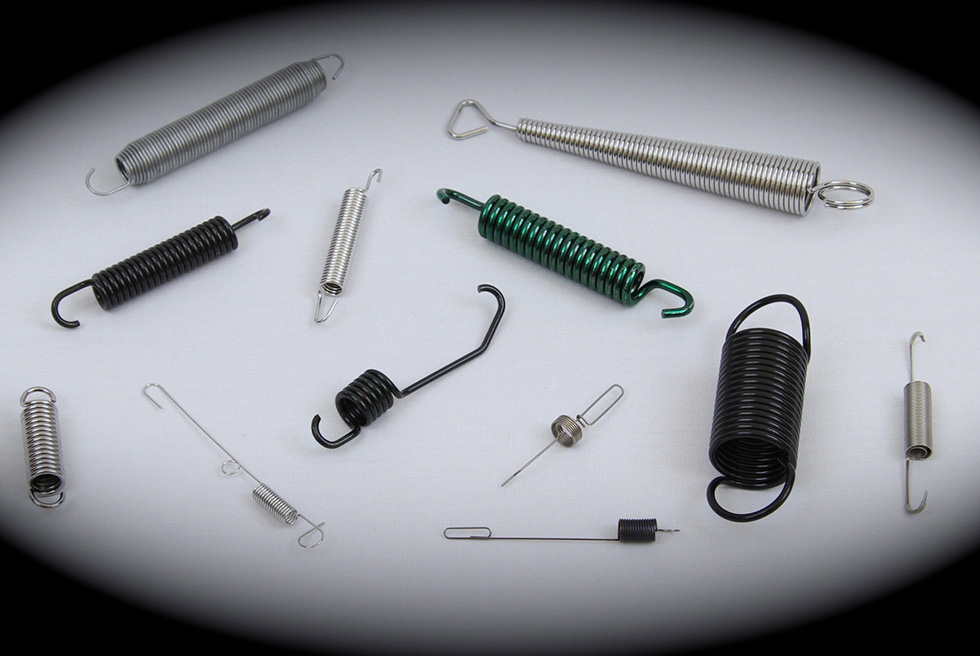

The global extension springs market is experiencing steady growth, driven by increasing demand across automotive, industrial machinery, and consumer electronics sectors. According to a report by Mordor Intelligence, the global spring market was valued at USD 10.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029, with extension springs representing a significant segment due to their critical role in energy storage and mechanical motion applications. Similarly, Grand View Research highlights the ongoing expansion of the automotive and aerospace industries—key end-users of precision extension springs—as a primary growth catalyst. With rising industrial automation and the need for high-performance mechanical components, manufacturers are focusing on advanced materials, tighter tolerances, and scalable production. In this competitive landscape, the following nine extension spring manufacturers stand out for their innovation, global reach, and technical expertise.

Top 9 Extension Springs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 IDC Spring

Domain Est. 2018

Website: idcspring.com

Key Highlights: IDC Spring is an industrial spring and supplier offering custom spring manufacturing. Find high-quality springs for various industries. Contact us today!…

#2 Century Spring

Domain Est. 1996

Website: centuryspring.com

Key Highlights: Looking to buy custom quick-delivery springs for sale? Century Spring is your go-to spring manufacturer for extension, torsion, compression springs, and……

#3 General Wire Spring Company

Domain Est. 1996

Website: generalwirespring.com

Key Highlights: General Wire Spring is a leading manufacturer of custom springs including compression, extension, & torsion springs for a variety of applications….

#4 Extension Springs Manufacturer

Domain Est. 1997

Website: newcombspring.com

Key Highlights: Newcomb Spring specializes in extension spring manufacturing, producing a diverse range of custom extension spring ends, sizes, and designs….

#5 Spring Manufacturer

Domain Est. 1997

Website: taylorspring.com

Key Highlights: Ajax Wire & Spring Company: American-made compression, extension & torsion springs. 80 years of spring manufacturing of the highest quality. Get a quote!…

#6 Heavy Duty, Custom Extension Spring Manufacturers

Domain Est. 2021

Website: lesjoforssprings.com

Key Highlights: We are experts in heavy-duty Extension Spring Manufacturing. We design, engineer and manufacture millions every year for custom specifications….

