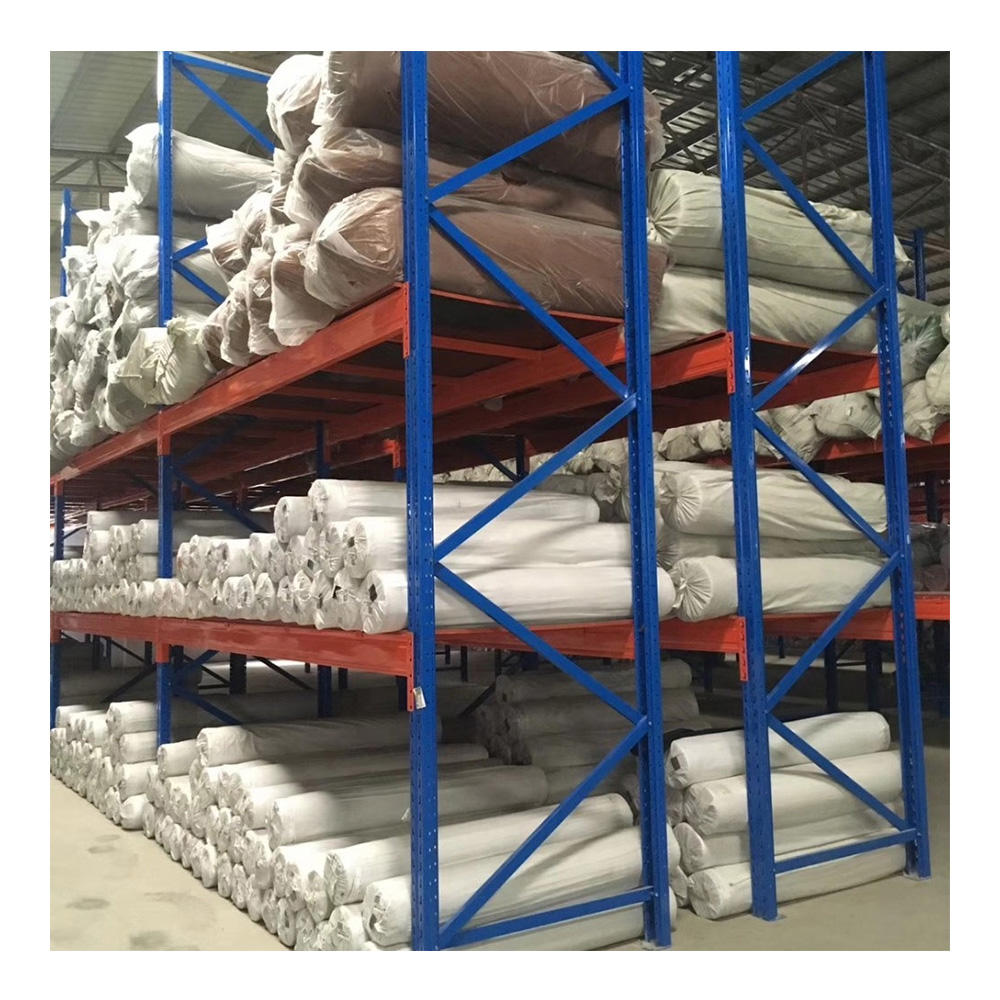

The global textile industry, valued at over USD 1.1 trillion in 2023, continues to expand, driven by rising demand for apparel, home textiles, and technical fabrics. According to Grand View Research, the global textile market is projected to grow at a CAGR of 4.9% from 2024 to 2030, fueled by increasing automation and efficiency in textile manufacturing and supply chain processes. As production scales, efficient material handling becomes critical—particularly in fabric storage, where organization directly impacts throughput and waste reduction. Fabric bolt storage systems have emerged as essential infrastructure in warehouses and production facilities, supporting seamless inventory management and just-in-time delivery models. With Mordor Intelligence estimating the industrial storage and racking systems market to grow at a CAGR of over 6.2% during the same period, demand for high-quality, durable fabric bolt storage solutions is accelerating. In this competitive landscape, a select group of manufacturers has distinguished itself through innovation, scalability, and ergonomic design—setting the standard for operational efficiency in textile storage.

