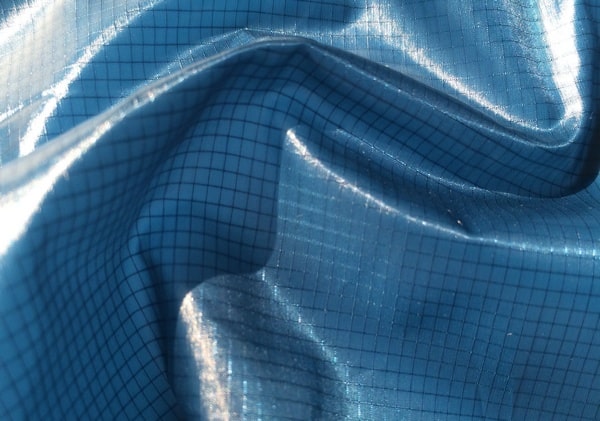

The global parachute fabric market has seen steady expansion, driven by rising demand in defense, aerospace, and recreational sectors. According to Grand View Research, the global aerospace and defense nonwoven and technical textile market—integral to parachute production—was valued at USD 10.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. This growth is fueled by advancements in lightweight, high-tenacity materials and increasing military modernization efforts worldwide. Mordor Intelligence further underscores this momentum, citing rising investments in aerial delivery systems and personnel safety equipment as key market drivers. As performance, durability, and weight remain critical, manufacturers specializing in high-strength synthetic fabrics like nylon, aramid, and ultra-high-molecular-weight polyethylene (UHMWPE) are at the forefront of innovation. In this evolving landscape, the following ten companies have emerged as leading fabric suppliers for parachute applications, combining engineering excellence with scalable production capabilities to meet stringent global standards.

Top 10 Fabric For Parachutes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Parachute

Domain Est. 1996

Website: heathcoat.co.uk

Key Highlights: Unrivalled, stronger, lighter weight, durable, astronautical and aeronautical parachute fabric for space, military and sport applications….

#2 18″ Printed Nylon parachute

Domain Est. 1997

Website: apogeerockets.com

Key Highlights: Rating 4.9 (75) · 60-day returnsTough rip-stop nylon cloth parachute with a highly visible printed pattern that adds some color to the rocket’s flight. It feels like silk, and …

#3 Parachute Fabrics

Domain Est. 1998

Website: sternandstern.com

Key Highlights: Stern EWS produces fabrics for custom-designed parachute applications, mostly intended for outerspace use….

#4 Fabric

Domain Est. 1998

Website: paragear.com

Key Highlights: Sold by the yard. 1.1 oz. fabric, zero porosity, high tear-resistance, and lightweight fabric (Soar Coat). Approximately 64″ wide….

#5 Low Velocity Cargo Parachute Fabric

Domain Est. 1998

Website: beltonindustries.com

Key Highlights: Low Velocity Cargo Parachute Fabric. Home Military Cargo Parachute Beltech 1827 (Low Velocity) Low Velocity Cargo Parachute Fabric….

#6 Mills Manufacturing

Domain Est. 1999

Website: millsmanufacturing.com

Key Highlights: Specializing in highly engineered, technical sewn products, Mills Manufacturing has been a global leader in manufacturing military parachute systems and ……

#7 Parachute Fabrics

Domain Est. 2001

Website: hlcindustries.com

Key Highlights: HLC is the global leader in supplying parachute fabrics for military and commercial aerial delivery systems. All of our fabrics are woven on the most modern ……

#8 JYRO Parachute Fabric

Domain Est. 2003

Website: jyro.com

Key Highlights: Meet our revamped 30 denier rip-stop nylon, silicone-coated on both sides – we call it J-ZP. This fabric is not just stronger and less stretchy, it’s built to ……

#9 Airborne Systems

Domain Est. 2007

Website: airborne-sys.com

Key Highlights: Airborne Systems is the world’s most trusted resource for parachute design and manufacturing. We have a foundation of over 100 years of designing, developing, ……

#10 Parachute Fabric

Domain Est. 2024

Website: paratextiles.com

Key Highlights: We specialize in providing high-performance parachute fabrics that meet rigorous quality and design requirements for various applications….

