The global feed pellet press market is experiencing robust growth, driven by rising demand for efficient animal feed production in the livestock and aquaculture sectors. According to a report by Grand View Research, the global animal feed manufacturing equipment market was valued at USD 4.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing livestock production, advancements in feed processing technology, and a growing emphasis on feed hygiene and nutrient consistency. Mordor Intelligence also highlights a similar trajectory, noting that rising investments in automated farming equipment and the need for sustainable feed solutions are accelerating adoption across both developed and emerging economies. As the industry scales, manufacturers of feed pellet presses are innovating to deliver higher throughput, energy efficiency, and durability. In this competitive landscape, identifying the top-performing manufacturers becomes critical for feed producers aiming to optimize output and maintain quality. Here’s a data-driven look at the top 10 feed pellet press manufacturers leading the charge in technology, reliability, and market reach.

Top 10 Feed Pellet Press Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pellet Mill & Pelleting Plant Manufacturer

Domain Est. 2012

Website: akahl.com

Key Highlights: PELLET MILL MANUFACTURER: Your expert in the field of flat die pellet mills for feed mills, wood pelleting plants, recycling plants and much more | AMANDUS…

#2 Pellet Mills

Domain Est. 2013

Website: onecpm.com

Key Highlights: From plastics to industrial products to commercial animal feed, this machine delivers rock-solid performance to meet your pelleting needs day after day….

#3 Feed Pellet Mill Manufacturer. Expert In Animal Feed pelletizing …

Domain Est. 2013

Website: feed-pellet-mill.com

Key Highlights: Offer complete animal feed pellet production solutions from raw materials crushing, feed mixing, pelletizing, cooling, coating, packing, etc. Affordable Price….

#4 Pellet mills, animal feed

Domain Est. 1995

Website: andritz.com

Key Highlights: ANDRITZ Feed & Biofuel Technologies manufactures high-quality pellet mills that ensure highly efficient and reliable pellet feed production….

#5 Pellet Mills

Domain Est. 2000

Website: buhlergroup.com

Key Highlights: Our pellet mills, equipment, process expertise and professional support can help you to create the perfect pellets for your specific application….

