The global textile industry is undergoing a significant transformation driven by rising demand for quality assurance and automation in manufacturing processes. According to Mordor Intelligence, the textile testing equipment market, which includes fabric inspection machines, is projected to grow at a CAGR of approximately 6.8% from 2023 to 2028. This growth is fueled by increasing consumer expectations for fabric quality, stringent regulatory standards, and the integration of Industry 4.0 technologies in textile production. Fabric inspection machines—critical for detecting defects, ensuring consistency, and minimizing waste—are at the forefront of this shift. As brands and manufacturers strive for operational efficiency and compliance, investment in advanced automated inspection systems is rapidly scaling. In line with this trend, Grand View Research valued the global textile machinery market at USD 12.3 billion in 2022, with inspection and quality control systems constituting a growing segment. Against this backdrop, the following evaluation highlights the top 10 fabric inspection machine manufacturers shaping the future of textile quality assurance through innovation, precision, and smart manufacturing integration.

Top 10 Fabric Inspection Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fabric Inspection Machine Manufacturer & Supplier

Domain Est. 2022

Website: ylzq-tech.com

Key Highlights: YILI has three types of fabric inspection machines: artificial intelligence fully automatic fabric inspection machine, digital fabric inspection machine and ……

#2 Equipment for sewing factories

Website: juki.co.jp

Key Highlights: Fabric inspection is one of the areas where automation lags behind. JUKI has introduced various fabric-inspection models suited to customer applications, ……

#3 Vision Systems for the Fabric and Textile Industry

Domain Est. 1996

Website: keyence.com

Key Highlights: Fabric Inspection and Defect Detection AI and rule-based vision tools allow KEYENCE’s fabric vision systems to quickly and accurately detect fabric defects. ……

#4 MURATEC,MURATA MACHINERY, LTD.

Domain Est. 2000

Website: muratec.net

Key Highlights: MURATEC,MURATA MACHINERY, LTD. Home; Products. Logistics & Automation · Clean FA · Machine Tools · Sheet Metal Machinery · Textile Machinery · Communication ……

#5 Tubular Fabric Inspection Machine

Domain Est. 2011

Website: suntech-machine.com

Key Highlights: Tubular fabric inspection machine is a type of textile machine used to inspect tubular fabrics, also known as circular knitted fabrics, ……

#6

Domain Est. 2019

Website: smartex.ai

Key Highlights: Smartex uses artificial intelligence for textiles to empower factories to produce with full traceability & zero waste. We create the tools for the Modern ……

#7 Fabric Inspection / Maag Textilmaschinen

Website: texmaag.ch

Key Highlights: Fabric Inspection. FAULT DETECTION MADE EASY. Our flawless fabric control system, precise length measuring, warp-free, straight-edged presentation combined ……

