The global expansion tank market is experiencing steady growth, driven by rising demand in HVAC, solar thermal, and plumbing systems across residential, commercial, and industrial sectors. According to a report by Mordor Intelligence, the expansion tank market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This trajectory is further supported by increasing infrastructure development and energy efficiency regulations, which amplify the need for reliable thermal expansion management—where mounting brackets play a critical, albeit often overlooked, role in system durability and safety.

As expansion tanks become more widely deployed, the demand for high-quality, corrosion-resistant mounting brackets has risen in tandem. These components ensure secure installation, reduce vibration, and extend system lifespan—making the manufacturers of such brackets essential players in the supply chain. With the market dynamics favoring durability, ease of installation, and compliance with regional plumbing codes, a handful of manufacturers have emerged as leaders in producing reliable, engineered bracket solutions.

Based on production capacity, geographic reach, product innovation, and material quality, the following six companies are recognized as top manufacturers of expansion tank mounting brackets in 2024.

Top 6 Expansion Tank Mounting Bracket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

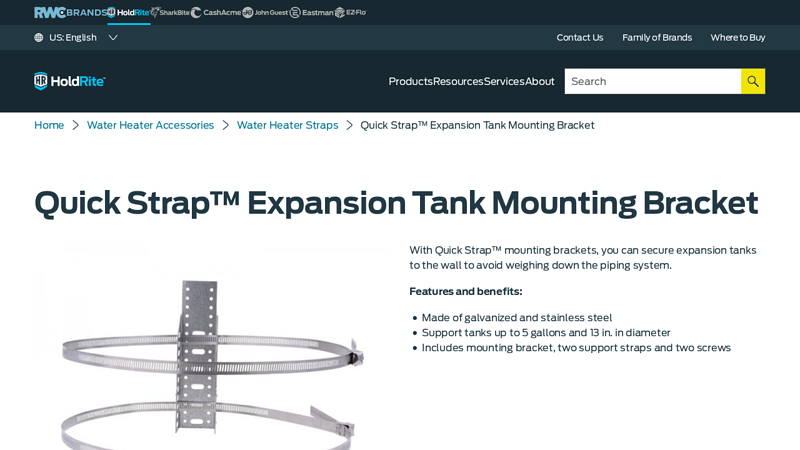

#1 Quick Strap Expansion Tank Mounting Bracket

Domain Est. 1997

Website: holdrite.com

Key Highlights: Support tanks up to 5 gallons and 13 in. in diameter; Includes mounting bracket, two support straps and two screws….

