The global refrigeration equipment market is experiencing robust expansion, driven by rising demand for cold chain solutions across food & beverage, healthcare, and retail sectors. According to Grand View Research, the global commercial refrigeration market was valued at USD 46.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth trajectory underscores the increasing importance of reliable, energy-efficient refrigeration manufacturers—particularly in specialized segments such as Falcon refrigeration systems, which serve critical roles in commercial kitchens and foodservice operations. As competition intensifies and sustainability standards evolve, identifying top-performing manufacturers with proven innovation, durability, and service support becomes essential for stakeholders in the hospitality and foodservice industries. Based on market presence, technological advancements, and customer performance metrics, the following eight companies stand out as leading manufacturers in the Falcon refrigeration space.

Top 8 Falcon Refrigeration Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cold Storage Room manufacturer In Pune

Domain Est. 2022

Website: falconrefrigeration.co.in

Key Highlights: Falcon Refrigeration excels as a Cold Storage Room manufacturer In Pune, utilizing state-of-the-art technology and the finest materials….

#2 Falcon Foodservice Equipment

Domain Est. 2000

Website: falconfoodservice.com

Key Highlights: Falcon Foodservice is the UK’s leading manufacturer of professional cooking equipment; supplying operators and chefs across all market sectors….

#3 Falcon Refrigeration

Domain Est. 2010

Website: falconrefrigeration.ca

Key Highlights: Specializing in commercial air conditioning and refrigeration service for commercial buildings and industrial facilities….

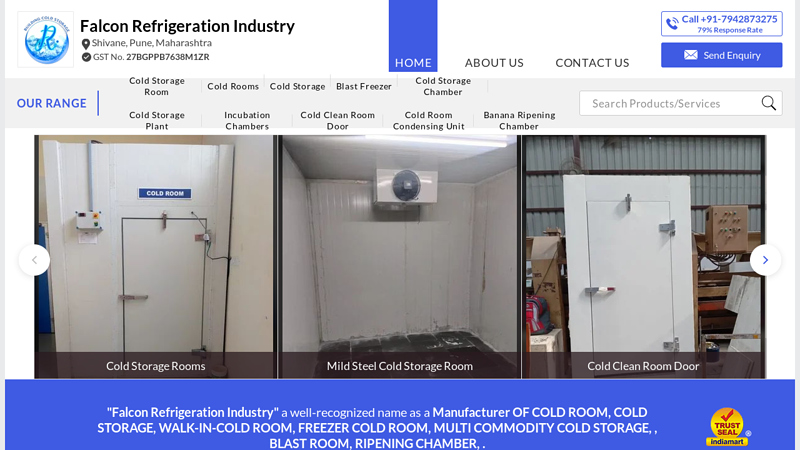

#4 Cold Storage Room and Cold Rooms Manufacturer

Domain Est. 2023

Website: falconrefrigerationindustry.com

Key Highlights: “Falcon Refrigeration Industry” a well-recognized name as a Manufacturer OF COLD ROOM, COLD STORAGE, WALK-IN-COLD ROOM, FREEZER COLD ROOM, MULTI COMMODITY ……

#5 Falcon Refrigeration Industry

Website: falconrefrigeration.net

Key Highlights: Falcon Refrigeration Industry is a premium producer and installer of full cold storage room solutions. Our products are known for their strength, accuracy, and ……

#6 Falcon Equipment

Domain Est. 2010

Website: falconequipment.com

Key Highlights: Falcon serves the foodservice industry with top-quality and affordable refrigeration and ice-making equipment for use in both the back and front of the house….

#7 Falcon Fabrication & Refrigeration Ahmedabad

Domain Est. 2021

Website: falconfabrication.co.in

Key Highlights: Falcon Fabrication & Refrigeration is a prestigious service provider offering the industry’s best AC annual inspection & maintenance service….

#8 Refrigeration Equipment

Domain Est. 2021

Website: falconrestaurantsupply.com

Key Highlights: Shop commercial refrigeration equipment at Falcon Restaurant Supply. Find reliable coolers, freezers, and prep tables to keep your kitchen running ……

Expert Sourcing Insights for Falcon Refrigeration

H2: Projected 2026 Market Trends for Falcon Refrigeration

As the global commercial refrigeration sector evolves, Falcon Refrigeration is poised to navigate a dynamic market landscape shaped by technological innovation, sustainability mandates, and shifting consumer demands. The following analysis outlines key trends expected to influence Falcon Refrigeration’s market position and strategy in 2026.

1. Accelerated Adoption of Natural Refrigerants

By 2026, regulatory pressure under the Kigali Amendment and tightening F-gas regulations in North America and the EU will drive widespread adoption of low-global warming potential (GWP) refrigerants. Falcon Refrigeration is expected to expand its lineup of units using natural refrigerants such as R290 (propane) and CO₂ (R744), aligning with environmental compliance and enhancing brand reputation among eco-conscious clients in retail, foodservice, and healthcare sectors.