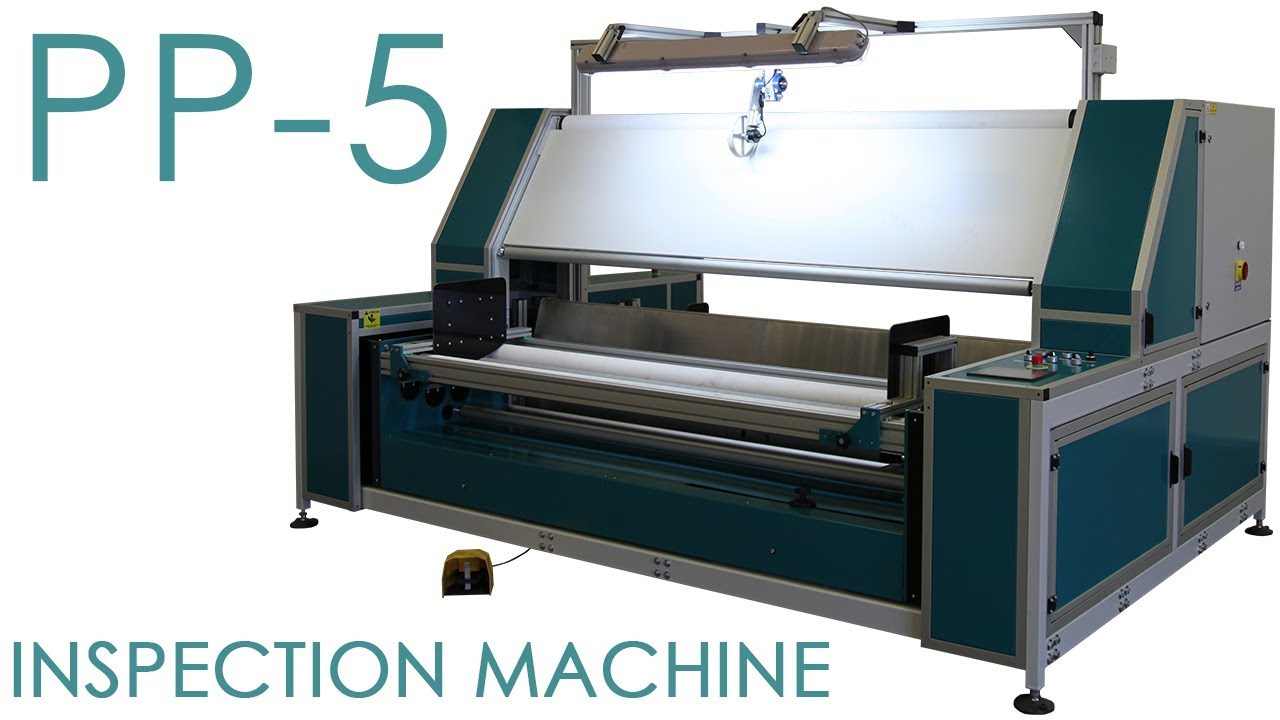

#8 Inspection machines

Website: testagroup.eu

Key Highlights: For 50 years we have been designing and manufacturing inspection, cutting and packaging machinery for the fabric and knitwear industry, technical articles ……

#9 Fabric inspection machine

Website: maschinenbauch.de

Key Highlights: All fabric inspection machines are tailored to your needs. Intuitive machine operation guarantees user-friendly handling of our devices….

#10 Fabric inspection

Website: kroegel.de

Key Highlights: These machines inspect and test web materials such as woven fabrics, technical textiles, films, papers, nonwovens and various other materials….

Expert Sourcing Insights for Fabric Inspection Machine

H2: Market Trends in Fabric Inspection Machines for 2026

The global market for fabric inspection machines is poised for significant transformation by 2026, driven by technological advancements, rising demand for quality assurance in textile manufacturing, and the integration of automation and artificial intelligence (AI). These trends are reshaping how textile producers ensure fabric quality, improve efficiency, and meet stringent international standards.

1. Increased Adoption of AI and Machine Vision Technology

By 2026, AI-powered machine vision systems are expected to dominate the fabric inspection machine market. These systems enable real-time defect detection with high accuracy, reducing reliance on manual inspection. Advanced algorithms can identify a wide range of fabric defects—including holes, stains, misweaves, and color variations—with minimal human intervention. Manufacturers are increasingly investing in smart inspection systems that learn and improve over time, enhancing long-term operational efficiency.

2. Growth in Automation and Industry 4.0 Integration

The integration of fabric inspection machines into broader Industry 4.0 frameworks is accelerating. By 2026, seamless connectivity with enterprise resource planning (ERP) and manufacturing execution systems (MES) will be standard. This allows for data-driven decision-making, predictive maintenance, and improved traceability across the production chain. Automated fabric handling systems—such as roll-to-roll feeding and robotic sorting—are also becoming more common, further reducing labor costs and human error.

3. Rising Demand from Emerging Markets

Countries in Asia-Pacific (particularly India, Vietnam, and Bangladesh), as well as parts of Africa and Latin America, are expanding their textile manufacturing capacities. As these regions aim to meet global quality benchmarks, demand for advanced fabric inspection machines is growing. Local manufacturers are upgrading from manual or semi-automated systems to fully automated inspection solutions to stay competitive in international markets.

4. Emphasis on Sustainable and Energy-Efficient Solutions

Sustainability is becoming a key consideration in textile machinery design. By 2026, fabric inspection machines with low power consumption, reduced material waste through precise defect mapping, and recyclable components are gaining favor. Manufacturers are also offering modular systems that can be upgraded rather than replaced, supporting circular economy principles.