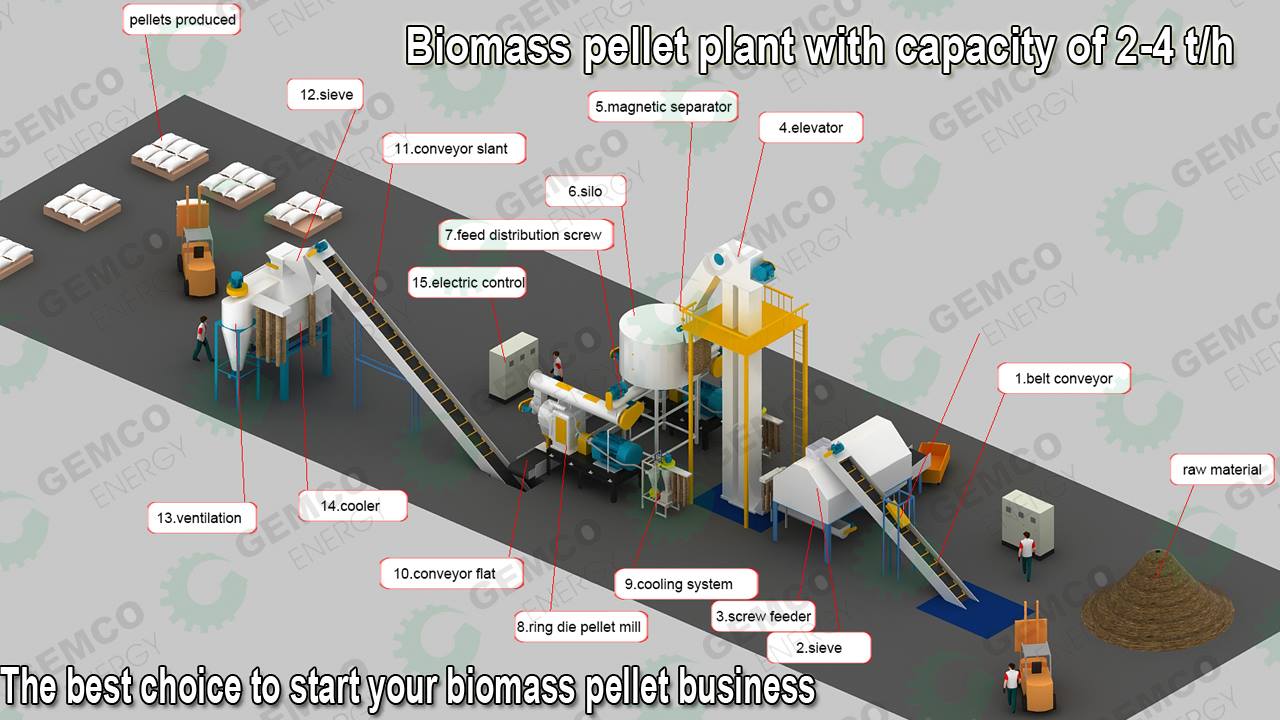

#6 GEMCO Pellet Press With Over 20

Domain Est. 2013

Website: gemco-energy.com

Key Highlights: GEMCO pellet press with over 20-year experience, relying on the innovation of the operation, working processing, power driver, craft of the polishing etc., ……

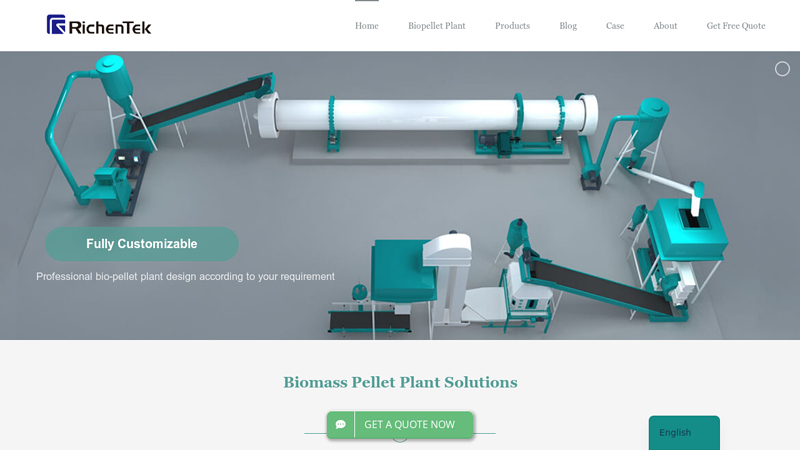

#7 Biomass Pellet Machine & Wood Pellet Plants Manufactures. One …

Domain Est. 2013

Website: biopelletmachine.com

Key Highlights: We specialize in providing reliable, efficient, and eco-friendly biomass pellet machines and complete biomass pellet plant solutions to customers worldwide….

