The global fiber laser welding machine market is experiencing robust expansion, driven by increasing demand for precision, efficiency, and automation across industries such as automotive, electronics, and aerospace. According to Mordor Intelligence, the fiber laser market was valued at USD 6.82 billion in 2022 and is projected to grow at a CAGR of over 7.5% from 2023 to 2028. This growth is fueled by the superior beam quality, energy efficiency, and low maintenance of fiber laser systems compared to traditional welding methods. As manufacturing sectors prioritize high-speed and high-accuracy joining processes, the adoption of fiber laser welding technology continues to accelerate worldwide. Against this backdrop, a select group of manufacturers has emerged as leaders, pushing innovation and setting benchmarks in performance, reliability, and integration capabilities. Based on market presence, technological advancements, and global reach, here are the top 10 fiber laser welder machine manufacturers shaping the future of industrial welding.

Top 10 Fiber Laser Welder Machine Manufacturers (2026 Audit Report)

(Ranked by Factory Capability & Trust Score)

#1 LaserStar Technologies

Website: laserstar.net

Key Highlights: LaserStar Technologies designs and manufactures high-performance laser welding, marking, and cutting systems for industrial, jewelry, ……

#2 Denaliweld

Website: denaliweld.com

Key Highlights: We Specialize in Laser Welding & Cleaning. DenaliWeld INC, is a proud employee-owned fiber laser welding machine manufacturer based in Chicago, USA….

#3 Equipment & Systems

Website: amadaweldtech.com

Key Highlights: Manufacturer of equipment and systems for welding, cutting, marking, micromachining, sealing, and bonding. Resistance welding. Laser….

#4 Laser Machines

Website: lclasers.com

Key Highlights: Distribution and manufacture of laser machinery. Sales of laser marking, laser cleaning, laser engraving and welding machines….

#5 Wuhan Raycus Fiber Laser Technologies Co., Ltd.

Website: en.raycuslaser.com

Key Highlights: Welding high anti-reflection materials in this way guarantees double the efficiency and half the work! Infrared lasers have always been difficult to handle the ……

#6 IPG Photonics

Website: ipgphotonics.com

Key Highlights: IPG Photonics manufactures high-performance fiber lasers, amplifiers, and laser systems for diverse applications and industries. Discover your solution….

#7 Fiber Laser Welding Machine

Website: fiberlaserwelding.com

Key Highlights: Fiber Laser Welder LLC provides top-quality fiber laser welding machines for precision, speed, and durability. Get the best solutions for your welding needs ……

#8 Fanuci & Falcon

Website: fanuci-falcon.com

Key Highlights: FANUCI & FALCON is an innovative high-tech enterprise specializing in the manufacturing of advanced fiber laser machines for metal processing applications ……

#9 Fiber laser cutting machine

Website: hsglaser.com

Key Highlights: HSG LASER is an international company dedicated to R&D, production, sales of laser cutting, bending, welding machines, automatic loading & unloading and ……

#10 Full Spectrum Laser

Expert Sourcing Insights for Fiber Laser Welder Machine

2026 Market Trends for Fiber Laser Welder Machines

The global market for fiber laser welder machines is poised for significant transformation by 2026, driven by technological advancements, expanding industrial automation, and increasing demand for high-precision manufacturing across key sectors. This analysis explores the major trends shaping the fiber laser welding industry in the coming years.

