The global fiber pots market is experiencing robust growth, driven by increasing demand for sustainable and biodegradable packaging solutions across agriculture, horticulture, and landscaping industries. According to Grand View Research, the global biodegradable pots market size was valued at USD 1.2 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 8.4% from 2023 to 2030. This growth is fueled by stricter environmental regulations, rising consumer awareness about plastic pollution, and a shift toward eco-friendly cultivation practices. Fiber pots, made from renewable materials such as wood pulp, peat, and recycled paper, offer a compostable alternative to plastic containers, supporting root development and reducing transplant shock in plants. With North America and Europe leading in adoption due to strong sustainability initiatives, and Asia-Pacific witnessing accelerated growth due to urban gardening trends, the demand for high-quality fiber pot manufacturers is surging. In this evolving landscape, identifying the top players who combine innovation, scalability, and environmental stewardship is essential for landscapers, nurseries, and retailers aiming to align with green procurement standards.

Top 10 Fiber Pots Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Manufacturer of Large Modern Fiberglass Planters & Containers

Domain Est. 2015

Website: taumanufacturing.com

Key Highlights: Manufacturers of high quality modern lightweight fiberglass & faux cement pots and planters for businesses, retailers, and brands around the world….

#2 Grow Green Planters

Domain Est. 2023

Website: growgreenplanters.com

Key Highlights: Get heavy-duty plastic pots from leading plastic pots manufacturers. Custom designs with fast, reliable bulk delivery for global buyers….

#3 Jairaj

Domain Est. 2024

Website: hariplanters.com

Key Highlights: Fiberglass Planter, FRP Pot & Decorative Planter Manufacturer offered by Jairaj from Jaipur, Rajasthan, India. … Frp Planter Pots · Rs 4,500 / Piece. Shape: ……

#4 Nursery Fiber Pots & Fiber Grow Pots

Domain Est. 1996

Website: griffins.com

Key Highlights: FiberGrow nursery pots are available in a wide variety of sizes suitable for container grown stock. FiberGrow insulates roots from temperature fluctuations….

#5 Campania International

Domain Est. 1999

Website: campaniainternational.com

Key Highlights: Welcome to Campania’s website! Browse our extensive line of handcrafted planters, fountains, statuary and more! See a product you love? Use our retail locator ……

#6 Smart Pots — USA-Made Fabric Grow Bags & Raised Beds

Domain Est. 2004 | Founded: 1984

Website: smartpots.com

Key Highlights: Smart Pot fabric planters grow bigger, healthier roots for vegetables, herbs, and flowers. USA-made, BPA & lead free since 1984. Shop fabric grow bags, ……

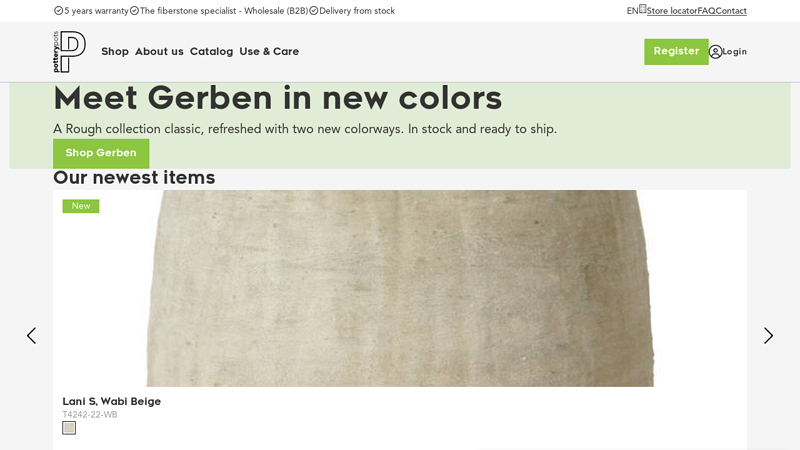

#7 Pottery Pots EU

Domain Est. 2005

Website: potterypots.com

Key Highlights: Our customers have been enthusiastic about Pottery Pots for years. The choice of pots is diverse and there is something for everyone….