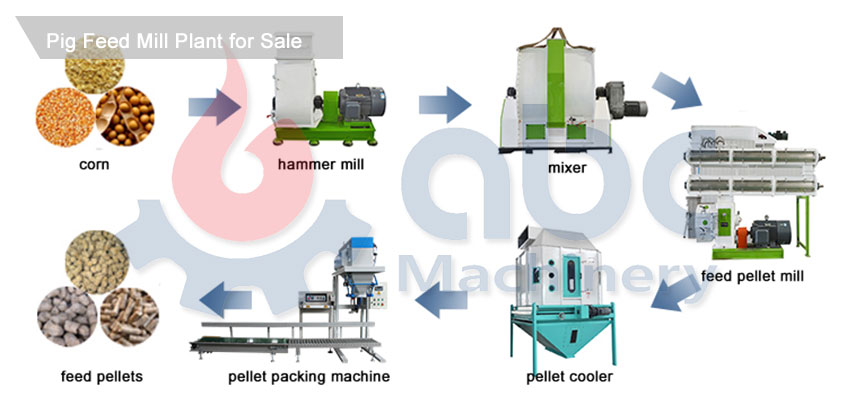

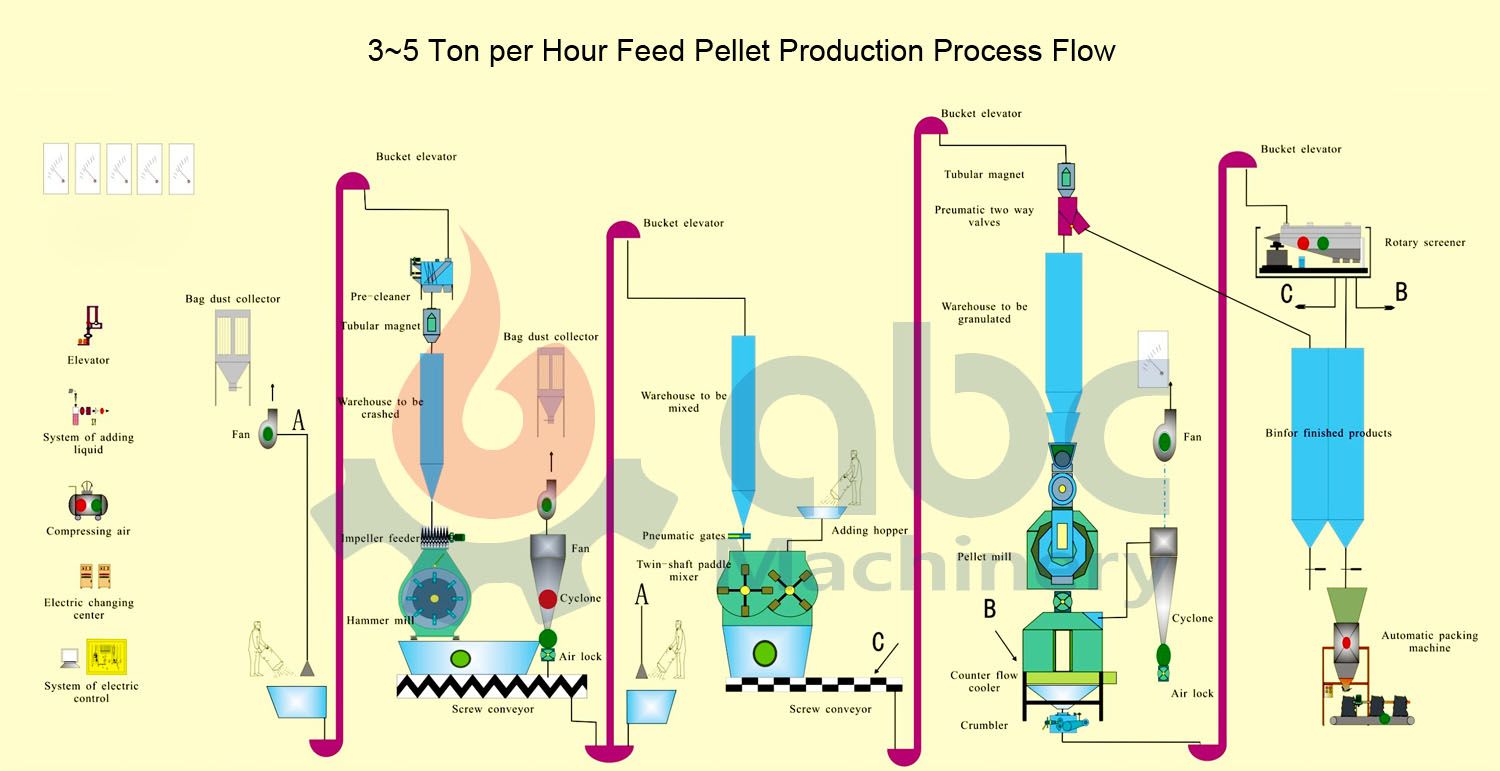

#8 Specialists In Feed Pellet Machines. Complete Animal Feed Pellet …

Domain Est. 2014

Website: feedpelletizer.com

Key Highlights: We specialize in designing, manufacturing, and supplying complete animal feed pellet production lines to customers worldwide. Whether you need a small feed ……

