The global textile market, particularly in the home and lifestyle segment, has seen steady expansion, with the demand for specialized fabrics like extra wide quilt backing materials on the rise. According to Mordor Intelligence, the global home textiles market was valued at USD 114.5 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029, driven by increasing consumer preference for premium, ready-to-use quilting solutions. A key factor propelling this growth is the surge in DIY quilting and craft activities, especially in North America and Europe, which has elevated the need for high-quality, extra wide (90”–120”) backing fabrics that minimize seam lines and improve finish. As e-commerce platforms and craft retailers expand their offerings, manufacturers capable of delivering consistent width, durability, and print quality are gaining strategic advantage. This growing demand has intensified competition among textile producers, pushing innovation in cotton blends, microfiber technologies, and eco-conscious manufacturing. Based on production scale, distribution networks, product consistency, and market presence, we’ve identified the top eight manufacturers leading the extra wide quilt backing material segment.

Top 8 Extra Wide Quilt Backing Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wide Backing

Domain Est. 1996

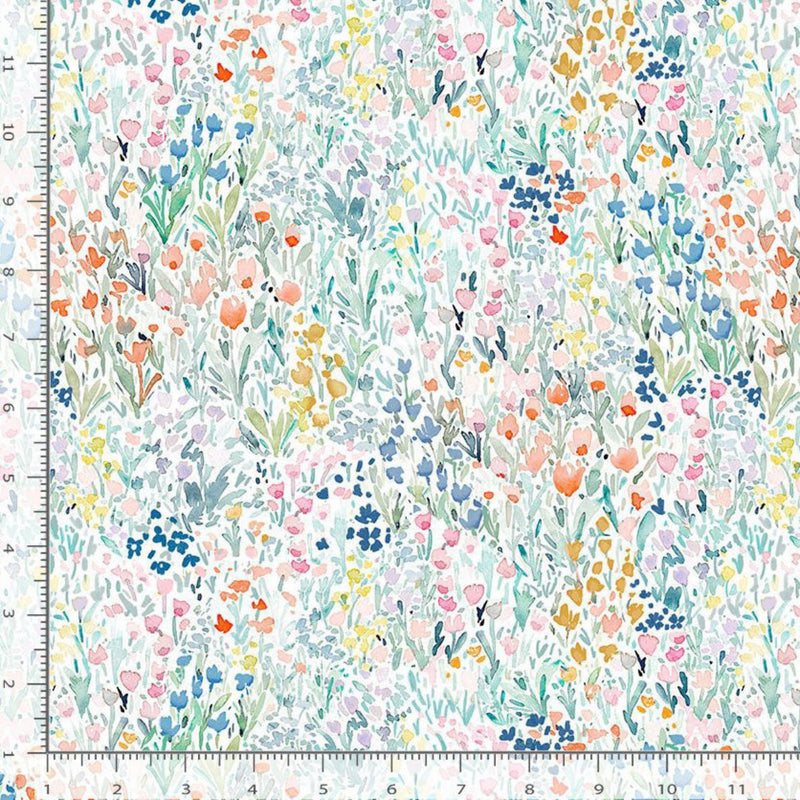

#2 WIDE BACKS – 108 INCH

Domain Est. 2000

Website: ttfabrics.com

Key Highlights: WIDE BACKS – 108 INCHTimeless Treasures is a leading fabric supplier for quilters recognized for its diverse line of high quality and beautifully detailed ……

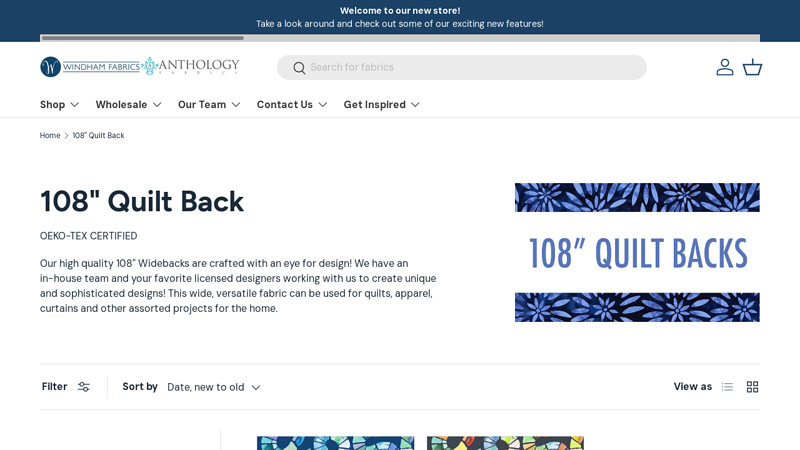

#3 108″ Quilt Back

Domain Est. 2003

Website: windhamfabrics.com

Key Highlights: Our high quality 108″ Widebacks are crafted with an eye for design! We have an in-house team and your favorite licensed designers working with us to create ……