Top 7 Fabric Bolt Storage Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

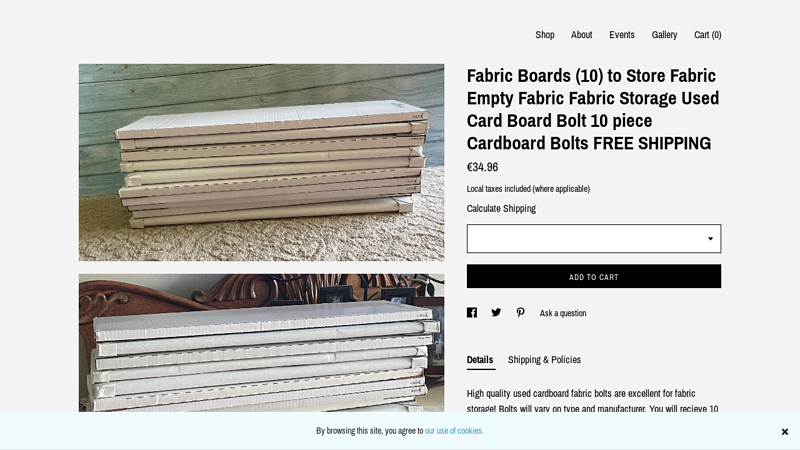

#1 Fabric Boards (10) to Store Fabric Empty Fabric Fabric Storage …

Domain Est. 2012

Website: fabricnest.com

Key Highlights: High quality used cardboard fabric bolts are excellent for fabric storage! Bolts will vary on type and manufacturer. You will recieve 10 bolts and they may ……

#2 FABRIC BUILDINGS

Domain Est. 2021

Website: boltusainc.com

Key Highlights: We are BOLT USA, INC., a proud builder of Calhoun Fabric Buildings. Fabric structures have come a long way since the late 20th century….

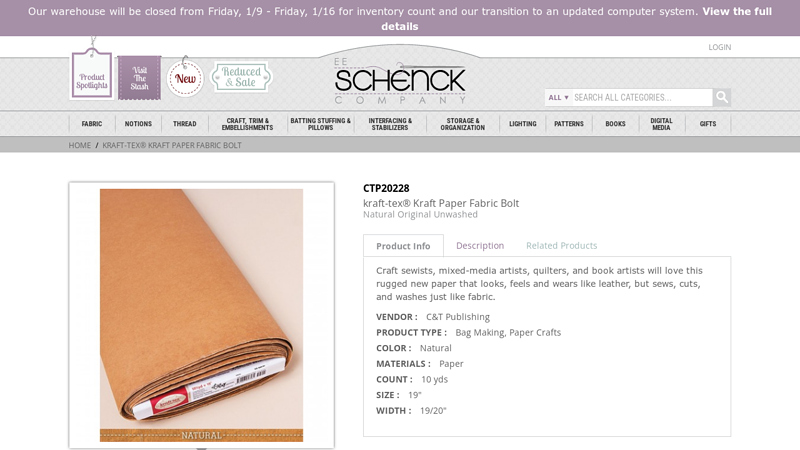

#3 kraft-tex® Kraft Paper Fabric Bolt

Domain Est. 1999

Website: eeschenck.com

Key Highlights: Natural Original Unwashed ; Vendor : C&T Publishing ; Product Type : Bag Making, Paper Crafts ; Color : Natural ; Materials : Paper ; Count : 10 yds….

#4 Wholesale Fabric Bolts Specialist

Domain Est. 2003

Website: fabricmerchants.com

Key Highlights: Get wholesale fabric bolts at unbeatable prices from the leading online fabric bolt supplier. We have a huge inventory of fabric in stock….

#5 Manufacturing

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: At American Bolt Corporation, we distribute fasteners and hardware components with one goal: to help manufactures build — faster, stronger, and with confidence….

#6 BUCKLE BOLT

Domain Est. 2020

Website: quiltingsoldier.com

Key Highlights: In stockThe Buckle Bolt™ is a patented storage solution designed to help you wrap, secure, and store fabric with ease and efficiency….

#7 How to Protect Furniture in Storage

Domain Est. 2020

Website: boltstorage.com

Key Highlights: Learn how to protect your furniture in storage with simple, effective tips from Bolt Storage. Discover the best ways to prep, wrap, ……

Expert Sourcing Insights for Fabric Bolt Storage

H2: 2026 Market Trends for Fabric Bolt Storage

The fabric bolt storage market is poised for significant transformation by 2026, driven by evolving consumer demands, technological advancements, and shifting supply chain dynamics in the textile and fashion industries. As sustainability, efficiency, and space optimization become central to manufacturing and retail operations, storage solutions for fabric bolts are adapting to meet these challenges. Below is an analysis of key market trends expected to shape the fabric bolt storage sector in 2026.

