The global fiber laser market is experiencing robust growth, driven by increasing demand for high-precision marking and engraving across industries such as automotive, electronics, aerospace, and medical devices. According to a recent report by Mordor Intelligence, the fiber laser market was valued at USD 6.72 billion in 2023 and is projected to reach USD 11.51 billion by 2029, growing at a CAGR of approximately 9.4% during the forecast period. Similarly, Grand View Research highlights the rising adoption of fiber laser technology due to its superior beam quality, energy efficiency, and low maintenance compared to traditional laser systems. As industrial automation and serialization requirements intensify—especially under regulatory traceability mandates—the need for reliable, durable, and efficient fiber marking laser machines has surged. This growth trajectory has spurred innovation and competition among manufacturers worldwide. Based on market presence, technological capabilities, product portfolio breadth, and customer reviews, we’ve identified the top 10 fiber marking laser machine manufacturers shaping the future of industrial marking.

Top 10 Fiber Marking Laser Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 Laserax

Website: laserax.com

Key Highlights: Laserax works with the world’s leading manufacturers to implement laser cleaning, welding, texturing, and marking solutions….

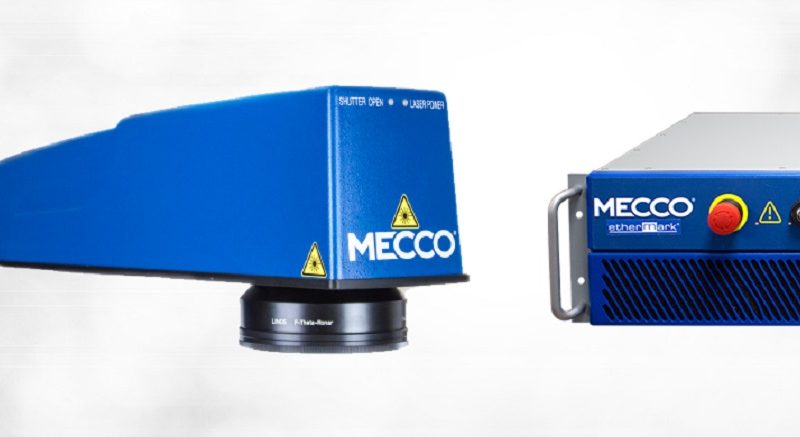

#2 MECCO

Website: mecco.com

Key Highlights: Manufacturers rely on MECCO engraving and marking systems to help problem-solve and ensure part traceability. Learn about our products for laser and pin ……

#3 Laser Marking for All Industries

Website: lasermarktech.com

Key Highlights: Discover innovative laser marking solutions tailored for various industries. Explore our cutting-edge technology as leaders in laser marking and engraving….

#4 Experts in Industrial Laser Marking + Engraving

Website: fobalaser.com

Key Highlights: For five decades, we have been writing with light, developing and manufacturing leading laser marking solutions for direct part and product marking….

#5 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#6 Fiber Laser Marker

Website: telesis.com

Key Highlights: Discover Telesis fiber laser markers: reliable, high-speed solutions for product identification, traceability, & branding. Request a quote!…

#7 Leader In Permanent Marking Solutions

Website: gravotech.us

Key Highlights: Gravotech designs, manufactures, and distributes innovative engraving, marking, and cutting solutions….

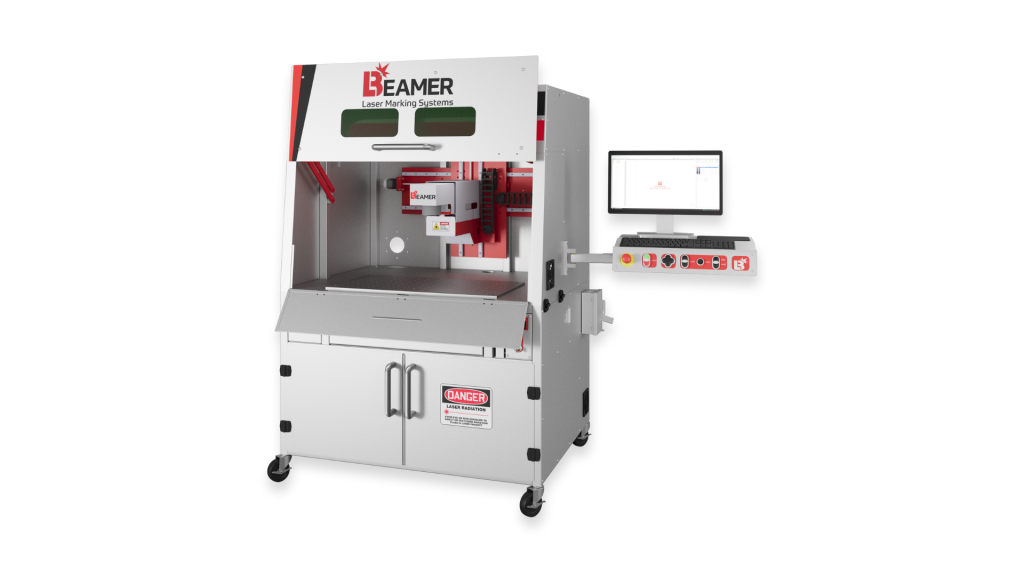

#8 Beamer Laser Marking Systems

Website: beamerlasermarking.com

Key Highlights: We offer a wide range of powerful standard, engineered, and inline 1064nm IR laser marking solutions with unmatched 100,000+ hour lifespan….

