The global fasteners market, driven by robust demand from automotive, construction, and industrial manufacturing sectors, is projected to grow at a CAGR of approximately 5.8% from 2024 to 2030, according to Grand View Research. With increasing infrastructure development and the rise of electric vehicles requiring precision-engineered components, the need for high-quality screw manufacturing has never been more critical. While the industry has historically been male-dominated, a growing number of female-led companies and women in leadership roles within manufacturing firms are reshaping the sector with innovation, sustainability, and operational excellence. These leaders are not only challenging industry norms but also capturing significant market share through agile supply chains and advanced production technologies. In this evolving landscape, we spotlight the top nine female screw manufacturers—entrepreneurs and executives who are driving progress and exemplifying the critical role of diversity in modern industrial manufacturing.

Top 9 Female Screw Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AMPG

Domain Est. 1997

Website: ampg.com

Key Highlights: AMPG is a trusted USA manufacturer of high-quality fasteners. We provide precision-engineered sex bolts, shoulder screws, washer, shims and other industrial ……

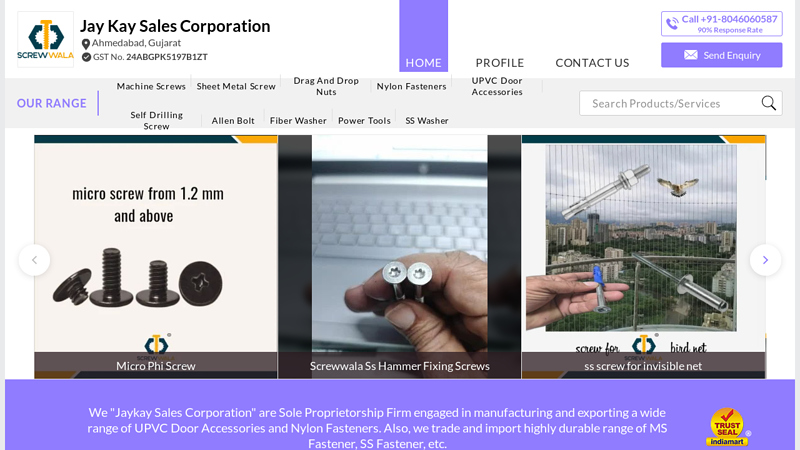

#2 Jay Kay Sales Corporation

Domain Est. 2005

Website: screwwala.com

Key Highlights: We “Jaykay Sales Corporation” are Sole Proprietorship Firm engaged in manufacturing and exporting a wide range of UPVC Door Accessories and Nylon Fasteners….

#3 Chin Jaan Screw Industrial CO.,LTD.

Domain Est. 2020

Website: chin-jaan.com

Key Highlights: Our comprehensive product range includes female thread rivets, flower head screws, cylinder stud bolts, custom screws, and more, with outer diameters ranging ……

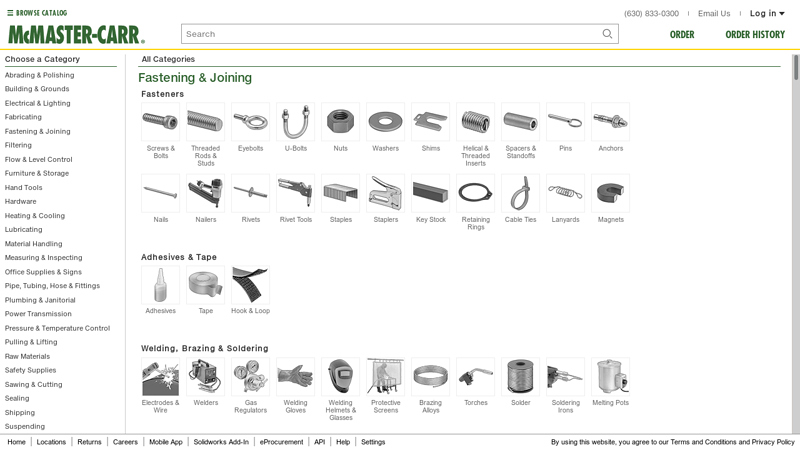

#4 McMaster

Domain Est. 1994

Website: mcmaster.com

Key Highlights: McMaster-Carr is the complete source for your plant with over 700000 products. 98% of products ordered ship from stock and deliver same or next day….

