The global backflow prevention devices market, which includes repair kits for widely used assemblies like the Febco 765–1, is experiencing steady growth driven by increasing regulatory requirements for water safety and infrastructure modernization. According to Grand View Research, the global backflow prevention valve market was valued at USD 2.3 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by heightened awareness of potable water contamination risks and stricter plumbing codes in both residential and commercial sectors. As one of the most commonly installed reduced pressure principle backflow preventers, the Febco 765–1 requires periodic maintenance using OEM-compliant repair kits, creating consistent demand for reliable replacement parts. With increasing procurement by municipalities, industrial facilities, and plumbing contractors, the need for high-quality repair kits has led to a competitive landscape of manufacturers ensuring compliance, durability, and ease of service. Based on product availability, OEM certification, and customer reviews, the following are eight leading manufacturers producing repair kits compatible with the Febco 765–1 assembly.

Top 8 Febco 765 1 Repair Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 765

Domain Est. 1995

Website: watts.com

Key Highlights: Series 765 Pressure Vacuum Breakers include a freeze sensor for use with SentryPlus Alert® technology to signal facility personnel when temperature nears and ……

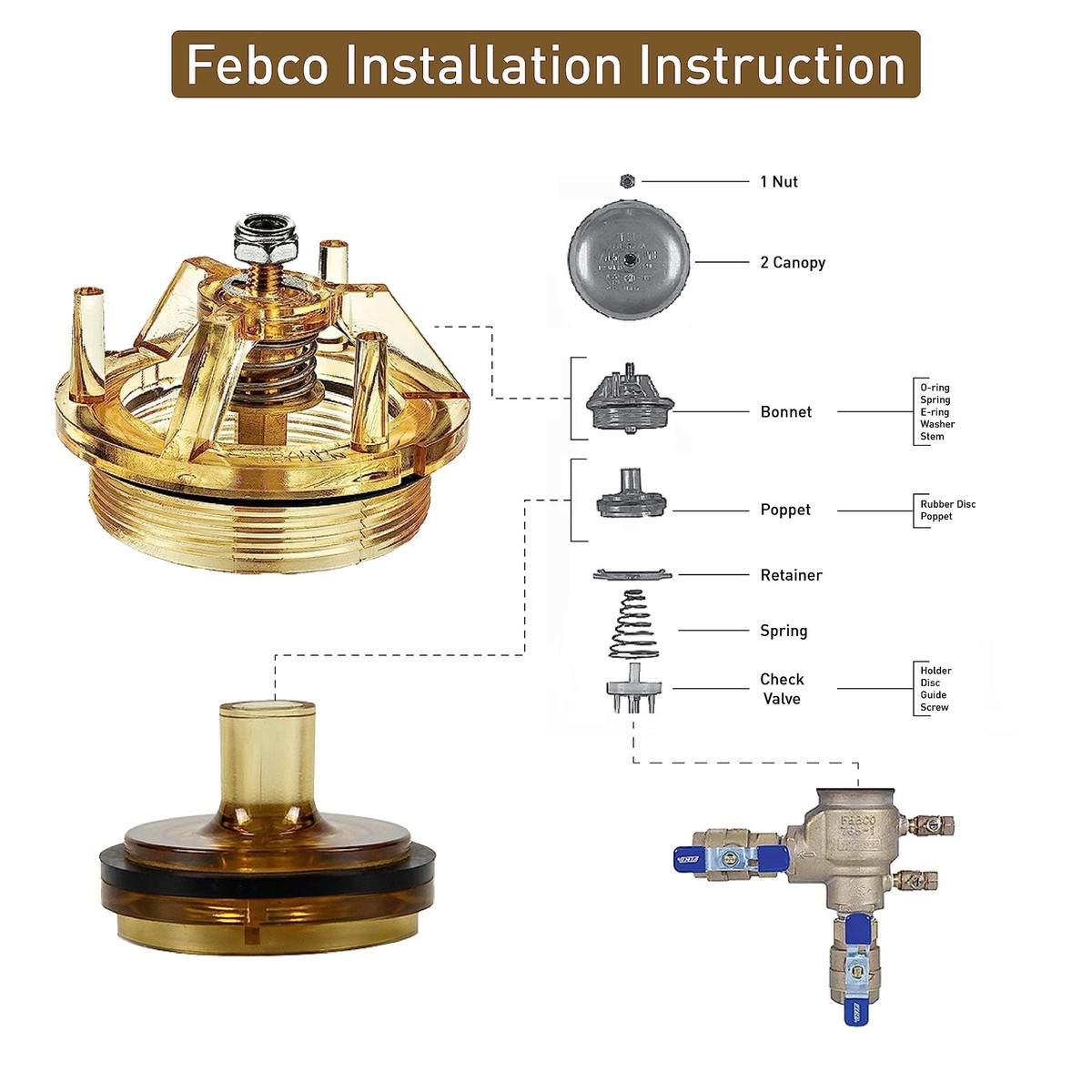

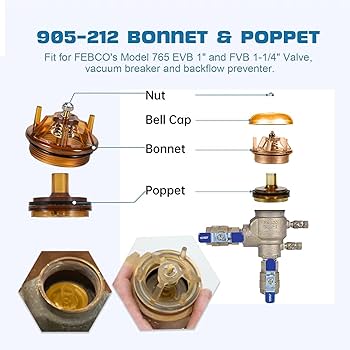

#2 FEBCO Bonnet/Poppet Repair Kit 1 in.

Domain Est. 1995

Website: siteone.com

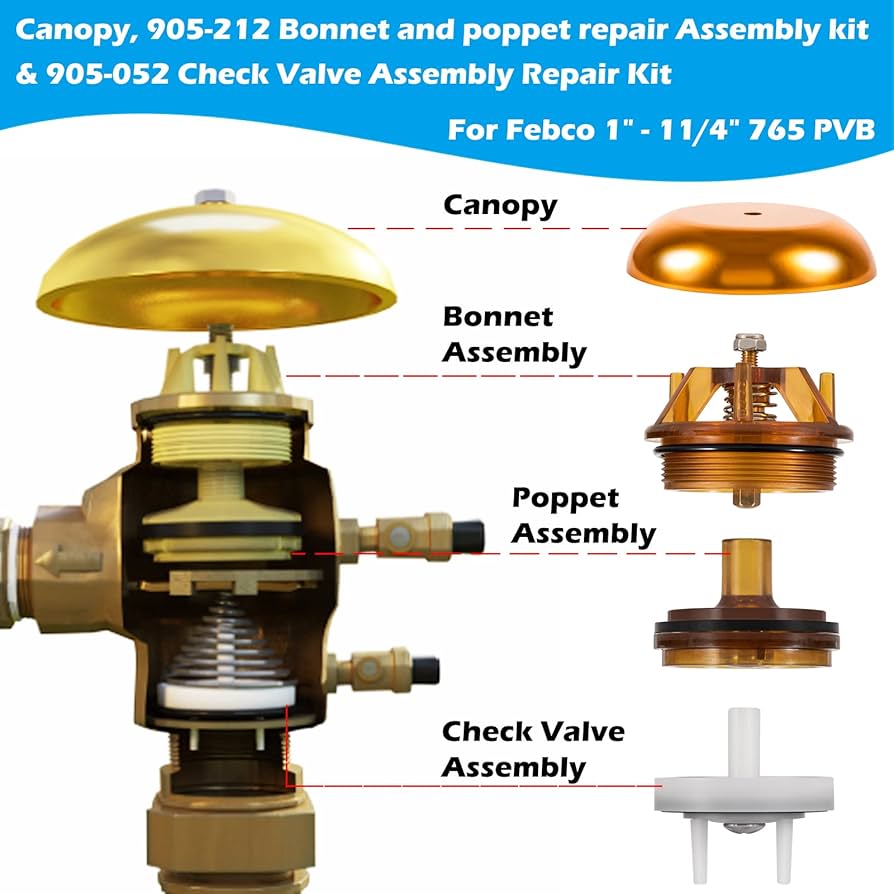

Key Highlights: This kit consists of bonnet, O-ring, spring, E-ring, washer, stem, rubber disc and poppet. All parts are genuine and original to the valve. More….

#3 FEBCO

Domain Est. 1997

Website: backflow-supply.com

Key Highlights: 6-day deliveryApollo, Watts, Wilkins, Febco and Ames Backflow Repair Kits on sale now. We keep a large selection of repair kits in stock. Have a question? We can help!…

#4 Backflow Repair Parts Febco 1″ 765

Domain Est. 1999

#5 Febco 1″ 765 PVB Repair Parts

Domain Est. 2010

Website: backflowpartsusa.com

Key Highlights: Febco 1″ 765 PVB Repair Parts · Rubber Total. $58.55. Febco: 1″ – 1 1/4″ – Rubber Parts Kit for a 765 PVB · Bonnet & Poppet. $90.47 · Retainer. $23.85 · Check ……

#6 FEBCO 765 1 1/2

Domain Est. 2021

Website: bavcostore.com

Key Highlights: FEBCO 765 1 1/2-2″ REPAIR KIT. Contains: Check & Air Inlet Assys. Model Overview. The Model 765 is a pressure vacuum breaker assembly….