#9 Fiber Laser Marking

Website: keyence.com

Key Highlights: Explore high-speed, precision-focused fiber laser marking machines by KEYENCE. Achieve accurate and permanent markings across a wide range of materials….

#10 Laser Cutting, Engraving & Marking Machines

Website: thunderlaser.com

Key Highlights: Aurora Lite, the most cost-effective fiber laser marking machine in the Aurora series. Priced lower than the Aurora 8, with higher power and speeds up to 7000mm ……

Expert Sourcing Insights for Fiber Marking Laser Machine

H2: 2026 Market Trends for Fiber Marking Laser Machines

The global market for fiber marking laser machines is poised for significant transformation by 2026, driven by technological advancements, rising industrial automation, and expanding applications across key sectors. These high-precision tools, known for their durability, efficiency, and minimal maintenance, are increasingly becoming indispensable in manufacturing and product identification processes.

One of the most prominent trends shaping the 2026 landscape is the integration of smart manufacturing and Industry 4.0 principles. Fiber marking lasers are being equipped with IoT-enabled controls, real-time monitoring, and remote diagnostics, allowing seamless integration into automated production lines. This shift enhances traceability, reduces downtime, and supports predictive maintenance—critical factors for industries like automotive, aerospace, and electronics.

Another key trend is the growing demand for permanent, high-contrast, and tamper-proof markings in regulated industries such as medical devices, pharmaceuticals, and aerospace. Fiber lasers excel in marking metals, plastics, and composites without contact, ensuring compliance with strict regulatory standards like UDI (Unique Device Identification) and serialization mandates. As global regulations tighten, the adoption of fiber marking systems is expected to accelerate.

Miniaturization and portability are also emerging as important market drivers. Compact and handheld fiber laser markers are gaining traction, especially among small and medium enterprises (SMEs) that require flexible and cost-effective solutions. These portable systems support on-site maintenance, field repairs, and localized production setups, broadening the market reach.

Geographically, Asia-Pacific is projected to lead market growth by 2026, fueled by rapid industrialization in China, India, and Southeast Asia. Increasing investments in electronics manufacturing, electric vehicles (EVs), and consumer goods are boosting demand for high-speed and reliable marking solutions. Meanwhile, North America and Europe continue to emphasize precision and sustainability, driving innovation in energy-efficient laser systems and eco-friendly marking processes.

Additionally, advancements in fiber laser technology—such as higher power outputs (up to 100W+), ultra-short pulse (picosecond and femtosecond) lasers, and improved beam quality—are enabling finer marking resolution and new applications in micro-machining and surface texturing. This technological evolution supports niche markets such as semiconductor packaging and photovoltaics.

Lastly, competitive pricing and the availability of localized support services are reducing entry barriers for new players and end-users. As the market becomes more saturated, manufacturers are focusing on value-added services, software integration, and customization to differentiate their offerings.

In conclusion, the fiber marking laser machine market in 2026 will be defined by digital integration, regulatory compliance, technological innovation, and regional expansion—positioning fiber lasers as a cornerstone of modern industrial marking and traceability solutions.

Common Pitfalls When Sourcing Fiber Marking Laser Machines: Quality and Intellectual Property Risks

Sourcing fiber marking laser machines, especially from international suppliers, involves several risks that buyers must carefully navigate. Two of the most critical areas of concern are product quality and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, legal complications, and financial losses.

1. Compromised Machine Quality

One of the most frequent pitfalls is receiving fiber laser marking machines that do not meet expected performance or durability standards. This often stems from:

- Inconsistent Component Quality: Lower-cost suppliers may use substandard optical components, laser sources (e.g., counterfeit or reconditioned fiber lasers), or control systems, leading to poor marking precision, frequent breakdowns, or reduced lifespan.

- Lack of Certification and Testing: Some manufacturers do not adhere to international standards (such as CE, FDA, or ISO certifications), increasing the risk of safety hazards or non-compliance with local regulations.

- Insufficient After-Sales Support: Buyers may discover too late that the supplier offers limited technical support, training, or spare parts availability—critical for maintaining uptime and machine performance.

To mitigate this, conduct thorough due diligence: request third-party inspection reports, review customer testimonials, and whenever possible, test the machine before purchase.