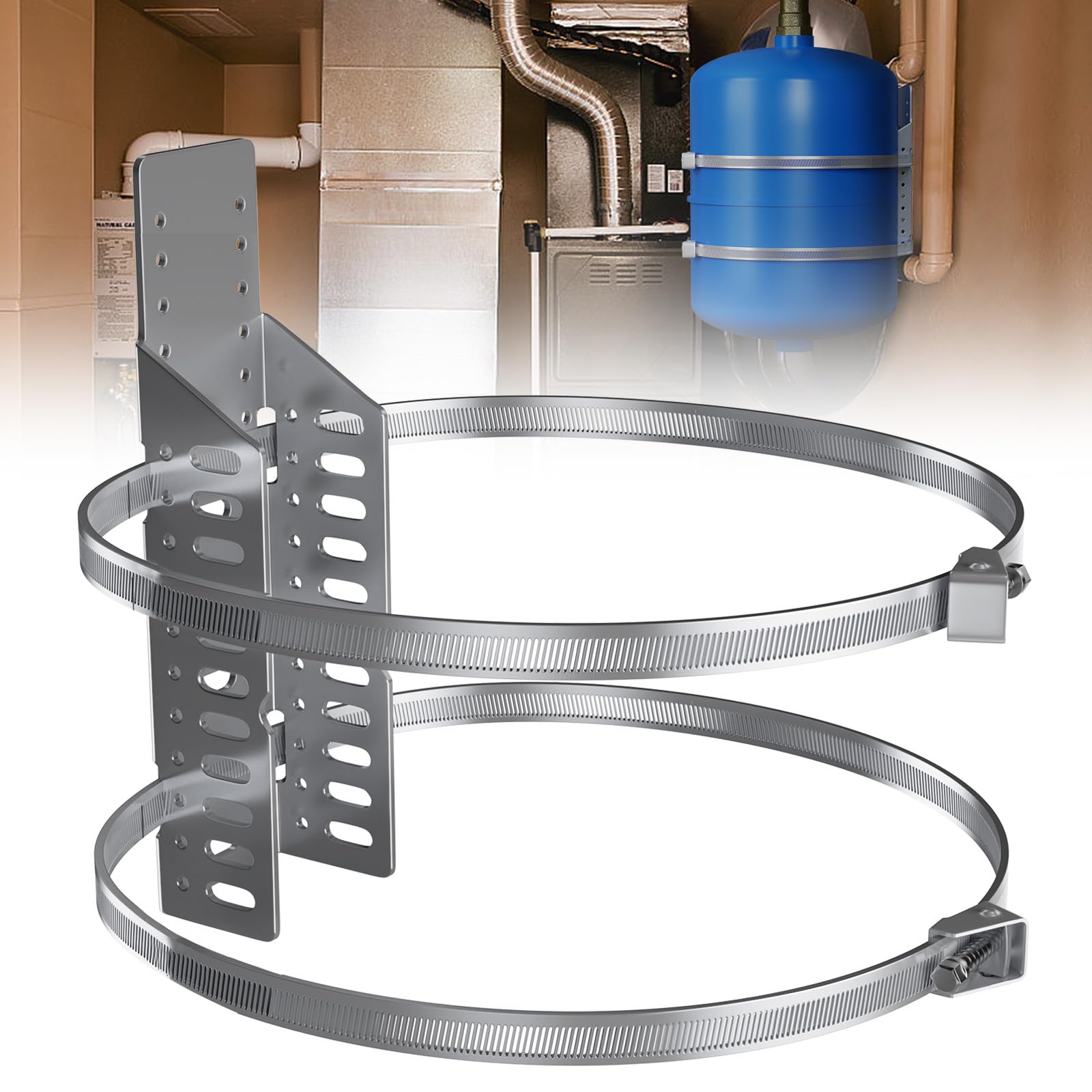

#2 Expansion Tank Brackets

Domain Est. 1998

#3 MFH

Domain Est. 1999

Website: monitorpro.com

Key Highlights: MFH-5344 – Component(s). Expansion Tank Mounting Bracket, 5000-2796. Component of kit MFH-5344. Qty per kit: 1. $17.60. MFH-5344 – Expansion Tank Mounting ……

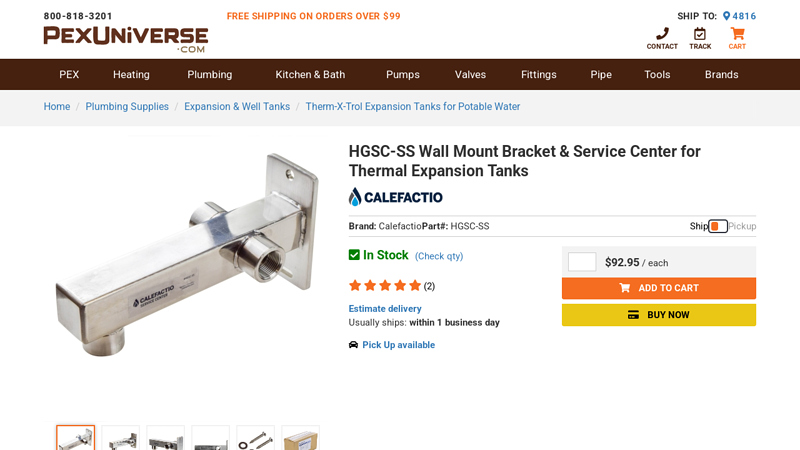

#4 Calefactio HGSC

Domain Est. 2009

Website: pexuniverse.com

Key Highlights: In stock Rating 5.0 (2) HGSC-SS is a stainless steel wall mounting bracket and service center for system-mount thermal expansion tanks. Compatible with up to 8-gallon tanks from …

#5 Qs

Domain Est. 2013

Website: lowlaundry.com

Key Highlights: In stock Rating 5.0 (7) Engineered for reliability: Manufactured to tight tolerances for dependable sealing and long service life. · Pro-grade materials: Constructed from durable…

#6 Eastman Stainless Steel Water Heater Expansion Tank Mounting …

Domain Est. 2021

Website: anaqha.com

Key Highlights: Universal kit for mounting water heater expansion tanks to the wall · Works with water heater thermal expansion tanks up to a 5 gallons in size ……

Expert Sourcing Insights for Expansion Tank Mounting Bracket

H2: 2026 Market Trends for Expansion Tank Mounting Bracket

The global market for expansion tank mounting brackets is poised for steady growth and transformation by 2026, driven by advancements in HVAC systems, increasing construction activities, and a rising emphasis on energy efficiency. These brackets, essential for securing expansion tanks in heating, ventilation, and plumbing systems, are witnessing evolving demand patterns due to technological innovation and sustainability initiatives.