#7 Febco® Backflow Preventer, Backflow Devices

Website: febcobrand.com

Key Highlights: FEBCO® stands as your trusted partner in water safety—where innovation meets reliability in backflow prevention. We don’t just manufacture devices; we engineer ……

#8 How To Repair Your Febco 765

Domain Est. 1999

Website: school.sprinklerwarehouse.com

Key Highlights: The Febco poppet bonnet assembly kit used in this demonstration contains the bonnet, poppet, and some lubricant or grease to aid in the repair process….

Expert Sourcing Insights for Febco 765 1 Repair Kit

H2: 2026 Market Trends for Febco 765-1 Repair Kit

The market for the Febco 765-1 Repair Kit is expected to experience steady demand through 2026, driven by several key industry and economic factors. As a critical component for backflow prevention in commercial and residential plumbing systems, the Febco 765-1 Repair Kit remains essential for compliance with municipal plumbing codes and water safety regulations.

One major trend shaping the 2026 outlook is the increasing emphasis on water conservation and infrastructure modernization. Governments and municipalities across North America are investing in upgrading aging water systems, which includes routine maintenance and certification of backflow prevention devices. This regulatory push is likely to sustain consistent demand for repair kits like the Febco 765-1, especially during annual testing and servicing cycles.

Additionally, the growth in construction activity—particularly in commercial, healthcare, and multi-family housing sectors—will contribute to higher installation rates of backflow preventers, subsequently increasing the need for replacement and repair components. As installations rise, so does the long-term service demand for repair kits.

Supply chain stabilization post-2023 disruptions is also expected to improve availability of the Febco 765-1 Repair Kit, reducing lead times and supporting contractor efficiency. Manufacturers and distributors are increasingly adopting inventory forecasting tools and e-commerce platforms, enhancing accessibility for plumbing professionals.

Another emerging trend is the rise of digital procurement in the plumbing and HVAC sectors. By 2026, more contractors are expected to source repair parts like the Febco 765-1 through online marketplaces and distributor portals, favoring brands with strong digital presence and technical support. Febco’s reputation for reliability and widespread compatibility positions it well in this evolving landscape.

Finally, environmental regulations may tighten around cross-connection control, potentially increasing inspection frequency and repair requirements. This would further bolster demand for trusted, code-compliant repair solutions such as the Febco 765-1.

In summary, the 2026 market for the Febco 765-1 Repair Kit is poised for stable growth, supported by regulatory compliance needs, infrastructure investment, construction activity, and digital transformation in procurement.

H2: Common Pitfalls When Sourcing a Febco 765-1 Repair Kit (Quality and IP Concerns)

Sourcing a Febco 765-1 Repair Kit — a critical component for maintaining backflow prevention assemblies — can be fraught with risks if not approached carefully. Buyers often encounter issues related to product quality and intellectual property (IP) violations, especially when opting for cheaper or non-OEM alternatives. Below are key pitfalls to avoid:

1. Substandard Quality from Non-OEM or Counterfeit Kits

One of the most common issues is purchasing low-quality repair kits that mimic genuine Febco parts but fail to meet performance standards. These kits may use inferior rubber materials, incorrect spring tension, or poor machining tolerances, leading to:

- Premature failure of the backflow preventer

- Leakage or loss of seal integrity

- Non-compliance with plumbing codes (e.g., UPC, IPC)

- Increased maintenance costs and downtime

Always verify that the repair kit is manufactured to original equipment manufacturer (OEM) specifications. Genuine Febco kits are tested for durability and compliance with ASSE 1015 and other relevant standards.

2. IP Infringement and Misrepresentation

Febco (a brand under Watts Water Technologies) holds intellectual property rights over the design and specifications of the 765-1 assembly and its components. Unauthorized manufacturers often produce “compatible” kits that closely replicate patented designs, potentially infringing on:

- Design patents

- Trademarks (e.g., using “Febco-style” or misleading branding)

- Technical documentation and part numbering systems

Purchasing such kits may expose contractors, municipalities, or facility managers to legal and compliance risks, especially in regulated environments like healthcare, food service, or municipal water systems.

3. Lack of Certification and Traceability

Genuine repair kits come with documentation verifying compliance with safety and performance standards. Counterfeit or generic kits often lack:

- Third-party certifications (e.g., ASSE, IAPMO, NSF)

- Lot traceability for quality control

- Warranty or technical support from the manufacturer

Without these, it’s impossible to ensure the kit will perform under real-world conditions or pass inspection.

