The global fiber optic glass market is experiencing robust expansion, driven by escalating demand for high-speed data transmission across telecommunications, data centers, and enterprise networks. According to a 2023 report by Mordor Intelligence, the market was valued at USD 14.8 billion in 2022 and is projected to grow at a CAGR of 8.5% from 2023 to 2028. This growth is fueled by the rapid deployment of 5G infrastructure, rising broadband penetration, and the increasing adoption of cloud-based services. Additionally, fiber-to-the-home (FTTH) rollouts and government-backed digital connectivity initiatives are amplifying demand for high-purity optical glass—core material in fiber optic cables. As the backbone of modern communication networks, fiber optic glass must meet stringent standards for clarity, strength, and signal efficiency. This has concentrated market leadership among a select group of technologically advanced manufacturers. Based on market presence, production capacity, innovation in glass preform and fiber drawing technologies, and global reach, the following nine companies have emerged as the leading producers in the fiber optic glass industry.

Top 9 Fiber Optic Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Multi

Domain Est. 2013

Website: fiberopticstech.com

Key Highlights: FTI is the largest leaded glass (soft glass) fiber drawing company in North America. Our volume provides customers with distinct process and cost advantages. ……

#2 Coractive

Domain Est. 1998 | Founded: 1998

Website: coractive.com

Key Highlights: Coractive is a leading manufacturer of innovative optical fibers and fiber lasers since 1998. Discover our complete and integrated solutions….

#3 Our Company|SUMITA OPTICAL GLASS, Inc.

Website: sumita-opt.co.jp

Key Highlights: SUMITA Optical Glass | Specializes in advanced optics, glass science, optical design, and fiber optics. SUMITA’s expertise includes advanced optical glass, ……

#4 Optical Fiber Products

Domain Est. 1991

Website: corning.com

Key Highlights: Bringing together a culture of innovation, quality, and manufacturing excellence to create life-changing optical fiber products….

#5 Glass optical fibers: Properties, applications, manufacturing

Domain Est. 1995

Website: schott.com

Key Highlights: Glass optical fibers are a thin, flexible, and transparent material used for transmitting light or images across various applications….

#6 Fiber Optic Center

Domain Est. 1998

Website: focenter.com

Key Highlights: Shop Now. International distributor for fiber optic components, equipment and accessories while providing invaluable technical consultation and support….