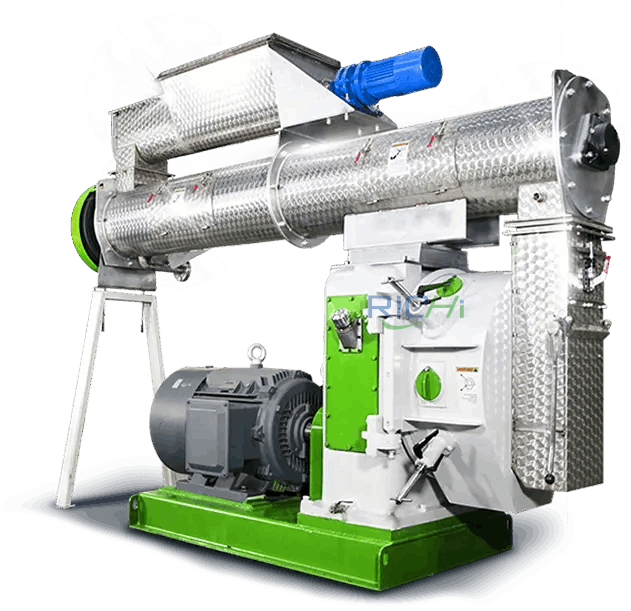

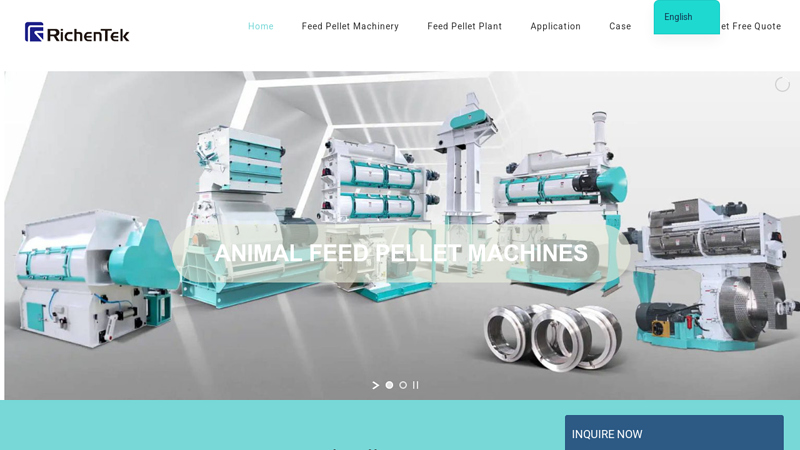

#9 RICHI Machinery

Domain Est. 2015

Website: cn-pellet.com

Key Highlights: RICHI Machinery offers cutting-edge pellet production equipment and complete pelletizing solutions for animal feed, biomass, and aquaculture industries….

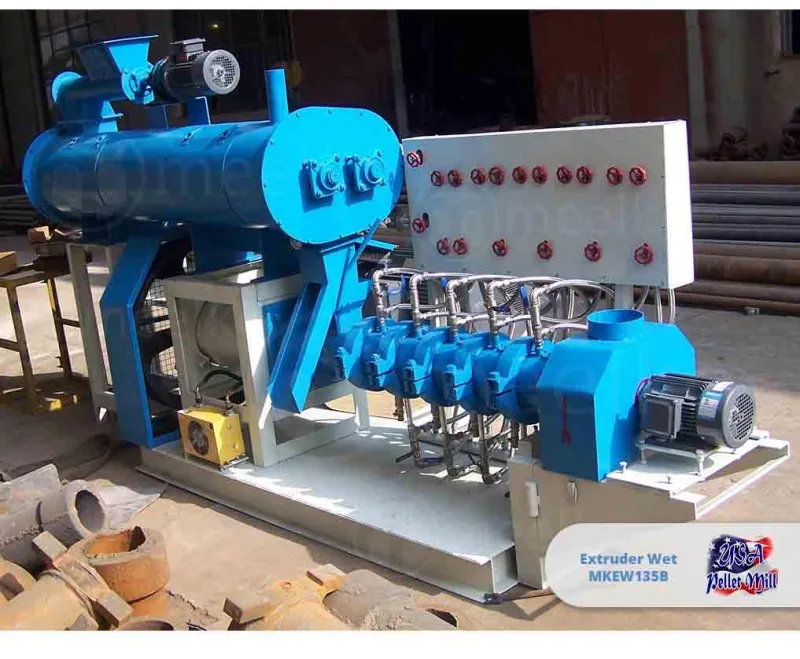

#10 USA Pellet Mill Pellet Mills & Extruders (Miami, FL)

