The global agricultural machinery market is witnessing robust expansion, driven by rising demand for mechanization to enhance farm productivity and address labor shortages. According to Mordor Intelligence, the agricultural machinery market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, with increasing adoption of specialized equipment across small and large-scale farms. A critical yet often overlooked component in this ecosystem is the farm jack—a heavy-duty tool essential for equipment maintenance, trailer support, and field repairs. As farm operations grow more mechanized, the reliability and performance of support tools like farm jacks become increasingly vital. This growing reliance, combined with surging investments in agricultural infrastructure, underscores the importance of choosing high-quality farm jack manufacturers. Based on market presence, product durability, innovation, and user reviews, we’ve identified the top seven manufacturers leading the industry in 2024.

Top 7 Farm Jack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

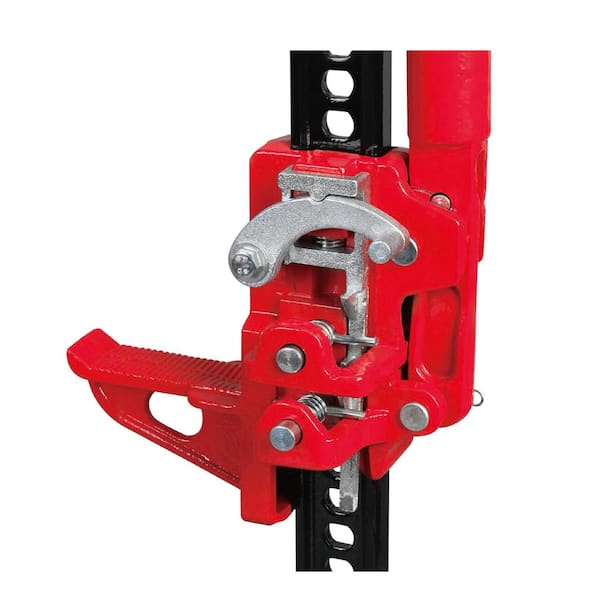

#1 Hi-Lift® Jack Co.

Domain Est. 1996

Website: hi-lift.com

Key Highlights: Manufacturer of “The Original Power Tool” Hi-Lift® Jack along with accessories and other recovery related equipment designed for off-road, farm, and rescue….

#2 HI

Domain Est. 1997

Website: farmking.com

Key Highlights: 48″ Hi-Lift Jack (Red). 323006. Farm King Price: $109.99. Farm King SKU: 323006; Manufacturer: HI LIFT JACK COMPANY; Manufacturer Part#:: HL-485. « Showing ……

#3 U.S. Jack

Domain Est. 1997

Website: usjack.com

Key Highlights: U.S. Jack is the provider of durable and dependable hydraulic jacks that give you the strong lift you need, where you need it….

#4 Hydraulic Recovery Jack 1060001

Domain Est. 1998

Website: store.arbusa.com

Key Highlights: In stockDesigned to suit the ARB JACK or farm jacks, the ARB Jack Base provides off-roaders with a sturdy surface during recovery missions to limit slippage or sinking ……

#5 Pro Eagle Off Road Jacks

Domain Est. 1999

#6 BIG RED

Domain Est. 2000

Website: torinjacks.com

Key Highlights: Free delivery 30-day returnsVendor: TORIN BIG RED. BIG RED Hydraulic Motorcycle Lift Jack, ATV Scissor Lift Jack, Portable Foot-Operated Hoist Stand for Motorcycle UTV Powersports….

#7 Garvee Farm Jack 3 Ton Utility 48 Inch 6600 Lbs Steel Off Road …

Domain Est. 2022

Expert Sourcing Insights for Farm Jack

H2 2026 Market Trends Analysis for Farm Jack

Heading into the second half of 2026, the agricultural sector is poised for significant transformation, driven by technological acceleration, shifting consumer demands, and evolving regulatory landscapes. For Farm Jack—a hypothetical or representative agricultural technology and equipment company—understanding these H2 2026 trends is critical for strategic positioning, innovation, and market expansion. Below is a detailed analysis of key market trends likely to impact Farm Jack during this period.

1. Advanced Automation and Robotics Penetration

By H2 2026, automation will move beyond large-scale agribusiness and become increasingly accessible to mid-sized and even smaller farms. Farm Jack can expect heightened demand for:

– Autonomous tractors and implements with improved AI navigation and task-specific attachments.

– Robotic harvesting systems tailored for delicate crops (e.g., fruits, vegetables), reducing labor dependency.

– Integrated fleet management software that allows remote monitoring and coordination of automated equipment.

Implication for Farm Jack: Invest in modular, scalable automation solutions and develop user-friendly interfaces to onboard less tech-savvy farmers.

2. AI-Driven Precision Agriculture Maturation

Artificial intelligence will be deeply embedded in farm operations by 2026. Key developments include:

– Predictive analytics platforms using real-time satellite imagery, soil sensors, and weather data to optimize planting, irrigation, and harvest timing.

– AI-powered pest and disease detection via drone-mounted cameras and mobile apps.

– Prescriptive agronomy tools that recommend precise input applications (fertilizer, pesticide) to maximize yield and minimize environmental impact.

