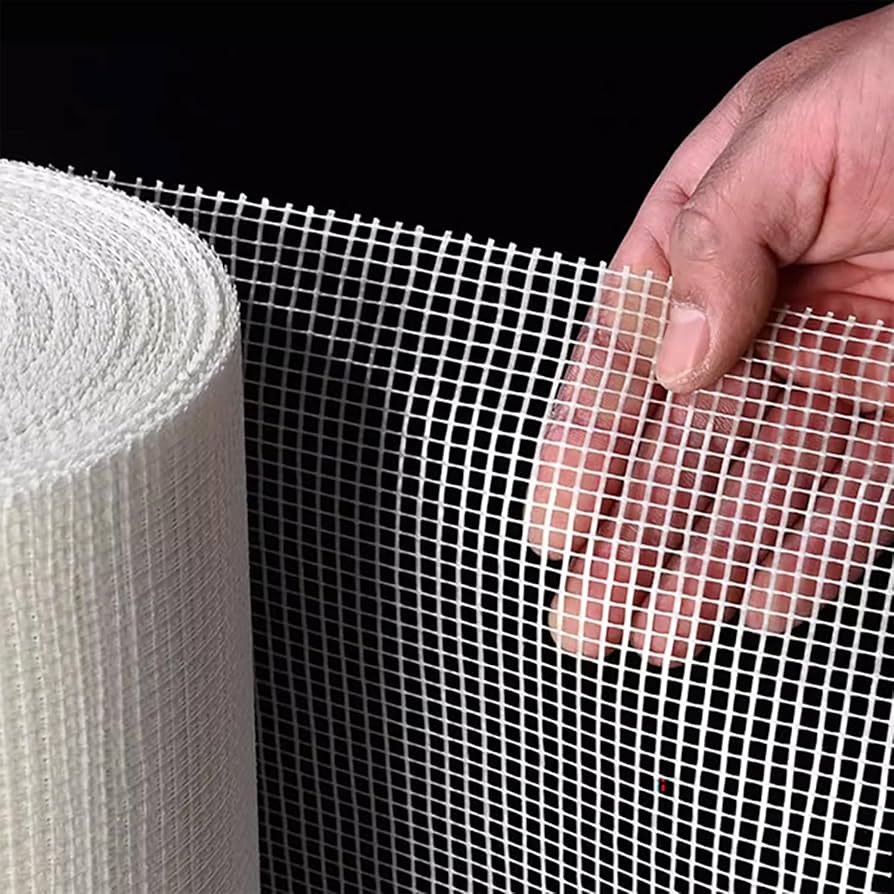

The global fiberglass mesh market is experiencing robust growth, driven by increasing demand in construction applications such as stucco reinforcement, external thermal insulation systems, and flooring. According to a report by Grand View Research, the global fiberglass mesh market size was valued at USD 3.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030. This growth is fueled by rising infrastructure development, stringent energy efficiency regulations, and the expanding adoption of exterior insulation and finish systems (EIFS) in both residential and commercial buildings. With stucco applications accounting for a significant share of fiberglass mesh demand—particularly in North America and the Middle East—manufacturers are focusing on product durability, alkali resistance, and tensile strength to meet evolving industry standards. As competition intensifies, identifying top-performing fiberglass mesh manufacturers becomes crucial for contractors, distributors, and specifiers seeking reliable, high-performance materials. In this context, the following list highlights the top seven fiberglass mesh manufacturers for stucco applications based on production capacity, innovation, global reach, and market reputation.

Top 7 Fiberglass Mesh For Stucco Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Reinforcing Mesh

Domain Est. 1995

Website: usa.sika.com

Key Highlights: SikaWall®-9000 SRT Mesh. Glass fiber mesh for use with stucco. Let’s Build Something Amazing. Contact Us · Find a Distributor · Download Literature. About Us….

#2 Fiberglass Mesh for Stucco

Domain Est. 1996

Website: stocorp.com

Key Highlights: Rating 4.7 (13) Sto Stucco Mesh is a tri-directional weave, flexible treated glass fiber mesh for use with portland cement stucco brown coats in vertical wall construction….

