The global feedthrough capacitor market is experiencing steady growth, driven by rising demand in medical devices, aerospace, defense, and telecommunications. According to Grand View Research, the global ceramic capacitor market—which includes feedthrough capacitors—was valued at USD 12.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.7% from 2023 to 2030. Similarly, Mordor Intelligence projects a CAGR of approximately 5.8% for the ceramic capacitor market through 2028, fueled by advancements in high-frequency applications and the miniaturization of electronic components. As electromagnetic interference (EMI) suppression becomes increasingly critical in high-reliability systems, feedthrough capacitors play a pivotal role in ensuring signal integrity. With the market gaining momentum, a handful of manufacturers have emerged as leaders in innovation, quality, and application-specific solutions. Below are the top five feedthrough capacitor manufacturers shaping the industry’s future.

Top 5 Feedthrough Capacitor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Filter Feedthrough capacitors

Domain Est. 1997

Website: presidiocomponents.com

Key Highlights: We provide high quality commercial capacitors, military capacitors, space capacitors, high temperature capacitors, pulse energy capacitors for EFI detonators….

#2 feedthrough capacitor manufacturer

Domain Est. 2004

Website: advance-capacitors.com

Key Highlights: Feedthrough Capacitors and Filters are used to reduce the unwanted RFI/EMI noise from entering and leaving the equipment. Applications : Power, Telecom and ……

#3 Advanced Electronic Components & Solutions

Domain Est. 2021

Website: kyocera-avx.com

Key Highlights: KYOCERA AVX is a leading global manufacturer of advanced electronic components & solutions engineered to accelerate innovation and build a better future….

#4 Custom Feedthru Capacitor Fabrication Services

Domain Est. 1998

Website: captorcorp.com

Key Highlights: Our talented team will design, engineer, manufacture, and assemble your ideal feedthru capacitor based on your unique specifications and application ……

#5 Customized High

Domain Est. 2022

Website: feedthroughcapacitor.com

Key Highlights: Feedthrough capacitors are usually used at power input or output ports as input filters, especially in power electronic equipment, communication ……

Expert Sourcing Insights for Feedthrough Capacitor

2026 Market Trends for Feedthrough Capacitors

The feedthrough capacitor market is poised for significant transformation and growth by 2026, driven by escalating demands for enhanced electromagnetic interference (EMI) filtering, miniaturization, and performance in increasingly complex electronic systems. Key trends shaping this market include:

Accelerated Adoption in Automotive Electronics and Electrification

The rapid shift towards electric vehicles (EVs), advanced driver-assistance systems (ADAS), and connected car technologies is a dominant driver. Feedthrough capacitors are critical for ensuring signal integrity and EMI suppression in high-voltage battery systems, onboard chargers, motor drives, and infotainment units. As automotive safety and reliability standards tighten, the demand for high-reliability, high-temperature feedthrough capacitors capable of withstanding harsh under-hood environments will surge, particularly for AEC-Q200-compliant components.

Expansion in 5G and Telecommunications Infrastructure

The ongoing global rollout of 5G networks necessitates dense installations of base stations, small cells, and high-frequency communication modules. These systems generate significant EMI, requiring robust filtering solutions. Feedthrough capacitors offer superior high-frequency performance compared to traditional capacitors, making them essential in RF front-ends, power amplifiers, and power supply lines. The trend towards higher frequency bands (e.g., mmWave) will further increase demand for precision, low-inductance feedthrough capacitors optimized for GHz-range operation.

Growth in Medical and Aerospace & Defense Applications

Stringent regulatory requirements in medical devices—such as implantables, diagnostic imaging, and patient monitoring systems—demand ultra-reliable EMI filtering to prevent signal interference and ensure patient safety. Similarly, aerospace and defense systems rely on feedthrough capacitors for avionics, radar, and secure communications, where failure is not an option. The trend toward miniaturization in implantables and portable medical devices will drive innovation in ultra-small, high-capacitance feedthrough designs, including ceramic-based and multi-layer variants.

