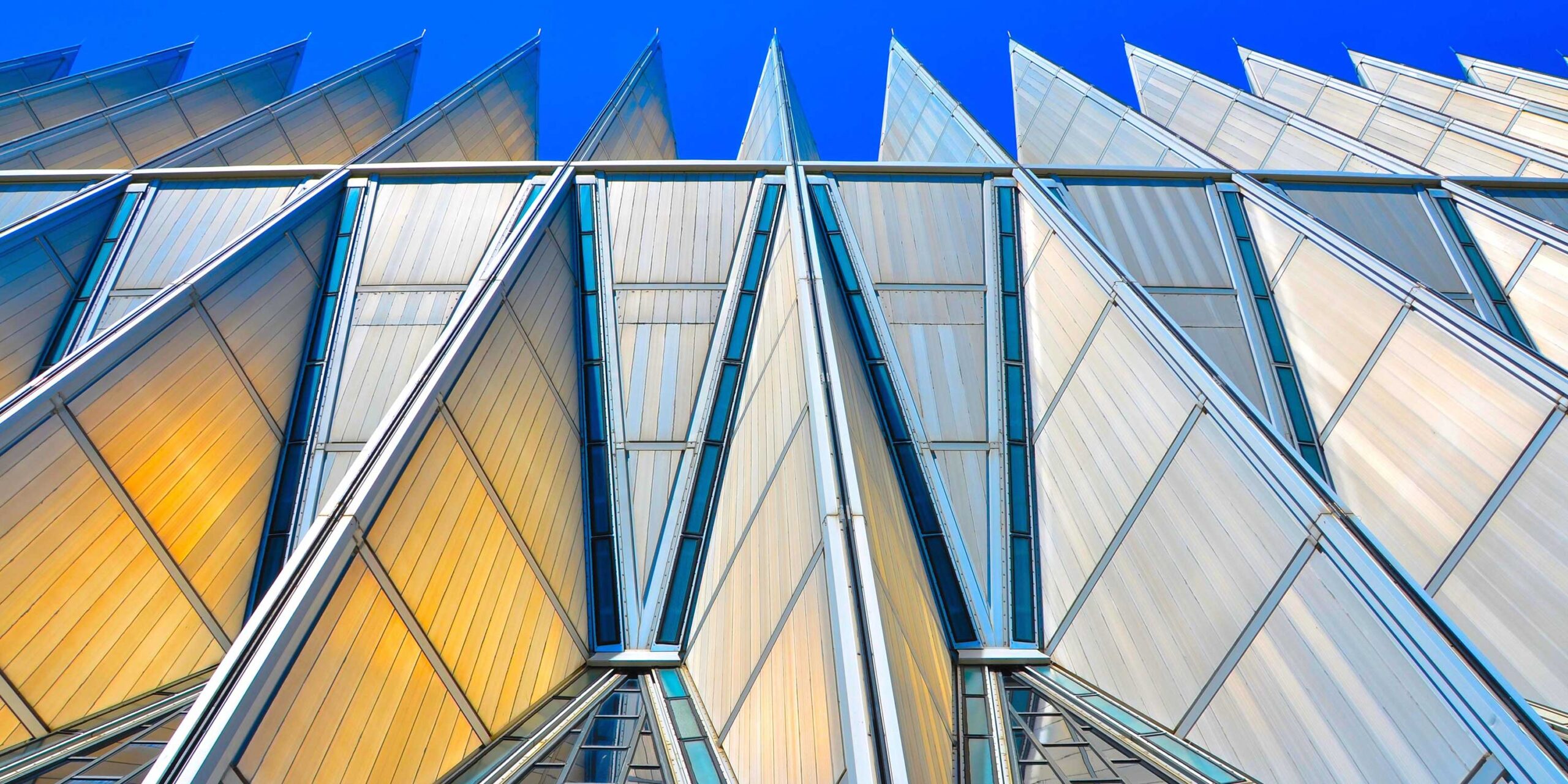

The global facade glass market is experiencing robust expansion, driven by rising demand for energy-efficient building envelopes and the surge in sustainable urban infrastructure. According to Grand View Research, the global architectural glass market size was valued at USD 108.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing construction activities in commercial and high-rise residential buildings, where aesthetic appeal and thermal performance are critical. Additionally, Mordor Intelligence forecasts similar momentum, highlighting regional development in Asia-Pacific—particularly in China and India—as a key growth driver due to rapid urbanization and government initiatives promoting green buildings. As demand for high-performance glazing solutions rises, manufacturers are focusing on innovations in low-emissivity (Low-E) glass, insulated glass units (IGUs), and smart glass technologies. In this evolving landscape, the following ten companies have emerged as leading facade glass manufacturers, recognized for their product innovation, global footprint, and contribution to sustainable construction.

Top 10 Facade Glass Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 seele

Domain Est. 1998

Website: seele.com

Key Highlights: seele is a technology leader in façade construction and a leading full-service supplier for ambitious glass façades and building envelopes….

#2 Fire Rated Glass, Security Glass Company, Processed Glass …

Domain Est. 2006

Website: fgglass.com

Key Highlights: FG Glass is a leading supplier & manufacturer of Fire Rated Glass, Doors, Frames and Glazing, Security Glass & Fire Resistant Glass, Bulletproof Glass ……

#3 Facade Glass

Domain Est. 2021

Website: zeyglass.com

Key Highlights: Facade Glass | Ankara Zey Glass serves as a corporate glass manufacturer in all individual and corporate projects with our 30 years of experience….

#4 Viracon

Domain Est. 1996

Website: viracon.com

Key Highlights: We partner with best-in-class architecture firms and glazing contractors to provide glass facades that inspire and turn buildings into icons….

#5 Facade Systems and Projects

Domain Est. 1996

Website: trelleborg.com

Key Highlights: Trelleborg is a global leader in glazing gaskets, weather seals, and accessories for facades, curtain walls, storefronts, and windows….

