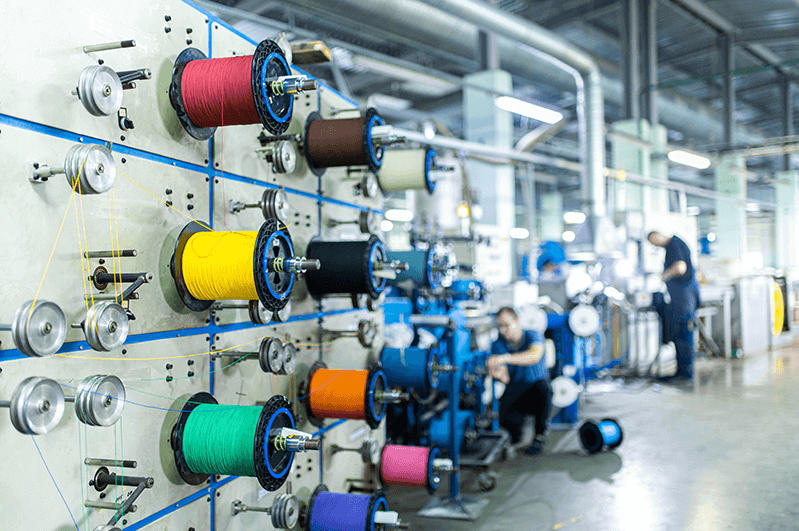

The global fiber optic splicing market is experiencing robust growth, driven by surging demand for high-speed internet, the expansion of 5G networks, and the ongoing deployment of fiber-to-the-home (FTTH) infrastructure. According to a report by Mordor Intelligence, the fiber optic market is projected to grow at a CAGR of over 8.5% from 2023 to 2028, with splicing technologies forming a critical component of network installation and maintenance. Similarly, Grand View Research estimates that the global fiber optics market size was valued at USD 10.5 billion in 2022 and is expected to expand at a CAGR of 8.9% through 2030, underpinned by increasing investments in broadband infrastructure across both developed and emerging economies. As the backbone of modern telecommunications, fiber splicing ensures reliable, low-loss connections in optical networks, making it indispensable to large-scale deployments. With this growing demand, a select group of manufacturers have emerged as leaders in innovation, product reliability, and global reach—setting the standard in the fiber splicing industry.

Top 10 Fiber Splicing Companies Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PLP

Domain Est. 1994

Website: plp.com

Key Highlights: PLP is a worldwide designer, manufacturer and supplier of high quality cable anchoring and control hardware and systems, fiber optic and copper splice ……

#2 Fibertronics, Inc.

Domain Est. 2000

Website: fibertronics.com

Key Highlights: 2–12 day deliveryFibertronics, Inc. is an SBA certified woman-owned small business providing USA manufactured customized fiber optic and low voltage cable assemblies, ……

#3 3SAE Technologies Inc.

Domain Est. 2000

Website: 3sae.com

Key Highlights: 3SAE Technologies Inc. designs, manufactures and distributes tools for optical fiber fusion splicing, glass processing and micro positioning….

#4 OZ Optics Ltd.

Domain Est. 1995 | Founded: 1985

Website: ozoptics.com

Key Highlights: Located in Canada’s capital city of Ottawa and established in 1985, OZ Optics Limited is a leading worldwide supplier of fiber optic products for existing ……

#5 Diamond SA: Fiber Optic Solutions for High

Domain Est. 1997

Website: diamond-fo.com

Key Highlights: Discover DIAMOND’s innovative fiber optic solutions built with 40+ years of expertise. Swiss precision for high-performance applications. Explore now!…

#6 FiberOptic Supply

Domain Est. 1998

Website: fiberopticsupply.com

Key Highlights: 1–2 day delivery · 30-day returnsWe offer fiber optic materials from Test Equipment, Bulk Cable and Fusion Splicers to Tools, Patch Cables and Consumables….

