The global feed grinder mixer market is experiencing robust growth, driven by rising demand for high-efficiency livestock and poultry feed processing solutions. According to Mordor Intelligence, the animal feed equipment market is projected to grow at a CAGR of over 6.8% from 2023 to 2028, fueled by increasing mechanization in agriculture and a growing emphasis on feed quality and homogeneity. As feed producers seek to optimize output and ensure consistent feed formulation, grinder mixers—equipment that combines size reduction and mixing in one system—have become essential in modern feed mills. Technological advancements, energy efficiency improvements, and automation integration are key factors shaping manufacturer competitiveness. This evolving landscape has intensified demand for reliable, high-capacity machines, making the selection of the right manufacturer critical. Based on production capacity, innovation, global reach, and customer reviews, the following list highlights the top 10 feed grinder mixer manufacturers leading the industry today.

Top 10 Feed Grinder Mixer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Supreme International Vertical Feed Mixers & Livestock Equipment

Domain Est. 1998

Website: supremeinternational.com

Key Highlights: Trusted TMR mixers, delivery boxes and environmental processors built for reliability and backed by decades of producer-focused innovation….

#2 Mixers

Domain Est. 1999

Website: hsmfgco.com

Key Highlights: H&S 9117 grinder mixer product Grinder Mixers; H&S 7117 roller mixer in front of barn Roller Mixers; H&S 1100 linewrap bale wrapper product Bale Wrappers; H&S ……

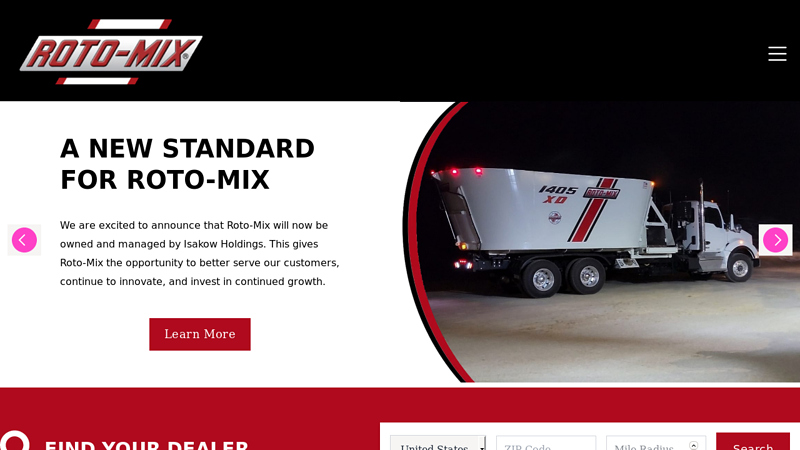

#3 Roto

Domain Est. 1997

Website: rotomix.com

Key Highlights: Boost livestock nutrition and efficiency with Roto-Mix’s advanced feed mixers, designed for optimal performance and consistent rations across your herd….

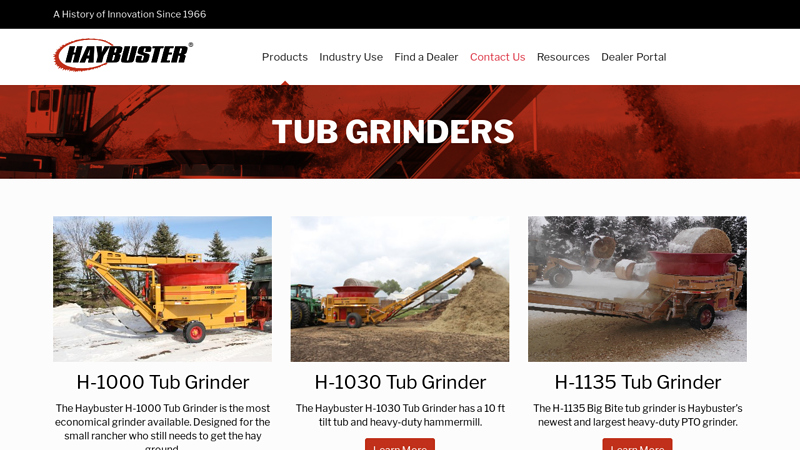

#4 Tub Grinders

Domain Est. 1999

Website: haybuster.com

Key Highlights: The Haybuster H-1000 Tub Grinder is the most economical grinder available. Designed for the small rancher who still needs to get the hay ground….