#8 Fiber Growing Containers, Planters, Plant Pots

Domain Est. 2015

Website: hc-companies.com

Key Highlights: We’re proud to offer a complete line of sustainable fiber plant containers manufactured with responsible growers and gardeners in mind….

#9 Biodegradable and Compostable Pots

Domain Est. 2018

Website: biodegradable-pots.com

Key Highlights: Biodegradable pots make planting without holes easy, as water will penetrate the natural fibre walls automatically after some time….

#10 About Fiber Kraft Pots: Premium Eco

Website: fiberkraftpots.com

Key Highlights: Rating 4.5 (27) Durable & Eco-Friendly Products: Made with high-quality fiber for long-lasting use. · Custom Designs: Planters tailored to your style, size, and project needs….

Expert Sourcing Insights for Fiber Pots

H2: Market Trends for Fiber Pots in 2026

The global fiber pots market is poised for significant transformation and growth by 2026, driven by increasing environmental awareness, advancements in sustainable packaging, and shifts in consumer and regulatory demands. As industries strive to reduce plastic usage and adopt eco-friendly alternatives, fiber pots—made from renewable, biodegradable, and compostable materials—are emerging as a preferred solution across multiple sectors, particularly foodservice, horticulture, and consumer goods.

1. Rising Demand for Sustainable Packaging Solutions

Environmental regulations and consumer preferences are accelerating the shift toward sustainable packaging. Governments worldwide are enforcing stricter rules on single-use plastics, creating a favorable environment for fiber-based alternatives. Fiber pots, typically manufactured from bamboo, molded fiber, or recycled paperboard, align with circular economy principles. By 2026, demand is expected to surge in regions like Europe and North America, where sustainability mandates are most stringent.

2. Expansion in Foodservice and Ready-to-Eat Markets

The foodservice industry is a major adopter of fiber pots, especially for takeout meals, soups, sauces, and desserts. With the continued growth of food delivery platforms and the need for microwave- and freezer-safe containers, fiber pots are being engineered with enhanced barrier coatings (e.g., PLA or water-based) to improve moisture and grease resistance. Innovations in performance will broaden their application, boosting market penetration by 2026.

3. Technological Advancements in Material Science

Ongoing R&D is improving the functionality of fiber pots, making them more durable, heat-resistant, and leak-proof. Manufacturers are investing in bio-based coatings and lidding systems that maintain compostability while ensuring product integrity. These advancements will reduce reliance on plastic linings and open new market opportunities in premium and frozen food segments.

4. Growth in Horticulture and Plant Packaging

The horticulture sector is increasingly using fiber pots as biodegradable plant containers that can be planted directly into the soil, reducing transplant shock and plastic waste. By 2026, this application is expected to expand, especially with urban gardening and indoor plant trends on the rise. Producers are developing fiber pots with controlled degradation rates tailored to specific plant growth cycles.

5. Regional Market Developments

Asia-Pacific is anticipated to be the fastest-growing region due to rapid urbanization, rising disposable incomes, and government initiatives to reduce plastic pollution. Countries like China and India are investing in green packaging infrastructure, supporting the local production of fiber pots. Meanwhile, North America and Europe will remain key markets due to strong regulatory frameworks and high consumer awareness.

6. Challenges and Competitive Landscape

Despite positive trends, challenges remain, including higher production costs compared to plastic, limited recycling infrastructure for compostable materials, and variability in raw material supply. However, economies of scale and increased automation are expected to lower costs. Major players such as Huhtamäki, DS Smith, and Pactiv Evergreen are expanding their fiber pot portfolios, driving competition and innovation.