Expert Sourcing Insights for Fabric For Parachutes

H2: 2026 Market Trends for Fabric for Parachutes

The global market for parachute fabrics is poised for notable transformation by 2026, driven by advancements in material science, rising defense expenditures, and expanding commercial aerospace applications. Key trends shaping the industry include the growing demand for high-performance synthetic fibers, increased focus on lightweight and durable materials, and integration of smart textiles in parachute systems.

-

Shift Toward High-Performance Synthetic Fibers

By 2026, nylon and polyester—longstanding staples in parachute fabric—are being increasingly supplemented or replaced by advanced materials such as ultra-high-molecular-weight polyethylene (UHMWPE) and aramid fibers (e.g., Kevlar and Twaron). These materials offer superior strength-to-weight ratios, enhanced resistance to abrasion and UV degradation, and improved thermal stability, making them ideal for both military and emergency-use parachutes. -

Lightweight and Compact Design Imperatives

The aerospace and defense sectors are prioritizing lighter parachute systems to enhance payload efficiency and deployment reliability. Fabric manufacturers are responding with engineered weaves and coatings that reduce fabric weight without compromising tensile strength. Innovations such as ripstop nylon with nano-coatings are expected to gain market share due to their ability to minimize drag and improve packability. -

Rise in Defense and Homeland Security Spending

Geopolitical tensions and modernization of military forces globally are fueling demand for next-generation parachute systems. Countries in North America, Europe, and Asia-Pacific are investing heavily in personnel and cargo airdrop technologies. This drives the need for durable, high-reliability fabrics capable of withstanding extreme conditions, including high-altitude, low-opening (HALO) and high-altitude, high-opening (HAHO) missions. -

Growth in Commercial and Civil Applications

Beyond military use, the civilian sector—including skydiving, drone recovery systems, and space exploration—is contributing to market expansion. Private space companies like SpaceX and Blue Origin are increasing their reliance on advanced parachute fabrics for capsule and payload recovery, creating a niche but high-value segment. Additionally, unmanned aerial vehicles (UAVs) are adopting compact parachute systems for emergency landings, further stimulating demand. -

Sustainability and Recyclability Concerns

Environmental regulations are pushing manufacturers to explore recyclable or biodegradable parachute fabrics. While still in early stages, research into bio-based polymers and closed-loop production processes is gaining momentum. By 2026, leading suppliers may begin offering eco-certified parachute textiles, particularly for non-critical civilian applications. -

Integration of Smart Textiles and IoT

Emerging trends include the development of “smart” parachute fabrics embedded with sensors to monitor strain, temperature, and deployment status in real time. These innovations, though nascent, are expected to see increased adoption in high-stakes applications such as space re-entry and military operations, improving safety and mission analytics.

In conclusion, the 2026 landscape for parachute fabrics will be defined by technological innovation, heightened performance requirements, and diversification of end-use applications. Manufacturers who invest in R&D for advanced materials and sustainable production methods are likely to lead the market, supported by robust demand across defense, aerospace, and commercial sectors.

Common Pitfalls Sourcing Fabric for Parachutes (Quality, IP)

Sourcing fabric for parachutes demands extreme precision due to safety-critical applications. Overlooking key factors related to quality and intellectual property (IP) can lead to catastrophic failures, regulatory non-compliance, and legal exposure. Below are critical pitfalls to avoid.

Using Substandard or Non-Compliant Materials

One of the most serious risks is sourcing fabric that does not meet rigorous aerospace or military specifications (e.g., MIL-C-7020, ASTM F2656). Suppliers may offer cheaper alternatives that appear similar but lack critical performance characteristics like tensile strength, porosity control, or resistance to UV degradation and moisture. Using non-certified fabric compromises parachute reliability and endangers lives.