One of the key trends shaping the 2026 market is the growing adoption of smart and modular HVAC systems. As buildings become more intelligent and energy-conscious, manufacturers are developing compact, easily installable components—including mounting brackets designed for quick integration and compatibility with a variety of expansion tank models. This modularity supports faster installations and reduces labor costs, appealing to contractors and developers alike.

Another significant factor is the surge in green building certifications, such as LEED and BREEAM, particularly in North America and Europe. These standards promote efficient and durable mechanical installations, which in turn boosts demand for high-quality, corrosion-resistant mounting brackets. Materials like stainless steel and powder-coated carbon steel are increasingly preferred for their longevity and performance in diverse environmental conditions.

Additionally, the residential and commercial construction boom in emerging economies, especially in Asia-Pacific and the Middle East, is fueling infrastructure development. Expansion tank mounting brackets are critical in hydronic heating and cooling systems common in these new constructions, contributing to market expansion. Regional manufacturers are responding by localizing production to reduce costs and improve supply chain efficiency.

Technological integration is also influencing design improvements. By 2026, expect to see mounting brackets engineered with vibration-dampening features and load-distribution enhancements to support larger tanks and improve system reliability. Some suppliers are incorporating anti-vibration rubber pads or adjustable mounting systems to accommodate thermal expansion and reduce mechanical stress.

Lastly, e-commerce and digital procurement platforms are transforming distribution channels. HVAC contractors and wholesalers are increasingly sourcing mounting brackets online, prompting manufacturers to enhance digital presence and offer detailed product specifications, CAD models, and compatibility guides to support informed purchasing decisions.

In summary, the 2026 market for expansion tank mounting brackets will be shaped by demand for durability, ease of installation, energy efficiency, and digital accessibility. Companies that innovate in materials, design, and customer engagement are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Expansion Tank Mounting Bracket (Quality, IP)

When sourcing an expansion tank mounting bracket, overlooking critical quality and intellectual property (IP) considerations can lead to significant downstream issues. Below are the most common pitfalls to avoid:

Poor Material Quality and Durability

Sourcing brackets made from substandard materials—such as low-grade steel or inadequately coated metals—can result in premature corrosion, reduced load-bearing capacity, and failure under vibration or thermal cycling. This compromises the integrity of the entire expansion tank assembly, especially in harsh environments. Always verify material specifications (e.g., stainless steel grade, galvanization type) and request test reports for corrosion resistance and tensile strength.

Inadequate Load Rating and Structural Design

Many low-cost brackets fail to meet required mechanical load specifications, risking bracket deformation or detachment. This is particularly critical in HVAC or industrial systems where tank weight and dynamic forces are substantial. Ensure the bracket is engineered for the specific tank model and operating conditions, and confirm compliance with relevant mechanical standards.

Lack of IP Verification and Risk of Infringement

Using or sourcing mounting brackets that replicate patented designs without authorization exposes buyers and integrators to intellectual property infringement claims. Some suppliers offer “compatible” or “universal” brackets that closely mimic original equipment manufacturer (OEM) designs, potentially violating design patents or utility patents. Always conduct due diligence on the supplier’s right to produce and sell the bracket, and request documentation confirming freedom to operate.

Non-Compliance with Industry Standards and Certifications

Brackets may appear suitable but fail to meet required certifications (e.g., ISO, ASME, or regional mechanical safety standards). This can lead to system non-compliance during inspections or audits. Confirm that the bracket, especially if part of a safety-critical assembly, carries relevant certifications and is traceable to a qualified manufacturer.

Inconsistent Manufacturing Tolerances

Low-quality suppliers may produce brackets with inconsistent hole placements, misaligned mounting points, or incorrect dimensions, making installation difficult or impossible. This leads to field modifications, delays, and potential warranty voids. Request samples and dimensional drawings for verification before bulk procurement.

Insufficient Corrosion Protection for Intended Environment

Even if the base material is adequate, poor surface treatment (e.g., inadequate powder coating or plating) can result in rust and degradation—especially in outdoor or high-humidity applications. Ensure the finish meets environmental protection standards (e.g., IP66-rated enclosures or compatibility with specified NEMA ratings).