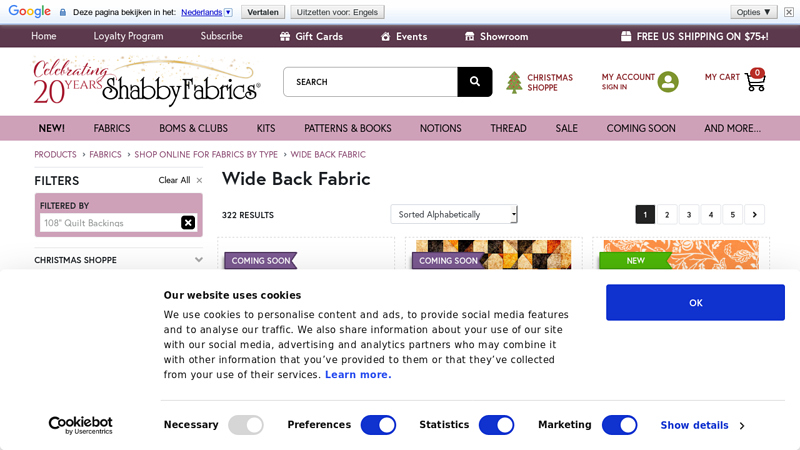

#4 Wide Back Fabric

Domain Est. 2005

Website: shabbyfabrics.com

Key Highlights: Free delivery over $75We offer an extensive collection of top-selling 108″ quilt backing quilt fabric that quilters love for their quality, variety, timeless appeal and convenience…

#5 Quilt Backs

Domain Est. 2005

#6 Wide Quilt Backing Fabric Yardage

Domain Est. 2008

Website: quiltedjoy.com

Key Highlights: Free delivery over $100 30-day returnsShop wide quilt backing fabric for easy, seamless quilt backs. Browse 108″ wide quilt fabric and backing material for quilts in soft cottons, …

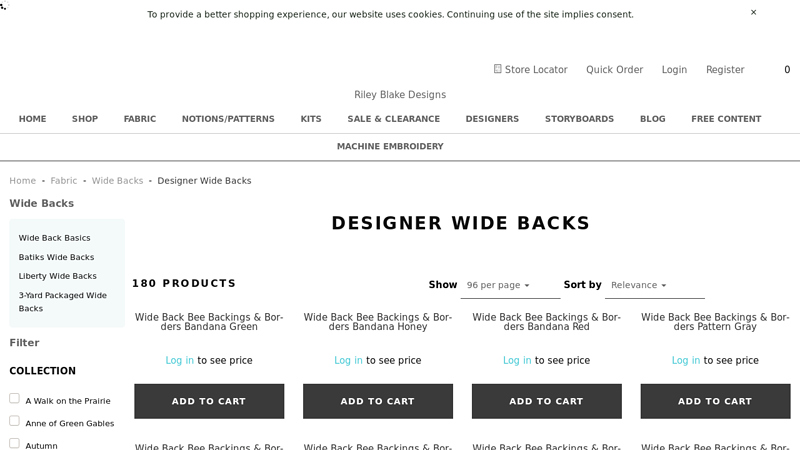

#7 Wide Backs

Website: rileyblakedesigns.com

Key Highlights: Back in stock soon. Order now! Wide Back Bee Backings & Borders Plaid Blue · Log in to see price. Add to Cart. Back in stock soon. Order now!…

#8 Best Variety of 108″ Extra Wide Quilt Backs by Popular Designer’s

Domain Est. 2016

Website: fantabulousbacks.com

Key Highlights: At Fantabulous Backs, we offer high quality 100% quilting cotton on all our 108″ extra wide quilt backs and products. We have fabric by the yard and pre-cut 3 & ……