In conclusion, the 2026 fiber pots market will be shaped by sustainability imperatives, technological enhancements, and expanding applications across industries. Companies that invest in scalable, eco-conscious production and align with global environmental goals are likely to lead the market.

Common Pitfalls When Sourcing Fiber Pots (Quality, IP)

When sourcing fiber pots—used in fiber optic termination and splicing applications—businesses often encounter challenges related to quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to performance failures, safety risks, and legal complications. Below are key pitfalls to avoid:

Inadequate Quality Control Standards

One of the most frequent issues is sourcing fiber pots from suppliers with inconsistent or subpar quality control. Low-quality materials or poor manufacturing can result in compromised mechanical strength, environmental resistance, or optical performance. For example, fiber pots with improper sealing may fail to maintain an IP (Ingress Protection) rating, leading to moisture or dust ingress that damages internal splices. Buyers should verify that suppliers adhere to international standards such as IEC 61300 or Telcordia GR-761, and request test reports for environmental, thermal, and sealing performance.

Misrepresentation of IP Ratings

Suppliers may falsely claim high IP ratings (e.g., IP68) without third-party certification. An improperly rated fiber pot might appear robust but fail under real-world conditions such as outdoor exposure or underground installation. Always require certified test documentation from accredited labs and conduct spot testing upon delivery. Relying solely on marketing claims without verification exposes projects to reliability issues and costly field failures.

Use of Non-Compliant or Counterfeit Materials

Some manufacturers use recycled or off-spec materials to reduce costs, which can affect flame resistance, UV stability, and long-term durability. This is particularly critical in fire-prone or outdoor environments. Additionally, counterfeit components may mimic reputable brands but lack performance integrity. Conduct material verification through independent lab testing and audit supply chains to ensure traceability and authenticity.

Lack of IP Protection in Design and Manufacturing

When custom fiber pots are developed, there’s a risk of IP theft if non-disclosure agreements (NDAs) and proper contractual safeguards are not in place. Suppliers in certain regions may replicate designs for resale or use them in competing products. Ensure that design rights, molds, and technical specifications are legally protected through patents, trademarks, or industrial design registrations, and include IP clauses in supplier contracts.

Insufficient Supplier Vetting and Traceability

Failing to audit suppliers thoroughly can result in sourcing from subcontractors with unknown quality practices. This lack of traceability makes it difficult to address quality issues or recalls. Establish a supplier qualification process that includes on-site audits, review of quality management systems (e.g., ISO 9001), and requirement for full material and production documentation.

Overlooking Long-Term Support and Warranty

Some suppliers offer attractive pricing but provide minimal after-sales support or short warranty periods. Fiber pot failures may emerge months or years after installation, making long-term reliability and technical support essential. Ensure warranty terms cover environmental and performance failures, and confirm the supplier’s ability to provide replacements or technical assistance over the product lifecycle.

By addressing these common pitfalls proactively—through rigorous supplier evaluation, independent testing, and strong IP safeguards—organizations can ensure reliable performance and legal security when sourcing fiber pots.

Logistics & Compliance Guide for Fiber Pots

Fiber pots, commonly used in horticulture and agriculture for growing seedlings, offer an eco-friendly alternative to plastic containers. However, transporting and selling fiber pots—especially across regions or internationally—requires adherence to specific logistics and regulatory standards. This guide outlines the key considerations to ensure smooth, compliant operations.

Understanding Fiber Pot Materials

Fiber pots are typically made from organic, biodegradable materials such as peat, coir (coconut fiber), wood pulp, or recycled paper. These materials are generally non-toxic and environmentally safe, but their composition can affect shipping classifications, import regulations, and phytosanitary requirements. Always verify the exact material composition and sourcing, as some raw materials may be subject to restrictions depending on their origin.