Domain Est. 2018

Website: usapelletmill.com

Key Highlights: U.S.-based supplier of pellet mills & extruders for feed, biomass & pet food. Shipping globally from Miami. Request your quote today and boost production!…

Expert Sourcing Insights for Feed Pellet Press

H2: 2026 Market Trends for Feed Pellet Press

The global feed pellet press market is poised for significant transformation by 2026, driven by converging forces in agriculture, sustainability, and technology. Key trends shaping this evolution include:

H2: Rising Global Demand for Animal Protein Fuels Expansion

The primary driver remains the escalating global demand for meat, dairy, and aquaculture products, particularly in developing economies across Asia-Pacific, Latin America, and Africa. As populations grow and incomes rise, dietary shifts towards higher protein consumption necessitate more efficient animal feed production. Pelleted feed offers superior digestibility, reduced waste, and easier handling compared to mash, making pellet presses essential infrastructure. This sustained demand will push both large-scale commercial feed mills and smaller, decentralized producers to invest in pellet press capacity, boosting market growth.

H2: Sustainability and Alternative Feed Ingredients Reshape Press Requirements

Environmental concerns and resource scarcity are forcing innovation. Key trends include:

* Utilization of Non-Traditional Biomass: Increased use of agricultural residues (rice husks, straw), food processing by-products, and insect meal in feed formulations. These materials often have different physical properties (e.g., lower density, higher lignin) than traditional grains, demanding pellet presses with enhanced durability, higher compression ratios, and specialized die designs to achieve adequate pellet quality and binding.

* Focus on Energy Efficiency: Stricter environmental regulations and rising energy costs are pushing manufacturers towards presses with lower specific energy consumption (kWh/ton). Innovations in die design, roller configuration, drive systems (e.g., variable frequency drives), and heat recovery systems will be critical differentiators.

* Circular Economy Integration: Pellet presses are increasingly used to process waste streams into feed (e.g., converting food waste or brewer’s spent grain), aligning with circular economy principles and creating new market niches for specialized, often smaller-scale, press units.

H2: Technological Advancements Drive Automation and Intelligence

The market is moving beyond basic mechanical function towards smart, connected equipment:

* Increased Automation & Integration: Seamless integration with upstream (grinding, mixing) and downstream (cooling, coating, packaging) processes via PLCs and SCADA systems will become standard, especially in large mills. This improves throughput, consistency, and reduces labor costs.

* Predictive Maintenance & IoT: Sensors monitoring critical parameters (bearing temperature, vibration, motor load, die wear) will feed data to cloud platforms. AI algorithms will predict maintenance needs, prevent unplanned downtime, optimize performance, and extend equipment lifespan.

* Advanced Control Systems: Sophisticated control systems will dynamically adjust parameters (e.g., feed rate, steam conditioning, roller pressure) based on real-time material flow and sensor feedback, ensuring optimal pellet quality (durability, density, moisture) despite variations in raw material composition.

H2: Growth of Decentralized and Small-Scale Production

Counterbalancing large industrial mills is a significant trend towards smaller-scale, localized feed production:

* On-Farm & Regional Mills: Farmers and cooperatives are investing in smaller, robust pellet presses to produce customized feed, reduce transportation costs, ensure freshness, and utilize locally available feedstocks (including on-farm by-products). This demands user-friendly, reliable, and cost-effective machines suitable for intermittent operation.

* Aquafeed & Specialty Feeds: The booming aquaculture sector and demand for specialized feeds (e.g., for pets, exotic animals, young livestock) often require smaller batch production and formulations with unique ingredients (high fat, high moisture, delicate additives), driving demand for versatile, smaller presses with precise control.

H2: Consolidation, Regional Shifts, and Cost Pressures

- Market Consolidation: Larger established players are likely to acquire innovative smaller manufacturers or expand globally, particularly targeting high-growth regions like Southeast Asia and Africa, leading to increased competition and potentially driving down prices for standardized models.