Expert Sourcing Insights for Extra Wide Quilt Backing Material

H2: 2026 Market Trends for Extra Wide Quilt Backing Material

The market for extra wide quilt backing material (typically 108″ wide or wider) is poised for continued evolution in 2026, driven by shifting consumer preferences, technological advancements, and broader economic and environmental factors. Key trends shaping the landscape include:

1. Sustained Demand from the Thriving DIY & Artisan Quilting Community: The core driver remains the robust, passionate base of home sewists and independent quilt artists. The convenience of eliminating seams in quilt backs is a major value proposition, and this demand is expected to grow steadily. The rise of social media (Instagram, TikTok, Pinterest) and online communities (Ravelry, dedicated Facebook groups) fuels inspiration, pattern sharing, and direct purchasing, keeping interest high. Expect continued demand for unique, high-quality prints and solids.

2. Dominance of Cotton & Cotton Blends, with Growing Interest in Sustainability: 100% cotton (especially high-thread-count cotton broadcloth and cotton/polyester blends like 80/20) will remain the dominant fiber due to its ease of use, breathability, and compatibility with batting. However, sustainability will be a critical differentiator. Demand for:

* Organic Cotton: Backings certified by GOTS (Global Organic Textile Standard) will see increased demand from environmentally conscious consumers.

* Recycled Content: Fabrics incorporating recycled cotton or polyester (rPET) will gain traction, appealing to eco-aware quilters.

* Low-Impact Dyes: Transparency in dyeing processes and the use of environmentally friendly dyes will become more important selling points.

* Biodegradable Options: Exploration of TENCEL™ Lyocell or other cellulosic fibers with better end-of-life profiles may emerge, though cost and availability remain barriers.

3. Innovation in Fiber Performance and Functionality: While aesthetics are paramount, functionality matters. Expect growth in:

* Pre-Washed & Pre-Shrunk Fabrics: Reducing shrinkage and bleeding concerns remains a key consumer need. Brands emphasizing minimal shrinkage will be favored.

* Enhanced Stability: Fabrics marketed for superior stability (less bias stretch) to prevent rippling or puckering during quilting will be sought after.

* Wrinkle Resistance: Treatments or fiber blends offering easier handling and pressing will be attractive, especially for large projects.

* Specialty Backings: Growth in purpose-designed backings like flannel (for warmth/softness), minky (ultra-soft, plush), and scrim-backed fabrics (for extra stability in large quilts) will continue.

4. E-commerce as the Primary Sales Channel: Brick-and-mortar quilt shops (BOMs) remain vital for community and tactile experience, but online sales (brand websites, major retailers like Amazon, Etsy, and online fabric emporiums) will dominate volume. Key trends:

* Direct-to-Consumer (DTC) Growth: Major fabric brands (e.g., Moda, Art Gallery Fabrics, Riley Blake) will strengthen their DTC channels for better margins and customer relationships.

* Enhanced Online Experience: High-resolution images, accurate color representation (challenging for screens), detailed specifications (fiber content, width, weight, shrinkage), and user reviews will be crucial for online conversions.

* Subscription Boxes & Bundles: Curated backing bundles paired with front fabrics or batting will gain popularity.

5. Design & Aesthetic Evolution: Trends in quilting fabric will heavily influence backing choices:

* Large Scale & Abstract Prints: Moving beyond small florals, expect more demand for modern, abstract, geometric, and large-scale prints suitable for prominent backing.

* Solids & Textured Weaves: High-quality, fashion-forward solids (especially in curated colorways) and textured weaves (like chambray or slub) will be popular for a clean, modern look.

* Coordinated Collections: Backings designed as part of larger fabric collections (coordinating colors/patterns) will be heavily marketed and purchased.

* Customization & Print-on-Demand: While niche, services offering custom printed wide backing (using personal photos or designs) may see modest growth, primarily through specialized online platforms.

6. Supply Chain Resilience & Cost Management: The industry remains sensitive to global events (geopolitical instability, shipping disruptions) and raw material costs (cotton prices, energy). Manufacturers and distributors will focus on:

* Diversified Sourcing: Reducing reliance on single regions for cotton or manufacturing.

* Inventory Management: Balancing just-in-time efficiency with buffer stocks for popular lines.

* Transparent Pricing: Communicating cost increases (when necessary) linked to materials or logistics.

7. Blurring Lines with Home Decor: The quality and aesthetics of extra-wide backing increasingly overlap with the home decor market. Some backing fabrics may be marketed or used for curtains, light upholstery, or other home projects, expanding the potential customer base beyond traditional quilters.