2. Intellectual Property (IP) Infringement Risks

Sourcing from regions with lax IP enforcement can expose buyers to significant legal and reputational risks:

- Use of Counterfeit or Pirated Software: Some machines come with unauthorized copies of proprietary control software or firmware, which can lead to legal action, software instability, or lack of updates.

- Design and Technology Theft: Reputable laser technologies (e.g., IPG Photonics’ fiber lasers or proprietary beam delivery systems) are sometimes replicated without licensing. Purchasing such machines may inadvertently support IP theft and expose your business to liability.

- Voided Warranties and Compliance Issues: Machines built with stolen or unlicensed technology often cannot offer valid warranties or may fail regulatory audits, particularly in industries like aerospace, medical devices, or automotive.

To protect against IP-related risks, verify that the supplier uses legitimate components and software. Request documentation proving licensing agreements and ensure contracts include IP indemnification clauses.

By addressing quality and IP concerns proactively, businesses can secure reliable, compliant, and legally sound fiber laser marking solutions.

Logistics & Compliance Guide for Fiber Marking Laser Machine

Shipping & Handling

Ensure the fiber marking laser machine is securely packed in a sturdy, shock-resistant container with adequate cushioning (e.g., foam inserts or wooden crate) to prevent damage during transit. Use tamper-evident seals and label the package with “Fragile,” “This Side Up,” and “Protect from Moisture.” Choose a reputable freight carrier experienced in handling precision machinery and consider purchasing insurance for added protection. Provide clear handling instructions to logistics personnel to avoid tipping or dropping the unit.

Import/Export Regulations

Verify compliance with international trade regulations such as Export Administration Regulations (EAR) or International Traffic in Arms Regulations (ITAR), as applicable. Classify the machine under the correct Harmonized System (HS) code—typically 8456.11 or 8515.21—depending on configuration and output. Obtain necessary export licenses if the laser exceeds power thresholds defined by the destination country. Ensure all documentation (commercial invoice, packing list, bill of lading, certificate of origin) is accurate and complete to prevent customs delays.

Safety Certification & Standards

Confirm the fiber marking laser meets relevant safety standards prior to shipment. Key certifications include:

– CE Marking (EU): Compliant with Machinery Directive 2006/42/EC and EN 60825-1 (laser safety).

– FDA/CDRH Registration (USA): Compliance with 21 CFR 1040.10 and 1040.11 for laser products.

– RoHS & REACH (EU): Restriction of hazardous substances and chemical compliance.

– IEC 60825-1: International standard for laser product safety classification (typically Class 1 when enclosed).

Provide users with a Declaration of Conformity and technical file upon request.

Laser Classification & Labeling

The fiber laser marking system must be properly classified based on accessible emission levels. Most industrial fiber lasers are integrated into Class 1 systems when interlocked and fully enclosed. Ensure all warning labels are affixed per IEC 60825, including laser radiation symbols, aperture labels, and safety instructions in the local language of the destination country. Include bilingual (English + local) safety signage if required.

Installation & Environmental Requirements

Deliver the machine to a clean, dry, and temperature-controlled environment (typically 10–40°C, 30–70% non-condensing humidity). Ensure stable power supply (e.g., 220V ±10%, 50/60 Hz) with proper grounding and surge protection. Provide adequate ventilation and avoid locations with excessive dust, vibration, or electromagnetic interference. Confirm that the end-user has access to compressed air (if required for chiller or marking head) and exhaust systems for fume extraction.

User Training & Documentation

Supply comprehensive documentation in the local language, including:

– Operation and maintenance manual

– Safety instructions and emergency procedures

– Laser hazard awareness guide

– Warranty and service information

Ensure end-users receive hands-on training on safe operation, maintenance protocols, interlock functionality, and emergency shutdown procedures. Maintain records of training completion.

After-Sales Compliance & Support

Establish a process for registering the laser with local regulatory bodies if required (e.g., FDA in the U.S.). Offer technical support for compliance-related inquiries and maintain records of software updates, service logs, and component replacements. Advise customers to perform regular safety checks and keep the machine in compliance with evolving local regulations.

Conclusion for Sourcing a Fiber Marking Laser Machine

After thorough evaluation of technical specifications, performance requirements, supplier credibility, and cost considerations, sourcing a fiber marking laser machine presents a strategic investment for enhancing manufacturing precision, product traceability, and operational efficiency. Fiber laser markers offer superior reliability, low maintenance, and excellent marking quality on metals and certain engineered plastics, making them ideal for industrial applications in automotive, aerospace, electronics, and medical device sectors.

Key factors such as laser power, marking speed, software compatibility, durability, and after-sales support should guide the final selection. Choosing a reputable supplier with proven industry experience and comprehensive service offerings ensures long-term machine performance and integration success.

In conclusion, acquiring a high-quality fiber marking laser machine aligns with goals of automation, regulatory compliance, and brand integrity. With proper due diligence in sourcing, the investment will deliver a strong return through improved production throughput, permanent marking solutions, and enhanced product lifecycle tracking.