#6 Pilkington Glass

Domain Est. 1996

Website: pilkington.com

Key Highlights: From the way we design and manufacture our glass to how we serve the communities around us, we are committed to protecting nature, supporting people, and ……

#7 Architectural Glass & Aluminum Glazing Systems

Domain Est. 1998

Website: obe.com

Key Highlights: As the industry’s only fully integrated architectural glass, metal and hardware partner, our comprehensive range and expert guidance provides architects and ……

#8 Glass facade for buildings

Domain Est. 2001

Website: guardianglass.com

Key Highlights: Our wide variety of glass façade products combine the best performance in structural glazing with the most appealing aesthetics that stunning architecture ……

#9 Enclos

Domain Est. 2001

Website: enclos.com

Key Highlights: CONSTRUCTING CUSTOM CURTAINWALL ; HIGH-PERFORMANCE FACADES ; FLEXIBILITY IN MANUFACTURING ; PEAK PERFORMANCE ; SPECIALTY AT ALL SCALES….

#10 facade glass

Domain Est. 2003

Website: sedak.com

Key Highlights: With innovative products in unique maximum formats, sedak glass creates iconic façades and structures worldwide with a transparency never before achieved….

Expert Sourcing Insights for Facade Glass

H2: 2026 Market Trends for Facade Glass

The facade glass market is poised for significant transformation by 2026, driven by advancements in sustainable construction, smart technologies, and evolving architectural aesthetics. As urbanization accelerates and green building certifications gain prominence, facade glass is no longer just a structural or aesthetic component but a critical enabler of energy efficiency and environmental performance.

One of the most influential trends shaping the 2026 market is the rising demand for energy-efficient building envelopes. With global regulations tightening around carbon emissions—such as the EU’s Energy Performance of Buildings Directive (EPBD) and similar initiatives in North America and Asia—architects and developers are increasingly adopting high-performance insulated glazing, low-emissivity (Low-E) coatings, and dynamic glass solutions. These technologies help reduce heating, cooling, and lighting loads, contributing to net-zero energy buildings.