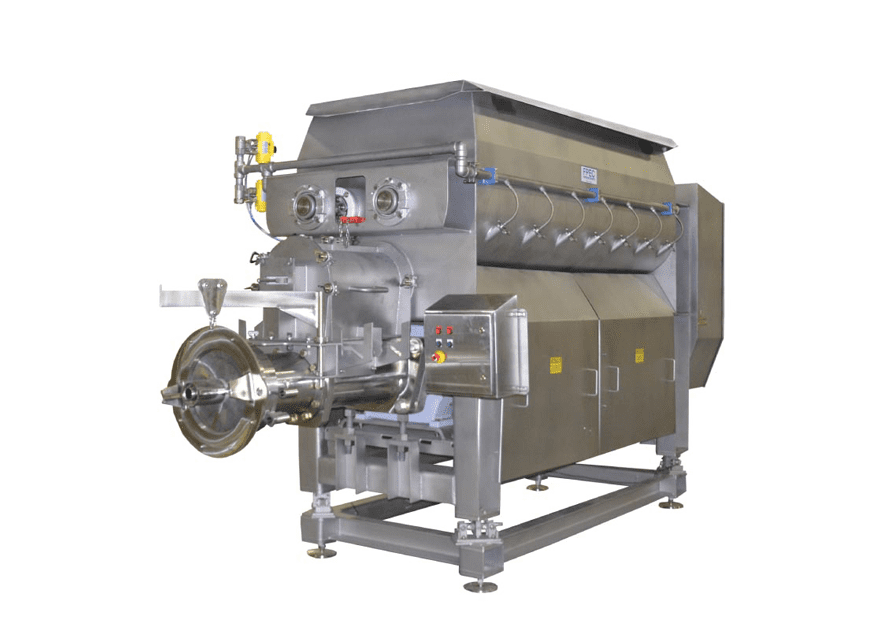

#5 Reliable Food Manufacturing Equipment

Domain Est. 1999

Website: fpec.com

Key Highlights: FPEC designs and manufactures industry-trusted equipment for food processing. Our meat grinders, tumblers, cookers, and other specialized equipment are ……

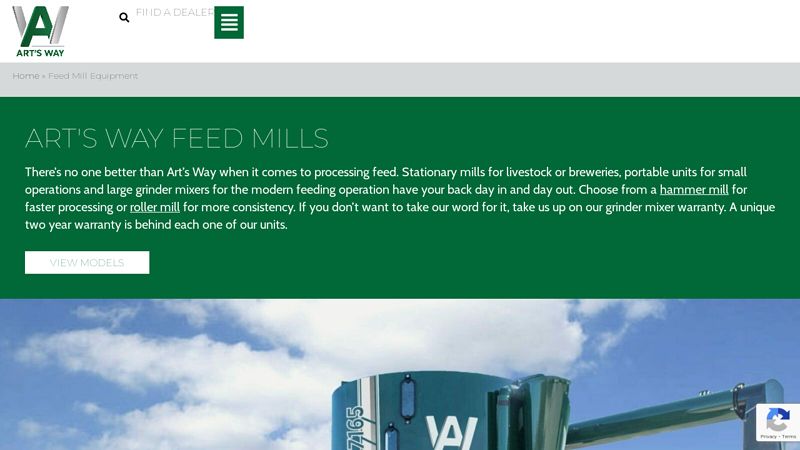

#6 Art’s Way Manufacturing

Domain Est. 2001

Website: artsway-mfg.com

Key Highlights: We take pride in the quality of our farm and construction equipment, agricultural buildings, and modular laboratories….

#7 Feed Mill Equipment – High-Quality Feed Processing

Domain Est. 2001

Website: artsway.com

Key Highlights: Discover high-quality feed mill equipment from Art’s Way. Efficient and reliable feed processing solutions for all your feed processing agricultural needs….