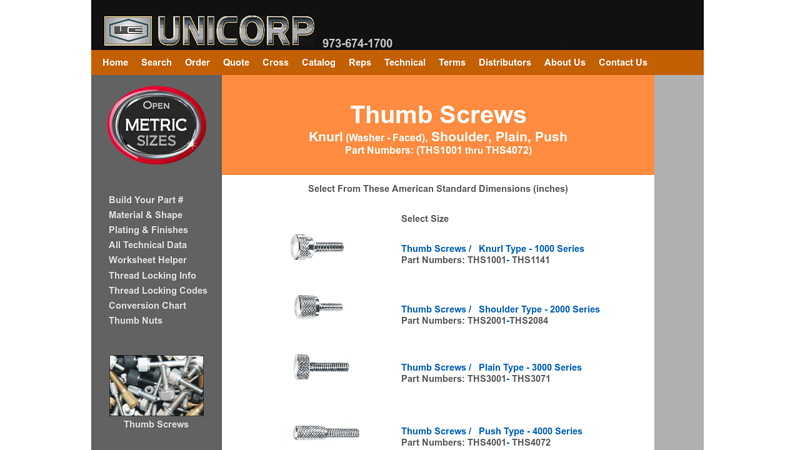

#5 Thumb Screws by UNICORP Standard/Metric

Domain Est. 1996

Website: unicorpinc.com

Key Highlights: UNICORP is a leader in manufacturing stock and custom electronic hardware, handles and precision fasteners used by leading companies in nearly every ……

#6 Chrome Bolts, Stainless Steel Bolts, Metric Bolts, Socket Head Cap …

Domain Est. 2002

#7 Barrel Nuts

Domain Est. 2003

Website: fastenright.com

Key Highlights: Wide range of Barrel Nuts & Sex Bolts including architectural barrel nuts, raised head, countersunk, low profile and security fixings – available now….

#8 Screws

Domain Est. 2017

Website: mwcomponents.com

Key Highlights: $15 delivery 30-day returnsFind shoulder screws, thread cutting screws & other specialized options or order custom screws in a range of materials from MW Components….

#9 Screw-Express

Domain Est. 2022

Website: screw-express.com

Key Highlights: The screw-express.com website specialises in the online sale of screws and fasteners for professionals and private individuals. Our e-commerce site is based on ……

Expert Sourcing Insights for Female Screw

It appears there may be a misunderstanding or typo in your request. The term “Female Screw” typically refers to a mechanical fastener component (such as a nut or threaded hole) that receives a male screw or bolt. However, if you’re referring to market trends related to products or industries associated with women—possibly a misphrasing of “female-focused products” or another concept—please clarify so I can provide an accurate analysis.

That said, if you are indeed requesting an analysis of the industrial fasteners market—specifically female screws (e.g., nuts, threaded inserts, couplers)—with a focus on trends projected for 2026, particularly under H2 (Second Half) of that year, here is a structured market analysis:

H2 2026 Market Trends Analysis: Female Screws (Industrial Fasteners)

1. Overview of the Female Screw Market

“Female screws” refer to internally threaded fastening components such as:

– Nuts (hex, cap, wing, etc.)

– Threaded inserts (e.g., helicoils, brass inserts)

– Coupling nuts

– T-nuts and cage nuts

These components are essential in automotive, aerospace, construction, electronics, and industrial machinery sectors.

The global fasteners market was valued at approximately $110 billion in 2023 and is projected to reach $140–150 billion by 2026, with female screws accounting for a significant portion due to their universal application.

2. Key Trends Shaping H2 2026 Market Dynamics

2.1. Growth in Electric Vehicles (EVs) and Lightweight Fasteners

- Trend: Rising EV production demands lightweight, corrosion-resistant female fasteners.

- Impact: Increased use of aluminum, titanium, and high-strength composites in female screw manufacturing.

- H2 2026 Outlook: OEMs will prioritize miniaturized, heat-resistant threaded inserts for battery packs and motor assemblies.

2.2. Automation and Smart Manufacturing

- Trend: Adoption of Industry 4.0 technologies in assembly lines.

- Impact: Demand for precision-engineered, standardized female screws compatible with robotic assembly.

- H2 2026 Outlook: Surge in smart fasteners with embedded sensors (e.g., torque-monitoring nuts) in aerospace and automotive sectors.

2.3. Supply Chain Localization Post-Pandemic

- Trend: Geopolitical tensions and supply chain disruptions push for regional manufacturing.

- Impact: Nearshoring in North America and Europe to reduce dependency on Asian suppliers.