#3 Dryvit Reinforcing Meshes

Domain Est. 1996

Website: dryvit.com

Key Highlights: A specially woven and treated glass fiber mesh is used with Dryvit base coats to provide strength and impact resistance….

#4 Fiber Base Coat

Domain Est. 1997

Website: specmix.com

Key Highlights: SPEC MIX Fiber Base Coat (FBC) is a dry, preblended cement based stucco engineered with proprietary admixtures and fibers that are computer batched for ……

#5 Mesh and Foam Shapes

Domain Est. 2010

Website: rescomproducts.com

Key Highlights: Our fiberglass mesh products are sourced for consistency, tested for strength, and trusted by foam fabricators, EIFS installers, and stucco ……

#6 FibaLath

Domain Est. 2012

Website: adfors.com

Key Highlights: FibaLath is an innovative fiberglass lath for use in stucco applications and exterior/interior manufactured stone and brick facades….

#7 Drywall Specialties

Domain Est. 2020

Website: drywallspecialtiesbm.com

Key Highlights: We offer a full line of fiberglass mesh products EIFS and stucco. We stock light mesh, heavy mesh, sticky mesh and standard mesh. By stocking a wide variety of ……

Expert Sourcing Insights for Fiberglass Mesh For Stucco

H2: 2026 Market Trends for Fiberglass Mesh for Stucco

The global market for fiberglass mesh used in stucco applications is projected to experience steady growth through 2026, driven by increasing construction activity, rising demand for energy-efficient and durable building materials, and advancements in exterior insulation and finish systems (EIFS). Here are the key trends shaping the fiberglass mesh for stucco market in 2026:

-

Growth in Residential and Commercial Construction

Urbanization, population growth, and infrastructure development—particularly in emerging economies across Asia-Pacific, Latin America, and Africa—are fueling demand for new residential and commercial buildings. Fiberglass mesh, a critical component in stucco reinforcement, benefits directly from this construction boom. In North America and Europe, renovation and retrofitting projects are also boosting demand, as builders seek long-lasting, crack-resistant wall systems. -

Increased Adoption of EIFS and Modern Stucco Systems

Exterior Insulation and Finish Systems (EIFS) continue to gain favor due to their energy efficiency and aesthetic flexibility. Fiberglass mesh is integral to these systems, providing tensile strength and crack resistance. As building codes evolve to emphasize energy conservation, the use of EIFS—and by extension, fiberglass mesh—is expected to rise, especially in green building projects. -

Focus on Durability and Weather Resistance

With climate change leading to more extreme weather events, builders and architects are prioritizing materials that offer enhanced durability. Fiberglass mesh provides excellent resistance to moisture, UV degradation, and thermal expansion, making it ideal for stucco applications in diverse climates. This resilience supports its growing adoption in hurricane-prone and high-humidity regions. -

Technological Advancements and Product Innovation

Manufacturers are investing in coated fiberglass mesh with improved alkali resistance and adhesion properties. Alkali-resistant (AR) coatings enhance the mesh’s compatibility with cementitious stucco, prolonging service life. Innovations such as hybrid meshes and variable weaves are also emerging to meet specific performance requirements, offering better flexibility and strength. -

Sustainability and Environmental Regulations

The construction industry is under increasing pressure to reduce its carbon footprint. Fiberglass mesh is seen as a sustainable reinforcement solution due to its long lifespan and recyclability. Additionally, regulatory standards promoting energy-efficient buildings are indirectly driving demand for stucco systems that incorporate fiberglass mesh. -

Regional Market Dynamics

- North America: Remains a dominant market due to widespread use of stucco in residential construction, especially in the U.S. Southwest. Building code updates and hurricane resilience requirements support continued demand.

- Europe: Growth is driven by renovation projects and stringent energy performance standards under the Energy Performance of Buildings Directive (EPBD).

- Asia-Pacific: Rapid urbanization in countries like China, India, and Indonesia is a major growth driver. Local production of fiberglass mesh is expanding to meet rising demand.

-

Middle East & Africa: Infrastructure development and government-led housing projects are increasing stucco usage in warm climates where moisture resistance is critical.