2. Growth in Smart and IoT-Enabled Refrigeration

The integration of Internet of Things (IoT) technology into commercial refrigeration systems will be a dominant trend in 2026. Falcon is likely to emphasize predictive maintenance, remote monitoring, and energy optimization through cloud-connected units. These smart features will appeal to large-scale operators seeking operational efficiency, reduced downtime, and compliance with energy management standards.

3. Expansion in Emerging Markets

Developing economies in Southeast Asia, Latin America, and Africa will experience rising demand for reliable commercial refrigeration due to urbanization, growth in cold chain infrastructure, and expansion of supermarket chains. Falcon Refrigeration may leverage cost-effective, modular designs and localized distribution partnerships to capture market share in these high-growth regions.

4. Focus on Energy Efficiency and ESG Compliance

Energy costs and corporate ESG (Environmental, Social, and Governance) goals will push end-users toward energy-efficient refrigeration solutions. Falcon’s investment in advanced insulation materials, variable-speed compressors, and LED lighting will position its products favorably in energy rating programs such as ENERGY STAR, supporting sales in both public and private sector contracts.

5. Consolidation and Competitive Pressures

The refrigeration industry is expected to see continued consolidation, increasing competition from global players and private-label manufacturers. To maintain differentiation, Falcon will likely emphasize its North American manufacturing base, rapid service response, and customizable product offerings—key value propositions in markets that prioritize reliability and local support.

6. Resilience in the Food Retail and Healthcare Sectors

Despite economic fluctuations, demand in grocery stores, convenience chains, and pharmaceutical cold storage will remain strong. Falcon’s specialized units for vaccine storage and pharmacy applications could see increased adoption, especially with ongoing emphasis on healthcare infrastructure resilience post-pandemic.

In conclusion, Falcon Refrigeration’s success in 2026 will depend on its ability to innovate sustainably, expand digitally, and respond agilely to regional market needs. By aligning with global decarbonization goals and embracing smart technology, Falcon can strengthen its foothold in both traditional and emerging segments of the commercial refrigeration industry.

Common Pitfalls Sourcing Falcon Refrigeration (Quality, IP)

Sourcing products branded under “Falcon Refrigeration” presents several potential risks, particularly concerning quality consistency and intellectual property (IP) integrity. Being aware of these pitfalls is crucial for distributors, retailers, and end-users to avoid financial loss, reputational damage, and legal complications.

Quality Inconsistency and Substandard Manufacturing

Falcon Refrigeration products available through unofficial or third-party suppliers often exhibit significant variations in build quality and performance. These units may use inferior materials, such as thinner gauge steel, lower-grade refrigerants, or subpar compressors, leading to reduced energy efficiency, shorter lifespans, and increased maintenance costs. Many of these products are manufactured in facilities without adherence to recognized quality standards (e.g., ISO 9001), resulting in inconsistent assembly and reliability issues not found in genuine, authorized Falcon equipment.

Intellectual Property (IP) Infringement and Counterfeiting

A major concern when sourcing Falcon Refrigeration equipment is the prevalence of IP violations. Unauthorized manufacturers frequently replicate Falcon’s distinctive designs, logos, and product names without licensing. These counterfeit or clone products mislead buyers into believing they are purchasing authentic Falcon units, undermining brand value and consumer trust. Distributing or using such infringing products can expose businesses to legal liability, including fines and injunctions, especially in jurisdictions with strict IP enforcement.

Lack of Warranty and After-Sales Support

Products sourced outside Falcon’s authorized distribution network typically do not come with valid manufacturer warranties. Even if a warranty is claimed, it may be unenforceable due to the product’s unauthorized origin. This leaves buyers without access to technical support, spare parts, or service networks, increasing downtime and long-term ownership costs. Genuine Falcon support channels cannot assist with cloned or counterfeit units, further isolating users from critical maintenance resources.

Regulatory and Compliance Risks

Unofficial Falcon-branded refrigeration units may fail to meet regional safety, electrical, and environmental regulations (e.g., CE, UL, or ENERGY STAR standards). These non-compliant products pose safety hazards and may be seized or rejected by customs or regulatory bodies upon import or inspection. Using such equipment can also result in violations during health and safety audits, particularly in food service and healthcare environments.

Supply Chain Opacity and Traceability Issues

Sourcing from unauthorized suppliers often involves opaque supply chains, making it difficult to verify the origin, manufacturing date, or component authenticity of Falcon-branded units. This lack of traceability complicates recalls, service planning, and inventory management. It also increases the risk of inadvertently supporting unethical manufacturing practices or counterfeit networks.