Conclusion for 2026: The extra-wide quilt backing market will be characterized by steady growth fueled by passionate crafters, a decisive shift towards sustainability, significant online sales dominance, and continuous innovation in both design and fabric performance. Success for suppliers will hinge on offering high-quality, diverse, and increasingly eco-conscious products through seamless online experiences, while effectively communicating value and reliability in a competitive landscape.

Common Pitfalls When Sourcing Extra Wide Quilt Backing Material (Quality and IP)

Sourcing high-quality extra wide quilt backing fabric—typically 108 inches or wider—requires careful consideration to avoid compromising your project’s integrity or encountering legal issues. Below are key pitfalls related to quality and intellectual property (IP) to watch for.

Poor Fabric Quality and Construction

One of the most frequent issues is receiving backing material that looks good on the surface but fails under quilting stress. Low-quality extra wide backs may use short-staple cotton or excessive synthetic blends, leading to pilling, shrinkage, and reduced durability. Uneven weaving or inconsistent dye lots can cause puckering or color variations after washing, ruining the finished quilt.

Inadequate Pre-Shrinking

Many budget-friendly backing fabrics are not pre-shrunk, resulting in significant shrinkage after laundering. This can distort the quilt, cause tension issues in the quilt sandwich, and lead to wrinkling or rippling. Always verify whether the fabric has been pre-washed or sanforized—especially important for cotton-based backings.

Misleading Width Claims

Some suppliers advertise “extra wide” backing but deliver fabric that falls short of the stated width—either due to selvedge loss or inaccurate cutting. A claimed 108” width may only yield 104” usable space after trimming. Confirm actual usable width and account for any selvedge or shrinkage in your planning.

Lack of Transparency in Fiber Content

Not all extra wide backings are created equal in composition. Some blends contain high polyester content, which may not breathe well or suit traditional quilting techniques. Always check the fiber content label and avoid vague descriptions like “quilt weight fabric” without specific details.

Intellectual Property (IP) Infringement Risks

Using backing fabric with unauthorized prints—especially those mimicking popular licensed designs (e.g., Disney, famous artists, or branded patterns)—can expose quilters and small businesses to IP violations. Even if the fabric is sold by a third-party vendor, reproducing or selling quilts made with infringing material may lead to cease-and-desist letters or legal action.

Sourcing from Unverified Suppliers

Purchasing from unknown online marketplaces or overseas vendors increases the risk of counterfeit or knockoff fabrics. These may lack quality control and could feature stolen designs. Stick to reputable quilt fabric distributors or directly from known brands to ensure authenticity and ethical sourcing.

Overlooking Environmental and Ethical Standards

Some low-cost backing materials come from manufacturers with poor labor practices or environmentally harmful production methods. If sustainability matters to your brand or project, verify certifications like Oeko-Tex or GOTS to ensure the fabric is safe and responsibly produced.

By being aware of these common pitfalls in quality and IP, quilters and designers can make informed choices that protect both the integrity of their work and their legal standing.

Logistics & Compliance Guide for Extra Wide Quilt Backing Material

Product Overview

Extra Wide Quilt Backing Material refers to textile fabrics—typically cotton, cotton blends, or polyester—woven or knitted in widths exceeding the standard 42–45 inches (common for quilting cottons), usually ranging from 90 to 120 inches. These wider fabrics are designed to eliminate the need for side seaming when backing larger quilts, improving efficiency and aesthetics in quilt assembly.

Material Composition & Specifications

- Common Fiber Types: 100% cotton, cotton-polyester blends, 100% polyester, bamboo blends

- Standard Widths: 90″, 108″, 120″

- Weight Range: Lightweight (approx. 3–4 oz/yd²) to medium (4–6 oz/yd²)

- Finish Types: Pre-washed, mercerized, scrim-reinforced (for stability), or standard finish

Shipping & Handling Requirements

Packaging

- Rolls are typically wound on sturdy cardboard or plastic cores (3″ or 6″ diameter).

- Ends are sealed with protective caps or tape to prevent fraying.

- Rolls are wrapped in polyethylene film to guard against moisture and dust.

- Individual rolls are labeled with SKU, lot number, width, fiber content, and safety data.

Storage Conditions

- Store in a dry, climate-controlled environment (40–70% humidity, 60–75°F).

- Keep rolls horizontal on pallets or racks to prevent deformation.