#7 Fiber Instrument Sales: FIS

Domain Est. 1999

Website: fiberinstrumentsales.com

Key Highlights: 7-day returnsLooking for one of the fiber optics industry leaders? Look no further, Fiber Instrument Sales inventories over $10 million in fiber optic merchandise….

#8 Lambert’s Cable Splicing Company

Domain Est. 2000

Website: lambertcable.com

Key Highlights: Lamberts Cable Splicing Company, LLC is one of the premier utility contractors serving the Northeast, Mid-Atlantic, and Southeast regions of the USA….

#9 Fusion Splicer Solutions, Tools, and Equipment

Domain Est. 2002

Website: ofsoptics.com

Key Highlights: Fusion splicer solutions for professionals. Highly accurate splicers to all fiber optic cable types. OFS is the official support center of Fitel splicers….

#10 AFL

Domain Est. 2008

Website: aflglobal.com

Key Highlights: AFL is a leading provider of fiber optic solutions for broadband networks, data centers, energy infrastructure, and other applications….

Expert Sourcing Insights for Fiber Splicing Companies

H2: Market Trends Shaping Fiber Splicing Companies in 2026

As global demand for high-speed internet and robust digital infrastructure continues to surge, the fiber splicing industry is poised for significant transformation by 2026. Driven by advancements in telecommunications, government broadband initiatives, and the proliferation of 5G and fiber-to-the-home (FTTH) networks, fiber splicing companies are adapting to a dynamic market landscape. Below are the key trends expected to define the industry in 2026:

-

Accelerated Deployment of Fiber Networks

Governments and private entities worldwide are investing heavily in expanding fiber-optic infrastructure to bridge the digital divide. In 2026, the continued rollout of national broadband programs—especially in rural and underserved regions—will drive demand for skilled fiber splicing services. The U.S., EU, India, and Southeast Asia are expected to lead deployment efforts, creating sustained opportunities for splicing contractors. -

Rise of 5G and Edge Computing

The full-scale implementation of 5G networks by 2026 will necessitate dense fiber backhaul and fronthaul infrastructure. Fiber splicing companies will play a critical role in connecting 5G small cells and edge data centers, requiring high-precision splicing in urban and challenging environments. This shift emphasizes faster turnaround times and improved splicing efficiency. -

Adoption of Automated and Smart Splicing Technologies

By 2026, fiber splicing companies are expected to increasingly adopt automated fusion splicers equipped with AI-driven diagnostics, real-time monitoring, and cloud-based reporting. These technologies improve splice accuracy, reduce training time for technicians, and enable remote quality assurance—key advantages in large-scale deployments. -

Workforce Shortages and Upskilling Initiatives

Despite rising demand, the fiber splicing industry faces a growing shortage of certified technicians. In response, companies are investing in training programs and partnerships with technical schools. Additionally, augmented reality (AR) training tools and remote expert guidance systems are expected to enhance workforce productivity and reduce onboarding time. -

Consolidation and Strategic Partnerships

Market consolidation is anticipated as larger infrastructure firms acquire regional splicing contractors to strengthen end-to-end service offerings. Strategic alliances between splicing companies and telecom OEMs or network operators will also rise, enabling faster project execution and integrated service delivery. -

Sustainability and Green Infrastructure

Environmental considerations are gaining traction. By 2026, fiber splicing companies are likely to face pressure to adopt sustainable practices, such as minimizing material waste, using energy-efficient equipment, and supporting low-carbon network builds. Some operators may require splicing partners to comply with ESG (Environmental, Social, and Governance) standards. -

Expansion into Emerging Markets

While mature markets like North America and Western Europe remain strong, growth in Africa, Latin America, and South Asia will present new opportunities. Fiber splicing companies with scalable models and experience in diverse terrains will be well-positioned to capture market share in these regions.