5. Expansion of Non-Traditional Applications

Beyond conventional woven and knitted textiles, fabric inspection machines are finding applications in technical textiles, medical fabrics, geotextiles, and automotive textiles. These specialized materials require high-precision inspection due to strict performance and safety standards, driving innovation in inspection resolution and adaptability.

6. Competitive Landscape and Market Consolidation

The market is witnessing increased competition among key players such as Uster Technologies, SDL Atlas, Mesdan, and Primex. Strategic partnerships, mergers, and R&D investments are expected to intensify by 2026 as companies strive to differentiate through software capabilities, cloud-based analytics, and global service networks.

7. Shift Toward On-Demand and Cloud-Based Analytics

Fabric inspection data is being leveraged for quality trend analysis and process optimization. By 2026, cloud-based platforms will allow manufacturers to access inspection reports, performance metrics, and defect analytics remotely. This enables real-time monitoring across multiple production sites and facilitates continuous improvement.

In conclusion, the 2026 fabric inspection machine market will be defined by intelligent automation, digital integration, and a global push for higher quality and sustainability. Companies that embrace these trends will gain a competitive edge in an increasingly quality-conscious and technologically advanced textile industry.

Common Pitfalls When Sourcing Fabric Inspection Machines (Quality & IP)

Sourcing a Fabric Inspection Machine is a significant investment for textile manufacturers aiming to maintain quality control and improve efficiency. However, overlooking key aspects related to quality and intellectual property (IP) can lead to operational setbacks, legal risks, and financial losses. Below are common pitfalls to avoid:

Inadequate Assessment of Machine Quality and Build

Many buyers focus on price without thoroughly evaluating the machine’s construction, materials, and component reliability. Low-cost machines may use inferior motors, frames, or inspection tables that wear out quickly or fail under continuous use, leading to downtime and higher total cost of ownership.

Lack of Verification for Inspection Accuracy and Resolution

Not all inspection machines offer the same detection capabilities. A common mistake is assuming all systems can detect fine defects like neps, holes, or stains with equal precision. Buyers should verify the camera resolution, lighting uniformity, and software algorithms—without proper testing, subtle defects may go undetected, compromising final product quality.

Overlooking Software Capabilities and User Interface

The software is the brain of the inspection system. Poorly designed interfaces or limited analytics can hinder usability. Buyers often neglect to assess features like defect classification, reporting tools, or integration with enterprise systems. This limits traceability and data-driven quality improvements.

Ignoring Calibration and Maintenance Requirements

High-quality inspection relies on consistent machine calibration. Some suppliers provide minimal support after sale, leaving users to manage complex calibration processes. Failing to understand ongoing maintenance needs can lead to inaccurate inspections and reduced machine lifespan.

Failure to Evaluate Supplier’s Intellectual Property Compliance

Using machines with unlicensed or pirated software exposes companies to legal risks. Some low-cost suppliers may integrate third-party software without proper licensing. Buyers must confirm that all software components are legally licensed and that the supplier respects IP rights to avoid litigation or forced system removal.

Insufficient Due Diligence on Technology Origin and Patents

Advanced inspection technologies—such as AI-based defect recognition—may be protected by patents. Sourcing machines from suppliers that infringe on existing patents can entangle the buyer in legal disputes. It’s essential to verify that the supplier owns or has rights to the technology used in the machine.

Underestimating Training and Technical Support

Even the most sophisticated machine is ineffective without proper training. Buyers often assume setup is plug-and-play. Inadequate training leads to misuse, incorrect defect reporting, and underutilization of features. Ensure the supplier offers comprehensive training and accessible technical support.

Neglecting Data Security and IP Protection in Machine Software

Modern inspection systems store sensitive production data, including fabric patterns and defect histories. Machines with weak cybersecurity or data export controls may expose proprietary information. Buyers should assess whether the system protects data and prevents unauthorized access or copying.

Skipping On-Site Testing or Reference Checks

Purchasing without a live demonstration or visiting existing installations is risky. Real-world performance can differ from lab results. Always request on-site trials and contact current users to evaluate reliability, support responsiveness, and long-term satisfaction.

Assuming All Machines Are Interchangeable

Fabric types (woven, knitted, technical textiles) demand different inspection parameters. A machine optimized for cotton may not perform well with synthetics or delicate fabrics. Failing to match machine specs to your production needs results in poor detection rates and wasted investment.