- H2 2026 Outlook: U.S. and EU-based fastener producers will expand capacity, supporting local demand in defense and infrastructure.

2.4. Sustainability and Circular Economy

- Trend: Green manufacturing and recyclability mandates.

- Impact: Shift toward recyclable materials and reusable fastening systems.

- H2 2026 Outlook: Growth in biodegradable polymer nuts for consumer electronics and packaging; stricter RoHS/REACH compliance.

2.5. Advancements in 3D-Printed and Custom Fasteners

- Trend: On-demand manufacturing using additive technologies.

- Impact: Rise in custom female screw designs for prototyping and niche applications.

- H2 2026 Outlook: Adoption in aerospace and medical devices where bespoke threaded inserts improve performance.

3. Regional Outlook for H2 2026

| Region | Key Drivers | Market Focus |

|——–|————-|————|

| Asia-Pacific | EV boom (China, India), electronics manufacturing | High-volume, cost-effective nuts and inserts |

| North America | Infrastructure spending, defense, reshoring | High-strength, corrosion-resistant fasteners |

| Europe | Green energy, automotive innovation | Lightweight, sustainable fasteners |

| Emerging Markets (MEA, LATAM) | Urbanization, construction | Standard metric female screws |

4. Competitive Landscape

- Major Players: Bossard, PennEngineering, STANLEY Engineered Fastening, Nippon Nyūs, Böllhoff.

- H2 2026 Strategy: Focus on R&D in smart fasteners, digital inventory platforms (e.g., vending machines for nuts), and AI-driven quality control.

5. Challenges

- Raw Material Volatility: Steel, brass, and rare earth prices may fluctuate.

- Counterfeit Products: Especially in emerging markets, affecting reliability.

- Regulatory Compliance: Increasing standards in EV and aerospace sectors.

6. Conclusion: H2 2026 Forecast

By the second half of 2026, the female screw market will be characterized by:

– Higher precision and customization

– Integration with smart systems

– Sustainability-driven material innovation

– Regional supply chain resilience

Suppliers who invest in automation, green materials, and digital logistics will lead the market. The demand for female screws will remain robust, driven by technological advancement and infrastructure development globally.

If you meant a different interpretation of “Female Screw” (e.g., slang, adult products, or gender-related market trends), please clarify so I can provide a relevant and professional analysis.

Common Pitfalls When Sourcing Female Screws (Quality, IP)

Poor Material Quality and Durability

One major pitfall is selecting female screws made from substandard materials, such as low-grade stainless steel or inferior zinc alloys. This compromises mechanical strength, corrosion resistance, and long-term reliability—especially in harsh environments. Always verify material specifications (e.g., 304 or 316 stainless steel) and request material certification to ensure durability.

Inaccurate Thread Tolerance and Fit

Sourcing female screws with inconsistent thread dimensions can lead to misalignment, cross-threading, or weak connections. Poor manufacturing tolerances affect assembly efficiency and joint integrity. Insist on ISO or ANSI thread standards and conduct sample testing to confirm thread accuracy before bulk ordering.

Inadequate or Misrepresented IP (Ingress Protection) Rating

A critical oversight is assuming a female screw offers environmental protection without verifying its actual IP rating. Many suppliers claim high IP ratings (e.g., IP67) without proper sealing design or testing. Ensure the screw includes integrated gaskets or O-rings and request third-party IP certification test reports.

Lack of Corrosion Resistance in Harsh Environments

Female screws used outdoors or in humid, saline, or chemical environments may fail prematurely if not properly coated or made from corrosion-resistant materials. Avoid passivated or uncoated fasteners in such conditions—opt for marine-grade stainless steel or PTFE-coated variants.

Insufficient Mechanical Performance Testing

Some suppliers do not perform torque, tensile, or vibration testing on female screws, leading to premature loosening or structural failure. Always request performance test data, especially for applications involving dynamic loads or critical assemblies.

Non-Compliance with Industry Standards

Using non-compliant screws can result in safety hazards or regulatory issues. Ensure products meet relevant standards such as ISO, DIN, or ASTM. Avoid generic or counterfeit parts that mimic genuine specifications but fail under real-world use.

Inadequate Supplier Quality Control

Sourcing from suppliers without robust quality management systems (e.g., ISO 9001 certification) increases the risk of inconsistent batch quality. Conduct supplier audits and require QC documentation, including inspection reports and traceability records.