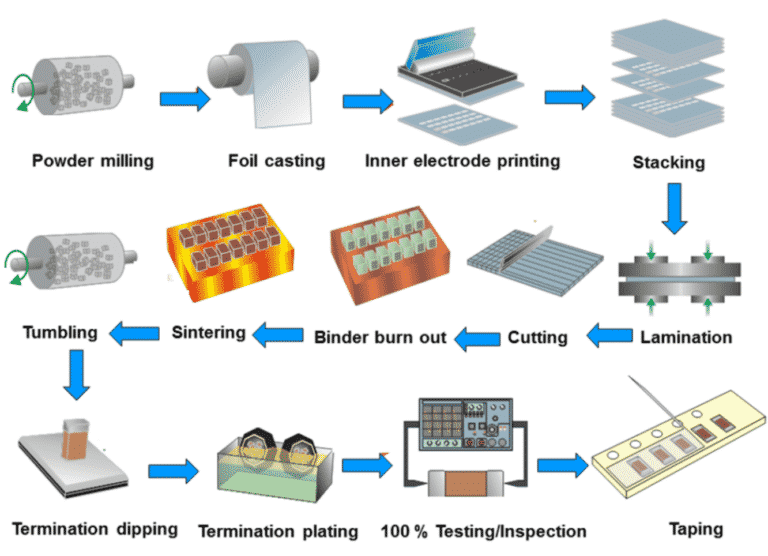

Technological Advancements and Miniaturization

Manufacturers are investing heavily in developing smaller footprint, higher capacitance, and broader frequency range feedthrough capacitors. Innovations include multi-layer ceramic feedthroughs (MLCFs), improved dielectric materials (e.g., X8R, X7R with tighter tolerances), and advanced packaging techniques. Integration with other passive components (e.g., feedthrough filters) is also emerging, enabling compact, high-performance filtering modules ideal for space-constrained applications.

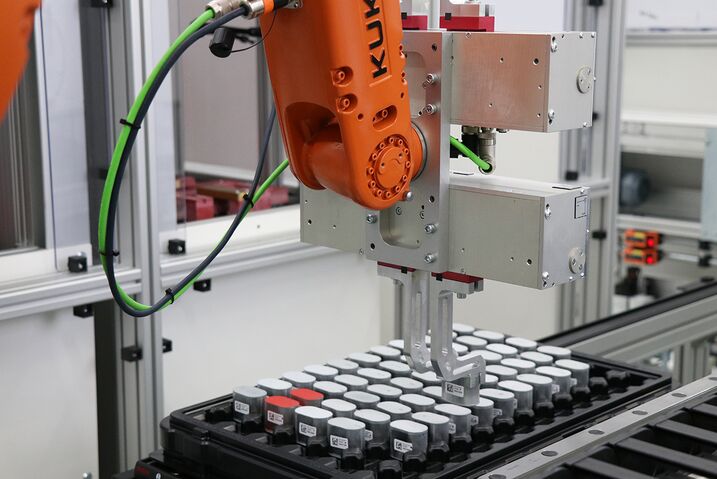

Supply Chain Resilience and Regional Manufacturing Shifts

Geopolitical tensions and supply chain disruptions have prompted a reevaluation of sourcing strategies. By 2026, there will be increased regionalization of manufacturing, particularly in North America and Europe, to reduce dependency on single geographic sources. This trend supports the growth of local suppliers and incentivizes investment in automated, high-yield production processes to maintain quality and scalability.

Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are influencing material choices. The phase-out of certain hazardous substances and a push for lead-free, RoHS-compliant components are accelerating. Research into eco-friendly dielectrics and recyclable packaging will gain momentum, aligning with broader industry sustainability initiatives.

In summary, the 2026 feedthrough capacitor market will be characterized by strong growth across high-tech sectors, propelled by technological innovation, stringent performance requirements, and evolving global supply dynamics. Companies that prioritize R&D in miniaturization, reliability, and application-specific solutions will be best positioned to capture emerging opportunities.

Common Pitfalls Sourcing Feedthrough Capacitors (Quality, IP)

Sourcing feedthrough capacitors requires careful attention to ensure reliable performance, particularly in high-frequency, high-reliability, or safety-critical applications. Overlooking key quality and intellectual property (IP) considerations can lead to system failures, compliance issues, or legal risks. Below are common pitfalls to avoid:

Inadequate Quality and Reliability Screening

Many feedthrough capacitors are used in demanding environments such as aerospace, medical, or defense systems. A frequent mistake is sourcing components without verifying their qualification to relevant industry standards (e.g., MIL-PRF-15, MIL-PRF-20, or AEC-Q200). Using commercial-grade capacitors in place of high-reliability (hi-rel) versions can result in early failure due to thermal cycling, vibration, or electrical overstress. Always confirm screening levels, lot traceability, and burn-in procedures with the supplier.