#8 Van Aarsen: For Leaders in High

Domain Est. 2002

Website: vanaarsen.com

Key Highlights: At Van Aarsen, we specialize in designing and manufacturing feed mill solutions that enhance efficiency, improve quality, and boost profitability….

#9 Homepage

Domain Est. 2012

Website: fgfmill.com

Key Highlights: From cleaning, drying, grinding and rolling your grains to animal health, farming supplies and water softeners—we go above and beyond to accommodate your needs….

#10 Exceed Manufacturing

Domain Est. 2021

Website: exceedmanufacturing.com

Key Highlights: Model 1320 Grinder Mixer. Our model 1320 Grinder Mixer has a 20″ hammermill, and a 130 bushel mixing tank with scales for feed grinding and batch mixing….

Expert Sourcing Insights for Feed Grinder Mixer

H2: 2026 Market Trends for Feed Grinder Mixers

The global Feed Grinder Mixer market is poised for significant transformation by 2026, driven by advancements in agricultural technology, rising demand for livestock products, and increasing emphasis on feed efficiency and sustainability. Key trends shaping the market during this period include:

-

Increased Demand from Intensive Livestock Farming

As global meat, dairy, and poultry consumption continues to rise—particularly in emerging economies—there is growing pressure on farmers to enhance feed production efficiency. Feed grinder mixers, essential for producing uniform, high-quality animal feed, are seeing heightened adoption across large-scale and commercial farms. This trend is especially evident in Asia-Pacific and Latin America, where livestock intensification is accelerating. -

Adoption of Smart and Automated Systems

By 2026, integration of IoT (Internet of Things) and automation in feed grinder mixers is expected to become more widespread. Smart systems that monitor grinding consistency, mixing ratios, and machine performance in real time are improving operational efficiency and reducing labor costs. These technologies enable precision feeding, minimizing waste and optimizing nutritional content. -

Focus on Energy Efficiency and Sustainability

With growing environmental regulations and energy costs, manufacturers are prioritizing energy-efficient designs. Innovations such as variable-speed motors, improved blade technology, and low-emission components are being incorporated into newer models. Additionally, the use of renewable energy sources to power feed processing units is gaining traction, particularly in off-grid or rural farming communities. -

Growth in Smallholder and Cooperative Farming Adoption

While large farms have traditionally dominated the market, feed grinder mixers are increasingly being adopted by smallholder farmers through cooperative models. Governments and NGOs are supporting such initiatives by subsidizing equipment purchases or promoting shared machinery hubs. This democratization of technology is expanding market reach, particularly in Africa and South Asia. -

Regional Market Expansion and Localization

The market is witnessing a shift toward localized manufacturing and customization. Companies are tailoring feed grinder mixer designs to regional feed ingredients (e.g., rice bran in Southeast Asia or maize in Sub-Saharan Africa) and power availability (e.g., diesel vs. electric). This localization enhances usability and drives regional market penetration. -

Consolidation and Strategic Partnerships

The competitive landscape is evolving, with key players engaging in mergers, acquisitions, and partnerships to expand distribution networks and R&D capabilities. Collaboration between equipment manufacturers and animal nutrition firms is also on the rise, aiming to develop integrated feed processing and formulation solutions. -

Regulatory Influence and Feed Safety Standards

Stricter feed safety regulations in regions like the EU and North America are pushing demand for hygienic, easily cleanable grinder mixer models. Features such as stainless steel construction, sealed systems, and compliance with food-grade standards are becoming differentiators in premium market segments.

Conclusion:

By 2026, the Feed Grinder Mixer market will be characterized by technological innovation, sustainability-driven design, and broader accessibility. The convergence of automation, energy efficiency, and regional customization will define competitive advantage, while rising global protein demand continues to underpin long-term growth. Producers and suppliers who align with these trends will be well-positioned to capture value in an increasingly dynamic agricultural machinery landscape.

