (typically 2 inches), embedment depth in base coat, and curing times. Deviations may void warranties and compromise system performance.

Safety Data Sheets (SDS)

Maintain up-to-date Safety Data Sheets for all components, including the mesh and accompanying coatings. Train workers on safe handling, use of personal protective equipment (PPE), and emergency procedures.

Inspection and Testing

Coordinate with third-party inspectors or building officials as required. Perform quality checks during installation, including mesh embedment and continuity at control joints. Document compliance with photos and inspection logs.

International Shipping Considerations

For cross-border shipments, adhere to international logistics standards.

Import/Export Documentation

Prepare commercial invoices, packing lists, and certificates of origin. Include product specifications and compliance documentation (e.g., ASTM test reports, ICC-ES reports) to facilitate customs clearance.

Hazard Classification

Fiberglass mesh is generally non-hazardous and not subject to dangerous goods regulations (e.g., IATA, IMDG). However, verify classification under local transport regulations to avoid delays.

Tariff and Duty Compliance

Classify the product under the correct Harmonized System (HS) code—typically under 7019.90 (Other glass fibers). Confirm duty rates and any applicable free trade agreements (e.g., USMCA, EU tariffs) to ensure cost-effective shipping.

Sustainability and Disposal

Recycling and Waste Management

Fiberglass mesh is not readily recyclable through standard municipal systems. Coordinate with specialty recyclers or dispose of offcuts and waste according to local regulations. Avoid open burning, which can release hazardous fumes.

Environmental Product Declarations (EPD)

Some manufacturers provide EPDs detailing lifecycle impacts. These can support LEED or other green building certifications. Request EPDs when sourcing materials for sustainable projects.

Conclusion

Effective logistics and strict compliance are essential for the successful use of fiberglass mesh stucco. By following proper handling, storage, regulatory, and installation protocols, contractors and distributors can ensure material performance, code adherence, and project longevity. Always consult product-specific guidelines and local authority requirements for optimal outcomes.

In conclusion, sourcing fiberglass mesh for stucco applications requires careful consideration of quality, durability, compatibility, and cost. Choosing a high-quality alkali-resistant fiberglass mesh ensures long-term performance, crack resistance, and structural integrity in stucco systems. It is essential to partner with reputable suppliers who adhere to industry standards and provide consistent product specifications. Additionally, evaluating factors such as mesh weight, coating type, and proper installation techniques contributes to a successful application. By prioritizing material quality and reliable sourcing channels, builders and contractors can enhance the longevity and aesthetic appeal of stucco finishes, ultimately delivering superior results for residential and commercial projects.