- Asia-Pacific Dominance: Asia-Pacific, led by China, India, and Southeast Asian nations, will remain the largest and fastest-growing market due to massive livestock and aquaculture industries and rising meat consumption.

- Cost Optimization: Intense competition will pressure manufacturers to innovate on cost reduction through design simplification, use of advanced (but cost-effective) materials, and localized manufacturing, while still meeting performance and durability expectations.

Conclusion: By 2026, the feed pellet press market will be characterized by a dual focus: highly automated, efficient, and intelligent systems for large-scale industrial production, alongside robust, user-friendly, and versatile presses for decentralized and specialized applications. Success will depend on manufacturers’ ability to innovate in energy efficiency, adaptability to diverse feedstocks, integration of smart technologies, and responsiveness to regional market dynamics and sustainability imperatives.

Common Pitfalls When Sourcing Feed Pellet Press Machines (Quality and Intellectual Property)

Sourcing feed pellet press machines from domestic or international suppliers can be a cost-effective way to expand production capacity, but it comes with several risks—particularly related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is essential for making informed procurement decisions and avoiding long-term operational or legal issues.

Quality-Related Pitfalls

Inconsistent Build Quality and Materials

One of the most common issues when sourcing feed pellet presses—especially from low-cost manufacturers—is inconsistent build quality. Some suppliers may use substandard steel, inferior bearings, or poorly machined components to cut costs. This leads to frequent breakdowns, higher maintenance costs, and reduced pellet mill lifespan.

Lack of Standardized Manufacturing Processes

Suppliers without proper quality control systems often lack standardized manufacturing procedures. This can result in unit-to-unit variability, where one machine performs adequately but the next fails prematurely, even within the same batch.

Inadequate Testing and Calibration

Many sourced machines are shipped without rigorous performance testing or proper calibration. As a result, buyers may receive equipment that does not meet the advertised capacity, energy efficiency, or pellet quality standards, requiring costly on-site adjustments.

Misleading Specifications and Performance Claims

Some suppliers exaggerate machine capabilities such as throughput, power efficiency, or durability. Without third-party verification or independent testing data, buyers risk investing in equipment that underperforms in real-world conditions.

Poor After-Sales Support and Spare Parts Availability

Low-cost suppliers may offer limited technical support, unclear warranty terms, or long lead times for spare parts. This can lead to extended downtime when components like dies or rollers need replacement—a critical issue in continuous feed production operations.

Intellectual Property (IP) Pitfalls

Risk of Infringing Patented Technology

Many modern feed pellet presses incorporate patented technologies, such as advanced die cooling systems, automatic lubrication, or energy-efficient motor designs. Sourcing from suppliers that replicate these features without proper licensing exposes the buyer to potential IP infringement claims, especially when importing into regulated markets like the EU or North America.

Purchasing Counterfeit or Clone Equipment

Some manufacturers produce unauthorized copies of well-known brands (e.g., mimicking designs from Muyang, CPM, or Andritz). While these “clone” machines may appear identical, they often lack performance, safety, and reliability. Purchasing such equipment may also expose the buyer to legal liability if the original IP holder takes action.

Lack of IP Documentation and Traceability

Reputable suppliers provide documentation proving the legitimacy of their designs and compliance with IP laws. When sourcing from unknown or offshore manufacturers, buyers may receive no proof of IP ownership or design originality, increasing legal and reputational risks.

Exposure to Export Restrictions or Seizures

Customs authorities in many countries actively monitor shipments for IP violations. If a feed pellet press is found to infringe on patented technology, shipments may be seized, fines imposed, or future imports blocked—disrupting supply chains and damaging business credibility.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough due diligence on suppliers, including factory audits and reference checks.

– Request third-party certifications (e.g., CE, ISO) and performance test reports.

– Work with legal counsel to verify IP compliance, especially for high-tech components.

– Prioritize suppliers with transparent documentation, strong after-sales support, and proven track records.

By addressing both quality and IP concerns proactively, businesses can source reliable, compliant feed pellet press equipment that supports long-term operational success.

Logistics & Compliance Guide for Feed Pellet Press

Overview

This guide outlines key logistics and compliance considerations for the transportation, installation, operation, and maintenance of feed pellet presses used in animal feed production. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and safety across the supply chain.