Another key trend is the integration of smart glass technologies. By 2026, electrochromic, thermochromic, and photochromic glass are expected to gain broader commercial adoption, particularly in high-rise commercial and mixed-use developments. These dynamic glazing systems adjust transparency in response to sunlight or temperature, enhancing occupant comfort and reducing reliance on HVAC systems. Major manufacturers are investing heavily in scaling production and lowering costs, making smart glass more accessible.

Sustainability is further influencing material innovation. Recycled glass content, low-carbon manufacturing processes, and lifecycle assessment (LCA) transparency are becoming differentiators among facade glass suppliers. Companies are also exploring bio-based interlayers and recyclable framing systems to improve the circularity of facade solutions.

Regionally, Asia-Pacific remains the fastest-growing market, fueled by urban megaprojects in China, India, and Southeast Asia. Meanwhile, North America and Europe are leading in the adoption of high-performance and multifunctional glass due to strict energy codes and strong green building standards like LEED and BREEAM.

Lastly, digitalization in design and construction—such as Building Information Modeling (BIM) and parametric design tools—is enabling more complex and customized facade systems. This trend supports the use of unitized curtain walls and prefabricated glass panels, improving installation speed and quality control.

In summary, by 2026, the facade glass market will be characterized by intelligent, sustainable, and highly integrated solutions that align with global decarbonization goals and the demand for resilient, people-centric buildings.

Common Pitfalls Sourcing Facade Glass (Quality, IP)

Inadequate Quality Control and Standards Compliance

One of the most frequent pitfalls when sourcing facade glass is failing to ensure that the product meets required quality standards and building codes. Buyers may accept samples or certifications at face value without independent verification, leading to substandard glass being installed. Issues such as poor thermal performance, inadequate UV resistance, or inconsistent tinting can emerge post-installation, resulting in energy inefficiency, occupant discomfort, and costly remediation.

Lack of Clarity on Intellectual Property Rights

Facade glass designs—especially custom or high-performance products—often involve proprietary technologies (e.g., low-emissivity coatings, insulating gas fills, or unique structural features). A common oversight is not clearly defining IP ownership or usage rights in contracts. This can lead to disputes if the supplier reuses design specifications for other clients or if the buyer unknowingly infringes on patented technologies, exposing the project to legal risks.

Overlooking Long-Term Performance and Durability

Buyers may focus on initial cost and aesthetics while underestimating long-term performance factors such as weathering, condensation resistance, and structural integrity. Sourcing glass without comprehensive testing data (e.g., for thermal cycling, humidity resistance, or wind load performance) can result in premature degradation, increased maintenance costs, and safety hazards.

Insufficient Supplier Vetting and Traceability

Working with unverified or subcontracted manufacturers increases the risk of receiving non-compliant or counterfeit products. Without proper traceability in the supply chain, it becomes difficult to confirm the origin of materials or ensure consistent manufacturing processes—especially critical when sourcing from regions with variable quality control practices.

Poor Communication of Technical Specifications

Ambiguities or omissions in technical documentation—such as glass thickness, coating type, edge finishing, or lamination requirements—can result in incorrect products being delivered. Miscommunication between architects, contractors, and suppliers often leads to rework, delays, and compromised facade performance.

Failure to Address Custom Design IP Protection

When commissioning bespoke glass units, clients may not secure exclusivity or protection for custom designs. Without contractual safeguards, suppliers might replicate the design for competitors, undermining the project’s uniqueness and potentially devaluing the architectural investment.

Underestimating Logistics and Handling Risks

Facade glass is fragile and sensitive to improper handling, transportation, and storage. Sourcing from distant manufacturers without accounting for packaging standards, transit conditions, or insurance coverage can result in damage, delays, and increased project costs.

Ignoring Warranty and After-Sales Support

Some suppliers offer limited or ambiguous warranty terms, particularly regarding coating longevity or seal failure in insulating glass units (IGUs). Failing to secure clear, enforceable warranties can leave project owners liable for unexpected repairs or replacements, especially in high-performance or large-scale facade installations.

Logistics & Compliance Guide for Facade Glass

Facility glass, a critical component in modern architectural design, requires specialized handling, transportation, and compliance protocols due to its size, fragility, and regulatory requirements. This guide outlines key logistics and compliance considerations to ensure safe, efficient, and lawful delivery and installation.