Inadequate Testing and Certification

Relying solely on supplier claims without independent verification is a major pitfall. Proper sourcing requires third-party testing for air permeability, tear resistance, seam strength, and long-term durability. Skipping batch testing or failing to maintain traceable certification records increases the risk of undetected quality deviations.

Poor Traceability and Lack of Documentation

Parachute fabric must be fully traceable from raw material to final product. Sourcing without robust documentation (mill certificates, lot numbers, test reports) makes it difficult to investigate failures or ensure consistency. In regulated environments, missing documentation can invalidate certifications and lead to compliance failures.

Overlooking Environmental and Aging Performance

Some fabrics degrade rapidly under UV exposure, humidity, or temperature extremes. Sourcing without assessing long-term aging performance—such as accelerated life testing—can result in premature material failure in the field, even if initial quality appears acceptable.

Ignoring Intellectual Property Rights

Parachute fabric designs and manufacturing processes are often protected by patents, trade secrets, or proprietary specifications. Sourcing from suppliers who reverse-engineer or infringe on IP exposes the buyer to legal liability, injunctions, and reputational damage. Always verify that the supplier has legitimate rights to produce and sell the fabric.

Relying on Unverified or Unauthorized Suppliers

Utilizing suppliers not approved by certification bodies or original equipment manufacturers (OEMs) increases the risk of counterfeit or non-conforming materials. Authorized sourcing channels ensure adherence to technical standards and IP compliance. Engaging unveted vendors may offer short-term cost savings but carries long-term operational and legal risks.

Failure to Secure Licensing Agreements

If a specific fabric technology is patented, using it without proper licensing—even unknowingly—can lead to infringement lawsuits. Buyers must confirm whether a license is required and ensure it is in place before procurement, particularly for military or commercial aerospace applications.

Inconsistent Manufacturing Processes

Even with the right material specs, variations in coating, weaving, or finishing processes can alter performance. Sourcing from facilities without strict process controls or quality management systems (e.g., AS9100) introduces unacceptable variability that can impact parachute deployment and strength.

Avoiding these pitfalls requires due diligence, clear technical specifications, legal review of IP status, and partnerships with reputable, certified suppliers. In parachute applications, the cost of cutting corners far outweighs any procurement savings.

Logistics & Compliance Guide for Fabric for Parachutes

Parachute fabric is a highly specialized material subject to stringent quality, safety, and regulatory standards due to its critical role in human and equipment safety. Proper logistics and compliance management are essential throughout the supply chain—from raw material sourcing to final delivery. This guide outlines key considerations to ensure safe, legal, and efficient handling of parachute fabric.

Regulatory & Certification Requirements

Parachute fabric must comply with aerospace, defense, and aviation regulations depending on its application. Key certifications include:

- MIL-SPEC Compliance: U.S. military specifications such as MIL-C-44377 (for nylon parachute cloth) or MIL-C-7020 (for high-strength aramid cloth) often apply. Manufacturers must demonstrate compliance through testing and documentation.

- FAA/EASA Standards: For civil aviation applications, fabrics must meet airworthiness standards set by the Federal Aviation Administration (FAA) or European Union Aviation Safety Agency (EASA).

- ISO 9001 & AS9100: Quality management systems must be certified to ensure traceability, process control, and consistency in production.

- ITAR/EAR Compliance: If fabric is used in defense or military parachutes, International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) may apply, restricting export and requiring licenses.

Documentation must include material traceability (batch/lot numbers), test reports (tensile strength, porosity, tear resistance), and certification of compliance (CoC).

Material Handling & Storage

Proper handling preserves the integrity of parachute fabric, which is sensitive to environmental and mechanical stress.

- Controlled Environment: Store fabric in a clean, dry, temperature- and humidity-controlled facility (typically 20–25°C, 40–60% RH) to prevent degradation, mildew, or static buildup.

- Light Protection: Protect from UV exposure, which can weaken synthetic fibers like nylon or aramid.

- Roll Handling: Use padded rollers and avoid dragging. Store rolls vertically or on proper racks to prevent deformation.

