The global faucet accessories market is experiencing steady growth, driven by rising residential and commercial construction activities, increasing demand for water-efficient fixtures, and a growing preference for easy-to-install plumbing solutions. According to Grand View Research, the global plumbing fixtures market was valued at USD 87.9 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. Within this expanding landscape, faucet supply line extenders have emerged as essential components, enabling seamless installation of faucets in non-standard sink configurations and supporting retrofit projects in both residential and institutional settings.

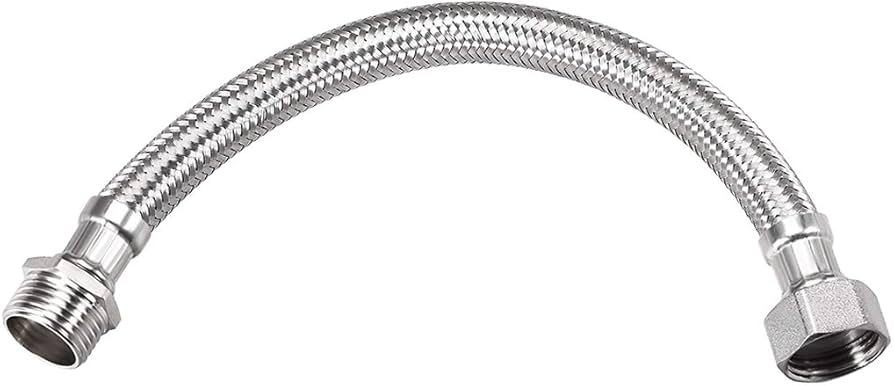

As demand for flexible, durable, and leak-resistant plumbing solutions increases, manufacturers specializing in supply line extenders are scaling innovation in materials—such as braided stainless steel and PEX—and connector compatibility. With North America and Europe leading in renovation activity and Asia-Pacific witnessing rapid urbanization, the need for reliable extender products continues to climb. Against this backdrop, the following analysis highlights the top seven manufacturers shaping the faucet supply line extender market through product performance, distribution strength, and technological advancement.

Top 7 Faucet Supply Line Extender Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Oatey® Faucet Supply Lines

Domain Est. 1996

Website: oatey.com

Key Highlights: Rating 4.8 (27) Oatey Faucet Supply Lines are designed to quickly and easily connect the water supply to your faucet. Constructed of durable, corrosion-resistant material.Missing…

#2 Faucet Supply Lines

Domain Est. 2015

Website: sharkindustrial.com

Key Highlights: The Shark Industrial faucet connectors are built to last with premium non-toxic PVC core with 304 stainless steel braided outer cover for strength and ……

#3 Flexible Hoses & Hose Assemblies

Domain Est. 1996

Website: tsbrass.com

Key Highlights: Faucets with Spray Assemblies, Medical & Lavatory Faucets, Medical & Lavatory Faucets, Workboard & Bar Sink Faucets, Workboard & Bar Sink Faucets, Big-Flo ……

#4 Jones Stephens

Domain Est. 1999

Website: jonesstephens.com

Key Highlights: Back; Drain Stoppers · Friction Lift Drains · Grid/Trip Lever Drains · Lift & Turn Drains · Replacement Parts · Roman Tub Drains · Toe Touch Drains….

#5 Faucet Supply Lines

Domain Est. 2001

Website: eastmanplumbing.com

Key Highlights: Faucet Supply Lines · Braided Flare Faucet Connector · Compression Braided Faucet Connector · Compression Braided Faucet Connector · Compression PVC Faucet ……

#6 SharkBite Plumbing Products

Domain Est. 2003

Website: sharkbite.com

Key Highlights: Cut repair & install time in half with SharkBite Plumbing Products. Explore our complete line of plumbing fittings, PEX pipe, valves, adapters and more….

#7 Faucet Connector

Domain Est. 1996

Expert Sourcing Insights for Faucet Supply Line Extender

2026 Market Trends for Faucet Supply Line Extender

As the home improvement and plumbing industries continue to evolve, the demand for specialized plumbing accessories such as faucet supply line extenders is expected to grow steadily through 2026. These small but essential components play a critical role in ensuring proper installation and functionality of modern faucets, especially as kitchen and bathroom designs become more customized and complex. This analysis explores key market trends shaping the faucet supply line extender industry in 2026.

Increasing Demand from DIY Home Improvement Projects

The do-it-yourself (DIY) home improvement sector has experienced significant growth in recent years, accelerated by the rise of online tutorials, e-commerce platforms, and consumer confidence in self-installation. In 2026, this trend continues to drive demand for user-friendly plumbing accessories like supply line extenders. Homeowners undertaking kitchen or bathroom upgrades often encounter misaligned plumbing connections, making extenders a practical and cost-effective solution. As more consumers opt for DIY installations to save on labor costs, the market for accessible and easy-to-install extenders is projected to expand.