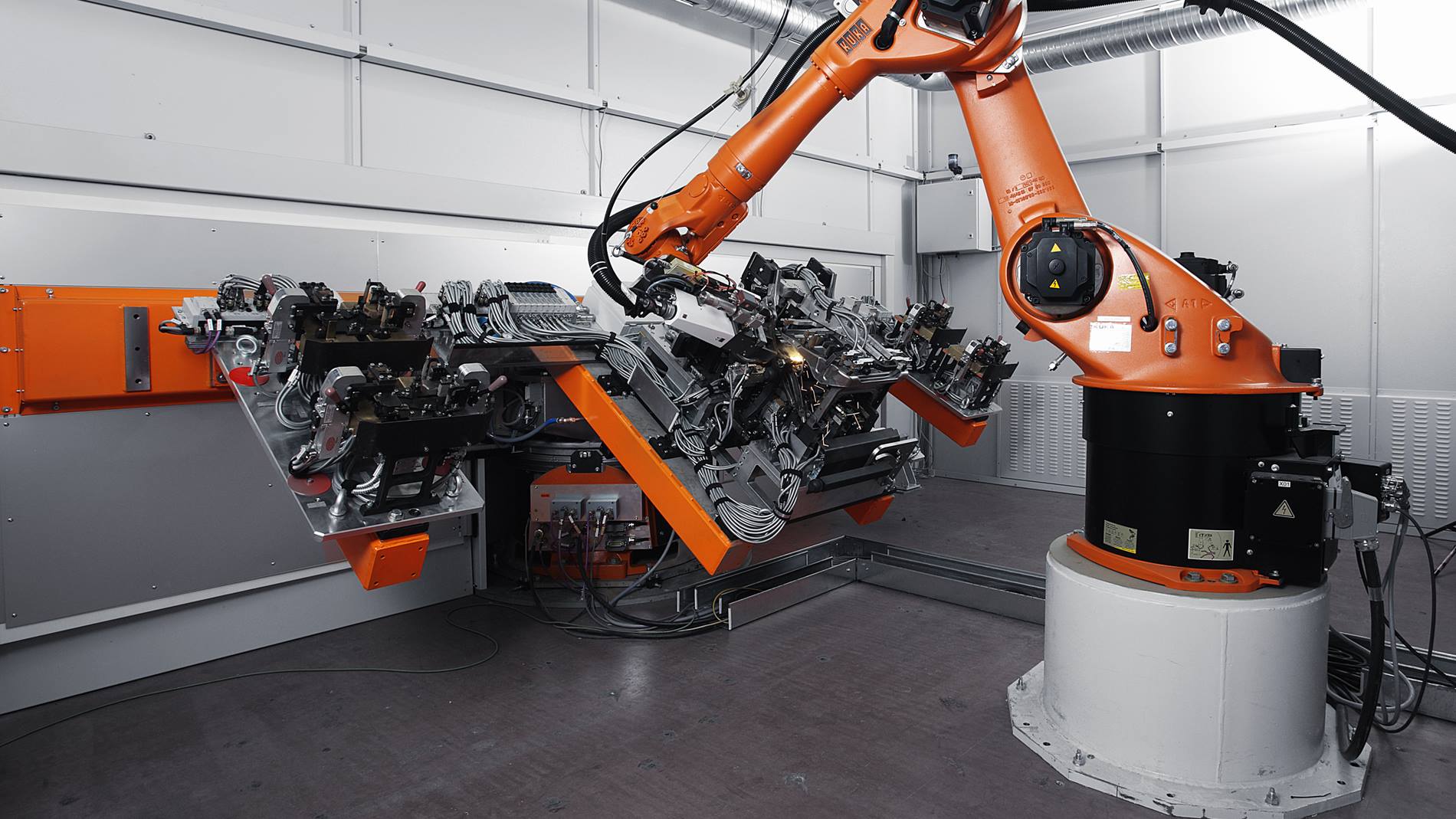

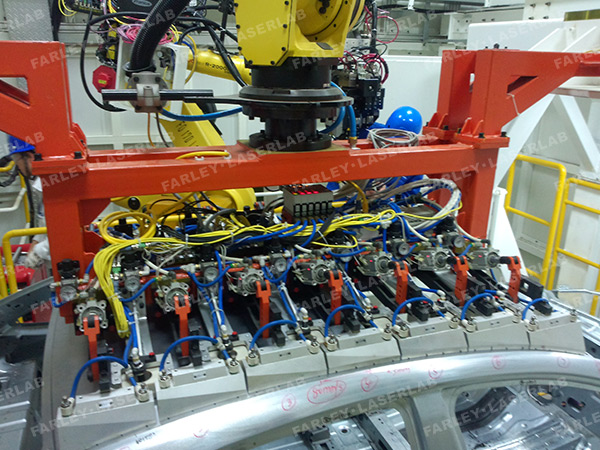

Rising Adoption in Electric Vehicle (EV) Manufacturing

One of the most influential drivers of the fiber laser welder market by 2026 is the booming electric vehicle (EV) industry. As automakers shift toward EV production, the need for lightweight, durable, and precisely welded components has intensified. Fiber laser welding offers high-speed, deep-penetration capabilities ideal for battery pack assembly, motor components, and structural parts. The precision and consistency of fiber lasers ensure strong, reliable welds critical for EV safety and performance, making them indispensable in modern EV production lines.

Advancements in High-Power and Ultrafast Fiber Lasers

By 2026, fiber laser technology is expected to see further advancements in power output and pulse control. Manufacturers are increasingly commercializing multi-kilowatt fiber lasers (10 kW to 30 kW) capable of thick-metal welding in heavy industries such as shipbuilding and aerospace. Simultaneously, ultrafast pulsed fiber lasers are gaining traction for micro-welding applications in electronics and medical devices. These innovations enhance versatility, allowing a single machine to perform both fine and heavy-duty welding tasks.