4. Sourcing from Unreliable or Unauthorized Distributors

Purchasing from third-party marketplaces (e.g., online auction sites, discount wholesalers) increases the risk of receiving counterfeit or expired parts. These suppliers may not adhere to strict inventory controls, leading to:

- Expired rubber seals (which degrade over time)

- Poor storage conditions affecting part integrity

- No recourse for defective or non-compliant products

Always source repair kits from authorized Febco or Watts distributors to ensure authenticity and support.

Best Practices to Avoid Pitfalls

– Purchase directly from authorized distributors or Watts-certified suppliers

– Verify part numbers and packaging authenticity (e.g., holograms, batch codes)

– Request certification documents and compliance statements

– Avoid “too good to be true” pricing, which often signals counterfeit goods

By prioritizing quality and respecting IP, you ensure reliable performance, regulatory compliance, and long-term cost savings in backflow prevention maintenance.

H2: Logistics & Compliance Guide for Febco 765-1 Repair Kit

The Febco 765-1 Repair Kit is designed for use with Febco double check valve assemblies (Model 765) to maintain optimal performance and ensure compliance with plumbing code requirements. This guide outlines key logistics and compliance considerations for handling, shipping, installing, and maintaining the repair kit in accordance with industry standards and regulatory requirements.

1. Product Identification & Contents

– Model Number: Febco 765-1 Repair Kit

– Compatible Units: Febco Model 765 Double Check Valve Assemblies

– Typical Kit Contents:

– (2) Check Valve Discs

– (2) Spring Assemblies

– (2) Check Valve Seats

– Gaskets and O-rings

– Installation instructions

2. Shipping & Handling

– Packaging: Supplied in sealed, tamper-evident packaging to protect components from contamination and damage.

– Storage Conditions:

– Store in a dry, temperature-controlled environment (40°F to 100°F / 4°C to 38°C).

– Avoid exposure to direct sunlight, moisture, or corrosive chemicals.

– Shelf Life: Components are durable for long-term storage when kept in original packaging; inspect for degradation before use.

– Transportation: Standard ground shipping is acceptable; avoid extreme temperature exposure during transit.

3. Regulatory Compliance

– ASSE 1013 Certified: The Febco 765-1 Repair Kit supports assemblies that meet ASSE 1013 standards for backflow prevention in low-hazard applications.

– ANSI/NSF Standard 61: All wetted materials comply with NSF/ANSI 61 for safe use in potable water systems.

– Uniform Plumbing Code (UPC) & International Plumbing Code (IPC): Installation of the repaired assembly must conform to local plumbing codes, which typically adopt UPC or IPC standards.

– State & Local Regulations: Some jurisdictions require licensed plumbers to perform repairs and annual testing of backflow preventers. Confirm local requirements before installation.

4. Installation & Certification

– Qualified Personnel: Installation and repair must be performed by a licensed plumber or certified backflow prevention assembly tester.

– Post-Repair Testing: After installing the repair kit, the double check valve assembly must be tested in accordance with cross-connection control program requirements.

– Documentation: Maintain records of repair, including date, technician name, test results, and parts used. Required for municipal or utility compliance audits.

5. Environmental & Safety Compliance

– Hazardous Materials: The repair kit contains no hazardous substances under OSHA or EPA definitions.

– Disposal: Replace components may be disposed of in accordance with local regulations. Rubber and metal parts can typically be recycled as non-hazardous waste.

– Safety Precautions:

– De-energize and depressurize the system before disassembly.

– Use appropriate personal protective equipment (PPE) during repair.

6. Warranty & Support

– Manufacturer Warranty: Febco (a Watts brand) offers a limited warranty against defects in materials and workmanship. Register the product via Watts Water Technologies for full warranty coverage.

– Technical Support: Contact Watts Technical Services at 1-800-331-4787 or visit www.wattswater.com for assistance.

7. Recordkeeping & Traceability

– Maintain a log of all repairs using the 765-1 kit, including:

– Date of repair

– Assembly serial number (if applicable)

– Technician certification number

– Test results and compliance documentation

This ensures traceability and supports ongoing compliance with water safety regulations.

By following this logistics and compliance guide, users ensure the Febco 765-1 Repair Kit is handled, installed, and documented in accordance with best practices and regulatory standards, protecting public water systems from contamination risks.

In conclusion, sourcing a Febco 765-1 repair kit requires identifying reliable suppliers such as plumbing supply stores, authorized distributors, or reputable online retailers like Ferguson, SupplyHouse, or Amazon. It is essential to ensure the kit is compatible with the specific model and meets relevant code requirements for backflow prevention. Verifying product authenticity, checking for included components (such as check valves, seats, springs, and O-rings), and reviewing warranty or return policies will help ensure a successful repair. Proper maintenance using the correct repair kit not only extends the life of the Febco 765-1 double check valve assembly but also maintains water safety and compliance with local plumbing codes.