To mitigate these risks, always procure Falcon Refrigeration equipment through authorized dealers and verify product authenticity via official channels. Conduct due diligence on suppliers and request documentation proving legitimacy, including warranty certificates and compliance marks.

Logistics & Compliance Guide for Falcon Refrigeration

This guide outlines the essential logistics procedures and compliance requirements for Falcon Refrigeration to ensure safe, efficient, and legally compliant operations across all supply chain activities.

Shipping & Transportation

All refrigeration units must be securely packaged using manufacturer-approved materials to prevent transit damage. Shipments must comply with international and domestic freight regulations, including proper labeling of heavy and fragile cargo. Use only certified carriers with experience in handling refrigeration equipment. Ensure temperature-sensitive components (if applicable) are shipped within specified environmental ranges. All shipments require accurate documentation, including commercial invoices, packing lists, and bills of lading.

Import & Export Compliance

Falcon Refrigeration strictly adheres to international trade regulations. All exports must be screened against denied party lists and classified according to the Export Administration Regulations (EAR) or relevant jurisdiction. Required export licenses must be obtained prior to shipment. Imports must comply with destination country regulations, including customs declarations, conformity assessments, and adherence to local energy efficiency and safety standards (e.g., CE, UKCA, ENERGY STAR). Maintain complete records for a minimum of five years.

Product Safety & Certification

All Falcon refrigeration products must meet or exceed mandatory safety standards in target markets, including UL (USA), CSA (Canada), CE (Europe), and other region-specific certifications. Regular third-party testing and certification audits must be conducted. Product labeling must include required safety warnings, electrical specifications, serial numbers, and certification marks. Non-compliant units must be quarantined and corrective actions documented.

Environmental & Refrigerant Regulations

Falcon Refrigeration complies with international environmental regulations governing refrigerants, including the Kigali Amendment to the Montreal Protocol and the EU F-Gas Regulation. Only approved low-GWP refrigerants may be used, and all handling, recovery, and recycling must follow EPA Section 608 (or equivalent) standards. Technicians must be properly certified. Accurate refrigerant usage logs and leak tracking records must be maintained.

Warehouse & Inventory Management

Warehousing operations must follow OSHA and local safety standards. Storage areas should be clean, dry, and well-ventilated. Equipment must be stored upright and secured to prevent tipping. Implement FIFO (First In, First Out) inventory practices to minimize obsolescence. Conduct regular cycle counts and annual physical inventories. Maintain a documented pest control program and fire safety protocol.

Documentation & Recordkeeping

All logistics and compliance documentation must be accurate, complete, and stored securely (digitally and/or physically). Required records include: shipping manifests, customs filings, compliance certifications, test reports, refrigerant logs, training records, and audit trails. Retention periods must meet legal requirements (minimum 5–7 years depending on document type). Access to sensitive data must be restricted and monitored.

Training & Accountability

All personnel involved in logistics, shipping, compliance, or product handling must receive regular training on relevant regulations, safety procedures, and company policies. Training records must be maintained. Designate a Compliance Officer responsible for overseeing adherence to this guide and updating procedures in response to regulatory changes. Non-compliance incidents must be reported and investigated promptly.

Conclusion for Sourcing Falcon Refrigeration

Sourcing Falcon Refrigeration equipment presents a strategic opportunity to enhance the reliability, efficiency, and performance of commercial refrigeration systems. As a well-established UK-based manufacturer with a strong reputation for quality and durability, Falcon offers a comprehensive range of refrigeration solutions suited for demanding environments in the hospitality, healthcare, and food service industries.

Key advantages of sourcing Falcon refrigeration include:

- Superior Build Quality: Robust construction using high-grade materials ensures longevity and consistent performance under heavy usage.

- Energy Efficiency: Modern Falcon units are designed with energy-saving technologies, contributing to lower operational costs and reduced environmental impact.

- Precision Temperature Control: Advanced refrigeration systems provide stable and accurate temperature management, critical for food safety and compliance.

- Comprehensive Support and Service: With established service networks and readily available spare parts, maintenance and downtime are minimized.

- Compliance and Certification: Falcon units meet rigorous industry standards, ensuring adherence to health, safety, and environmental regulations.

While initial investment costs may be higher compared to some competitors, the total cost of ownership is favorable due to durability, energy efficiency, and low maintenance requirements. Additionally, sourcing directly or through authorized distributors ensures authenticity, warranty coverage, and technical support.

In conclusion, sourcing Falcon refrigeration is a sound decision for organizations prioritizing performance, reliability, and long-term value. It supports operational excellence and aligns with sustainability goals, making Falcon a trusted partner in commercial refrigeration solutions.