The global fabricated aluminum market is experiencing robust growth, driven by increasing demand across key industries such as automotive, aerospace, construction, and renewable energy. According to Grand View Research, the global aluminum market size was valued at USD 218.1 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2023 to 2030. This expansion is fueled by aluminum’s favorable strength-to-weight ratio, corrosion resistance, and recyclability—qualities that make it indispensable in lightweighting initiatives and sustainable manufacturing. Mordor Intelligence further highlights that rising automotive production, especially in electric vehicles (EVs), and growing infrastructure development in emerging economies are key factors accelerating market demand. As the need for high-performance, engineered aluminum components rises, manufacturers specializing in fabrication—encompassing extrusion, casting, forging, and machining—are playing a pivotal role in meeting evolving industrial requirements. Against this backdrop, we spotlight the top 10 fabricated aluminum manufacturers leading innovation, scaling production, and shaping the future of the industry.

Top 10 Fabricated Aluminum Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SAF

Domain Est. 1992

Website: saf.com

Key Highlights: SAF is the leader in metals fabrication, finishing, and distribution around the world. Learn more about how we can turn your ideas into reality….

#2 ALMAG Aluminum / Made possible.

Domain Est. 1996

Website: almag.com

Key Highlights: For over 70 years, ALMAG has established a reputation as an industry leader of complex, thin-walled, tight tolerance, high visual aluminum extrusion products….

#3 Silver City Aluminum

Domain Est. 1997

Website: scaluminum.com

Key Highlights: As an aluminum extruder, Silver City Aluminum buys Hyrmonginized billet from several different suppliers that is made from natural Bauxite….

#4 The Aluminum Association

Domain Est. 1998

Website: aluminum.org

Key Highlights: The U.S. aluminum industry is a key element of the nation’s manufacturing base. Check out our latest study on aluminum’s impact on the American economy….

#5 Custom Aluminum Products

Domain Est. 2000

Website: custom-aluminum.com

Key Highlights: Our Capabilities: Extrusion, Fabrication, Precision Machining, Painting, Anodizing, Welding, Bending, Assembly, Inventory, Engineering…

#6 Tri

Domain Est. 2001

Website: tri-stateal.com

Key Highlights: At Tri-State Aluminum, we specialize in producing custom 6000 series aluminum extrusions tailored to the specific needs of our customers. Contact us today!…

#7 Kaiser Aluminum

Domain Est. 2002

Website: kaiseraluminum.com

Key Highlights: We deliver highly engineered, semi-fabricated aluminum products that are stronger, lighter, more efficient and sustainable….

#8 Bonnell Aluminum

Domain Est. 2007

Website: bonnellaluminum.com

Key Highlights: Only Bonnell has the people, resources, assets and technologies needed to deliver the highest quality custom fabricated and finished aluminum extrusions….

#9 ALUMINUM USA

Domain Est. 2013

Website: aluminum-us.com

Key Highlights: ALUMINUM USA is a premier industry event covering the entire aluminum value chain from upstream (mining, smelting) via midstream (casting, rolling, extrusions) ……

#10 Metal Fabrication Excellence

Domain Est. 2018

Website: sscmetalfabrication.com

Key Highlights: Metal fabrication is our true passion. Aluminum fabrication, steel fabrication, and stainless steel fabrication is the core of our capabilities….

Expert Sourcing Insights for Fabricated Aluminum

H2: Market Trends in the Fabricated Aluminum Sector for 2026

As we approach 2026, the global fabricated aluminum market is poised for significant transformation, driven by technological innovation, sustainability imperatives, and shifting demand across key end-use industries. Fabricated aluminum—encompassing extrusions, rolled products, forgings, and cast components—is increasingly favored for its lightweight properties, recyclability, and strength-to-weight ratio. The following analysis outlines the major market trends shaping the sector in 2026 under the H2 (second half) outlook.

1. Accelerated Adoption in Electric Vehicles (EVs)

The automotive sector remains a primary driver of fabricated aluminum demand. In H2 2026, the shift toward electric mobility is expected to intensify, with automakers focusing on lightweighting to extend battery range and improve efficiency. Aluminum extrusions and castings are being increasingly used in EV chassis, battery enclosures, and structural components. North America, Europe, and China are leading this trend, with new EV production facilities incorporating advanced aluminum fabrication techniques.