Overlooking Hermeticity and Seal Integrity

The effectiveness of a feedthrough capacitor depends heavily on its hermetic seal, especially in vacuum or harsh environments. Poor sealing can allow moisture or contaminants to ingress, leading to dielectric breakdown or corrosion. Suppliers may not consistently test for helium leak rates or provide certified hermeticity data. Ensure specifications include measurable leak rate requirements (e.g., <1×10⁻⁸ atm·cc/s He) and that testing is performed on a lot-by-lot basis.

Misunderstanding Electrical Specifications

Feedthrough capacitors are often specified only by capacitance and voltage, but critical parameters like self-resonant frequency (SRF), insertion loss, and impedance vs. frequency are frequently overlooked. Using a capacitor with an SRF below the operating frequency drastically reduces filtering performance. Always request full impedance and insertion loss curves across the intended frequency range and verify performance under actual operating conditions.

Insufficient Attention to Mechanical and Environmental Compatibility

Mismatched thermal expansion coefficients between the capacitor body, feedthrough pin, and housing can cause cracking during temperature cycling. Similarly, improper mounting torque or flange design can compromise the seal. Ensure the capacitor’s materials (e.g., Kovar, Inconel, alumina) are compatible with the host system’s materials and operating environment (temperature, pressure, chemicals).

Lack of IP and Traceability Verification

A major risk when sourcing from non-franchised or offshore suppliers is the potential use of counterfeit or reverse-engineered components. Some vendors may offer “equivalent” feedthrough capacitors that infringe on patented designs or trademarks (e.g., Syfer, AVX, Johanson Technology). This poses legal liability and reliability concerns. Always procure from authorized distributors or directly from original manufacturers, and verify part numbers against public datasheets and patents.

Insufficient Supplier Qualification

Relying on suppliers without a proven track record in high-reliability components increases risk. Evaluate suppliers based on their quality certifications (e.g., AS9100, ISO 13485), process controls, and ability to provide full documentation (material certifications, test reports, RoHS compliance). Unqualified suppliers may lack the capability to consistently meet tight tolerances or environmental requirements.

Incomplete or Missing Documentation

Poor documentation—such as missing or generic datasheets, lack of test reports, or unclear revision control—hinders design validation and regulatory compliance. Ensure all sourced feedthrough capacitors come with detailed performance data, material disclosures, and compliance certificates. This is especially critical for regulated industries like medical or aerospace.

Avoiding these pitfalls requires diligence in supplier selection, rigorous specification review, and proactive verification of both quality and IP integrity. Prioritizing certified sources and demanding comprehensive technical data will mitigate risks and ensure long-term system reliability.

Logistics & Compliance Guide for Feedthrough Capacitors

Overview

Feedthrough capacitors are specialized electronic components used primarily for electromagnetic interference (EMI) filtering in high-frequency applications. Due to their use in critical systems—such as medical devices, aerospace, defense, and industrial equipment—their logistics and regulatory compliance must be carefully managed. This guide outlines key considerations for handling, transporting, storing, and ensuring regulatory compliance for feedthrough capacitors.

Regulatory Compliance

RoHS (Restriction of Hazardous Substances)

Feedthrough capacitors must comply with the RoHS Directive (2011/65/EU and 2015/863) in the European Union, which restricts the use of hazardous materials such as lead, mercury, cadmium, and certain flame retardants. Ensure that suppliers provide RoHS-compliant certificates of conformity (CoC) and material declarations.

REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

Compliance with REACH (EC 1907/2006) is mandatory for products shipped to the EU. Manufacturers must register substances of very high concern (SVHCs) and communicate safe use throughout the supply chain. Request SVHC declarations from suppliers.

Conflict Minerals (Dodd-Frank Act Section 1502)

If supplying to U.S. markets, ensure your feedthrough capacitor supply chain does not source conflict minerals (tantalum, tin, tungsten, and gold) from conflict-affected regions, particularly the Democratic Republic of Congo. Suppliers should provide conflict minerals reporting templates (CMRT).

IPC and MIL Standards

Many feedthrough capacitors used in defense or aerospace applications must meet military specifications (MIL-PRF-22097, MIL-STD-202) or IPC standards for reliability and quality. Verify compliance during procurement and maintain documentation for audits.