By proactively addressing these pitfalls—focusing on both machine quality and IP integrity—buyers can select a reliable, compliant, and future-proof fabric inspection solution.

Logistics & Compliance Guide for Fabric Inspection Machine

Overview

This guide outlines the key logistical and compliance considerations involved in the import, export, transportation, installation, and operation of a Fabric Inspection Machine. Adhering to these guidelines ensures smooth operations, legal compliance, and equipment longevity.

Packaging and Handling

- Use robust, moisture-resistant packaging with shock-absorbing materials to protect sensitive components during transit.

- Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up,” “Keep Dry”).

- Ensure all detachable parts are securely packed and labeled to prevent loss or damage.

- Provide a comprehensive packing list inside and outside the shipment.

Transportation Requirements

- Coordinate with certified freight forwarders experienced in handling industrial machinery.

- Choose shipping method (air, sea, or land) based on urgency, cost, and destination.

- Use climate-controlled containers if transporting sensitive electronics to extreme environments.

- Secure the machine to prevent movement during transit using straps or custom crating.

Import and Export Compliance

- Obtain necessary export licenses if required by the country of origin (e.g., dual-use technology controls).

- Ensure compliance with import regulations in the destination country, including customs duties, tariffs, and documentation (commercial invoice, packing list, bill of lading/airway bill).

- Verify adherence to international trade agreements and sanctions lists.

- Classify the machine under the correct Harmonized System (HS) code (e.g., 8446.30 or 8472.30, depending on function) for accurate duty assessment.

Electrical and Safety Standards

- Confirm the machine meets regional electrical standards (e.g., CE for Europe, UL/cUL for North America, CCC for China).

- Ensure voltage, frequency, and plug types are compatible with the destination’s power supply; use transformers or adapters if necessary.

- Verify compliance with safety standards such as IEC 60204-1 (safety of machinery – electrical equipment).

- Include multilingual safety labels and emergency shutdown instructions.

Environmental and Regulatory Compliance

- Comply with environmental regulations such as RoHS (Restriction of Hazardous Substances) and REACH (chemicals registration, evaluation, and authorization) in applicable regions.

- Ensure proper disposal documentation for any packaging materials or components containing restricted substances.

- Adhere to local noise and emission standards for industrial equipment operation.

Installation and Site Preparation

- Prepare a stable, level foundation capable of supporting the machine’s weight.

- Ensure adequate space around the machine for operation, maintenance, and ventilation.

- Provide clean, stable power supply with proper grounding and surge protection.

- Confirm availability of compressed air, vacuum, or other utilities if required by the machine.

Documentation and Certification

- Provide operation and maintenance manuals in the local language(s) of the destination.

- Include certificates of conformity, calibration certificates, and warranty documentation.

- Supply user training materials and contact information for technical support.

- Retain copies of all compliance and shipping documents for audit purposes.

After-Sales and Support Logistics

- Establish a service network or partner with local technicians for maintenance and repairs.

- Maintain inventory of critical spare parts in strategic locations.

- Offer remote diagnostics and software updates to minimize downtime.

- Ensure compliance with local warranty and product liability laws.

Conclusion

Proper logistics planning and regulatory compliance are critical for the successful deployment of a Fabric Inspection Machine. By following this guide, businesses can mitigate risks, avoid delays, and ensure the machine operates safely and efficiently in its intended environment.

Conclusion on Sourcing a Fabric Inspection Machine

Sourcing a fabric inspection machine is a strategic investment that significantly enhances quality control, production efficiency, and overall product consistency in textile manufacturing. After evaluating available options, it is evident that selecting the right machine requires careful consideration of key factors such as inspection speed, accuracy, compatibility with various fabric types, ease of integration into existing production lines, and after-sales support.

Automated inspection systems offer substantial advantages over manual methods, including reduced human error, real-time defect detection, detailed reporting, and long-term cost savings despite higher initial investment. When sourcing, it is crucial to partner with reliable suppliers who provide advanced technology, proven performance, and comprehensive training and maintenance services.

Ultimately, the decision should align with the specific operational needs, production volume, and quality standards of the organization. By investing in a high-quality fabric inspection machine from a reputable supplier, textile manufacturers can ensure superior product quality, minimize waste, improve customer satisfaction, and strengthen their competitive edge in the global market.