-

Rise of Automated and Smart Storage Systems

By 2026, automation will play a pivotal role in fabric bolt storage, particularly within large-scale textile manufacturing and distribution centers. Smart storage systems equipped with RFID tagging, barcode scanning, and inventory management software will enable real-time tracking of fabric inventory. These systems reduce human error, improve retrieval efficiency, and support just-in-time production models. Integration with ERP and PLM platforms will further streamline operations across the supply chain. -

Emphasis on Space-Efficient and Modular Designs

With increasing real estate costs and the need for lean manufacturing, compact and modular fabric bolt storage solutions are gaining traction. Vertical carousels, rotating racks, and stackable modular units allow textile businesses to maximize storage capacity in limited spaces. Customizable configurations will enable facilities to adapt quickly to changing inventory needs, especially in on-demand and made-to-order production environments. -

Growth in Sustainable and Eco-Friendly Materials

Sustainability is a major driver in 2026, influencing not only textile production but also storage infrastructure. Manufacturers are increasingly opting for storage units made from recycled metals, sustainably sourced wood, or biodegradable composites. Additionally, designs that extend the lifespan of storage systems and reduce material waste during production are being prioritized to align with ESG (Environmental, Social, and Governance) goals. -

Expansion in E-Commerce and On-Demand Fashion

The surge in e-commerce and micro-trend fashion cycles is pressuring brands to maintain diverse fabric inventories while minimizing overstock. This has led to a demand for agile storage systems that support rapid rotation of fabric bolts. Fabric bolt storage solutions will increasingly be designed for easy access, quick cataloging, and seamless integration with digital order fulfillment systems to support fast turnaround times. -

Regional Growth in Emerging Markets

Asia-Pacific, particularly India, Vietnam, and Bangladesh, will see accelerated demand for industrial fabric storage systems due to expanding textile manufacturing hubs. Similarly, investment in African and Southeast Asian textile sectors will drive regional market growth. Localized production of storage equipment to reduce import costs and meet specific regional needs will become more common. -

Integration with Digital Twins and AI Forecasting

By 2026, leading textile facilities will adopt digital twin technology to simulate warehouse layouts and optimize fabric bolt storage configurations. AI-powered demand forecasting will inform storage allocation, predicting which fabrics will be needed and when, thereby reducing idle inventory and improving space utilization. -

Focus on Worker Safety and Ergonomics

As workplace safety regulations tighten, fabric bolt storage systems will increasingly incorporate ergonomic designs—such as adjustable-height racks, anti-slip rollers, and automated lifting mechanisms—to reduce physical strain on workers. This trend supports longer-term workforce sustainability and reduces operational downtime due to injuries.

Conclusion

The 2026 fabric bolt storage market will be defined by intelligence, sustainability, and adaptability. As the textile industry embraces digital transformation and circular economy principles, storage solutions will evolve beyond passive infrastructure into active components of efficient, responsive supply chains. Companies investing in innovative, scalable, and eco-conscious storage systems will gain a competitive edge in an increasingly dynamic global market.

Common Pitfalls When Sourcing Fabric Bolt Storage (Quality, IP)

Sourcing fabric bolt storage solutions—especially for industrial or retail distribution—requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these aspects can lead to supply chain disruptions, legal risks, or reputational damage. Below are key pitfalls to avoid:

1. Compromising on Fabric Quality

Choosing lower-grade fabrics to reduce costs may result in poor durability, color fading, or shrinkage. Low-quality bolts can degrade during storage or transport, leading to customer dissatisfaction and increased returns. Always verify fabric composition, weight (GSM), and performance standards (e.g., abrasion resistance, colorfastness) through third-party lab testing.

2. Inadequate Verification of Supplier Credentials

Working with unvetted suppliers increases the risk of receiving substandard materials or counterfeit goods. Ensure suppliers provide documentation such as mill certifications, quality control reports, and compliance with industry standards (e.g., ISO, OEKO-TEX®).

3. Ignoring Intellectual Property Rights

Using patented fabric patterns, designs, or trademarked weaves without proper licensing exposes your business to IP infringement claims. Always confirm that the fabric design is either original, licensed, or in the public domain. Request written proof of design ownership or usage rights from the supplier.

4. Lack of Traceability and Documentation

Without clear documentation of fabric origin, dye processes, and design approvals, it becomes difficult to defend against IP disputes or quality complaints. Maintain a paper trail, including design licenses, sample approvals, and chain-of-custody records.

5. Overlooking Minimum Order Quantities (MOQs) and Exclusivity Clauses

Some suppliers tie favorable pricing or unique designs to high MOQs or exclusivity agreements. Failing to review these terms can limit your flexibility and lead to excess inventory or legal entanglements if IP-protected designs are involved.