-

Supply Chain and Raw Material Challenges

Fluctuations in the price of raw materials such as E-glass and polymer resins may impact production costs. However, regional manufacturing expansion and supply chain optimization are helping mitigate these challenges. Additionally, some producers are exploring recycled glass content to reduce costs and environmental impact. -

Competitive Landscape and Consolidation

The market is moderately consolidated, with key players such as Owens Corning, Saint-Gobain, Jushi Group, and Taishan Fiberglass leading innovation and global distribution. Strategic partnerships, mergers, and capacity expansions are expected to intensify competition and improve product accessibility.

In conclusion, the fiberglass mesh for stucco market in 2026 is characterized by robust demand driven by construction growth, technological improvements, and sustainability trends. As buildings become more resilient and energy-efficient, fiberglass mesh will remain a cornerstone material in modern stucco and EIFS applications worldwide.

Common Pitfalls When Sourcing Fiberglass Mesh for Stucco (Quality and Intellectual Property)

Poor Material Quality and Inadequate Specifications

One of the most frequent issues when sourcing fiberglass mesh for stucco applications is receiving substandard material that fails to meet industry performance standards. Low-quality mesh may use inferior alkali-resistant (AR) glass fibers or insufficient polymer coating, leading to early degradation when exposed to the high pH environment of cementitious stucco. This can result in cracks, delamination, and reduced structural integrity over time. Buyers often overlook technical specifications such as tensile strength, weight per square meter, and mesh size, leading to the selection of mesh that is too weak or too sparse for the intended application.

Lack of Compliance with Industry Standards

Many suppliers, particularly in unregulated or offshore markets, provide fiberglass mesh that does not comply with ASTM C1172 or other relevant standards for exterior insulation and finish systems (EIFS) and stucco reinforcement. Without proper certification or third-party testing, contractors and builders risk using non-compliant products that may fail inspections or result in costly remediation. Always verify that the product meets ASTM, ISO, or local building code requirements.

Inconsistent Coating and Bonding Performance

A critical factor in fiberglass mesh performance is the quality of the polymer coating, which protects the glass fibers from alkaline attack. Inconsistencies in coating weight or application can create weak spots that compromise the mesh’s durability. Poorly coated mesh may also exhibit poor adhesion to stucco, reducing its effectiveness as a reinforcement layer. Buyers should request coating specifications and conduct adhesion tests when evaluating new suppliers.

Counterfeit or Misrepresented Products

The market for construction materials, including fiberglass mesh, is susceptible to counterfeit or misrepresented goods. Some suppliers may falsely advertise their mesh as alkali-resistant or ASTM-compliant without proper verification. This is especially common with online marketplaces or intermediaries lacking direct oversight of manufacturing. Conducting due diligence—such as factory audits, material testing, and supplier verification—is essential to avoid intellectual property (IP) violations and product fraud.

Intellectual Property and Brand Infringement

Reputable manufacturers invest in proprietary formulations, coatings, and branding for their fiberglass mesh products. Sourcing from unauthorized distributors or counterfeit producers can lead to the use of IP-infringing materials, exposing contractors and developers to legal liability. Brands such as Saint-Gobain (Polynet®), Owens Corning, and ETS (Exterior Technologies) hold trademarks and technical patents; using knock-off versions undermines innovation and can void warranties or building certifications.

Inadequate Supply Chain Transparency

Many sourcing pitfalls stem from a lack of visibility into the supply chain. Buyers may unknowingly purchase mesh produced in facilities with poor quality control or unethical labor practices. Without transparency, it’s difficult to trace material origin, verify manufacturing processes, or ensure consistent batch-to-batch quality. Partnering with suppliers who offer full traceability and documentation helps mitigate these risks.

Conclusion

To avoid common pitfalls in sourcing fiberglass mesh for stucco, prioritize quality verification, compliance with standards, and supplier credibility. Ensure that intellectual property rights are respected and that materials come from transparent, auditable sources. Investing time in proper due diligence ultimately protects project integrity, reduces liability, and ensures long-term performance.