Logistics Handling and Storage

Packaging Requirements

- Use anti-static packaging (e.g., conductive foam, shielded bags) to protect against electrostatic discharge (ESD).

- Ensure moisture-sensitive devices (MSDs) are packed with desiccant and humidity indicator cards, and labeled with Moisture Sensitivity Level (MSL) per J-STD-033.

- Seal packages in vacuum or dry nitrogen environments for long-term storage, particularly for ceramic-based capacitors sensitive to moisture.

Transportation

- Ship in temperature-controlled environments when possible; avoid exposure to extreme temperatures (>60°C or <–40°C) and high humidity (>85% RH).

- Use shock-absorbing materials to prevent mechanical damage during transit.

- For international shipments, comply with IATA/ICAO regulations if transporting air, especially if components contain restricted materials.

Storage Conditions

- Store in a clean, dry environment with temperatures between 15°C and 30°C and relative humidity between 30% and 60%.

- Follow first-in, first-out (FIFO) inventory practices.

- Monitor shelf life, especially for components with moisture-sensitive or adhesive elements.

Export Controls and Trade Compliance

ITAR/EAR Compliance

- Determine if feedthrough capacitors fall under the International Traffic in Arms Regulations (ITAR) or the Export Administration Regulations (EAR).

- High-performance capacitors used in military or aerospace systems may be listed on the U.S. Munitions List (USML) or Commerce Control List (CCL). Classify the component using ECCN (Export Control Classification Number); common classifications include 3A001 or 3A999.

- Obtain necessary export licenses for restricted destinations.

Customs Documentation

- Provide accurate Harmonized System (HS) codes (e.g., 8532.24 for fixed capacitors) for customs declarations.

- Include commercial invoices, packing lists, and certificates of origin.

- For EU shipments, ensure compliance with CE marking requirements where applicable.

Quality and Traceability

Lot Traceability

Maintain full traceability of feedthrough capacitors from manufacturer to end use. Record lot numbers, date codes, and supplier batch information to support recalls or failure analysis.

Incoming Inspection

Perform visual and electrical inspections upon receipt, including:

– Checking for physical damage

– Verifying capacitance, insulation resistance, and dielectric withstanding voltage (if required)

– Confirming labeling and marking accuracy

Supplier Qualification

Source feedthrough capacitors only from qualified and audited suppliers with ISO 9001, AS9100 (aerospace), or IATF 16949 (automotive) certifications where applicable.

End-of-Life and Disposal

Dispose of defective or obsolete feedthrough capacitors in accordance with WEEE (Waste Electrical and Electronic Equipment) and local environmental regulations. Partner with certified e-waste recyclers to ensure safe and compliant disposal.

Summary

Proper logistics and compliance management for feedthrough capacitors ensures product reliability, legal adherence, and smooth supply chain operations. Key actions include verifying RoHS, REACH, and export compliance; using ESD-safe packaging; maintaining controlled storage; and ensuring full traceability. Work closely with suppliers and regulatory experts to stay current with evolving standards.

Conclusion for Sourcing Feedthrough Capacitors

In conclusion, sourcing feedthrough capacitors requires a strategic approach that balances performance requirements, application environment, reliability, and cost. These specialized components play a critical role in high-frequency filtering and noise suppression, particularly in aerospace, medical, defense, and telecommunications systems where signal integrity and EMI reduction are paramount.

Key considerations when sourcing feedthrough capacitors include electrical specifications (capacitance value, voltage rating, frequency response), mechanical compatibility (mounting style, size, termination type), dielectric material (e.g., ceramic, C0G/NP0 for stability), and environmental robustness (temperature range, hermeticity). Additionally, selecting qualified suppliers with adherence to industry standards (such as MIL-PRF-125, ISO, or AEC-Q200) ensures consistent quality and reliability.

Prioritizing suppliers with strong technical support, traceability, and proven experience in mission-critical applications will mitigate risks associated with component failure. Furthermore, evaluating long-term availability and potential obsolescence is essential for sustainable design and production.

Ultimately, successful sourcing of feedthrough capacitors involves close collaboration between engineering, procurement, and supply chain teams to ensure the selected components meet both technical demands and project timelines—contributing to the overall performance, durability, and compliance of the end system.