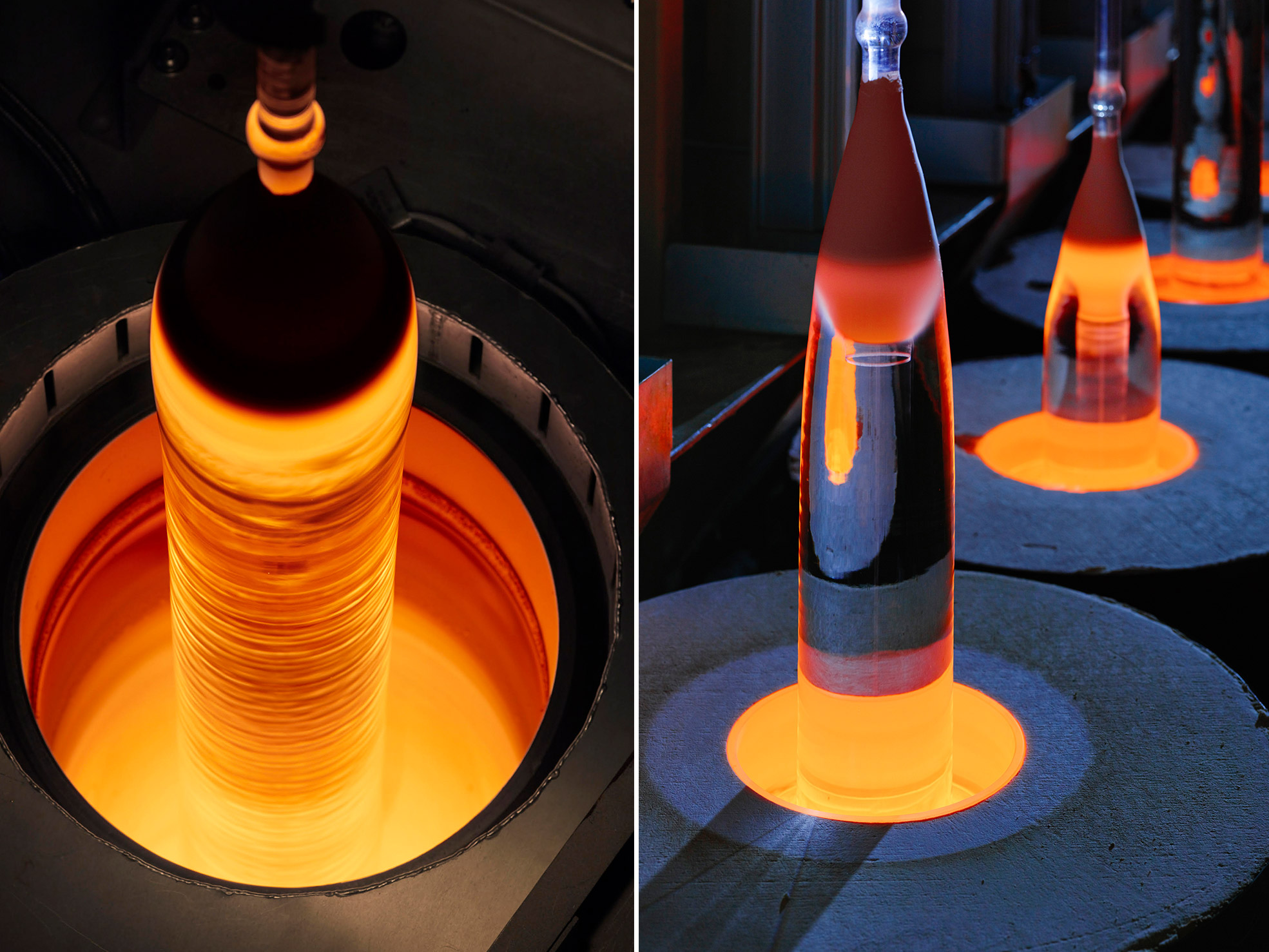

#7 Fiber Optics/Glass

Domain Est. 1999

Website: nabertherm.com

Key Highlights: Nabertherm offers a wide range of products for the production of glass and fiber optics. From cooling/stress relieving of glass, to curing coatings to ……

#8 Tailored fiber optic sensing components & solutions

Domain Est. 2002

Website: fbgs.com

Key Highlights: With our unique fiber optic technologies we offer high-quality components and groundbreaking total solutions for the next generation of optical fiber ……

#9 j

Domain Est. 2004

Website: j-fiber.com

Key Highlights: j-fiber is one of the world’s leading suppliers of standard and specialty fibers and preforms. As experts, we support modern local area networks and data ……

Expert Sourcing Insights for Fiber Optic Glass

H2: 2026 Market Trends for Fiber Optic Glass

The global fiber optic glass market is poised for significant transformation and expansion by 2026, driven by escalating demand for high-speed connectivity, the rollout of 5G networks, and advancements in data center infrastructure. Key trends shaping the market include:

-

Rising Demand from Telecommunications and 5G Deployment

The global push for 5G network infrastructure is accelerating the adoption of fiber optic glass, which serves as the backbone for high-bandwidth, low-latency communication. As telecom operators expand fiber-to-the-home (FTTH) and fiber-to-the-premises (FTTP) networks, fiber optic glass consumption is expected to grow substantially through 2026. -

Growth in Data Center Investments

Hyperscale data centers and cloud service providers are increasingly deploying fiber optic solutions to manage growing data traffic. The need for faster interconnects within and between data centers is fueling demand for high-purity silica glass and advanced fiber types such as multimode and single-mode fibers. -

Advancements in Fiber Optic Technology

Innovations such as hollow-core fiber, bend-insensitive fiber, and multi-core fiber are enhancing data transmission speeds and reducing signal loss. These technological improvements are driving upgrades in existing networks and opening new applications in aerospace, defense, and medical sectors. -

Expansion in Asia-Pacific Markets

Countries like China, India, and South Korea are leading the regional growth in fiber optic glass demand due to government-led digitalization initiatives, smart city projects, and expanding broadband access. China, in particular, remains a major producer and consumer of fiber optic glass preforms and cables. -

Supply Chain Resilience and Vertical Integration

In response to geopolitical tensions and supply chain disruptions, key manufacturers are investing in vertical integration—securing access to raw materials like silicon tetrachloride and increasing domestic production of fiber preforms. This trend is expected to strengthen regional self-sufficiency, especially in North America and Europe. -

Sustainability and Green Manufacturing

Environmental regulations are pushing manufacturers to adopt cleaner production methods for fiber optic glass, which traditionally involves energy-intensive processes. By 2026, increased focus on reducing carbon emissions and recycling silica byproducts is expected to influence production strategies. -

Increased Competition and Consolidation

The market is witnessing strategic mergers and partnerships among major players such as Corning, Prysmian, Sumitomo Electric, and YOFC to enhance R&D capabilities and global reach. This consolidation is likely to shape competitive dynamics and drive innovation.