Logistics & Compliance Guide for Fiberglass Mesh For Stucco

Product Overview and Classification

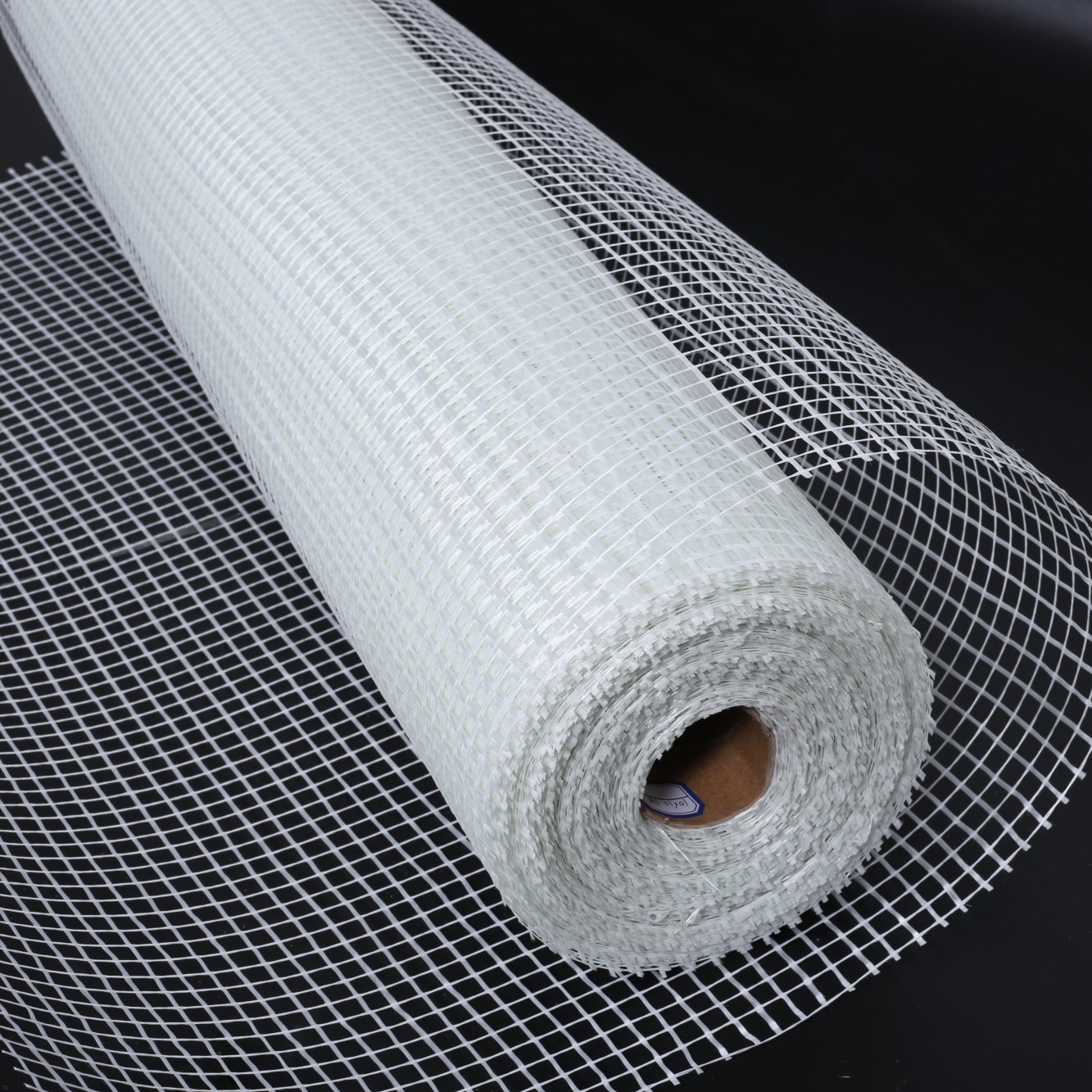

Fiberglass mesh for stucco is a reinforcing material used in exterior insulation finishing systems (EIFS) and cement-based stucco applications. It is typically made from alkali-resistant glass fibers woven into a mesh and coated with a polymer to resist cracking and enhance durability. Proper classification ensures correct handling, shipping, and compliance with international and domestic regulations.