Implication for Farm Jack: Enhance Farm Jack’s existing precision tools with AI integration and partner with agronomic data providers to offer bundled insights-as-a-service.

3. Sustainability and Regenerative Farming Adoption

Regulatory pressure and consumer preferences will drive widespread adoption of sustainable practices. Trends include:

– Carbon credit monetization programs where farmers earn revenue for sequestering carbon through cover cropping and reduced tillage.

– Demand for low-emission machinery, including electric and hydrogen-powered tractors.

– Traceability requirements from food retailers pushing for full supply chain transparency.

Implication for Farm Jack: Develop or adapt equipment to support regenerative practices (e.g., no-till drills, cover crop seeders) and explore partnerships with carbon market platforms.

4. Supply Chain Resilience and Localization

Post-pandemic and geopolitical disruptions have emphasized the need for resilient food systems. In H2 2026:

– Regional food hubs will grow, increasing demand for mid-sized, versatile equipment suitable for diversified farms.

– On-farm processing and storage solutions will gain traction, requiring integrated equipment offerings.

– Digital marketplaces for farm equipment will expand, enabling peer-to-peer rentals and used equipment trading.

Implication for Farm Jack: Diversify product lines to support diversified and local food systems; consider launching a digital platform for equipment leasing or sharing.

5. Labor Shortages and Workforce Transformation

Agricultural labor scarcity will persist, accelerating the shift toward mechanization and remote operations.

– Remote operation of equipment via 5G-enabled control systems will become standard.

– Upskilling programs for farm operators in digital tool management will be in high demand.

– Human-machine collaboration tools (e.g., smart exoskeletons, AR-guided maintenance) may emerge.

Implication for Farm Jack: Offer comprehensive training and support services alongside equipment; explore AR-based maintenance guides and remote diagnostics.

6. Regulatory and Policy Shifts

Governments will continue to incentivize sustainable technology adoption:

– Subsidies for green machinery (e.g., electric tractors, solar-powered irrigation).

– Stricter emissions standards for diesel engines, affecting legacy equipment.

– Data privacy regulations governing on-farm data collection and usage.

Implication for Farm Jack: Align product development with emerging regulations; ensure data governance compliance and communicate transparent data policies to customers.

Strategic Recommendations for Farm Jack – H2 2026

- Launch an AI-Integrated Equipment Suite: Bundle Farm Jack machinery with proprietary AI analytics for yield optimization.

- Enter the Carbon Economy: Partner with carbon registries to enable customers to monetize sustainable practices using Farm Jack equipment.

- Expand into Electric and Hybrid Models: Accelerate development of low-emission machinery to capture early-mover advantage.

- Develop a Digital Ecosystem: Create a Farm Jack-branded platform for equipment sharing, data analytics, and remote monitoring.

- Strengthen Customer Education: Roll out a certified training program for smart farming technologies to support adoption.

Conclusion

H2 2026 presents both challenges and significant opportunities for Farm Jack. The convergence of automation, sustainability mandates, and digital transformation will redefine competitive advantage in the ag-tech space. By proactively aligning its product roadmap, services, and partnerships with these trends, Farm Jack can solidify its position as a forward-thinking leader in the next generation of smart, sustainable agriculture.

Common Pitfalls When Sourcing a Farm Jack (Quality and Intellectual Property)

Sourcing a Farm Jack—whether for agricultural use, equipment manufacturing, or distribution—can present several challenges, particularly concerning quality assurance and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Poor Build Quality and Material Standards

One of the most frequent issues when sourcing Farm Jacks, especially from low-cost manufacturers, is substandard build quality. Inferior materials such as low-grade steel or weak welds can compromise load capacity and safety. Farm Jacks subjected to heavy-duty use may fail prematurely, leading to equipment damage or injury. Buyers should verify material specifications, load testing certifications, and manufacturing processes to avoid sourcing products that do not meet industry safety standards.

Lack of Compliance with Industry Certifications

Reputable Farm Jacks often comply with standards such as ASME B30.1 or other regional safety regulations. Sourcing from suppliers who do not provide evidence of compliance increases the risk of purchasing non-certified equipment. This not only affects reliability but can also lead to liability issues in case of accidents. Always confirm that the product meets applicable safety and performance standards for your market.

Inadequate Intellectual Property Protection

When sourcing Farm Jacks, especially from overseas manufacturers, there is a risk of inadvertently purchasing counterfeit or IP-infringing products. Many designs, including patented lifting mechanisms or branding elements, may be protected under intellectual property law. Sourcing unlicensed copies can expose your business to legal action, product seizures, or reputational damage. Conduct due diligence by verifying the manufacturer’s rights to produce and sell the design.

Misrepresentation of Origin or Manufacturer

Some suppliers may falsely claim to be original equipment manufacturers (OEMs) or authorized distributors. This misrepresentation can lead to receiving off-brand or reverse-engineered products that don’t match the expected quality or design. Always verify the supplier’s credentials, request proof of manufacturing capability, and, if possible, conduct on-site audits or third-party inspections.