Regulatory Compliance

Feed pellet presses must comply with regional and international standards governing food safety, machinery safety, and environmental protection. Key regulations include:

– CE Marking (EU): Ensures conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

– OSHA Standards (USA): Applies to workplace safety, including machine guarding and operator training.

– FDA Regulations (USA): Relevant if the press is used in facilities producing feed for animals raised for human consumption; adherence to Current Good Manufacturing Practices (cGMP) is required.

– ISO 22000 & FSSC 22000: Applicable food safety management systems that may require equipment to meet hygiene and traceability standards.

– Local Environmental Regulations: May include noise levels, dust emissions, and waste disposal protocols.

Ensure all equipment documentation includes compliance certificates, technical specifications, and safety data sheets.

Import/Export Requirements

When shipping feed pellet presses internationally:

– Verify customs classifications (HS codes)—typically under 8437.80 (machinery for cleaning, sorting, or grading seed, grain, or dried leguminous vegetables).

– Obtain export licenses if required by the country of origin.

– Prepare commercial invoices, packing lists, and certificates of origin.

– Confirm phytosanitary or sanitary certificates are not required for machinery (usually not applicable unless part of a turnkey feed plant with biological components).

– Comply with import regulations of the destination country, including electromagnetic compatibility (EMC) and electrical safety standards.

Transportation & Handling

- Use palletized or crated packaging to protect components during transit.

- Clearly label equipment with handling instructions (e.g., “Fragile,” “This Side Up”).

- Secure machinery on trucks or containers using straps or braces to prevent shifting.

- For oversized units, coordinate special transport permits and route planning.

- Ensure receiving site has loading equipment (e.g., forklifts, cranes) and clear access for unloading.

Installation & Site Preparation

- Verify floor load capacity can support the pellet press’s weight (typically 500–5,000 kg depending on model).

- Provide adequate ventilation to manage heat and dust during operation.

- Ensure access to required power supply (voltage, phase, frequency—e.g., 380V/3-phase/50Hz).

- Install dust collection systems to meet occupational health standards (e.g., OSHA PEL for particulates).

- Follow manufacturer’s installation manual and conduct post-installation safety checks.

Operational Compliance

- Train operators in safe operating procedures, lockout/tagout (LOTO), and emergency shutdown.

- Maintain a preventive maintenance schedule to ensure reliability and compliance with safety standards.

- Keep records of equipment inspections, repairs, and calibration for audit purposes.

- Implement cleaning protocols to prevent cross-contamination, especially when processing different feed types.

Documentation & Recordkeeping

Maintain the following for compliance audits:

– Equipment user manuals and safety instructions in local language.

– CE Declaration of Conformity or equivalent.

– Maintenance logs and service history.

– Operator training records.

– Incident reports and corrective actions.

Disposal & End-of-Life

- Follow WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for decommissioned units.

- Recycle metal components and dispose of electrical parts through certified e-waste handlers.

- Remove and properly dispose of any contaminated parts (e.g., those exposed to mold or chemicals).

Conclusion

Proper logistics planning and strict compliance with regulatory requirements are essential for the safe and legal operation of feed pellet presses. Regular audits, staff training, and documentation help mitigate risks and ensure long-term operational success. Always consult local authorities and equipment manufacturers for region-specific requirements.

Conclusion for Sourcing a Feed Pellet Press

Sourcing a feed pellet press is a critical decision that directly impacts the efficiency, quality, and profitability of animal feed production. After evaluating various factors such as production capacity, power requirements, pellet quality, durability, maintenance needs, and cost, it is clear that selecting the right machine requires a balanced approach between performance and long-term value.

It is essential to choose a reputable supplier offering reliable technical support, spare parts availability, and proven machine performance in similar operational environments. Whether opting for a flat die or ring die pellet press, the decision should align with the scale of operations, types of raw materials used, and target feed specifications.

In conclusion, a well-researched sourcing strategy—incorporating thorough supplier evaluation, pilot testing when possible, and lifecycle cost analysis—ensures the acquisition of a feed pellet press that enhances productivity, maintains feed quality, and supports sustainable growth in feed manufacturing operations.