#7 Lee Spring

Domain Est. 1996

Website: leespring.com

Key Highlights: Lee Spring is your go-to supplier for stock and custom springs, wireforms, fourslide parts and stampings. With thousands of products in stock and engineers ……

#8 Extension Springs

Domain Est. 1996

Website: acxesspring.com

Key Highlights: Here at Acxess Spring we manufacture precision extension springs from 0.006 wire diameter to 1.00 inch in wire diameter. As quality extension spring ……

#9 Exacto Spring

Domain Est. 1996

Website: exacto.com

Key Highlights: Exacto Spring manufactures custom compression, torsion and extension springs, wire form products, and medical products to your specifications….

Expert Sourcing Insights for Extension Springs

H2: 2026 Market Trends for Extension Springs

The global extension springs market is poised for steady growth by 2026, driven by increasing demand across various industrial and consumer sectors. Several key trends are expected to shape the market landscape in this period:

-

Rising Industrial Automation and Manufacturing Demand

As industries continue to adopt automation and advanced manufacturing technologies, the need for reliable mechanical components like extension springs is growing. Extension springs are critical in assembly lines, robotics, and automated machinery, particularly in sectors such as automotive, aerospace, and consumer electronics. By 2026, the push for Industry 4.0 will amplify demand for precision-engineered springs capable of withstanding repetitive stress and maintaining performance under variable loads. -

Growth in Automotive and Transportation Sectors

The automotive industry remains a dominant consumer of extension springs, used in suspension systems, seat mechanisms, engine components, and trunk closures. With the projected rise in electric vehicle (EV) production and light commercial vehicle output, manufacturers are increasingly sourcing high-tensile, corrosion-resistant springs. Lightweight materials such as high-grade stainless steel and composite alloys will gain traction to support fuel efficiency and durability goals by 2026. -

Advancements in Material Science and Spring Design

Innovations in metallurgy and manufacturing processes are enabling the development of extension springs with enhanced fatigue resistance, temperature tolerance, and longevity. By 2026, the integration of simulation software and finite element analysis (FEA) in spring design will allow for customized solutions tailored to specific applications, improving efficiency and reducing material waste. -

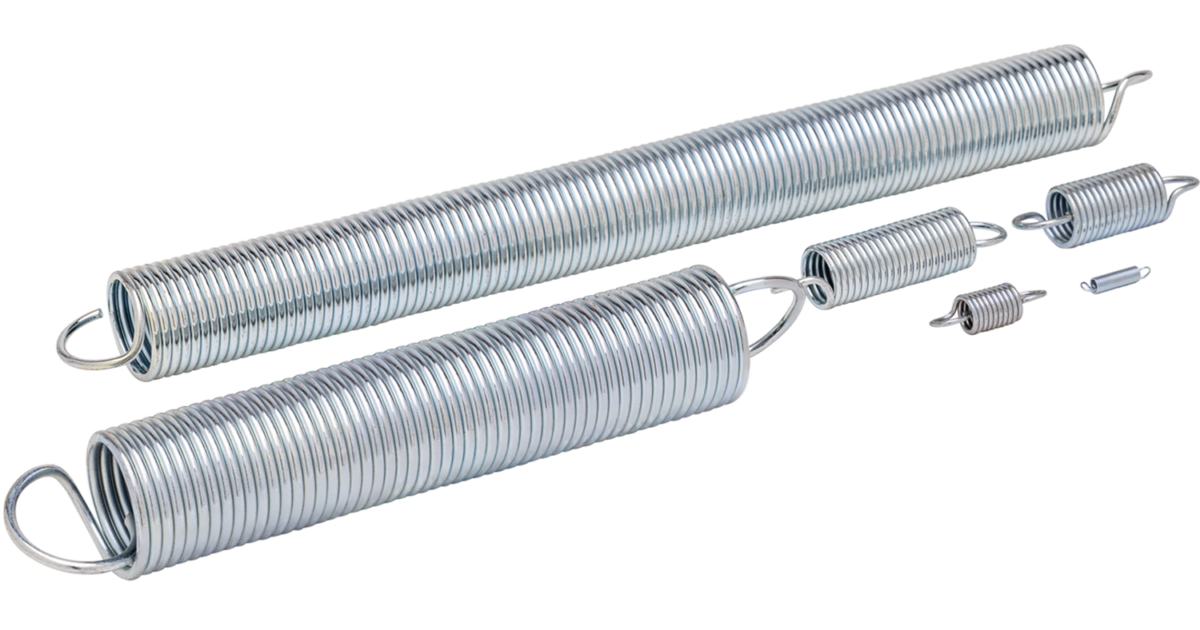

Expansion in Consumer and Residential Applications

Extension springs are widely used in household items such as garage doors, trampolines, and exercise equipment. As global urbanization and home improvement activities rise—especially in emerging economies—this segment is expected to contribute significantly to market growth. Demand for durable, low-maintenance springs in residential settings will drive product innovation and aftermarket sales. -