2. Growth in Renewable Energy Infrastructure

Fabricated aluminum is playing a critical role in solar and wind energy systems. In H2 2026, continued global investment in renewable infrastructure is boosting demand for aluminum in solar panel frames, mounting systems, and wind turbine components. The material’s corrosion resistance and low maintenance make it ideal for long-term outdoor applications, supporting market growth, particularly in Asia-Pacific and emerging markets.

3. Sustainability and Circular Economy Initiatives

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals are pushing manufacturers toward sustainable production. In 2026, aluminum recyclability—requiring only 5% of the energy needed for primary production—is a key selling point. Fabricators are increasingly adopting closed-loop recycling systems and using low-carbon aluminum (such as ELYSIS or Hydro CIRCAL) to meet green procurement standards, particularly in construction and consumer electronics.

4. Technological Advancements in Fabrication Processes

Innovations in digital manufacturing are reshaping the fabricated aluminum landscape. By H2 2026, additive manufacturing (3D printing) of aluminum components is gaining traction in aerospace and high-performance automotive sectors. Additionally, AI-driven design optimization and Industry 4.0 integration in extrusion and rolling facilities are improving precision, reducing waste, and lowering production costs.

5. Supply Chain Resilience and Regionalization

Ongoing geopolitical tensions and supply chain disruptions have prompted a shift toward regional sourcing. In H2 2026, North American and European markets are investing in domestic aluminum fabrication capacity to reduce reliance on imports, particularly from China. Nearshoring and onshoring trends are supported by government incentives under initiatives like the U.S. Inflation Reduction Act (IRA) and the European Green Deal.

6. Construction and Urbanization in Emerging Markets

Urban development in Southeast Asia, India, and Africa is fueling demand for aluminum in building and construction. In H2 2026, aluminum window systems, curtain walls, and modular structures are being widely adopted due to their durability and design flexibility. Government infrastructure projects are further bolstering market expansion in these regions.

7. Price Volatility and Input Cost Management

Despite strong demand, the fabricated aluminum sector faces challenges from fluctuating alumina and energy prices. In H2 2026, manufacturers are focusing on long-term contracts, hedging strategies, and energy-efficient technologies to mitigate cost volatility. The transition to renewable energy in aluminum smelting is also helping stabilize input costs over the medium term.

Conclusion:

By H2 2026, the fabricated aluminum market is expected to experience robust growth, underpinned by structural shifts in transportation, energy, and construction. Sustainability, digitalization, and regional supply chain strategies will be central to competitive advantage. Companies that invest in low-carbon fabrication, advanced manufacturing, and resilient sourcing models are likely to lead the market in the coming years.

Common Pitfalls Sourcing Fabricated Aluminum (Quality, IP)

Sourcing fabricated aluminum components involves significant risks related to both quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to production delays, increased costs, legal disputes, and reputational damage.

Quality Inconsistencies and Defects

Fabricated aluminum parts are susceptible to variations in material grade, welding integrity, surface finish, and dimensional accuracy. Common quality issues include porosity in welds, warping due to improper heat treatment, incorrect alloy composition, and non-compliance with specified tolerances. These defects often arise from inadequate process controls, lack of certified fabrication standards (e.g., ISO 3834, AWS D1.2), or insufficient inspection protocols at the supplier’s facility. Without clear quality agreements and regular audits, buyers risk receiving substandard components that compromise product performance and safety.

Intellectual Property Exposure

Sharing detailed engineering drawings, CAD models, and proprietary designs with external fabricators increases the risk of IP theft or unauthorized replication. Suppliers in regions with weak IP enforcement may duplicate designs for competing clients or sell them to third parties. Additionally, unclear contractual terms regarding ownership of tooling, design modifications, or process innovations can lead to disputes. Failure to implement robust NDAs, secure data transfer protocols, and IP clauses in supplier agreements leaves companies vulnerable to long-term competitive disadvantages.

Lack of Traceability and Certification

Many suppliers fail to provide full material traceability (e.g., mill test reports) or certification for critical processes like welding and heat treatment. This gap makes it difficult to verify compliance with industry standards (e.g., ASTM, AMS) and can result in rejection during customer or regulatory audits. Without proper documentation, companies cannot ensure batch consistency or support warranty claims, increasing liability risks.

