The global fiber optic sensor market is experiencing robust expansion, driven by increasing demand for high-precision sensing solutions across industries such as oil and gas, healthcare, aerospace, and civil infrastructure. According to a 2023 report by Mordor Intelligence, the market was valued at USD 1.78 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 9.8% through 2028. Similarly, Grand View Research estimates that the market could reach USD 3.4 billion by 2030, fueled by advancements in smart infrastructure and the integration of fiber optic sensors in Internet of Things (IoT) applications. With rising investments in structural health monitoring and growing adoption in harsh environments where traditional sensors fail, fiber optic technology is becoming indispensable. In this rapidly evolving landscape, a select group of manufacturers lead in innovation, scalability, and application diversity—shaping the future of sensing technology.

Top 10 Fiber Optic Sensor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 1997

Website: fibersensys.com

Key Highlights: Fiber SenSys, Inc., (FSI) is the market-leading manufacturer of fiber-optic intrusion detection systems for outdoor perimeters and physical data networks….

#2 Fiso

Domain Est. 1997

Website: fiso.com

Key Highlights: FISO is a leading developer and manufacturer of fiber optic sensors & signal conditioners used in medical, energy, process control, and R&D applications….

#3 OZ Optics Ltd.

Domain Est. 1995 | Founded: 1985

Website: ozoptics.com

Key Highlights: Located in Canada’s capital city of Ottawa and established in 1985, OZ Optics Limited is a leading worldwide supplier of fiber optic products for existing ……

#4 Fiber Optic Sensors

Domain Est. 1996

Website: keyence.com

Key Highlights: KEYENCE America provides Fiber Optic Sensors; Any application in any environment. Universal amplifiers with flexible and compact fiber optic heads….

#5 FIBERPRO

Domain Est. 1996

Website: fiberpro.com

Key Highlights: FIBERPRO, a specialist in optical fiber sensors SENSORS EVERYWHERE! Doesn’t support video….

#6 Tailored fiber optic sensing components & solutions

Domain Est. 2002

Website: fbgs.com

Key Highlights: We offer high quality FBG sensing components such as Draw Tower Gratings (DTG®s), All Grating Fiber (AGF®), FemtoSecond Gratings (FSG®s), FBG-Sensors and ……

#7 Fiber Optic Sensing

Domain Est. 2002

Website: ofsoptics.com

Key Highlights: Fiber optic sensors detect changes in temperature, strain, and other parameters by using the physical properties of light as it travels down an optical fiber….

#8 Luna Innovations

Domain Est. 2003

Website: lunainc.com

Key Highlights: Luna fiber optic sensing and measurement systems help design, build and maintain products and processes for aerospace, energy, and more….

#9 FiSens GmbH: Cutting

Domain Est. 2018

Website: fisens.com

Key Highlights: FiSens develops, manufactures, and markets accurate fiberoptic sensor solutions based on fiber Bragg grating (FBG) sensor arrays and fiber-integrated ……

#10 Fibercore

Domain Est. 2019

Website: fibercore.humaneticsgroup.com

Key Highlights: Fibercore has over 30 years experience of the Specialty Optical Fiber industry. We’re the world leader in the design, manufacture and commercialization of ……

Expert Sourcing Insights for Fiber Optic Sensor

H2: Market Trends for Fiber Optic Sensors in 2026

By 2026, the fiber optic sensor market is poised for significant transformation driven by technological advancements, expanding applications, and increasing demand across key industries. The global market is expected to grow at a robust compound annual growth rate (CAGR) of approximately 9–11%, reaching an estimated value of USD 7.5 to 8.2 billion, according to industry forecasts.