Packaging and Handling Requirements

To prevent damage during transit, fiber pots should be packed in sturdy, moisture-resistant packaging. Since many fiber pots are susceptible to humidity and compression, use layered stacking with dividers or shrink-wrapping to maintain structural integrity. Palletized loads should be stretch-wrapped and clearly labeled with handling instructions (e.g., “Fragile,” “Keep Dry,” “This Side Up”). Avoid exposure to rain or high humidity during storage and transport.

Domestic Transportation Regulations

Within domestic markets, fiber pots are generally not classified as hazardous materials. However, ensure compliance with general freight regulations for packaged goods. If transporting large volumes, adhere to carrier-specific guidelines for pallet dimensions, weight limits, and load securing. For shipments via freight carriers, proper labeling with product description, weight, quantity, and contact information is essential.

International Shipping and Customs Compliance

Exporting fiber pots internationally may require compliance with additional regulations due to the organic nature of the materials:

- Customs Documentation: Prepare a commercial invoice, packing list, and bill of lading. Clearly describe the product as “biodegradable fiber pots for horticultural use” and include Harmonized System (HS) code—commonly 4803.00 or 6307.90, depending on composition.

- Phytosanitary Certificates: While fiber pots themselves are not plants, some countries require phytosanitary certificates if the raw materials (e.g., wood pulp, coir) are considered potential vectors for pests or diseases. Check requirements with the importing country’s agricultural authority.

- Material Restrictions: Certain countries restrict the import of products made from specific raw materials (e.g., peat from protected bogs). Ensure your materials comply with the destination country’s environmental and agricultural policies.

Environmental and Sustainability Standards

Many markets, especially in the EU and North America, favor eco-friendly products. To enhance market access:

- Obtain certifications such as FSC (Forest Stewardship Council) for wood-based fiber pots or OMRI (Organic Materials Review Institute) for use in organic farming.

- Clearly label products with recyclability and compostability claims, ensuring compliance with advertising standards (e.g., FTC Green Guides in the U.S.).

Labeling and Traceability

All shipments should include accurate product labeling with:

– Product name and description

– Net quantity

– Manufacturer or distributor name and address

– Batch or lot number for traceability

– Country of origin

– Disposal instructions (e.g., “Compostable” or “Biodegradable in soil”)

Storage Conditions

Store fiber pots in a dry, well-ventilated warehouse to prevent mold, premature degradation, or weakening of the material. Avoid direct contact with concrete floors and maintain space between pallets for air circulation. Rotate stock using a first-in, first-out (FIFO) system to minimize aging and moisture absorption.

Regulatory Monitoring and Updates

Regulations related to organic materials and packaging are subject to change. Stay informed by monitoring updates from:

– U.S. Department of Agriculture (USDA)

– European Plant Protection Organization (EPPO)

– International Plant Protection Convention (IPPC)

– Local environmental and customs authorities

Regularly consult with customs brokers or compliance experts when entering new markets to ensure up-to-date adherence.

By following this logistics and compliance guide, businesses can ensure that fiber pots are transported safely, meet regulatory requirements, and maintain their value as sustainable horticultural products.

Conclusion for Sourcing Fiber Pots

In conclusion, sourcing fiber pots presents a sustainable, cost-effective, and eco-friendly solution for horticultural and agricultural applications. Made from renewable materials such as peat, coir, wood fiber, or composted paper, fiber pots reduce environmental impact by eliminating plastic waste and allowing for direct transplanting into soil, minimizing root disturbance and promoting healthier plant growth. When sourcing fiber pots, it is essential to consider factors such as material composition, durability, biodegradability rate, supplier reliability, and cost-efficiency to ensure compatibility with specific growing needs and sustainability goals.

By partnering with reputable suppliers who prioritize environmentally responsible production methods, businesses and growers can enhance their green credentials while maintaining operational efficiency. As consumer and regulatory demand for sustainable products continues to grow, investing in fiber pots aligns with long-term environmental and economic benefits. Ultimately, sourcing fiber pots supports a circular economy, promotes plant health, and contributes to a more sustainable future in agriculture and gardening.