Common Pitfalls When Sourcing a Feed Grinder Mixer (Quality and Intellectual Property)

Sourcing a feed grinder mixer involves more than just comparing prices and specifications. Overlooking critical aspects related to quality and intellectual property (IP) can lead to operational inefficiencies, safety hazards, legal disputes, and long-term financial losses. Below are key pitfalls to avoid:

Poor Build Quality and Substandard Materials

One of the most frequent issues is selecting equipment constructed with low-grade materials or inadequate manufacturing standards. Cheap grinder mixers may use thin steel, inferior bearings, or poorly welded joints, leading to rapid wear, structural failure, or contamination of animal feed. This compromises both equipment lifespan and feed safety.

Inadequate Grinding and Mixing Performance

Some suppliers exaggerate performance metrics such as throughput, particle size consistency, or mixing homogeneity. Purchasing a machine based on inflated claims can result in inefficient feed production, inconsistent rations, and increased energy consumption. Always request third-party test reports or conduct on-site trials before finalizing procurement.

Lack of Quality Certifications and Compliance

Reputable feed grinder mixers should comply with international standards such as ISO, CE, or GOST. Suppliers who cannot provide valid certifications may be cutting corners in design, safety, or environmental compliance. This increases the risk of equipment failure and may lead to regulatory issues, especially in commercial feed mills.

Counterfeit or Copycat Equipment

A significant IP-related pitfall is purchasing machines that infringe on patented designs or technologies. Some manufacturers replicate branded models without authorization, offering them at lower prices. While tempting, these copies often lack performance reliability and expose buyers to legal risks, especially in regions with strict IP enforcement.

Missing or Invalid Patents and Technical Documentation

When sourcing advanced grinder mixers, verify whether the technology is patented and whether the supplier holds legitimate rights to manufacture and sell it. Absence of proper documentation or inability to provide patent details may indicate IP violations, which could lead to shipment seizures or legal action downstream.

No After-Sales Support or Spare Parts Availability

Low-cost suppliers, especially those involved in IP infringement, often lack established service networks. This means limited access to technical support, replacement parts, or maintenance guidance—critical for minimizing downtime. Poor post-purchase service directly impacts operational continuity and total cost of ownership.

Hidden Design Flaws Due to Reverse Engineering

Copycat machines are often reverse-engineered without full understanding of the original engineering principles. This can result in hidden flaws—such as improper rotor balance, inadequate dust extraction, or suboptimal chamber design—that only become apparent after prolonged use, leading to safety hazards and costly repairs.

Risk of Legal Liability for IP Infringement

Purchasing equipment that violates intellectual property rights—even unknowingly—can expose your business to legal liability. In some jurisdictions, importers and users can be held accountable for using or distributing infringing products, resulting in fines, injunctions, or reputational damage.

Insufficient Testing and Quality Control Processes

Reliable suppliers implement rigorous quality control during production, including load testing, vibration analysis, and safety checks. Suppliers lacking these processes may deliver inconsistent units, increasing the likelihood of field failures and safety incidents.

Failure to Verify Supplier Authenticity

It’s essential to conduct due diligence on the manufacturer, including site visits, reference checks, and validation of business credentials. Fraudulent suppliers may present forged certifications or fake client testimonials, putting buyers at risk of receiving non-compliant or non-functional equipment.

Avoiding these pitfalls requires thorough vetting of suppliers, insistence on verifiable quality standards, and attention to intellectual property integrity. Investing time in due diligence upfront can prevent significant losses and ensure long-term operational success.

Logistics & Compliance Guide for Feed Grinder Mixer

Overview

A Feed Grinder Mixer is essential equipment in animal feed production, combining grinding and mixing functions to prepare uniform feed rations. Proper logistics planning and regulatory compliance are critical for safe transportation, installation, and operation. This guide outlines key considerations for handling, shipping, import/export, and regulatory adherence.

Equipment Specifications and Handling

- Weight and Dimensions: Confirm the grinder mixer’s weight, height, width, and length to select appropriate lifting and transport equipment.

- Lifting Points: Use only designated lifting lugs or attachment points; avoid chains on belts, gears, or motor housings.

- Forklift Use: Ensure forks are properly positioned under reinforced frame sections. Never lift by the mixing drum or grinder housing.

- Protective Covers: Install protective caps on drive shafts, motor couplings, and electrical panels during handling to prevent damage.