Sustainability and Regulatory Compliance

Environmental regulations and corporate sustainability goals are influencing material selection and production methods. By 2026, manufacturers are expected to prioritize recyclable materials, energy-efficient manufacturing, and reduced emissions. Compliance with international standards (e.g., ISO 10243 for spring tolerances) will become increasingly critical for global competitiveness. -

Regional Market Dynamics

Asia-Pacific is anticipated to lead the extension springs market by 2026, supported by rapid industrialization in China, India, and Southeast Asia. North America and Europe will maintain strong demand due to advanced manufacturing ecosystems and ongoing infrastructure upgrades. Meanwhile, Latin America and the Middle East are emerging as growth regions, with increasing investments in construction and transportation. -

Digitalization and Supply Chain Optimization

The integration of IoT and predictive maintenance technologies will create new opportunities for smart springs equipped with load-sensing capabilities. Additionally, digital supply chain platforms and just-in-time (JIT) manufacturing models will enhance delivery speed and reduce inventory costs, benefiting both suppliers and end-users.

In conclusion, the extension springs market in 2026 will be characterized by technological innovation, material advancements, and expanding application areas. Companies that invest in R&D, sustainability, and global supply chain resilience are likely to capture greater market share in this evolving landscape.

Common Pitfalls When Sourcing Extension Springs (Quality, IP)

Sourcing extension springs may seem straightforward, but overlooking key quality and intellectual property (IP) considerations can lead to performance failures, safety risks, and legal complications. Being aware of these common pitfalls helps ensure reliable supply and protects your business.

Poor Material Quality and Inconsistent Manufacturing

One of the most frequent issues is receiving springs made from substandard materials or produced with inconsistent processes. Low-grade steel or incorrect alloy composition can lead to premature fatigue, corrosion, or failure under load. Inconsistent heat treatment, coiling, or hook formation results in variable spring rates and reduced lifespan. Always verify supplier certifications (e.g., ISO 9001), request material test reports, and conduct incoming quality inspections.

Inadequate Tolerance Control

Extension springs must meet precise dimensional and force tolerances to function correctly in their intended application. Suppliers may cut corners on precision to reduce costs, leading to fitment issues or inconsistent performance. Clearly specify required tolerances in RFQs and ensure the supplier has capable measurement systems (e.g., calibrated load testers, micrometers) to verify conformance.

Lack of Traceability and Documentation

Without proper traceability—such as lot numbers, material certifications, and process records—it’s difficult to investigate field failures or perform root cause analysis. This is especially critical in regulated industries (e.g., medical, aerospace). Ensure suppliers provide full documentation and can trace components back through the manufacturing process.

Overlooking Environmental and Corrosion Resistance

Many applications expose springs to moisture, chemicals, or extreme temperatures. Using standard uncoated springs in corrosive environments leads to rust and early failure. Suppliers may offer cost-effective but unsuitable finishes (e.g., basic zinc plating instead of dacromet or stainless steel). Clearly define environmental requirements and validate the chosen material and coating accordingly.

Intellectual Property (IP) Risks in Custom Designs

When sourcing custom extension springs, there’s a risk of IP leakage or unauthorized replication. Some overseas suppliers may copy designs and sell them to competitors or reverse-engineer them for other clients. Always use robust non-disclosure agreements (NDAs), specify IP ownership in contracts, and consider working with trusted partners in jurisdictions with strong IP enforcement.

Inadequate Testing and Validation

Suppliers might claim compliance without performing proper testing. Relying solely on supplier-provided data without independent validation can be dangerous. Require proof of performance testing (e.g., load testing, cycle life testing) and consider third-party verification for critical applications.

Supply Chain Transparency Issues

Complex supply chains, especially with offshore suppliers, can obscure the true origin of materials and components. This increases risks related to counterfeit materials, unethical labor practices, or compliance with regulations like REACH or RoHS. Audit suppliers and demand transparency in their sub-tier sourcing.