Growth in Remodeling Activities and Modern Fixture Adoption

Residential remodeling remains a key driver for the faucet supply line extender market. With increasing emphasis on modern, high-efficiency, and aesthetically pleasing fixtures, many homeowners are replacing older faucets with newer models that may not align with existing plumbing. This creates a need for extenders to bridge gaps and maintain proper water line connections. In 2026, the continued adoption of vessel sinks, wall-mounted faucets, and smart fixtures—often requiring non-standard installations—will further boost demand for flexible and adjustable supply line solutions.

Advancements in Material and Design Innovation

Manufacturers are responding to market demands by innovating in materials and design. By 2026, expect to see a shift toward extenders made from durable, corrosion-resistant materials such as braided stainless steel, PEX, and lead-free brass. These materials offer longer lifespans and improved leak resistance, addressing consumer concerns about reliability and water safety. Additionally, modular and telescoping extender designs are gaining traction, offering greater adaptability across different faucet types and installation scenarios.

E-Commerce Expansion and Distribution Channels

Online retail platforms are playing an increasingly dominant role in the distribution of plumbing accessories. In 2026, a majority of faucet supply line extenders are expected to be sold through e-commerce channels such as Amazon, Home Depot, and specialized plumbing supply websites. These platforms provide consumers with easy access to a wide variety of products, detailed specifications, and customer reviews—factors that enhance purchasing confidence. As a result, manufacturers are investing in digital marketing and optimizing product listings to capture online market share.

Focus on Sustainability and Water Efficiency

Environmental concerns and regulatory standards are influencing product development across the plumbing industry. While supply line extenders themselves do not directly impact water usage, their role in enabling efficient faucet installations aligns with broader water conservation goals. In 2026, products that promote leak-free connections and support the installation of WaterSense-labeled or low-flow faucets may gain preference among eco-conscious consumers and contractors. Sustainable packaging and recyclable materials are also becoming differentiators in the marketplace.

Regional Market Variations

North America is expected to remain the largest market for faucet supply line extenders in 2026, driven by high homeownership rates, robust renovation activity, and stringent plumbing codes. However, emerging markets in Asia-Pacific and Latin America are showing rapid growth due to urbanization and rising middle-class demand for modern home fixtures. Localized product offerings and compliance with regional plumbing standards will be critical for manufacturers aiming to expand globally.

Conclusion

The faucet supply line extender market in 2026 is characterized by steady growth, innovation, and shifting consumer behaviors. Driven by DIY culture, remodeling trends, and technological advancements, the industry is adapting to meet diverse installation needs with reliable, high-quality solutions. As demand increases, manufacturers that prioritize ease of use, durability, and sustainability will be best positioned to succeed in this evolving landscape.

Common Pitfalls When Sourcing Faucet Supply Line Extenders (Quality & IP)

Sourcing faucet supply line extenders may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to product failures, compliance issues, and legal risks. Here are the most common pitfalls to avoid:

Choosing Low-Quality Materials and Construction

Many extenders on the market use substandard materials—such as thin-walled brass, low-grade plastic, or inferior rubber seals—that degrade quickly under water pressure and temperature fluctuations. This can result in leaks, bursts, or premature failure, leading to costly repairs and customer dissatisfaction. Always verify material specifications (e.g., lead-free brass per NSF/ANSI 61, reinforced braided stainless steel) and insist on third-party certifications.

Ignoring Pressure and Temperature Ratings

Not all extenders are rated for the same operating conditions. Using a line not rated for high-pressure or hot water applications can lead to catastrophic failure. Ensure the extender meets or exceeds local plumbing code requirements (e.g., ANSI/ASME standards) and is clearly labeled with maximum pressure (PSI) and temperature (°F/°C) ratings.

Overlooking Leak-Proof Connection Design

Poorly designed or manufactured compression fittings, O-rings, or thread seals are a leading cause of leaks. Inadequate thread sealing (e.g., missing or low-quality PTFE tape or integrated seals) increases the risk of cross-threading or seepage. Prioritize suppliers who use standardized, tested connection types (e.g., 3/8″ compression to 1/2″ MIP) with reliable sealing mechanisms.

Falling for Counterfeit or IP-Infringing Products

Many extenders mimic patented designs from major brands (e.g., proprietary quick-connect systems or unique braiding patterns). Sourcing counterfeit or IP-infringing products exposes your business to legal liability, product recalls, and reputational damage. Conduct due diligence: verify trademarks, examine design patents, and require suppliers to provide proof of IP clearance or licensing.

Skipping Compliance and Certification Verification

Plumbing products must meet regional safety and health standards (e.g., NSF/ANSI 61 for lead content, UPC or IPC code compliance). Suppliers may claim compliance without certification. Always request valid test reports and certifications from accredited labs—do not rely on self-declared claims.