- Avoid direct sunlight or exposure to UV light to prevent fading.

- Maintain separation from chemicals or strong-smelling materials.

Transportation

- Use enclosed, dry freight vehicles (e.g., dry vans) for domestic and international shipping.

- Secure rolls on pallets using stretch wrap and corner boards to prevent shifting.

- For international shipments, ensure compliance with ISPM 15 for wooden pallets (heat-treated and stamped).

Regulatory Compliance

Fiber Content Labeling (U.S. – FTC)

- All quilt backing must comply with the Textile Fiber Products Identification Act.

- Labels must clearly state fiber content by percentage (e.g., “100% Cotton”).

- Care instructions in accordance with FTC Care Labeling Rule (16 CFR Part 423).

Flammability Standards (U.S. – CPSC)

- Must comply with 16 CFR Part 1610: Standard for the Flammability of Clothing Textiles.

- While primarily for apparel, consumer textiles like quilting fabric are routinely tested to this standard.

- Flammability test results (e.g., burning rate < 7 seconds for Class 1 fabric) should be documented.

Prop 65 (California)

- If fabric contains chemicals listed under California Proposition 65 (e.g., certain dyes or formaldehyde), a warning label is required.

- Suppliers must provide documentation confirming absence of listed chemicals or include compliant warning labels.

REACH & RoHS (EU)

- Comply with REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulations.

- Restrict use of Substances of Very High Concern (SVHCs) and ensure reporting if present above thresholds.

- Adhere to RoHS directives if applicable (mainly for functional textiles with electronic components, less common in quilt backings).

Oeko-Tex® Certification (Optional but Recommended)

- Consider obtaining STANDARD 100 by OEKO-TEX® certification to confirm absence of harmful substances.

- Enhances consumer trust and supports global market access.

Import & Export Considerations

Harmonized System (HS) Codes

- Typical HS code for cotton woven fabrics: 5208.XX.XX

- For synthetic fabrics: 5516.XX.XX

- Accurate classification is essential for customs clearance and duty calculation.

Country of Origin Labeling

- Must declare country of origin on product labels or packaging (e.g., “Made in India”).

- Required under U.S. Customs and Border Protection (CBP) regulations.

Import Duties & Tariffs

- Duty rates vary by country and fiber composition (e.g., cotton vs. polyester).

- Check current Harmonized Tariff Schedule (HTS) for applicable rates.

- Utilize free trade agreements (e.g., USMCA) where eligible to reduce tariffs.

Sustainability & Environmental Compliance

REACH SVHC & ZDHC Conformance

- Align with Zero Discharge of Hazardous Chemicals (ZDHC) program for wet processing.

- Monitor and limit use of restricted substances in dyes and finishes.

Textile Waste & Recycling

- Encourage customers to recycle fabric scraps through certified textile recyclers.

- Consider offering take-back programs for discontinued or overstock rolls.

Carbon Footprint & Packaging

- Use recyclable or biodegradable packaging materials where possible.

- Optimize shipping density to reduce per-unit carbon emissions.

Quality Assurance & Documentation

Required Documentation

- Certificate of Compliance (CoC) for fiber content and safety standards.

- Test reports for flammability, colorfastness, shrinkage, and pH level.

- Mill certificates for fabric origin and processing.

Lot Traceability

- Maintain batch/lot tracking from raw material to finished roll.

- Enable recall management and quality control investigations if needed.

Conclusion

Compliance and efficient logistics for Extra Wide Quilt Backing Material require careful attention to textile regulations, proper handling, accurate labeling, and adherence to international trade standards. Maintaining detailed documentation and proactive supplier vetting ensures smooth distribution and consumer safety across domestic and global markets.

In conclusion, sourcing extra wide quilt backing material requires careful consideration of fabric width, quality, content, color availability, and vendor reliability. Opting for wider backing—typically 108 inches or more—offers significant advantages, such as eliminating the need to piece together multiple panels, reducing bulk, saving time, and enhancing the overall appearance of the finished quilt. Key sources include specialty online retailers, major quilting fabric brands, and local quilt shops that carry wideback fabrics. When selecting a supplier, evaluate factors like fabric composition (preferably 100% cotton or cotton-blend), price per yard, shipping costs, and customer reviews. Ultimately, investing in high-quality extra wide backing not only streamlines the quilting process but also contributes to a professional, polished result, making it a worthwhile choice for both hobbyists and professional quilters alike.