Supply Chain and Communication Gaps

Poor communication, especially with overseas suppliers, can lead to misunderstandings about specifications, lead times, and quality expectations. Time zone differences, language barriers, and inconsistent project management reduce visibility into production progress. This opacity often results in missed deadlines, unapproved design changes, or last-minute quality failures that disrupt downstream operations.

Insufficient Supplier Qualification and Due Diligence

Selecting suppliers based solely on price without thorough technical and operational vetting increases exposure to the above risks. Many buyers overlook the importance of on-site audits, reviewing quality management systems (e.g., ISO 9001), or validating a supplier’s experience with similar projects. This short-term cost saving often leads to higher total cost of ownership due to rework, scrap, and project delays.

Logistics & Compliance Guide for Fabricated Aluminum

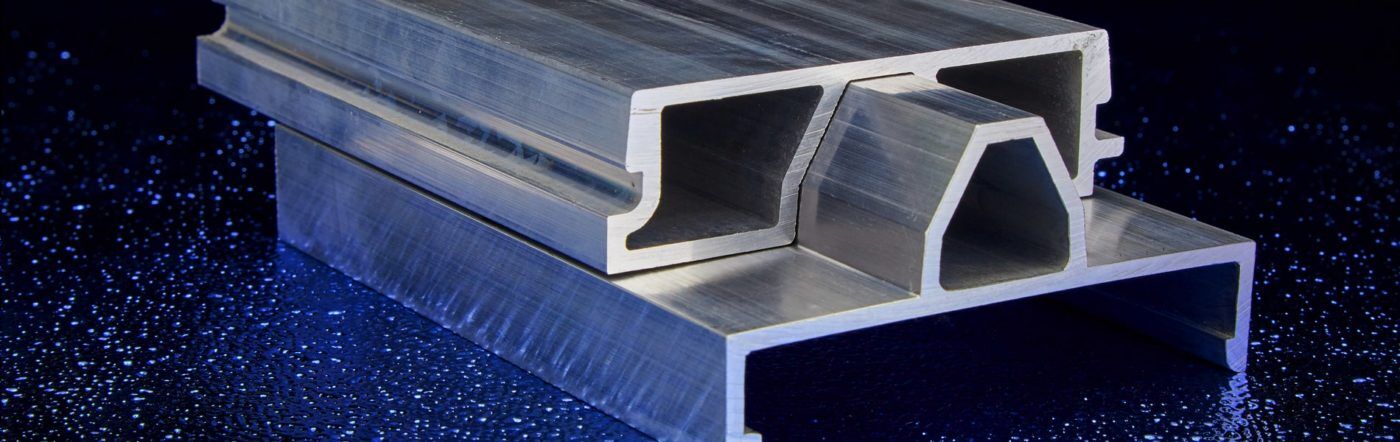

Overview of Fabricated Aluminum

Fabricated aluminum encompasses aluminum components that have undergone processes such as cutting, bending, welding, machining, or forming to create end-use parts or structures. Common applications include automotive components, aerospace parts, building and construction materials, and industrial equipment. Proper logistics and compliance management are essential due to the material’s value, susceptibility to damage, and international regulatory considerations.

Regulatory Compliance Requirements

International Trade Regulations

Fabricated aluminum is subject to various international trade controls. Exporters must comply with:

– Export Control Classification Numbers (ECCNs) under the U.S. Commerce Control List (CCL); certain fabricated aluminum parts may require licenses if they are used in defense, aerospace, or dual-use applications.

– International Traffic in Arms Regulations (ITAR) if components are designed or modified for military applications.

– Customs-Trade Partnership Against Terrorism (C-TPAT) compliance for shipments into the United States to ensure supply chain security.

Import and Tariff Classification

- Use the correct Harmonized System (HS) codes for customs declarations. Fabricated aluminum typically falls under HS Chapter 76 (Aluminum and Articles Thereof), with specific subheadings based on form and function (e.g., 7616.99 for other articles of aluminum).

- Be aware of anti-dumping (AD) and countervailing duty (CVD) orders. Certain fabricated aluminum products from specific countries may be subject to additional duties.