By proactively addressing these pitfalls, procurement teams can ensure they source extension springs that meet both performance standards and legal requirements, minimizing risk and enhancing product reliability.

Logistics & Compliance Guide for Extension Springs

This guide outlines key logistics and compliance considerations for the handling, transportation, and regulatory adherence related to extension springs across various industries.

Product Classification and HS Codes

Extension springs are typically classified under specific Harmonized System (HS) codes for international trade. Common classifications include:

– HS Code 7320.20: Springs and leaves for springs, not assembled with other components, of steel (includes many extension springs).

– HS Code 7320.90: Other springs (used for non-steel or specialized materials).

Accurate classification ensures proper tariffs, import/export declarations, and customs clearance.

Packaging and Handling Requirements

Proper packaging is essential to prevent deformation, corrosion, and damage during transit:

– Use anti-corrosion packaging (e.g., VCI paper or desiccants) for carbon or alloy steel springs.

– Secure springs in rigid containers or palletized units to prevent shifting.

– Label packages with orientation indicators (e.g., “This Side Up”) and handling warnings.

– Avoid over-compression or tangling, especially in bulk shipments.

Transportation and Shipping

- Domestic Shipping: Comply with carrier-specific guidelines (e.g., UPS, FedEx, or freight carriers) regarding weight, dimensions, and hazardous materials.

- International Shipping: Adhere to IMDG (maritime), IATA (air), or ADR (road) regulations as applicable. While extension springs are generally non-hazardous, accompanying materials (e.g., coatings or lubricants) may require special handling.

- Use trackable and insured shipping methods for high-value or critical components.

Regulatory Compliance

Extension springs used in regulated industries must conform to relevant standards:

– ISO 10243: Industrial standard for dimensions and tolerances of cold-coiled extension springs.

– ASTM A401 / A401M: Standard specification for steel wire, chrome-vanadium alloy, used in springs.

– RoHS and REACH: Ensure materials comply with EU restrictions on hazardous substances, especially for electronic or consumer products.

– ITAR/EAR: If springs are used in defense or aerospace applications, verify if they fall under export control regulations.

Documentation Requirements

Maintain comprehensive documentation for traceability and compliance:

– Certificates of Conformance (CoC): Certify that springs meet specified material and dimensional standards.

– Material Test Reports (MTRs): Provide chemical and mechanical properties of spring materials.

– Customs Documentation: Include commercial invoices, packing lists, and origin declarations for cross-border shipments.

– SDS (Safety Data Sheets): Required if springs are coated with lubricants or protective chemicals.

Storage and Inventory Management

- Store in a dry, temperature-controlled environment to prevent rust and material degradation.

- Use FIFO (First In, First Out) inventory practices to minimize aging and obsolescence.

- Segregate different spring types and materials to avoid mix-ups and contamination.

Environmental and Sustainability Considerations

- Recycle scrap metal and packaging materials where possible.

- Partner with suppliers committed to sustainable manufacturing practices.

- Comply with local environmental regulations regarding waste disposal from spring finishing processes (e.g., shot peening, coating).

Quality Assurance and Traceability

Implement quality control measures throughout the logistics chain:

– Conduct incoming inspection upon receipt.

– Maintain batch/lot traceability from manufacturer to end-user.

– Audit suppliers regularly for compliance with ISO 9001 or industry-specific quality standards.

Adhering to this logistics and compliance framework ensures safe, efficient, and legally sound handling of extension springs across the supply chain.

Conclusion for Sourcing Extension Springs

Sourcing extension springs requires a strategic approach that balances quality, cost, and reliability. A successful procurement process involves clearly defining technical specifications such as load requirements, material type, finish, dimensions, and operational environment. By identifying reputable suppliers with proven manufacturing capabilities and quality assurance processes—such as ISO certification—companies can ensure consistent performance and durability of the springs.

Additionally, evaluating factors like lead times, minimum order quantities, and scalability supports long-term supply chain efficiency. Engaging in collaborative partnerships with suppliers fosters innovation, enables customization, and enhances responsiveness to design changes or market demands. Ultimately, effective sourcing of extension springs contributes to improved product performance, reduced maintenance costs, and increased customer satisfaction. By prioritizing technical compatibility, supplier reliability, and total cost of ownership, organizations can optimize their sourcing strategy and achieve sustainable operational success.