In conclusion, the fiber optic glass market in 2026 will be characterized by robust growth, technological innovation, and strategic realignments, underpinned by the global need for faster, more reliable digital infrastructure.

Common Pitfalls in Sourcing Fiber Optic Glass: Quality and Intellectual Property

Sourcing fiber optic glass involves navigating complex technical, legal, and supply chain challenges. Buyers and manufacturers must be vigilant to avoid common pitfalls related to material quality and intellectual property (IP) risks. Failure to address these issues can lead to performance failures, legal disputes, and reputational damage.

Quality-Related Pitfalls

Inadequate Material Purity and Consistency

Fiber optic glass performance heavily depends on the purity of silica and dopants used. Impurities such as hydroxyl (OH⁻) ions or metallic contaminants can significantly increase signal attenuation. Sourcing from suppliers without stringent quality control measures may result in inconsistent refractive index profiles or weak mechanical strength.

Poor Manufacturing Standards

Not all suppliers adhere to international standards such as ITU-T G.652 or IEC 60793. Using substandard drawing and coating processes can lead to microcracks, poor tensile strength, or high splice loss. Buyers relying solely on price may overlook certifications and process audits, risking long-term reliability.

Lack of Traceability and Documentation

Reputable suppliers provide full traceability, including batch records, spectral attenuation data, and mechanical test reports. When documentation is missing or incomplete, it becomes difficult to verify compliance or troubleshoot field failures—especially in mission-critical applications like telecommunications or defense.

Intellectual Property (IP) Pitfalls

Risk of Infringing Proprietary Technologies

Fiber optic glass manufacturing often involves patented processes such as Modified Chemical Vapor Deposition (MCVD), Vapor Axial Deposition (VAD), or specialty doping techniques. Sourcing from suppliers that use unlicensed methods may expose buyers to third-party IP infringement claims, even if unintentional.

Ambiguous IP Ownership in Custom Designs

When working with suppliers on custom fiber designs (e.g., for dispersion-shifted or radiation-hardened fibers), unclear contractual terms may result in disputes over IP ownership. Buyers may assume they own the design, while the supplier retains rights—limiting future production flexibility or resale rights.

Use of Counterfeit or Reverse-Engineered Products

In regions with weak IP enforcement, some suppliers may offer “compatible” or “generic” fibers that mimic high-performance brands. These products may be reverse-engineered or counterfeit, leading to performance issues and potential liability for IP violations.

Best Practices to Mitigate Risks

- Conduct supplier audits focusing on quality systems (e.g., ISO 9001) and manufacturing capabilities.

- Require full compliance documentation and performance test data for each batch.

- Perform independent lab testing for critical parameters like attenuation, bandwidth, and tensile strength.

- Engage legal counsel to review contracts for IP clauses, especially for custom-developed fibers.

- Verify patent landscapes relevant to the fiber type and manufacturing process to avoid infringement.

By proactively addressing these quality and IP pitfalls, organizations can ensure reliable performance, regulatory compliance, and protection against legal exposure when sourcing fiber optic glass.

Logistics & Compliance Guide for Fiber Optic Glass

Fiber optic glass, a critical component in telecommunications and data transmission systems, requires specialized handling, transportation, and regulatory compliance due to its fragility, high value, and international trade implications. This guide outlines key considerations for safe and compliant logistics operations.

Classification and Regulatory Framework

Fiber optic glass is typically classified under specific Harmonized System (HS) codes for international trade. Common classifications include:

– HS Code 7002.31 or 7002.39: Glass in the form of “optical fibers” or “bundles of optical fibers”

– HS Code 9001.10: Optical fiber cables for transmission of light

Accurate classification is essential for determining import/export duties, restrictions, and origin requirements. Compliance with International Trade Administration (ITA) regulations and the World Trade Organization (WTO) frameworks is mandatory.