In conclusion, the 2026 fiber splicing market will be defined by technological innovation, infrastructure expansion, and evolving service demands. Companies that embrace automation, invest in talent, and align with broader digital transformation goals will lead the industry in this high-growth era.

Common Pitfalls When Sourcing Fiber Splicing Companies (Quality, IP)

Sourcing fiber splicing services is a critical decision for network infrastructure projects, whether in telecom, data centers, or enterprise environments. While cost and speed are often prioritized, overlooking quality and intellectual property (IP) concerns can lead to long-term operational, legal, and security risks. Below are key pitfalls to avoid.

Inadequate Quality Assurance and Certification Standards

One of the most common issues is selecting a splicing provider without verifying their adherence to industry quality standards. Poor splicing can result in high signal loss, network downtime, and costly rework.

- Lack of Certified Technicians: Not all technicians are certified by recognized bodies such as FOA (Fiber Optic Association) or BICSI. Unqualified personnel may produce inconsistent splice results.

- Outdated Equipment: Providers using older fusion splicers or OTDRs may not meet current performance benchmarks, leading to signal attenuation or weak splice points.

- Insufficient Testing and Documentation: Reputable providers perform end-to-end testing (e.g., OTDR traces, power meter readings) and provide detailed reports. Omitting this step risks undetected faults.

Poor Workmanship Leading to Network Reliability Issues

Even with certified staff, inconsistent field practices can undermine quality.

- Inconsistent Splice Protection: Improper heat-shrinking or sealing of splice sleeves exposes fibers to moisture and mechanical stress.

- Substandard Cable Management: Poor organization in splice enclosures or patch panels leads to future maintenance difficulties and increased risk of damage.

- Lack of Environmental Adaptability: Some providers fail to account for harsh environmental conditions (e.g., temperature extremes, humidity), compromising splice longevity.

Intellectual Property and Data Security Risks

Fiber splicing often involves access to sensitive network infrastructure, raising IP and cybersecurity concerns.

- Unauthorized Access to Network Design: Splicing teams may gain access to network topologies, data center layouts, or proprietary configurations. Without NDAs or strict access controls, this information could be exposed.

- Inadequate Data Handling Policies: Providers without formal data security protocols may store or transmit OTDR traces, network maps, or site photos insecurely.

- Third-Party Subcontracting Without Oversight: Some companies subcontract work to unvetted technicians or firms, increasing the risk of IP leakage or non-compliance with contractual security terms.

Lack of Traceability and Accountability

When issues arise post-installation, identifying responsibility becomes difficult without proper documentation.

- Missing Splice Records: Failure to log splice locations, loss values, and technician IDs hinders troubleshooting and maintenance.

- No Warranty or Service-Level Agreements (SLAs): Providers that don’t offer warranties on splices may avoid accountability for future failures.

- Limited Audit Rights: Contracts without audit or inspection clauses prevent clients from verifying compliance with agreed-upon standards.

Geographic and Regulatory Compliance Gaps

Depending on the project location, regulatory and logistical challenges can affect quality and IP protection.

- Non-Compliance with Local Regulations: Some providers may not follow regional safety, environmental, or telecom regulations, risking project delays or fines.

- Cross-Border Data Transfer Risks: If splicing data (e.g., network schematics) is processed or stored in another country, it may violate data sovereignty laws (e.g., GDPR, CCPA).

Conclusion

To mitigate these pitfalls, organizations should rigorously vet fiber splicing providers by checking certifications, requesting sample work, reviewing security policies, and including IP protection clauses in contracts. Prioritizing quality and IP safeguards upfront ensures long-term network performance and protects sensitive infrastructure information.

Logistics & Compliance Guide for Fiber Splicing Companies

Overview and Importance

Fiber splicing companies play a critical role in deploying and maintaining high-speed telecommunications and data networks. Efficient logistics and strict compliance with regulations are essential to ensure safety, reliability, and legal operation. This guide outlines key logistical considerations and compliance requirements specific to fiber splicing operations.