Overlooking Design for IP Sealing Integration

Even with a high IP-rated enclosure, a poorly designed female screw can become a weak point for moisture or dust ingress. Ensure the screw design includes proper sealing interfaces—such as conical seats or captive washers—that integrate seamlessly with gasketed enclosures.

Logistics & Compliance Guide for Female Screw

This guide outlines essential logistics and compliance considerations for the handling, transportation, and regulatory adherence of female screws—commonly used threaded fasteners in manufacturing, construction, and industrial applications.

Product Classification & HS Code

Female screws are typically classified under international tariff nomenclature based on material (e.g., steel, stainless steel, brass), size, and intended use. A common Harmonized System (HS) code for threaded fasteners like nuts and screws is 7318.15 (Steel screws, bolts, and nuts, threaded). Accuracy in classification is vital for customs clearance, duty assessment, and trade compliance.

Packaging & Labeling Requirements

- Packaging: Female screws should be packaged in sealed, moisture-resistant containers (e.g., polybags, boxes with desiccants) to prevent corrosion and physical damage.

- Labeling: Each package must include:

- Product description (e.g., “Stainless Steel Female Screw, M6 x 1.0 thread”)

- Quantity per unit

- Material specification (e.g., ASTM A193, ISO 898-1)

- Lot or batch number

- Country of origin

- Supplier/part number

- Handling symbols (e.g., “Fragile”, “Keep Dry”)

Transportation & Handling

- Mode of Transport: Suitable for air, sea, and ground freight. Choose based on urgency, cost, and destination.

- Weight & Dimensions: Optimize packaging to minimize volume and weight for cost efficiency.

- Handling: Use pallets and stretch-wrapping for bulk shipments. Avoid exposure to moisture, extreme temperatures, and corrosive environments during transit.

- Stackability: Ensure packages are designed to support stacking without deformation.

Import/Export Compliance

- Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (if claiming preferential tariffs)

- Material Test Reports (MTRs) or Certificates of Conformity (CoC), if required

- Regulatory Requirements:

- Comply with destination country import regulations (e.g., U.S. CBP, EU CE marking standards).

- Ensure adherence to trade sanctions and embargoes.

- Verify if export licenses are needed (e.g., for high-strength or specialty alloys under ITAR or EAR).

Quality & Standards Compliance

- Female screws must conform to recognized international standards:

- ISO 261 – ISO general-purpose metric screw threads

- ISO 965 – Tolerances for ISO threads

- ASTM A193/A193M – Alloy steel and stainless steel bolting for high-temperature service

- DIN 934 – Hexagonal nuts (if applicable)

- Provide test reports or inspection certificates upon request.

Environmental & Safety Regulations

- REACH & RoHS Compliance: For shipments to the EU, ensure screws are free from restricted substances (e.g., lead, cadmium) above permissible limits.

- Material Safety Data Sheets (MSDS): Not typically required for inert metal fasteners, but may be needed if coated with lubricants or anti-corrosion agents.

- Waste & Recycling: Follow local regulations for metal waste disposal and recycling.

Traceability & Recordkeeping

- Maintain records of:

- Supplier certifications

- Batch/lot tracking

- Inspection and testing results

- Shipping and customs documentation

- Retain documentation for a minimum of 5 years, or per local regulatory requirements.

Risk Mitigation

- Insurance: Secure cargo insurance covering loss, damage, or delay.

- Supplier Verification: Audit suppliers for quality management systems (e.g., ISO 9001 certification).

- Force Majeure Planning: Establish contingency plans for supply chain disruptions.

Adherence to this logistics and compliance guide ensures efficient, legal, and safe distribution of female screws across global markets.

Conclusion for Sourcing Female Screws:

After a thorough evaluation of suppliers, material options, quality standards, and cost considerations, it is concluded that sourcing female screws (such as nuts, threaded inserts, or internally threaded components) requires a balanced approach focusing on quality, reliability, and long-term value. Key factors such as material compatibility (e.g., stainless steel, brass, or nylon), thread precision, adherence to international standards (e.g., ISO, ANSI), and corrosion resistance must align with the application requirements.

Preferred suppliers should demonstrate consistent quality control, on-time delivery performance, and the ability to scale with demand. Additionally, considering total cost of ownership—beyond unit price—to include shipping, lead times, and potential downtime due to defects—is essential for making a sustainable sourcing decision.

In summary, establishing partnerships with certified, reputable suppliers—supported by sample testing and audit processes—ensures the reliable supply of high-quality female screws, contributing to overall product performance, safety, and operational efficiency.