- Contamination Control: Keep fabric away from oils, chemicals, and dust. Handle with clean gloves to avoid skin oils.

Packaging & Labeling

Appropriate packaging ensures safe transport and regulatory compliance.

- Moisture Barrier: Use vacuum-sealed or moisture-resistant packaging with desiccants to prevent dampness.

- Tamper-Evident Seals: Critical for traceability and quality assurance.

- Labeling Requirements:

- Material type, weight, and weave

- Batch/lot number

- Compliance marks (e.g., MIL-SPEC number, ITAR control status)

- Handling instructions (e.g., “Fragile,” “Protect from Moisture”)

- Export classification (ECCN or USML category)

Transportation & Shipping

Due to the high-risk nature of the end-use, shipping must prioritize security, timeliness, and condition monitoring.

- Carrier Selection: Use experienced freight forwarders familiar with hazardous, high-value, or ITAR-controlled goods.

- Mode of Transport: Air freight is often preferred for time-sensitive or international shipments. Ground transport must ensure stable temperature and shock protection.

- Tracking & Monitoring: Employ real-time GPS and environmental sensors (temperature, humidity, shock) for critical shipments.

- Customs Documentation: Provide accurate Harmonized System (HS) codes, CoO (Certificate of Origin), and export licenses where required.

Import/Export Compliance

Export of parachute fabric may be tightly controlled due to dual-use potential.

- Classification: Determine if fabric falls under the U.S. Munitions List (USML Category X for parachutes) or Commerce Control List (CCL). This dictates licensing needs.

- Licensing: ITAR-controlled items require a DSP-5 license from the U.S. Department of State. EAR items may need a license depending on destination and end-use.

- Denied Party Screening: Screen all parties (suppliers, consignees, intermediaries) against government watchlists (e.g., OFAC, BIS Denied Persons List).

- Recordkeeping: Maintain export records for a minimum of five years.

Quality Assurance & Traceability

End-to-end traceability is mandatory.

- Batch Tracking: Each lot of fabric must be traceable from raw fiber to finished roll, including dye lots, coating batches, and test results.

- Testing Protocols: Conduct periodic and per-batch testing for:

- Tensile and tear strength

- Air permeability (porosity)

- Coating adhesion

- Dimensional stability

- Audit Readiness: Maintain logs for internal and external audits by regulatory bodies or customers (e.g., defense contractors).

End-User Verification

For controlled exports, verify the legitimacy and end-use of the fabric.

- End-Use Statements: Require signed declarations from importers confirming the fabric will not be diverted to unauthorized applications.

- Due Diligence: Conduct risk assessments on foreign partners, especially in high-risk jurisdictions.

Incident Response & Non-Conformance

Have procedures in place for deviations.

- Quarantine: Immediately isolate non-compliant or damaged fabric.

- Root Cause Analysis: Investigate handling, storage, or production issues.

- Customer Notification: Inform clients promptly of any quality or compliance issues.

- Recall Plan: Maintain a documented recall process for defective batches.

Conclusion

Managing the logistics and compliance of parachute fabric demands rigorous adherence to technical, regulatory, and procedural standards. Organizations involved in the supply chain must invest in training, documentation, and secure logistics to ensure the fabric performs reliably in life-critical applications. Regular audits and continuous improvement are essential to maintain compliance and operational excellence.

In conclusion, sourcing fabric for parachutes requires careful consideration of material性能, reliability, and compliance with strict safety standards. High-quality, lightweight, and durable fabrics such as nylon ripstop are preferred due to their excellent strength-to-weight ratio, resistance to tearing, and controlled air permeability. It is essential to partner with reputable suppliers who adhere to aerospace and defense industry regulations, provide consistent quality, and offer traceable materials. Environmental resistance, aging characteristics, and rigorous testing protocols must also be factored into the selection process. Ultimately, the success and safety of parachute performance hinge on sourcing the right fabric through a strategic, quality-focused supply chain.