Overlooking Traceability and Documentation

Reputable suppliers provide material test reports, Certificates of Conformance (CoC), and traceability data. Sourcing from vendors who cannot supply such documentation increases the risk of receiving counterfeit or non-conforming parts, which can jeopardize system reliability and compliance.

By addressing these quality and IP-related pitfalls early in the sourcing process, organizations can ensure reliable performance, legal compliance, and long-term cost savings.

Logistics & Compliance Guide for Expansion Tank Mounting Bracket

Product Overview

The Expansion Tank Mounting Bracket is a structural support component designed to securely install expansion tanks in hydronic heating and cooling systems. It ensures safe, stable positioning of the tank and complies with mechanical safety and building code standards.

Logistics Management

Packaging Specifications

- Standard Packaging: Each mounting bracket is individually wrapped in recyclable polyethylene film and placed in a corrugated cardboard box.

- Pallet Configuration: 20 units per box; 10 boxes per pallet (200 units total).

- Pallet Dimensions: 120 cm × 100 cm × 140 cm (L×W×H), secured with stretch wrap and corner protectors.

- Weight: Net weight per unit: 1.8 kg; Gross weight per pallet: ~400 kg.

Shipping & Handling

- Freight Classification: Class 60 (NMFC 111560-4) for LTL shipments.

- International Shipping: Complies with ISPM 15 regulations; pallets are heat-treated and stamped.

- Labeling: Each package includes a barcode, product code (ET-MB-01), handling symbols (e.g., “This Side Up,” “Fragile”), and safety warnings.

- Storage Conditions: Store indoors at temperatures between 5°C and 40°C, away from corrosive substances and moisture.

Inventory & Lead Times

- Standard Lead Time: 3–5 business days for in-stock orders.

- Backorder Policy: Notification within 24 hours; estimated fulfillment provided.

- Drop-Shipping Capability: Available upon request with coordinated logistics partner.

Regulatory Compliance

Safety & Installation Standards

- Compliance with ASME A112.18.1/CSA B125.1: Ensures mechanical strength and load-bearing performance.

- IBC (International Building Code) Section 604: Meets requirements for mechanical equipment support in commercial and residential installations.

- OSHA 1910.28: Adheres to workplace safety standards for fall protection during installation at elevated locations.

Material & Environmental Compliance

- RoHS Directive 2011/65/EU: Free from lead, mercury, cadmium, and other restricted substances.

- REACH Regulation (EC 1907/2006): Registered and compliant with SVHC (Substances of Very High Concern) guidelines.

- Material Composition: Made from powder-coated carbon steel (SAE 1020), with zinc-plated hardware; fully recyclable.

Regional Certifications

- North America: Certified to IAPMO/ANSI Z124 for plumbing support devices.

- European Union: CE-marked under the Construction Products Regulation (CPR) EN 1090-1 for structural metal components.

- Australia/New Zealand: Complies with AS/NZS 1660 for mechanical fasteners and supports.

Installation & Usage Compliance

Required Tools & Procedures

- Use calibrated torque wrench (tightening torque: 25–30 Nm for anchor bolts).

- Install on load-bearing walls or structural beams only.

- Verify level alignment during mounting per manufacturer’s instructions.

Documentation & Traceability

- Each batch includes a Certificate of Conformity (CoC) and Material Test Report (MTR).

- Serialized lot tracking enables full traceability for quality and recall purposes.

Disposal & End-of-Life

- Recycling: Components are 98% recyclable through standard metal recycling streams.

- Disposal Guidance: Follow local regulations for metal waste; no hazardous waste classification.

For questions or compliance documentation, contact [email protected].

Conclusion for Sourcing Expansion Tank Mounting Bracket:

After a thorough evaluation of potential suppliers, material options, cost considerations, and technical specifications, the sourcing strategy for the expansion tank mounting bracket has been finalized. The selected supplier offers a balanced combination of quality, cost-efficiency, and reliable delivery timelines, ensuring compatibility with existing system requirements and adherence to industry standards. The chosen bracket design provides durable, vibration-resistant support, contributing to the long-term reliability and safety of the expansion tank assembly. This sourcing decision supports operational efficiency, reduces maintenance risks, and aligns with both current production needs and future scalability objectives. Continued supplier performance monitoring will ensure sustained quality and supply chain resilience.