Failing to Evaluate Long-Term Durability

Short-term cost savings can lead to long-term expenses if the extender corrodes, kinks, or deteriorates. Assess resistance to kinking, UV exposure (for outdoor use), and water chemistry (e.g., chlorine levels). Request sample testing under real-world conditions before mass procurement.

Underestimating Packaging and Labeling Requirements

Improper packaging can damage extenders during shipping, while inadequate labeling may violate regulations or confuse end users. Ensure packaging protects against moisture and impact, and labeling includes safety warnings, installation instructions, compliance marks, and traceability information (e.g., lot numbers).

By addressing these quality and IP-related pitfalls proactively, you can source reliable, compliant, and legally sound faucet supply line extenders that protect both your customers and your business.

Logistics & Compliance Guide for Faucet Supply Line Extender

This guide outlines key logistics considerations and compliance requirements for the distribution and sale of Faucet Supply Line Extenders.

Product Classification and Tariff Codes

Faucet Supply Line Extenders are typically classified under Harmonized System (HS) codes related to plumbing fixtures or pipe fittings. A common classification is 8481.80 – “Taps, cocks, valves and similar appliances for pipes, boiler shells, tanks, vats or the like, including pressure-reducing valves and thermostatically controlled valves: Other.” However, classification may vary by country and specific product design. Verify the correct HS code with local customs authorities or a licensed customs broker to ensure accurate tariff application and avoid import delays.

Packaging and Labeling Requirements

Ensure packaging is durable enough to prevent damage during transit. Each unit should be clearly labeled with the following information:

– Product name: Faucet Supply Line Extender

– Dimensions and thread specifications (e.g., 3/8″ Compression x 1/2″ FIP)

– Material composition (e.g., Braided Stainless Steel, Brass)

– Manufacturer or brand name

– Country of origin

– UPC or SKU number

– Compliance markings (e.g., NSF/ANSI 61, ASME A112.18.1)

Retail packaging should also include installation instructions and safety warnings.

Regulatory Compliance

Faucet Supply Line Extenders must comply with plumbing and water safety standards in the target market:

– United States: Must meet NSF/ANSI 61 (Drinking Water System Components – Health Effects) and NSF/ANSI 372 (Lead Content) standards. Products should be certified by an accredited body such as NSF International or IAPMO.

– Canada: Must comply with CSA B125.1 and may require cUPC (Canadian Underwriters Laboratories) certification.

– European Union: Must conform to EN 817 and EN 1111 standards. CE marking is required under the Construction Products Regulation (CPR) for applicable plumbing components.

– Australia/New Zealand: Should meet AS/NZS 3500 plumbing code and may require WaterMark certification.

Always verify local regulations as compliance requirements can vary by jurisdiction.

Transportation and Storage

- Store in a dry, temperature-controlled environment to prevent corrosion or material degradation.

- Avoid exposure to direct sunlight or extreme temperatures during transport.

- Use standard parcel shipping for small quantities; palletized freight for bulk orders.

- Ensure proper stacking and secure loading to prevent damage in transit.

Import/Export Documentation

For international shipments, the following documents are typically required:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Product Compliance Certificates (e.g., NSF, CE, WaterMark)

– Import Declaration or Customs Entry Form

Ensure all documentation accurately reflects product details to avoid customs delays or penalties.

Warranty and Returns Logistics

Establish a clear returns policy for defective or incorrect items. Include:

– Return window (e.g., 30 days)

– Condition requirements (unused, original packaging)

– Prepaid return labels (if applicable)

– Warranty period (e.g., 5 years limited)

– Process for handling customer claims

Coordinate with fulfillment centers or distributors to streamline reverse logistics.

Environmental and Disposal Considerations

Faucet Supply Line Extenders contain metal components (brass, stainless steel) that are recyclable. Encourage end-users to dispose of old or damaged units through local metal recycling programs. Comply with any applicable WEEE (Waste Electrical and Electronic Equipment) directives if electronic components are present (e.g., smart water sensors).

Conclusion: Sourcing Faucet Supply Line Extenders

Sourcing faucet supply line extenders requires careful consideration of material quality, compatibility, length, threading standards, and durability to ensure reliable performance and leak-free connections. Whether for residential, commercial, or industrial applications, selecting the right extender involves evaluating product specifications against the existing plumbing system. Stainless steel braided hoses are often preferred for their strength and resistance to bursting, while flexible materials like PEX or reinforced rubber offer ease of installation in tight spaces.

Reliable suppliers, whether wholesale distributors, plumbing specialty stores, or online marketplaces, should provide certified products that meet industry standards (e.g., NSF, UPC, or CSA). Additionally, considering factors such as lead time, cost-effectiveness, and warranty support contributes to efficient sourcing and long-term satisfaction.

In conclusion, a strategic sourcing approach—emphasizing quality, compatibility, and supplier reliability—ensures that faucet supply line extenders effectively extend functionality without compromising safety or performance in any plumbing system.