Packaging and Handling Requirements

Due to its sensitivity to moisture, temperature, and mechanical stress:

– Protective Spools: Optical glass fibers must be wound on rigid, corrosion-resistant spools.

– Sealed Packaging: Use moisture-barrier bags with desiccants to prevent water damage.

– Shock-Absorbing Materials: Employ foam inserts, corner protectors, and cushioning to absorb vibrations and impacts.

– Labeling: Include “Fragile,” “This Side Up,” “Protect from Moisture,” and product-specific identifiers (e.g., fiber type, length, attenuation specs).

Transportation Modes and Conditions

Choose transport modes based on urgency, volume, and destination:

– Air Freight: Preferred for high-value, time-sensitive shipments. Use IATA-compliant packaging and temperature-controlled cargo holds when possible.

– Ocean Freight: Suitable for bulk shipments. Ensure containers are dry, ventilated, and secured against movement.

– Road Freight: Use climate-controlled, shock-minimized vehicles for regional distribution.

Maintain stable temperature (typically 0°C to 40°C) and relative humidity (<85%) during transit to prevent microcracking and signal loss.

Export and Import Compliance

- Export Licenses: Check EAR (Export Administration Regulations) under the U.S. Department of Commerce. Some fiber optic technologies may be controlled under ECCN 5A991 (telecommunications equipment) if they meet certain performance thresholds.

- ITAR Considerations: Generally not applicable unless integrated into defense systems.

- Certificates of Origin: Required for preferential tariff treatment under free trade agreements.

- Customs Documentation: Include commercial invoices, packing lists, bill of lading/air waybill, and conformity certificates (e.g., CE, RoHS).

- Import Restrictions: Verify destination country regulations (e.g., China’s CCC certification, India’s BIS standards).

Safety and Environmental Regulations

- RoHS Compliance: Ensure fiber optic glass and associated coatings are free from restricted substances (lead, cadmium, etc.).

- REACH: Register and communicate SVHCs (Substances of Very High Concern) if shipping to the EU.

- Waste Management: Follow local and international WEEE directives for end-of-life disposal or recycling.

Insurance and Risk Management

- All-Risk Cargo Insurance: Cover physical loss or damage during transit, including breakage and theft.

- Value Declaration: Accurately declare shipment value to ensure adequate coverage.

- Incoterms: Use appropriate Incoterms (e.g., FOB, CIF, DDP) to define liability and cost responsibilities.

Quality Control and Traceability

- Pre-Shipment Inspection: Verify fiber integrity, coating quality, and spool condition.

- Batch Tracking: Maintain lot numbers and manufacturing dates for traceability.

- Compliance Certificates: Provide test reports (e.g., tensile strength, attenuation) upon request.

Best Practices Summary

- Partner with logistics providers experienced in high-tech, fragile cargo.

- Conduct regular compliance audits of export documentation and trade classifications.

- Train staff on proper handling and emergency response procedures.

- Monitor regulatory updates from agencies such as BIS (Bureau of Industry and Security), USTR, and customs authorities.

Adherence to these logistics and compliance guidelines ensures the secure, legal, and efficient movement of fiber optic glass across global supply chains.

Conclusion for Sourcing Fiber Optic Glass

Sourcing fiber optic glass requires a strategic approach that balances quality, cost, reliability, and long-term supply chain sustainability. As the backbone of high-speed data transmission in telecommunications, healthcare, defense, and industrial applications, the performance of fiber optic systems is highly dependent on the purity, consistency, and precision of the glass used. Therefore, selecting reputable suppliers with proven manufacturing capabilities—particularly in producing ultra-pure silica glass with low attenuation and high tensile strength—is critical.

Key considerations include evaluating supplier certifications, adherence to international standards (such as ITU-T and IEC), capacity for scalability, and geographic proximity to mitigate logistical risks. Additionally, ongoing advancements in fiber technology—such as bend-insensitive fibers and multi-core designs—highlight the need for partners who invest in R&D and can support innovation.

In conclusion, successful sourcing of fiber optic glass hinges on building strong, collaborative relationships with suppliers who combine technical excellence with supply chain resilience. As demand for bandwidth continues to grow, a proactive and quality-focused sourcing strategy will be essential to maintaining competitive advantage and ensuring the performance and reliability of next-generation optical networks.