Integration with Smart Manufacturing and Industry 4.0

The integration of fiber laser welders with smart factory ecosystems is a defining trend for 2026. These machines are increasingly equipped with IoT connectivity, real-time monitoring, and AI-driven process optimization. Predictive maintenance, remote diagnostics, and adaptive welding parameters powered by machine learning improve uptime and weld quality. This alignment with Industry 4.0 standards enables seamless data flow between design, production, and quality control systems, boosting overall manufacturing efficiency.

Growth in Asia-Pacific Due to Industrial Expansion

The Asia-Pacific region is projected to dominate the fiber laser welder market by 2026, fueled by rapid industrialization in China, India, South Korea, and Japan. Government initiatives promoting advanced manufacturing and domestic robotics adoption are accelerating demand. Chinese manufacturers, in particular, are investing heavily in localized high-end laser production, reducing reliance on imports and fostering competitive pricing that expands market accessibility.

Sustainability and Energy Efficiency as Competitive Advantages

With growing emphasis on green manufacturing, fiber laser welders are gaining favor due to their high wall-plug efficiency—often exceeding 40%, significantly higher than traditional CO₂ lasers. Their lower energy consumption, reduced need for consumables, and minimal waste generation align with corporate sustainability goals. By 2026, energy-efficient models with modular designs for easy maintenance and recycling are expected to become standard, further enhancing their appeal.

Competitive Landscape and Price Dynamics

The fiber laser welder market is becoming increasingly competitive, with both established players (e.g., IPG Photonics, TRUMPF, Han’s Laser) and emerging manufacturers driving innovation and cost reduction. By 2026, intensified competition is likely to result in price stabilization or moderate declines, making high-performance systems more accessible to small and medium-sized enterprises (SMEs). This democratization of technology is expected to broaden application reach across diverse industries.

Conclusion

By 2026, the fiber laser welder machine market will be characterized by technological sophistication, sector-specific customization, and deeper integration into automated production systems. Driven by EVs, smart manufacturing, and regional industrial growth—particularly in Asia—the industry is set for sustained expansion. Companies that invest in R&D, sustainability, and digital integration will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing a Fiber Laser Welder Machine (Quality and Intellectual Property)

Sourcing a fiber laser welder machine involves significant investment and technical considerations. Buyers often encounter challenges related to quality assurance and intellectual property (IP) risks. Being aware of these pitfalls can help avoid costly mistakes and ensure long-term operational success.

1. Compromised Build Quality and Component Sourcing

One of the most common issues is receiving machines built with substandard components. Some suppliers use low-cost optical fibers, inadequate cooling systems, or inferior laser sources to reduce prices. These compromises lead to reduced machine lifespan, frequent breakdowns, and inconsistent weld quality.

- Red Flags: Unusually low pricing, vague specifications, or lack of transparency about component brands (e.g., IPG vs. generic laser sources).

- Best Practice: Request detailed technical documentation, verify component origins, and insist on third-party quality inspections before shipment.

2. Misrepresentation of Laser Power and Performance

Suppliers may advertise inflated laser power ratings (e.g., labeling a 1,500W machine as 2,000W) or quote peak power instead of continuous output. This misleads buyers about actual welding capabilities, especially for thick materials or high-speed applications.

- Red Flags: Exaggerated performance claims without test reports or video demonstrations.

- Best Practice: Demand certified power output test results and conduct live performance trials under real-world conditions.

3. Lack of Intellectual Property Protection

Many fiber laser machines, especially from certain manufacturing regions, incorporate copied or reverse-engineered technology. Using such machines can expose buyers to IP infringement risks, particularly in markets with strong IP enforcement (e.g., EU, US).

- Red Flags: Suppliers unwilling to provide IP ownership documentation or patents related to the laser control software or beam delivery systems.

- Best Practice: Require proof of legitimate licensing or original design rights. Work with legal counsel to assess IP compliance, especially for export-oriented operations.

4. Inadequate Software and Control Systems

Proprietary software is a critical part of laser welding systems. Machines with pirated, unlicensed, or poorly developed control software may suffer from bugs, lack updates, or be incompatible with industry standards (e.g., CAD/CAM integration).

- Red Flags: Generic user interfaces, no software version tracking, or refusal to provide license keys or source code details.

- Best Practice: Verify software authenticity and ensure access to regular updates, technical support, and customization options.

5. Poor After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance. Some suppliers disappear after delivery or fail to provide timely technical support and spare parts, leading to extended downtime.

- Red Flags: No local service centers, long response times, or unavailability of critical spare parts like focusing heads or cooling units.

- Best Practice: Choose suppliers with a proven service network, clear SLAs (Service Level Agreements), and stocked spare parts inventory.

6. Hidden Costs from Non-Compliance with Safety and Certification Standards

Machines that lack proper safety certifications (e.g., CE, FDA, IEC 60825) may be barred from operation in certain countries. Modifying or retrofitting such machines post-import can be expensive.