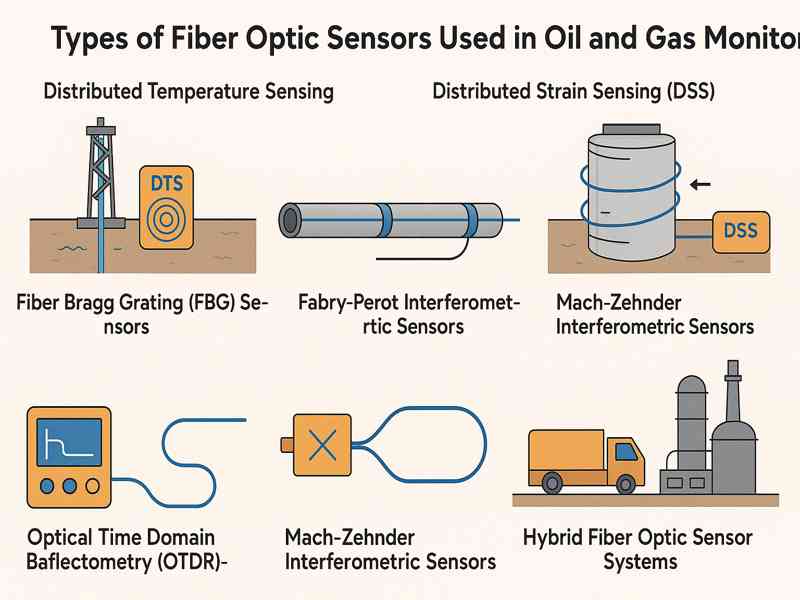

One of the dominant trends shaping the 2026 landscape is the rising deployment of fiber optic sensors in smart infrastructure. Governments and private enterprises are increasingly investing in structural health monitoring (SHM) for bridges, tunnels, dams, and railways. Distributed fiber optic sensing (DFOS) technologies, such as distributed temperature sensing (DTS), distributed acoustic sensing (DAS), and distributed strain sensing (DSS), are enabling real-time, large-scale monitoring with high precision and long-range capabilities.

The oil and gas industry continues to be a major adopter, particularly in downhole monitoring and pipeline integrity management. Fiber optic sensors offer intrinsic safety, immunity to electromagnetic interference, and the ability to operate in extreme environments—critical advantages in upstream and midstream operations. Enhanced oil recovery (EOR) techniques are increasingly reliant on DAS and DTS for reservoir characterization and production optimization.

In the renewable energy sector, fiber optic sensors are gaining traction in wind turbine blade monitoring and geothermal plant operations. Their ability to detect micro-fractures, temperature variations, and mechanical stress ensures improved operational efficiency and predictive maintenance, reducing downtime and maintenance costs.

Another key trend is the integration of fiber optic sensors with Internet of Things (IoT) platforms and artificial intelligence (AI). By 2026, sensor networks are increasingly being paired with edge computing and machine learning algorithms to enable predictive analytics and autonomous decision-making. This convergence enhances system responsiveness and supports Industry 4.0 initiatives in manufacturing and smart cities.

Advancements in photonic integrated circuits (PICs) and miniaturization are reducing the size and cost of fiber optic sensor systems, broadening their accessibility. Innovations in multiplexing techniques allow multiple sensors to operate on a single fiber, improving scalability and cost-efficiency for large-scale deployments.

Geographically, North America and Europe lead in adoption due to stringent safety regulations and advanced industrial infrastructure. However, Asia-Pacific is emerging as the fastest-growing market, fueled by rapid urbanization, infrastructure development in China and India, and government investments in smart city projects.

Challenges remain, including standardization issues, high initial deployment costs, and the need for specialized expertise in installation and data interpretation. Nevertheless, ongoing R&D and strategic partnerships between sensor manufacturers, telecom providers, and system integrators are expected to address these barriers.

In summary, the 2026 fiber optic sensor market is characterized by technological convergence, expanding application domains, and strong growth momentum. As industries prioritize safety, efficiency, and digital transformation, fiber optic sensors are becoming indispensable tools for real-time monitoring and intelligent infrastructure management.

Common Pitfalls When Sourcing Fiber Optic Sensors (Quality, IP)

Sourcing fiber optic sensors involves navigating technical complexity and supply chain risks. Overlooking key factors related to quality and intellectual property (IP) can lead to performance issues, delays, or legal complications.

Inadequate Quality Assurance Processes

One major pitfall is selecting suppliers without rigorous quality control systems. Fiber optic sensors require precision manufacturing, and inconsistencies in materials, calibration, or assembly can drastically affect performance. Buyers often fail to verify ISO certifications, test documentation, or traceability records, leading to unreliable sensor outputs in real-world applications.

Poor Environmental and IP Rating Verification

Many buyers assume that a product’s IP (Ingress Protection) rating guarantees suitability for harsh environments. However, misinterpretation or misleading claims—such as IP67 without proper testing under real conditions—can result in sensor failure due to dust, moisture, or temperature extremes. Always request independent test reports and verify the rating applies to both the sensor and connector interfaces.

Lack of IP (Intellectual Property) Clarity

Sourcing from manufacturers or third parties without clear IP ownership is risky. Using sensors that incorporate patented technologies without proper licensing can expose buyers to infringement claims. Ensure suppliers provide documentation confirming freedom to operate and that any custom designs are assigned to the buyer if required.

Overlooking Long-Term Supply and Support

Fiber optic sensor projects often span years, especially in industrial or infrastructure applications. A common mistake is not securing long-term supply agreements or access to firmware/software updates. Suppliers may discontinue products or lack technical support, jeopardizing maintenance and scalability.

Insufficient Testing and Validation Protocols

Relying solely on datasheet specifications without independent validation is a frequent oversight. Performance in lab conditions may not reflect field performance. Conducting application-specific testing—such as thermal cycling, vibration, or signal-to-noise analysis—helps avoid integration issues post-deployment.

Choosing Based on Price Alone

Opting for the lowest-cost option often sacrifices durability, accuracy, and support. Low-cost sensors may use inferior fibers, uncalibrated components, or lack proper shielding, leading to premature failure. Total cost of ownership—including downtime and replacement—should inform sourcing decisions.