Harmonized System (HS) Code

The standard Harmonized System (HS) code for fiberglass mesh used in construction is:

7019.90.00 – “Other glass fibers and articles thereof (e.g., yarn, fabrics), not elsewhere specified or included.”

Note: Specific sub-codes may vary by country (e.g., 7019.90.50 in the U.S. for certain reinforced fabrics). Confirm with local customs authorities for accurate tariff classification.

Packaging and Labeling Requirements

- Packaging: Fiberglass mesh is generally supplied in rolls, wrapped in polyethylene film to protect against moisture and physical damage. Rolls should be securely palletized using stretch wrap and corner boards for stability.

- Labeling: Each package must include:

- Product name and specifications (e.g., weight per square meter, roll dimensions)

- Batch/lot number

- Manufacturer name and contact information

- Country of origin

- Handling symbols (e.g., “Fragile,” “This Side Up”)

- Compliance markings (e.g., CE marking if applicable)

Shipping and Transportation

- Mode of Transport: Suitable for road, sea, and air freight. Avoid exposure to extreme temperatures and moisture during transit.

- Stacking and Stowage: Pallets must be stacked flat and not exceed recommended load heights. Avoid placing heavy items on top of mesh rolls to prevent deformation.

- Hazard Classification: Non-hazardous material (UN3077, Class 9 not typically applicable). No special handling required under ADR, IMDG, or IATA regulations.

Import/Export Documentation

Essential documentation includes:

– Commercial Invoice (with HS code, value, and product description)

– Packing List (detailing weight, dimensions, and number of units)

– Bill of Lading or Air Waybill

– Certificate of Origin (required for preferential tariff treatment under trade agreements)

– Import Declaration (as required by destination country)

Regulatory Compliance

- United States: Complies with ASTM C1170 for stucco base coats and reinforcing meshes. No TSCA (Toxic Substances Control Act) restrictions apply to standard fiberglass mesh.

- European Union: Must comply with CE marking requirements under Construction Products Regulation (CPR) EN 13496 for glass fiber mesh used in thermal insulation.

- Canada: Meets requirements of CAN/ULC-S716.1 for EIFS components.

- Other Regions: Verify local building codes and material standards (e.g., AS/NZS 4256.13 in Australia/New Zealand).

Environmental and Safety Considerations

- Handling: Wear gloves and protective clothing to minimize skin irritation from glass fibers. Use in well-ventilated areas.

- Disposal: Classified as non-hazardous waste. Dispose of in accordance with local municipal regulations. Recyclable in designated glass fiber recycling streams where available.

- REACH and RoHS: Standard fiberglass mesh typically contains no SVHCs (Substances of Very High Concern) and complies with REACH and RoHS directives.

Storage Guidelines

- Store indoors in a dry, climate-controlled environment.

- Keep away from direct sunlight and moisture to prevent degradation of polymer coating.

- Elevate pallets off the floor to prevent water absorption.

- Max storage duration: 12 months from manufacturing date (check manufacturer’s recommendations).

Quality Assurance and Traceability

- Maintain batch traceability through lot numbers.

- Conduct periodic quality checks for tensile strength, alkali resistance, and coating integrity per ASTM D885 or EN 13496.

- Retain test reports and certifications (e.g., ISO 9001, factory production control) for audits and compliance verification.

Conclusion

Proper logistics and compliance management ensures smooth international trade and regulatory acceptance of fiberglass mesh for stucco. Adherence to packaging, documentation, and regional standards minimizes delays and supports product performance in the field. Always consult with legal and customs experts for market-specific requirements.

In conclusion, sourcing fiberglass mesh for stucco applications requires careful consideration of quality, compatibility, durability, and cost-effectiveness. High-quality alkali-resistant fiberglass mesh is essential to ensure long-term performance, crack resistance, and structural integrity in stucco systems. It is important to select a reputable supplier who provides consistent product specifications, relevant certifications, and technical support. Evaluating factors such as mesh weight, coating type, tensile strength, and warranty can significantly impact the success of the stucco installation. By prioritizing reliability and performance in the sourcing process, contractors and builders can enhance the longevity and aesthetic appeal of stucco finishes while minimizing maintenance and repair costs over time.