Handling and Packaging Requirements

Facade glass must be handled with extreme care to prevent breakage, scratches, or structural compromise. Panels should be stored and transported vertically, never horizontally, to minimize stress and risk of cracking. Use edge protectors and interlayer paper or foam to prevent surface damage. Crated packaging with robust wooden frames or custom steel racks is recommended, especially for insulated glass units (IGUs) or laminated glass. Each package must be clearly labeled with handling instructions (e.g., “This Side Up,” “Fragile,” “Do Not Stack”).

Transportation and Shipping

Due to their size and weight, facade glass panels require specialized flatbed or curtain-sided trucks with secure tie-down systems and protective side rails. Route planning should avoid sharp turns, rough terrain, and low clearances. Temperature control may be necessary for coated or insulated glass to prevent condensation or thermal shock during transit. Coordinate deliveries with site schedules to minimize on-site storage, and ensure unloading equipment (e.g., vacuum lifters, forklifts with glass clamps) is available and operated by trained personnel.

Import and Export Compliance

When shipping facade glass across international borders, compliance with customs regulations is essential. Accurate Harmonized System (HS) codes must be used—typically 7008 (safety glass) or 7016 (other treated glass). Required documentation includes commercial invoices, packing lists, certificates of origin, and bills of lading. Some countries impose import duties, anti-dumping measures, or require conformity assessments (e.g., CE marking in the EU, CCC in China). Engage licensed customs brokers to ensure timely clearance.

Regulatory and Safety Standards

Facade glass must comply with regional building codes and safety standards. In the U.S., this includes ASTM standards (e.g., ASTM E1300 for glass load resistance) and local codes such as the International Building Code (IBC). In the EU, compliance with EN 12150 (toughened glass), EN 14179 (heat-strengthened), and CE marking under the Construction Products Regulation (CPR) is mandatory. Fire-rated, hurricane-resistant, or blast-resistant glass must meet additional testing requirements (e.g., UL, BS, or ISO standards).

Environmental and Sustainability Compliance

Increasingly, projects require environmental documentation for facade materials. Ensure glass suppliers provide Environmental Product Declarations (EPDs) and confirm compliance with sustainability standards such as LEED, BREEAM, or Green Star. Recyclability of glass and use of low-emission manufacturing processes may influence compliance and project certification eligibility.

On-Site Logistics and Installation Coordination

Coordinate closely with general contractors and glazing subcontractors to align delivery times with crane availability and hoisting schedules. Establish designated laydown areas protected from weather and foot traffic. Implement site-specific safety protocols, including PPE requirements and fall protection during installation. Maintain traceability through batch numbering and quality control logs to support compliance audits and warranty claims.

Documentation and Traceability

Maintain comprehensive records for each glass panel, including material certifications, test reports, handling instructions, and installation logs. This documentation supports quality assurance, regulatory compliance, and liability management throughout the building’s lifecycle. Digital tracking systems (e.g., barcodes or RFID) are recommended for large-scale projects.

Conclusion for Sourcing Facade Glass:

In conclusion, sourcing facade glass requires a strategic approach that balances aesthetic goals, performance requirements, sustainability objectives, and cost efficiency. The selection process must consider key factors such as thermal insulation, solar control, acoustic performance, durability, safety standards, and compliance with local building codes. Engaging with reputable suppliers and fabricators early in the design phase ensures technical feasibility, material availability, and seamless integration with the building envelope system.

Additionally, evaluating life-cycle costs rather than focusing solely on initial prices contributes to long-term value and energy efficiency. Embracing innovative glazing technologies—such as low-E coatings, insulated glazing units (IGUs), or smart glass—can significantly enhance building performance and occupant comfort.

Ultimately, successful sourcing of facade glass hinges on collaboration between architects, engineers, contractors, and suppliers to deliver a high-performing, visually striking, and sustainable building envelope. By prioritizing quality, technical expertise, and sustainability, project stakeholders can ensure that the facade glass not only meets but exceeds project objectives.