- Red Flags: Absence of compliance documentation or vague answers about certification status.

- Best Practice: Require original certification documents and confirm that the machine meets the regulatory requirements of the target market.

By carefully evaluating suppliers against these common pitfalls, buyers can ensure they acquire a reliable, high-performance fiber laser welder that meets both technical and legal standards.

Logistics & Compliance Guide for Fiber Laser Welder Machine

Overview

This guide outlines the essential logistics and compliance considerations for transporting, importing, and operating a fiber laser welder machine. Ensuring adherence to international shipping standards, safety regulations, and local requirements is crucial for smooth deployment and operational safety.

Packaging and Handling

Fiber laser welder machines are sensitive industrial equipment requiring secure and protective packaging. Use custom-designed crates with internal cushioning (e.g., foam inserts or shock-absorbing materials) to prevent movement during transit. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators. Include desiccants to prevent moisture damage, especially during sea freight.

Transportation Modes

Choose transportation based on urgency, cost, and destination. Air freight offers speed and is ideal for time-sensitive deliveries but is costlier. Sea freight is economical for heavy and bulky machines but requires longer lead times. Ensure proper securing of the machine on pallets or in containers to prevent shifting. For land transport, use shock-absorbing suspension systems and avoid rough routes where possible.

Export and Import Documentation

Prepare complete documentation to avoid customs delays. Required documents typically include: commercial invoice, packing list, bill of lading or air waybill, certificate of origin, and technical specifications. For laser equipment, include a laser safety compliance certificate (e.g., IEC 60825-1). Some countries may require import licenses or pre-shipment inspections—verify requirements with local customs authorities.

Regulatory Compliance

Ensure the laser welder meets international safety standards such as IEC 60825 (laser safety), IEC 61010 (safety requirements for electrical equipment), and CE (Europe), UKCA (UK), or FCC (USA) certifications as applicable. Machines must include proper warning labels, interlocks, and emission indicators. Confirm compliance with local electrical standards (voltage, frequency, plug type) at the destination.

Hazardous Materials and Restrictions

While fiber laser welders do not typically contain hazardous materials, associated components (e.g., cooling fluids or batteries) may be regulated. Declare all such items and comply with ADR (road), IMDG (sea), or IATA (air) regulations if applicable. Avoid shipping incompatible items in the same container.

Customs Clearance and Duties

Work with a licensed customs broker to facilitate clearance. Classify the machine correctly using the Harmonized System (HS) Code—common codes include 8456.20 (laser welding machines). Duties and taxes vary by country; account for VAT, import tariffs, and potential anti-dumping fees. Provide accurate valuation to prevent assessments or penalties.

Installation and Site Readiness

Verify the installation site meets operational requirements: stable power supply (with correct voltage and grounding), adequate ventilation, and sufficient space for operation and maintenance. Ensure the facility has appropriate laser safety zones, protective barriers, and emergency shut-offs in accordance with OSHA (USA) or equivalent local regulations.

Training and Certification

Operators must receive certified training on machine operation, emergency procedures, and laser safety. Maintain training records and ensure personnel wear appropriate PPE (laser safety goggles, protective clothing). Employers are responsible for compliance with occupational health and safety regulations.

After-Sales Support and Warranty

Confirm warranty terms cover international use and understand logistics for spare parts and service. Maintain communication with the manufacturer or authorized service provider for technical support and software updates. Keep all compliance and maintenance documentation for audits or inspections.

Environmental and Disposal Compliance

At end-of-life, dispose of the machine according to local e-waste regulations. Components such as lasers, power supplies, and electronic boards may require special handling. Partner with certified recycling facilities to ensure environmentally responsible disposal and compliance with WEEE (EU) or similar directives.

Conclusion: Sourcing a Fiber Laser Welder Machine

Sourcing a fiber laser welder machine is a strategic decision that can significantly enhance manufacturing efficiency, precision, and product quality. After evaluating technical specifications, supplier credibility, cost considerations, and long-term operational needs, it is evident that fiber laser welding technology offers superior performance compared to traditional welding methods—delivering faster processing speeds, lower maintenance, improved energy efficiency, and excellent weld quality on a variety of metals.

When selecting a supplier, it is crucial to prioritize machines with robust build quality, reliable after-sales support, comprehensive training, and warranty coverage. Additionally, compatibility with existing production systems and scalability for future demands should be carefully assessed.

Ultimately, investing in a high-quality fiber laser welder from a reputable source not only optimizes production capabilities but also provides a strong return on investment through reduced operational costs and increased throughput. With the right machine and support in place, businesses can achieve greater competitiveness in industries such as automotive, aerospace, electronics, and precision manufacturing.