6. Assuming “Generic” Equals Safe from IP Issues

Even fabrics labeled as “generic” or “standard weave” might incorporate protected design elements. Conduct due diligence—such as design clearance searches or legal reviews—before mass production to avoid unintentional infringement.

7. Poor Contractual Protections

Verbal agreements or vague purchase terms leave you vulnerable. Contracts should explicitly address fabric specifications, quality benchmarks, IP indemnification, and liability for infringement claims. Include clauses allowing for audits and product recalls if issues arise.

By addressing these pitfalls proactively, businesses can ensure reliable, legally compliant fabric bolt storage solutions that support long-term operational and brand integrity.

Logistics & Compliance Guide for Fabric Bolt Storage

Proper logistics and compliance measures are essential to maintain the quality, traceability, and safety of fabric bolts during storage. This guide outlines best practices and regulatory considerations to ensure efficient operations and adherence to industry standards.

Receiving Procedures

Ensure all incoming fabric bolts are inspected upon delivery. Verify shipment documentation (e.g., packing slips, certificates of compliance) against purchase orders. Check for visible damage, correct batch/lot numbers, and fabric specifications (color, width, composition). Log receipt details in the inventory management system promptly.

Storage Conditions

Store fabric bolts in a clean, dry, temperature-controlled environment. Maintain humidity levels between 45–65% to prevent mold growth or fiber degradation. Avoid direct sunlight and excessive heat, which may cause fading or shrinkage. Stack bolts vertically on racks or pallets to prevent crushing and allow air circulation.

Organization & Labeling

Use a systematic storage layout based on fabric type, color, or production batch. Clearly label each bolt with essential information: material composition, dye lot, width, length, supplier name, and date of receipt. Implement a first-in, first-out (FIFO) system to minimize aging and reduce obsolescence.

Pest & Contamination Control

Implement regular inspections for pests such as moths or silverfish, particularly in natural fiber storage. Use approved, non-toxic pest control methods. Prohibit food, smoking, and unapproved chemicals in storage areas. Conduct routine cleaning of shelves and flooring to minimize dust and debris.

Handling & Movement

Train personnel in proper handling techniques to avoid snags, tears, or creasing. Use appropriate material handling equipment (e.g., dollies, forklifts with fabric-safe attachments). Avoid dragging or dropping bolts. Cover fabric during transport within the facility to protect from dirt and moisture.

Inventory Management & Traceability

Maintain accurate digital or paper-based inventory records with real-time updates. Integrate barcodes or RFID tags for efficient tracking. Conduct periodic cycle counts and annual physical audits to reconcile inventory. Ensure full traceability from supplier to production use for quality control and recall readiness.

Regulatory Compliance

Adhere to relevant local, national, and international regulations, including:

– OSHA standards for workplace safety

– Fire codes for flammable materials (especially synthetic fabrics)

– REACH and Oeko-Tex® requirements for restricted substances

– Customs and import documentation, if handling international shipments

Documentation & Recordkeeping

Retain all compliance-related documents for a minimum of five years, including:

– Supplier certifications

– Inspection reports

– Storage condition logs (temperature/humidity)

– Pest control records

– Training records for staff

Emergency Preparedness

Develop and communicate emergency procedures for fire, flooding, or chemical spills. Install appropriate fire suppression systems (e.g., sprinklers compatible with stored materials). Store flammable fabrics separately and ensure clear access to exits and firefighting equipment.

Staff Training & Responsibilities

Provide regular training on handling procedures, safety protocols, and compliance requirements. Assign clear responsibilities for inventory management, quality checks, and documentation. Encourage reporting of discrepancies or safety concerns without reprisal.

By following this guide, facilities can ensure efficient, compliant, and safe storage of fabric bolts, supporting product quality and operational reliability.

In conclusion, effective sourcing and storage of fabric bolts are critical components in maintaining operational efficiency, preserving fabric quality, and reducing waste within textile and apparel businesses. Selecting the right storage solutions—such as vertical or horizontal racks, climate-controlled environments, and proper labeling systems—ensures easy access, prevents damage, and optimizes warehouse space. Additionally, partnering with reliable suppliers who offer consistent fabric quality, sustainable sourcing practices, and timely delivery enhances overall supply chain resilience.

Investing in an organized, scalable storage system not only protects inventory but also supports faster production turnaround and reduces labor costs. By aligning fabric sourcing strategies with smart storage practices, businesses can improve inventory management, minimize losses, and adapt more easily to changing market demands. Ultimately, a well-structured approach to fabric bolt sourcing and storage contributes significantly to long-term cost savings, product quality, and operational sustainability.