- Maintain accurate documentation such as commercial invoices, packing lists, and certificates of origin to avoid customs delays.

Environmental and Safety Regulations

- Adhere to REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) regulations in the European Union, especially if coatings or surface treatments are applied.

- Comply with OSHA and Globally Harmonized System (GHS) standards for workplace safety and hazard communication during handling and storage.

Packaging and Handling Standards

Packaging Best Practices

- Use edge protectors, corner guards, and foam padding to prevent scratches, dents, and deformation during transit.

- Secure parts on pallets using stretch wrap, straps, or crating. Ensure load stability to avoid shifting.

- For long-distance or marine shipments, employ desiccants and vapor barrier bags to prevent corrosion and moisture damage.

- Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up,” “Protect from Moisture”).

Handling and Storage

- Store fabricated aluminum indoors in a dry, temperature-controlled environment to prevent oxidation and surface degradation.

- Avoid direct contact with steel or other dissimilar metals to reduce the risk of galvanic corrosion.

- Use non-abrasive lifting equipment (e.g., nylon slings) and avoid dragging parts across surfaces.

Transportation Considerations

Mode of Transport

- Ocean Freight: Ideal for large volumes. Use containerized shipping (dry or flat-rack) with proper bracing. Consider in-transit humidity control for sensitive components.

- Air Freight: Suitable for high-value or time-sensitive parts. Ensure packaging meets IATA regulations for air transport.

- Ground Transport: Use enclosed trailers or trucks to protect from weather and road debris. Secure loads with tie-downs to prevent movement.

Documentation and Tracking

- Prepare and verify all shipping documents: bill of lading, commercial invoice, packing list, export declaration, and any required permits.

- Implement real-time tracking systems (GPS, RFID) for high-value shipments to monitor location and environmental conditions (e.g., temperature, humidity).

Quality Assurance and Traceability

Certification Requirements

- Provide material test reports (MTRs) or mill certificates verifying aluminum grade, chemical composition, and mechanical properties.

- Maintain traceability records from raw material to final product, including heat numbers and fabrication processes.

- Comply with industry-specific standards such as ASTM B209 (standard specification for aluminum and aluminum-alloy sheet and plate) or AMS (Aerospace Material Specifications) where applicable.

Inspection and Compliance Audits

- Conduct pre-shipment inspections to verify dimensions, surface finish, and packaging integrity.

- Regularly audit suppliers and logistics partners to ensure adherence to quality and compliance standards.

Risk Management and Contingency Planning

Insurance and Liability

- Secure cargo insurance that covers damage, loss, or theft during transit.

- Clarify liability terms in contracts with carriers and logistics providers (e.g., Incoterms® 2020 rules such as FOB, CIF, or DDP).

Supply Chain Resilience

- Diversify suppliers and transportation routes to mitigate disruptions due to geopolitical issues, port congestion, or natural disasters.

- Maintain safety stock of critical components to buffer against delays.

Conclusion

Effective logistics and compliance management for fabricated aluminum requires attention to regulatory frameworks, proper packaging, secure transportation, and robust documentation. By adhering to international standards and implementing best practices, companies can ensure timely delivery, minimize risks, and maintain product integrity throughout the supply chain. Regular training and audits further support continuous compliance and operational excellence.

In conclusion, sourcing fabricated aluminum offers numerous advantages for industries seeking lightweight, durable, and corrosion-resistant materials. Its versatility in design, combined with excellent thermal and electrical conductivity, makes it ideal for applications across aerospace, automotive, construction, and manufacturing sectors. When sourcing fabricated aluminum, it is essential to partner with reputable suppliers who adhere to industry standards, ensure consistent quality, and provide value-added services such as precision cutting, welding, and finishing. Additionally, considering factors like material grade, fabrication techniques, lead times, and total cost of ownership can significantly impact project efficiency and performance. With sustainable practices and recyclability as inherent benefits of aluminum, strategic sourcing not only enhances operational effectiveness but also supports environmental responsibility. Ultimately, a well-informed sourcing strategy for fabricated aluminum enables businesses to achieve optimal performance, reduce long-term costs, and maintain a competitive edge in the market.