Inconsistent Product Quality Across Batches

Even when initial samples meet expectations, subsequent production batches may vary significantly in quality. This inconsistency often stems from lax quality control processes at the supplier’s facility. To mitigate this risk, implement a rigorous incoming inspection process and consider requiring third-party quality audits during production.

Failure to Secure IP Rights in Custom Designs

If you’re sourcing a custom-designed Farm Jack, failing to formalize IP ownership in the contract is a major pitfall. Without clear agreements, the manufacturer may retain rights to the design, allowing them to sell it to competitors or reuse it without your consent. Ensure that contracts explicitly transfer IP rights to your company and include non-disclosure and non-compete clauses.

Overlooking After-Sales Support and Spare Parts

Low-cost Farm Jacks may come without reliable after-sales support or availability of spare parts. This can lead to extended downtime when repairs are needed. Evaluate the supplier’s ability to provide technical support, replacement components, and warranties before finalizing a sourcing decision.

Avoiding these pitfalls requires thorough supplier vetting, clear contractual terms, and ongoing quality monitoring—ensuring both product reliability and IP compliance.

Logistics & Compliance Guide for Farm Jack

Overview

This guide outlines the key logistics and compliance considerations for the distribution, handling, and use of the Farm Jack—a manual hydraulic lifting tool commonly used in agricultural and off-road vehicle applications. Adherence to these guidelines ensures safe transportation, regulatory compliance, and proper product stewardship.

Shipping & Transportation

Farm Jack units must be securely packaged to prevent damage during transit. Use original manufacturer packaging or equivalent protective materials (e.g., corrugated cardboard, foam inserts). Units should be palletized and stretch-wrapped for bulk shipments. Ensure proper labeling with handling instructions such as “Fragile” and “This Side Up.” Coordinate with carriers compliant with Department of Transportation (DOT) regulations for ground freight, especially when shipping in large volumes.

Import & Export Compliance

When moving Farm Jack products across international borders, verify compliance with destination country regulations. Provide accurate Harmonized System (HS) codes—typically under heading 8425 (hoists, jacks) or 8431 (parts of lifting machinery). Ensure all export documentation, including commercial invoices, packing lists, and certificates of origin, are complete. Comply with U.S. Export Administration Regulations (EAR) if applicable, though Farm Jacks generally fall under low-technology consumer goods not subject to strict export controls.

Product Labeling & Documentation

Each Farm Jack must include permanent labeling with the manufacturer’s name, model number, load capacity (e.g., 3-Ton), and safety warnings. User manuals must be provided in the language(s) of the target market and include assembly instructions, operating procedures, maintenance guidance, and safety precautions. Conform to ANSI Z535 and OSHA standards for safety signage and hazard communication.

Regulatory Standards & Certifications

Farm Jack products should meet recognized industry standards such as ASME B30.1 (Jack Standards) and comply with OSHA 29 CFR 1910.184 (Slings and Lifting Devices). While not always required, third-party testing by organizations like UL or CSA can enhance market acceptance. Ensure compliance with CPSC guidelines if sold directly to consumers in the U.S., particularly regarding mechanical hazards and product liability.

Storage & Handling

Store Farm Jack units in a dry, temperature-controlled environment to prevent hydraulic fluid degradation and metal corrosion. Keep units off the floor on shelves or pallets to avoid moisture exposure. Handle with care to prevent damage to the hydraulic cylinder, lifting arm, and base. Train warehouse staff on proper stacking and material handling protocols to prevent accidents.

Environmental & Safety Compliance

Dispose of damaged or obsolete units according to local environmental regulations. Hydraulic fluid must be drained and recycled or disposed of as hazardous waste where required. The steel components are recyclable; coordinate with certified metal recyclers. Maintain Safety Data Sheets (SDS) for hydraulic fluid used in the device and make them available to distributors and service personnel.

Warranty & Recall Procedures

Implement a clear warranty policy in line with federal and state consumer protection laws. Register end-users when possible to facilitate recall communications. In the event of a product defect or safety issue, follow CPSC and FTC guidelines for reporting and executing a recall. Notify distributors, retailers, and customers promptly and provide instructions for return or repair.

Training & End-User Compliance

Encourage end-users to review the operator manual before use. Distributors and dealers should offer basic training on safe operation, load limits, and maintenance. Emphasize that misuse—such as side loading or exceeding rated capacity—voids warranty and creates safety risks. Promote adherence to OSHA and ANSI safety practices in agricultural and industrial settings.

Conclusion

Proper logistics and compliance practices are essential for the safe and legal distribution of Farm Jack products. By following this guide, manufacturers, distributors, and retailers can ensure product integrity, regulatory adherence, and user safety across the supply chain.

In conclusion, sourcing a farm jack requires careful consideration of factors such as durability, lifting capacity, intended use, and compatibility with existing equipment. It is essential to evaluate reputable suppliers, compare product specifications, and consider customer reviews to ensure reliability and long-term performance. Whether purchasing locally or online, verifying warranty options and after-sales support can further enhance value. By conducting thorough research and aligning the farm jack’s features with specific agricultural or off-road needs, users can make a cost-effective and efficient investment that enhances productivity and safety on the farm or job site.