Equipment and Material Logistics

Proper management of splicing equipment, fiber cables, enclosures, and consumables is vital for minimizing downtime and project delays. Maintain an inventory tracking system for:

- Fusion splicers, OTDRs, cleavers, and power meters

- Fiber optic cables (various types and lengths)

- Splice closures, patch panels, and distribution boxes

- Safety gear (gloves, goggles, face shields)

Ensure all equipment is calibrated regularly and stored in climate-controlled environments to preserve performance. Establish relationships with reliable suppliers to guarantee timely delivery of materials, especially in remote or time-sensitive projects.

Workforce Deployment and Scheduling

Coordinate technician teams efficiently based on project scope, location, and skill requirements. Use digital scheduling tools to:

- Assign jobs based on technician certifications and proximity

- Track labor hours and overtime compliance

- Monitor travel time and site access permissions

Provide mobile logistics support, including GPS-tracked service vehicles stocked with essential tools and materials, to increase on-site efficiency.

Regulatory Compliance Requirements

Fiber splicing companies must comply with federal, state, and local regulations to ensure safety and legality. Key regulations include:

OSHA Standards

Adhere to Occupational Safety and Health Administration (OSHA) guidelines, particularly:

– Hazard Communication Standard (29 CFR 1910.1200)

– Personal Protective Equipment (PPE) requirements (29 CFR 1910.132)

– Confined Space Entry procedures (29 CFR 1910.146), where applicable

Conduct regular safety training and maintain documentation of employee training records.

DOT and Transportation Regulations

When transporting hazardous materials (e.g., isopropyl alcohol, batteries), comply with Department of Transportation (DOT) rules:

– Proper labeling and containment of hazardous substances

– Driver training and certification (if applicable)

– Vehicle safety inspections

FCC and Industry Standards

Follow Federal Communications Commission (FCC) and industry best practices for network installation:

– Adherence to GR-3120 (generic requirements for fiber splice closures)

– Compliance with National Electrical Safety Code (NESC) for aerial installations

– Documentation of network performance testing (e.g., OTDR traces, loss budgets)

Environmental and Right-of-Way Compliance

Secure necessary permits before commencing work, especially for:

– Public right-of-way access (city, county, or state approvals)

– Environmental impact assessments (e.g., near wetlands or protected areas)

– Underground utility locates (call 811 in the U.S.)

Follow local excavation laws (e.g., dig alerts, potholing requirements) to avoid damaging existing infrastructure.

Data Security and Documentation

Maintain secure records of:

– As-built drawings and splice maps

– Test results and certification reports

– Customer agreements and regulatory permits

Ensure compliance with data privacy laws when handling customer or project-related information. Use encrypted digital systems to store and transmit sensitive data.

Incident Reporting and Emergency Response

Establish protocols for:

– Reporting workplace injuries or near-misses

– Responding to fiber cable cuts or network outages

– Managing chemical spills or equipment failures

Keep emergency contact lists and first-aid supplies in all service vehicles.

Conclusion

Effective logistics and rigorous compliance are foundational to the success of any fiber splicing company. By implementing structured processes for material handling, workforce management, and regulatory adherence, companies can ensure safe, efficient, and legally sound operations across all project phases. Regular audits and continuous improvement practices will further strengthen operational resilience and client trust.

In conclusion, sourcing fiber splicing companies requires a strategic approach that balances technical expertise, reliability, cost-efficiency, and industry compliance. It is essential to evaluate potential vendors based on their certifications, experience with similar projects, quality assurance processes, response times, and geographic coverage. Prioritizing companies with a proven track record, modern equipment, and skilled technicians ensures high splice quality and network reliability. Additionally, considering scalability and customer support can enhance long-term partnership success. By conducting thorough due diligence and aligning vendor capabilities with project requirements, organizations can secure dependable fiber splicing services that support robust, high-performance telecommunications infrastructure.