Logistics & Compliance Guide for Fiber Optic Sensors

Product Classification and Regulatory Overview

Fiber optic sensors are sophisticated devices used for measuring physical parameters such as temperature, pressure, strain, and vibration via optical fibers. Due to their technical nature and application across industries—including oil & gas, healthcare, aerospace, and civil engineering—these sensors are subject to various international logistics and compliance requirements. Understanding classification, transportation regulations, and industry-specific standards is essential for global distribution.

International Shipping and Transportation

Fiber optic sensors may contain optical fibers, electronic components, and sometimes laser sources, which influence their shipping classification. Most sensors are non-hazardous and classified under standard electronics (UN 3481, PI 966/967 for lithium batteries if applicable). Ensure that any integrated power sources comply with IATA/IMDG/ADR regulations. Packaging must prevent breakage of fragile optical components, using anti-static, shock-resistant materials. Temperature and humidity controls may be required during transit, particularly for calibrated or sensitive units.

Export Controls and Trade Compliance

Fiber optic sensors may fall under export control regimes such as the U.S. Export Administration Regulations (EAR) or the International Traffic in Arms Regulations (ITAR), depending on technical specifications and end-use. Sensors with high accuracy, military applications, or use in submarine monitoring may be listed on the Commerce Control List (CCL) or U.S. Munitions List (USML). Conduct a classification review (e.g., ECCN determination) before export. Similar controls exist under the EU Dual-Use Regulation (Regulation (EU) 2021/821). Obtain required licenses for restricted destinations or end-users.

Product Certification and Standards

Compliance with regional and industry standards is critical for market access:

– Electromagnetic Compatibility (EMC): IEC/EN 61326 (industrial environments), IEC/EN 60601 (medical applications)

– Laser Safety: IEC 60825-1 (for sensors with laser components)

– Electrical Safety: IEC/EN 61010-1 (measurement, control, and laboratory equipment)

– Environmental Protection: IP ratings (e.g., IP67 for dust/water resistance) per IEC 60529

– RoHS and REACH: Ensure compliance with EU directives restricting hazardous substances and regulating chemical safety.

– ATEX/IECEx: Required for sensors used in explosive atmospheres (hazardous locations).

Certifications such as CE (Europe), UKCA (UK), FCC (USA), and CCC (China) may be required depending on the target market.

Import Requirements and Documentation

Prepare accurate documentation for customs clearance, including: commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Include technical specifications, ECCN or HTS codes, and relevant test reports or certificates. For medical or industrial safety applications, additional conformity declarations (e.g., EU Declaration of Conformity) may be required. Be aware of import duties, VAT, and local labeling requirements in destination countries.

Labeling and Packaging Requirements

Packaging must include: product identifier, manufacturer details, CE/FCC marks (if applicable), laser classification (if applicable), and handling instructions (e.g., “Fragile,” “Do Not Bend”). Labels should be durable and multilingual if shipping to non-English-speaking regions. Include user manuals with safety warnings and compliance information in the local language.

End-of-Life and Environmental Compliance

Fiber optic sensors contain electronic and optical components that may be subject to WEEE (Waste Electrical and Electronic Equipment) directives in the EU and similar recycling laws elsewhere. Provide take-back or recycling options where mandated. Avoid non-compliant materials and ensure proper disposal guidance is included in product documentation.

Best Practices for Compliance Management

- Maintain a Product Compliance File with all test reports, certifications, and declarations.

- Conduct regular audits of supply chain components for substance compliance (e.g., conflict minerals, REACH SVHCs).

- Train logistics and sales teams on export controls and shipping requirements.

- Use a compliance management system (CMS) to track regulations by region and product line.

Adhering to these logistics and compliance guidelines ensures smooth international operations, reduces risk of shipment delays or penalties, and supports market access for fiber optic sensor technologies.

Conclusion for Sourcing Fiber Optic Sensors

In conclusion, sourcing fiber optic sensors requires a comprehensive evaluation of technical specifications, application requirements, supplier reliability, and total cost of ownership. These advanced sensing solutions offer significant advantages such as immunity to electromagnetic interference, high sensitivity, compact size, and suitability for harsh environments, making them ideal for industries including aerospace, energy, healthcare, and civil infrastructure monitoring.

When selecting a supplier, it is essential to consider factors such as product quality, customization capabilities, technical support, and compliance with international standards. Partnering with reputable manufacturers or distributors who offer proven performance, reliable after-sales service, and scalability ensures long-term success and integration efficiency.

Furthermore, emerging trends such as smart sensing networks and integration with IoT platforms underscore the importance of forward-looking procurement strategies. By carefully assessing current needs and anticipating future technological developments, organizations can make informed decisions that optimize performance, reduce downtime, and enhance overall system reliability.

Ultimately, strategic sourcing of fiber optic sensors not only supports operational excellence but also drives innovation and competitiveness in an increasingly data-driven industrial landscape.