Transportation and Shipping

- Domestic Shipping:

- Secure equipment on flatbed trailers using rated straps and corner protectors.

- Comply with road transport regulations (e.g., DOT in the U.S.) regarding over-dimensional loads, permits, and signage.

- International Shipping:

- Package in weather-resistant, skid-mounted crates with desiccants to prevent moisture damage.

- Use International Standards for Phytosanitary Measures (ISPM-15) compliant wooden pallets for cross-border shipments.

- Provide detailed packing lists, commercial invoices, and certificates of origin.

Import and Export Compliance

- Harmonized System (HS) Code: Classify the grinder mixer under appropriate HS code (e.g., 8437.80 for agricultural grinding machinery).

- Customs Documentation: Prepare bill of lading, commercial invoice, packing list, and import/export licenses as required.

- Tariff and Duties: Verify duty rates and eligibility for trade agreements (e.g., USMCA, EU preferential tariffs).

- Restricted Components: Confirm if motors or electrical systems comply with destination country voltage, frequency, and plug standards.

Regulatory and Safety Standards

- Electrical Compliance:

- Ensure motor and control panels meet regional standards (e.g., NEC/UL in North America, CE/IEC in Europe).

- Include proper grounding, overload protection, and emergency stop mechanisms.

- Mechanical Safety:

- Comply with OSHA (U.S.) or equivalent local regulations for guarding moving parts (belts, pulleys, augers).

- Install safety interlocks on access hatches and grinder lids.

- Noise and Dust Control:

- Meet permissible noise exposure limits (e.g., OSHA 29 CFR 1910.95).

- Equip with dust collection systems to comply with air quality regulations (e.g., EPA NESHAP, EU Directive 2004/37/EC).

Installation and Site Compliance

- Foundation Requirements: Install on level, reinforced concrete base per manufacturer specifications to prevent vibration damage.

- Utility Connections: Verify availability of correct power supply (voltage, phase, amperage) and compressed air (if applicable).

- Environmental Permits: Obtain permits for operations involving dust emissions or wastewater from equipment cleaning (e.g., under Clean Water Act or local ordinances).

Operational and Maintenance Compliance

- Operator Training: Train personnel on safe operation, lockout/tagout (LOTO) procedures, and emergency response.

- Maintenance Records: Maintain logs of inspections, repairs, and safety checks to comply with OSHA or equivalent standards.

- Waste Management: Dispose of metal shavings, worn screens, and spent lubricants according to local hazardous waste regulations.

Documentation and Certification

- Retain copies of:

- Equipment manuals and schematics

- CE/UL/CSA certification marks and test reports

- Risk assessments and safety declarations

- Calibration records for load cells or automated controls

Conclusion

Proper logistics and compliance planning ensures the safe and legal deployment of a Feed Grinder Mixer. Adhering to transportation guidelines, customs requirements, and regional safety standards minimizes delays, avoids penalties, and supports long-term operational efficiency. Always consult local regulations and involve certified professionals during installation and commissioning.

Conclusion for Sourcing a Feed Grinder Mixer

In conclusion, sourcing a feed grinder mixer is a critical decision that significantly impacts the efficiency, quality, and cost-effectiveness of livestock feed production. After evaluating various suppliers, models, and specifications, it is evident that selecting the right equipment requires careful consideration of factors such as capacity, power requirements, durability, ease of maintenance, and after-sales support.

The ideal feed grinder mixer should align with the operational scale of the farm or feed mill, ensure consistent particle size reduction and uniform mixing, and be constructed from high-quality, wear-resistant materials to withstand continuous use. Energy efficiency and safety features are also important for long-term sustainability and operator protection.

Additionally, establishing a relationship with a reputable supplier offering reliable technical support, spare parts availability, and training can greatly enhance equipment performance and longevity. Whether sourcing locally or internationally, conducting thorough due diligence and possibly testing a unit before full purchase will mitigate risks and ensure optimal investment returns.

Ultimately, a well-chosen feed grinder mixer not only improves feed conversion ratios and animal health but also contributes to streamlined operations and increased profitability in animal production enterprises.